-

燃煤火力电厂是国内电力的基础负载主力,其烟气排放主要包括粒状污染物及气状污染物2类。粒状污染物主要为飞灰,气状污染物则分为氮氧化物(NOx)及硫氧化物(SO2) 2种。各种污染物的排放标准因设备种类及地区性的差异而不同。一般燃煤火电厂550 MW燃烧器锅炉排放的飞灰质量浓度约为1 100~10 000 mg·m−3,NOx质量浓度约为400~600 mg·m−3,SO2质量浓度可达900~ 3 000 mg·m−3[1-4]。目前,国内外燃煤电厂常见的处理工艺是选择性催化还原设备(selective catalytic reduction,SCR),实际应用中常常会串联静电集尘器及除硫系统以来保证排放达标,但往往会增加处理与管理的复杂性。

燃煤电厂烟气控制技术中常见的SCR催化剂是将活性催化相(TiO2、V2O5、Pt等金属)负载于蜂巢式、平板式、柱状式滤材或滤袋等反应器中[5-9]。该领域的研究重点集中在不同活性及抗毒化特性催化剂的制备方法[10-13]。研究中一般采用模拟的单一气体或少数混合气体,侧重探讨反应机理。反应中高质量浓度颗粒物对催化剂的影响研究并不多见。前述反应器虽然对高灰环境有一定忍受度,但随着操作时间的增加会出现催化剂表面物理失活(deactivation)及磨耗(erosion)现象[6]。为减少颗粒物对催化剂活性的影响,可考虑将颗粒床反应器与SCR催化剂协同使用,以达到同时处理气状和粒状污染物的目标。

颗粒床除尘设备[14-18]具有下列优势:1)高热/质传系数,高气/固、固/固接触面积及连续操作等特点;2)可避免类似固定床反应器的堵塞现象;3)相对于蜂窝状反应器,气体流量的变化对污染物与反应器的接触效率较不敏感。因此,本研究结合CuO/活性炭(activated carbon,AC)催化剂对NO与SO2的控制[19-23]及颗粒床反应器对飞灰的过滤能力,并通过改变模拟粒状物的粒径、成分,探讨模拟烟气环境下协同工艺的操作参数,以期达到同时去除NO、SO2及飞灰的目标。

全文HTML

-

1) AC的制备。选用经高温(800 ℃)蒸气处理的商业化竹制活性炭(芝星活性炭有限公司,型号G840)为催化剂载体材料。AC使用前需经研磨及筛分,粒径范围为840~1 190 μm(16~20目);经30%HNO3溶液预处理48 h后以蒸馏水冲洗,至淋洗液呈中性;洗净后的AC置于110 ℃空气中烘干24 h备用。

2) CuO/AC催化剂的制备。用含浸法制备CuO/AC催化剂,选择硝酸铜(Cu(NO3)2·3H2O;J.T. Baker Co.,USA)为前驱物质。将预处理后的AC加入前驱物水溶液中(固液质量比为1∶2),持续加热、搅拌直至溶液完全蒸发;将半成品置于空气环境中进行干燥(110 ℃、2 h)、锻烧(400 ℃、4 h,加热速率为10 ℃·min−1)后得到CuO/AC催化剂;将催化剂成品装入玻璃瓶中存于防潮箱。根据文献[15-16, 24],负载CuO的质量分数为3%时,催化剂对NO和SO2的催化效果最佳,故本研究制备的催化剂选用3%CuO/AC催化剂。

-

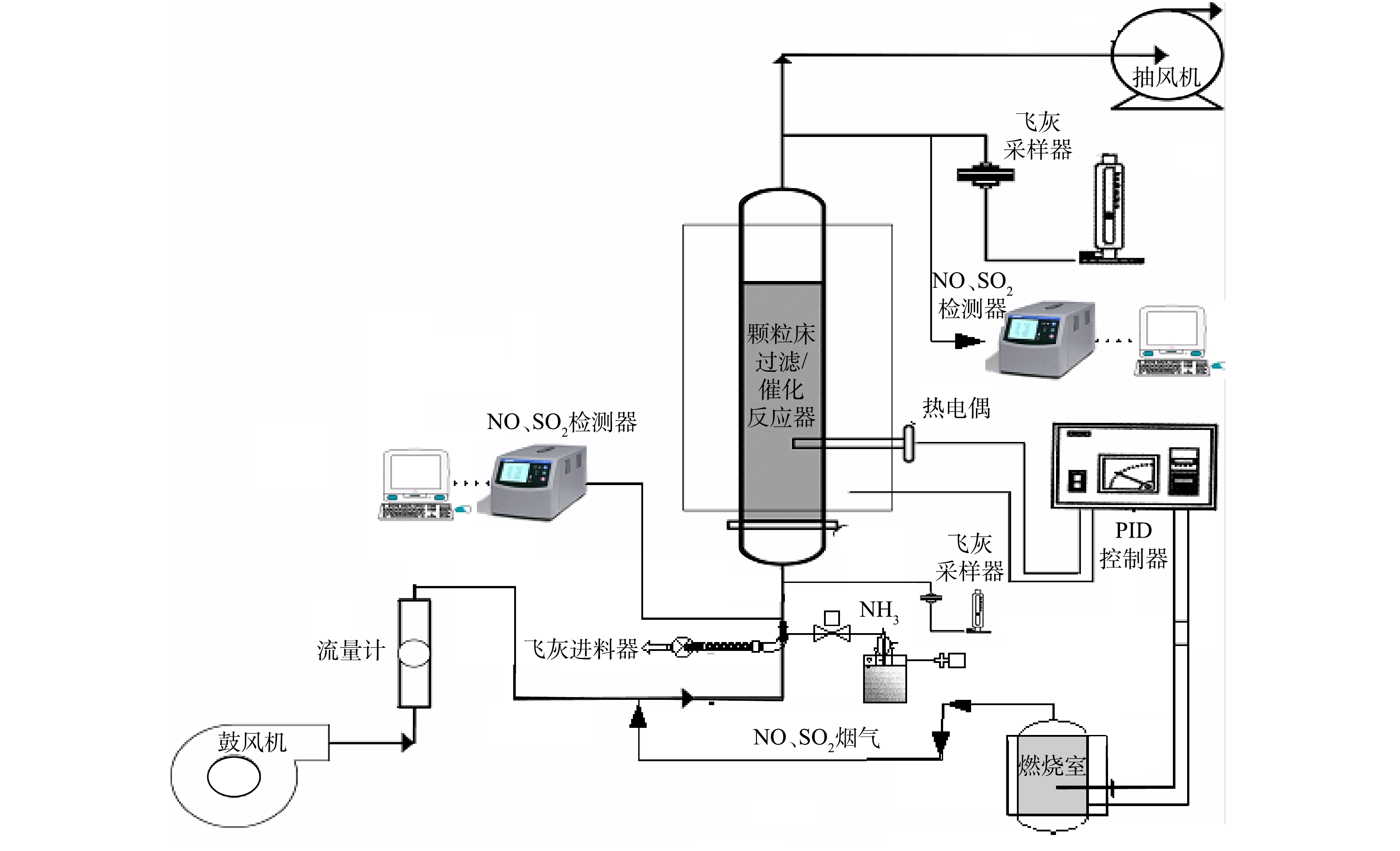

1)反应设备。设备采用实验室规模的颗粒床过滤/催化反应器(见图1),分3个部分:①燃烧系统。以燃烧尿素和硫粉产生的NO和SO2,并曝入不同组分(Al2O3或SiO2)及不同粒径(4 μm或40 μm)的模拟烟尘。其中,NO质量浓度为(458 ± 98) mg·m−3,SO2质量浓度为(1 440 ± 193) mg·m−3,飞灰质量浓度为900~1 400 mg·m−3;②颗粒床直径为5.5 cm,高度为120 cm,最小流化速度为0.32 m·s−1,操作流速为0.51 m·s−1,操作流量为35 L·min−1;③污染物监测系统。

2)模拟气体。用称量纸包覆进料按批次每20 s投进燃烧室燃烧,产生的烟气流向颗粒床过滤/催化反应设备。人工进料物的元素成分为:称量纸(C占41.25%,H占7.18%,O占50.03%),硫粉(S占99.9%),尿素(N占47.68%,C占20.17%,H占6.84%,O占0.49%)。在颗粒床过滤/催化反应器入口下方约50 cm处,用鼓风机高压气化(鼓风机曝气流量2~4 L·min−1)以批次方式将模拟飞灰引入烟道内。曝气间隔为:每20 s曝气1次,直至实验结束,以维持实验所需烟尘量。

3)实验方法。将89 g催化剂加入反应管中(静床高约8 cm),待温度达设定值后,将模拟烟道气体通入颗粒床过滤/催化反应设备内。反应前后用烟道气体分析仪及粒状物采样装置监测其质量浓度。

-

反应开始前,先进行90 min床质淘失实验,以避免因磨损产生的催化剂小颗粒影响实验结果。采样滤膜为37 mm的玻璃纤维滤膜(Waterman),滤膜在湿度平衡箱隔夜放置后秤重。模拟烟气中的NO和SO2分析采用Online烟气分析仪(Multi-Gas Online Analyzer,Horiba,PG-250)。每5 s记录反应前后NO和SO2的质量浓度。

反应进行时,每10 min在颗粒/催化床反应器的进出口处进行1次等速采样,每次采样3 min;采样完成后再过10 min进行下一次采样;依此时间间隔连续采样至试程结束。反应过程中,未进入反应器的飞灰质量都控制在进料飞灰量的10%以内,以保证飞灰进料的稳定性。NO、SO2和飞灰的去除效率(R)计算式为式(1)。

式中:C0和Cf分别表示入口及出口污染物的质量浓度, mg·m−3。

-

1)光射线绕射分析(XRD)。催化剂表面的活性相晶体结构由X光粉末绕射仪(MAC Sience,MXP18,Japan)进行分析。分析选用CuK为辐射靶,绕射角度为20°~80°,绕射速率4(°)·min−1。

2)比表面积分析(BET)。重复升高或降低系统压力或温度,使催化剂在比表面积分析仪(High Resolution Surface Area and Porosimetry Analyser)中发生循环吸附和脱附,带入总比表面积分析法(Brunauer Emmett Teller method,BET)来分析总孔洞体积、比表面积、孔洞型态分析及平均孔洞大小等数据。

3)催化剂表面型态分析(SEM-EDS)。用扫描电镜(Field Emission Scanning Electron Microscope,FESEM)观察催化剂的表面型态,X射线能谱分析(EDS)分析催化剂的表面元素。

4)激光粒度分析仪。使用Topsizer Plus激光粒度分析仪,进行反应后飞灰的粒径分析,测试范围为0.02~2 000 μm,采用50%的酒精分散液为测试溶液。取5 g样品放入分散液中进行粒径测试。

1.1. CuO/AC催化剂制备

1.2. 实验设备、原料及方法

1.3. 气状物和粒状物的采样分析

1.4. 表征特性分析仪器

-

不同模拟条件下,颗粒床过滤/催化反应器对NO、SO2和模拟飞灰的去除效果见图2。在催化剂CuO/AC粒径为840~1 190 μm、模拟烟气中NO和SO2质量浓度分别为(438±102) mg·m−3和(1 400±322) mg·m−3、反应温度为250 ℃的条件下,系统对SO2的去除效率随反应时间为79.5%~71.1%;反应前15 min,系统对NO的去除效率随反应时间为59.5%~57.4%;当SO2的吸附量增加时,系统对NO的去除效率提升至63.6%。这是由于催化剂表面在吸收一定量SO2后产生了CuSO4,而CuSO4对NO具有还原能力[18-22],可提升表面的布朗斯特和路易斯酸度,以及对还原剂NH3的吸附能力,相关化学反应见式(2)~(5)。其中,CuO催化剂与SO2的反应见式(2)~(4),催化剂上的NO还原反应如式(5)所示。

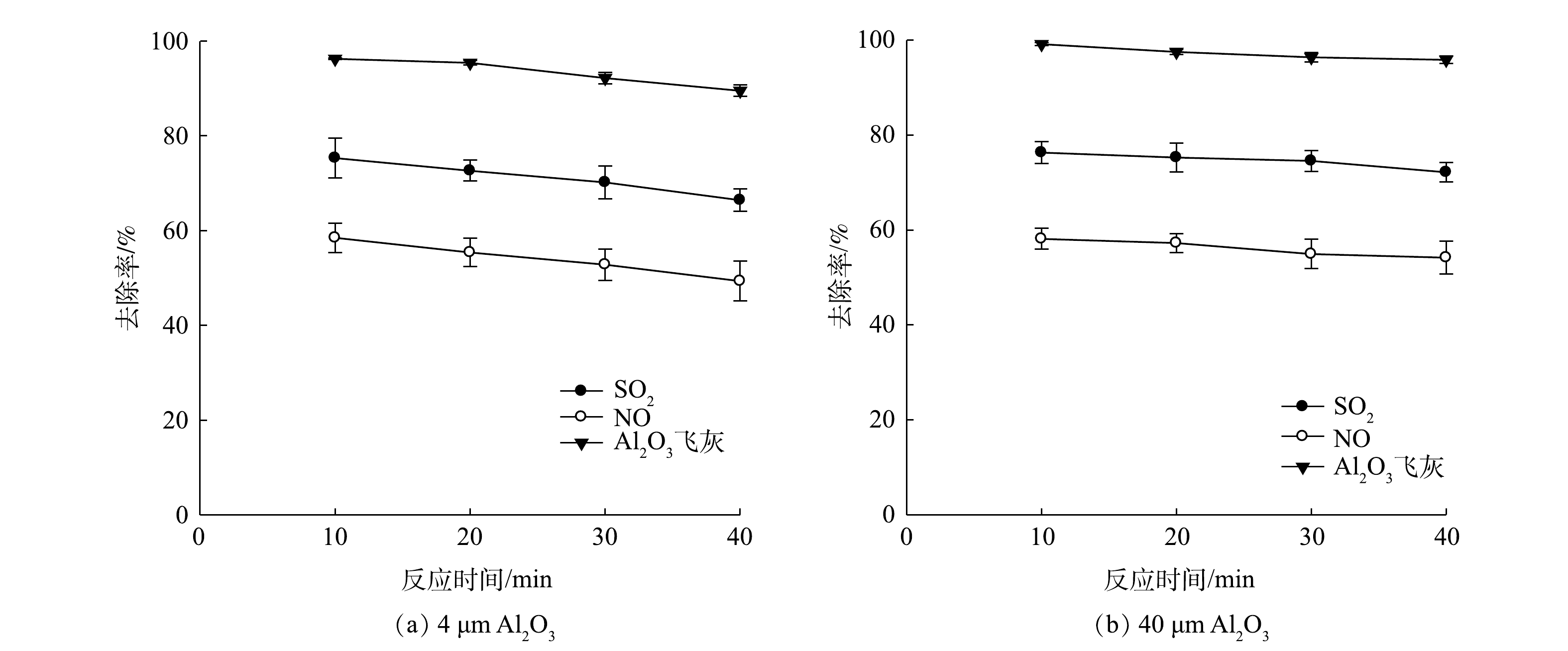

当模拟烟气中加入飞灰为粒径4 μm和40 μm的Al2O3时,在反应温度为250 ℃的条件下,系统对NO、SO2和Al2O3飞灰的处理效果如图3所示。该反应条件下,模拟烟气中NO质量浓度为(470±87) mg·m−3、SO2质量浓度为(1 235±239) mg·m−3,Al2O3飞灰质量浓度为(1 142±225) mg·m−3。由图4可知,加入Al2O3粒径分别为40 μm时,系统对飞灰、NO和SO2的去除效率较粒径为4 μm时要大一点;而随时间变化均为反应时间增加,去除率下降。将模拟烟气中加入的飞灰换成粒径为4和40 μm的SiO2时,考察反应温度250 ℃的条件下,系统对NO、SO2和SiO2飞灰的处理效果,结果如图4所示。该反应条件下,模拟烟气中NO质量浓度为(427±108) mg·m−3、SO2质量浓度为(1 351±285) mg·m−3,SiO2飞灰质量浓度为(1 207±177) mg·m−3。图4数据表明,加入的SiO2粒径为40 μm时系统对飞灰、NO和SO2的去除效率,比粒径为4 μm相比要高一点;而随时间变化情况也是去除率逐渐下降。

结合文献[15]及以上结果可知,粒径大的飞灰颗粒受到较强的惯性力作用时,去除效率提升明显;在滤除4 μm的颗粒时,作用机制以扩散作用为主,导致气相污染物的去除效率降低;由于过滤作用,较大的颗粒会截流在床质中。细颗粒(4 μm)的飞灰累积在催化剂表面会造成物理性失活,从而抑制催化剂的去除性能[25-26]。另外,在此过程中,随着SO2在催化剂表面吸附量的增加,NO转化率并没有明显提升,这可能是由于飞灰在催化剂表面的累积导致;随着反应进一步发生,NO和SO2的去除效率达到平衡而不会明显下降,这是由于床质的磨耗作用使催化剂表面的飞灰被去除,降低了催化剂表面的物理失活的现象。以上现象表明颗粒床过滤/催化反应器对飞灰有较好的耐受能力。

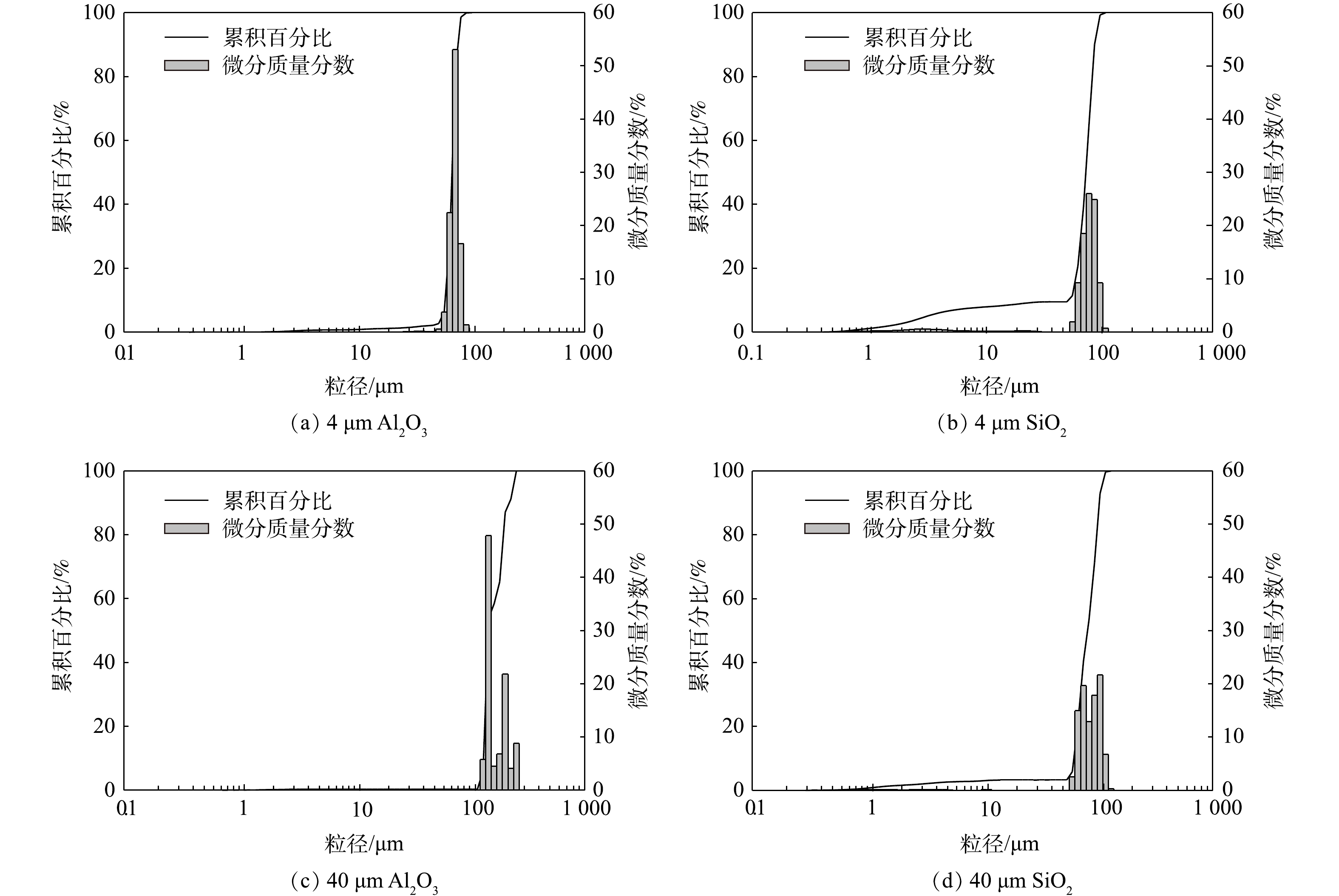

图5为经颗粒床过滤/催化反应器协同去除后,飞灰的粒径分布情况(particle size distribution,PSD)。其中,图5(a)和(b)为过滤4 μm粒径飞灰的PSD图。过滤Al2O3后的PSD图呈现单峰分布,主要分布于1.1~10.2 μm和67.4~105.1 μm这2个粒径范围,分别占0.05%和77.5%;过滤SiO2后的PSD图亦呈现单峰分布,主要分布于1.1~11.4 μm和75.3~117.3 μm这2个粒径范围,分别占7.8%和60.9%。图5(c)和(d)为过滤40 μm粒径的PSD图,过滤40 μmAl2O3时主要颗粒物粒径分布于75.3~255.0 μm,占99.7%;而过滤SiO2主要颗粒物粒径分布于67.4~131.1 μm,占94.1%。上述结果表明,颗粒床过滤/催化反应器后端出口的飞灰主要为床质的磨耗与淘失作用造成,而模拟飞灰几乎都截留在颗粒床内,成为床质一部分。以上结果与文献[22-23]报道的研究结果类似。

-

图6为协同去除前后CuO/AC催化剂表面的微观结构图。其中,图6(a)为协同去除前CuO/AC催化剂的表面形态,该图显示出CuO活性金属在AC表面具有较好的分散型态,活性晶相粒径为20~100 nm。协同去除后的CuO/AC催化剂表面形态如图6(b)~(e)所示。在滤除Al2O3飞灰时,拍摄到的微观图均有细微粒存在,而CuO/AC催化剂表面颗粒的粒径主要在4 μm以下。另外,滤除SiO2时,同样发现附着于CuO/AC催化剂孔洞与表面上的颗粒粒径小于4 μm,且有明显SiO2团聚现象并赌塞催化剂孔洞,造成了催化剂活性的降低。这些颗粒除添加的Al2O3和SiO2模拟飞灰外,亦有可能是催化剂磨耗产生的颗粒。

-

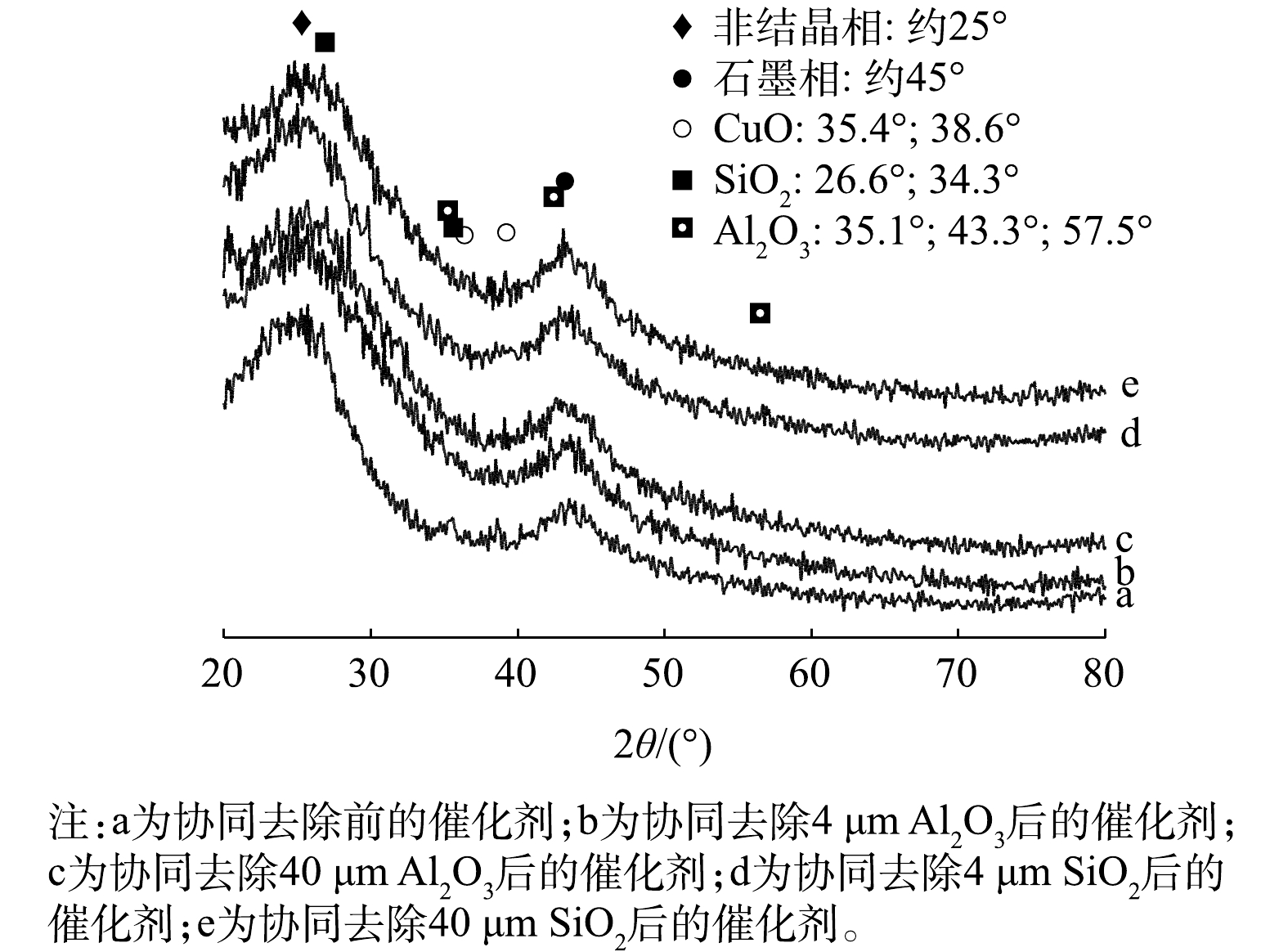

图7为协同去除前后CuO/AC催化剂的晶相结构分析图谱。该图谱表明,协同去除前CuO/AC催化剂主要以CuO晶相的型态存在(35.4°(002)与38.6°(111))。图7(b)~(e)为协同去除后的床质(CuO/AC催化剂)晶相型态。图7表明,在滤除Al2O3飞灰时,无明显Al2O3(35.1°、43.3°及57.5°)晶相产生,而在滤除SiO2飞灰时,有微量SiO2讯号(26.6°)产生,所以可推测,催化剂表面小颗粒为SiO2颗粒或催化剂本身磨耗。文献[27-28]报道的结果表明,当待测物浓度低于侦测极限(<3%)或是分布均匀时,XRD无法侦测其晶相结构;亦有可能是由于Al2O3颗粒已成为床质一部份,因此,催化剂表面的XRD图谱并无明显Al2O3结晶讯号产生。

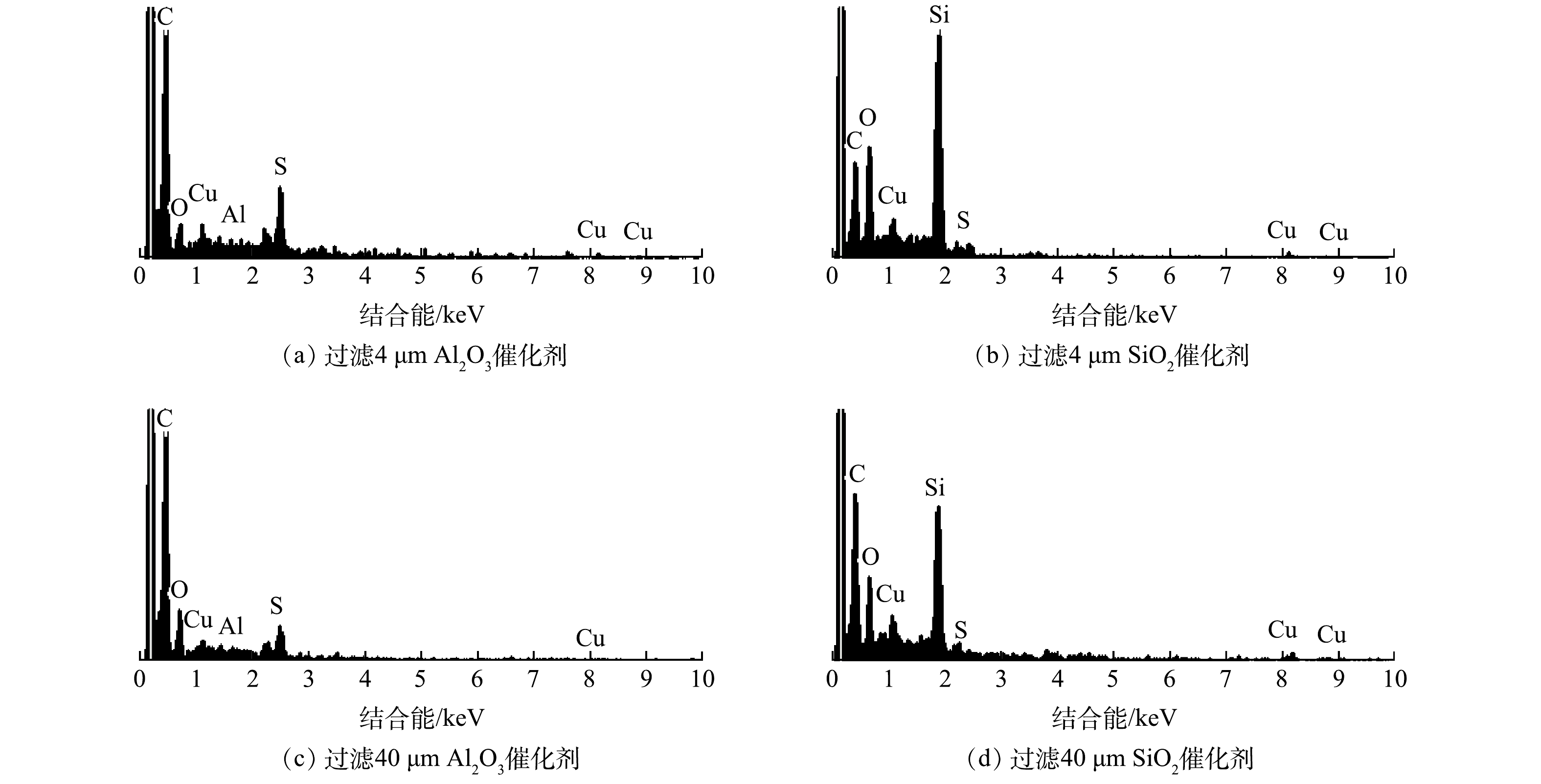

图8为协同去除前后CuO/AC催化剂的EDS能谱图。图8(a)和(c)表明,滤除SiO2颗粒时,有Si的能量讯号存在,表明催化剂表面有SiO2颗粒附着;此外,由在滤除Al2O3飞灰时(图8(a)和(c)),也有Al的能量显示,这表明催化剂表面有Al2O3的存在,可能因为总量小于3%而未被在XDR分析出。

-

表1为协同去除前后CuO/AC催化剂的BET分析结果。该结果表明,协同去除后的催化剂的比表面积为951.3~1 100.8 m2·g−1,比表面积会随着模拟细微粒(粒径小于4 μm)被过滤而呈现下降趋势,总孔洞体积亦随着过滤细微粒减小。另外,在滤除Al2O3颗粒时,催化剂的巨孔及介孔的孔隙并无明显变化。而在滤除SiO2颗粒时,巨孔及介孔的孔隙被堵塞,致使催化剂表面物理失活,从而降低了对NO及SO2的去除效率。这与图4显示的数据及SEM结果相符。

2.1. 不同操作条件对协同去除NO、SO2及模拟飞灰的影响

2.2. 反应前后催化剂表面微观结构分析

2.3. 反应前后催化剂表面晶相结构与EDS分析

2.4. 反应前后CuO/AC催化剂的BET分析

-

1)颗粒床反应器搭配CuO/AC催化剂可实现协同处理模拟烟尘中的气-固相污染物。滤除模拟粗颗粒(40 μm)时,过滤机理以惯性力作用为主,去除效率可达98%以上;当滤除模拟细颗粒(4 μm)时,过滤作用以扩散为主,PSD结果指出出口飞灰以PM131~PM204为主,显示出颗粒床反应器对模拟颗粒皆具有良好的去除效果。

2)协同处理系统中,细微粒的SiO2飞灰较容易堵塞催化剂巨孔及介孔孔隙,导致催化剂表面失活,降低气相污染物去除效率,表明飞灰中SiO2成分高易导致催化剂物理失活。

3)随着进一步协同处理反应的进行,NO和SO2的去除反应会达到平衡,但去除效率不会明显下降。这是由于床质的磨耗作用使催化剂表面的飞灰被去除,降低了催化剂表面的物理失活的现象。上述现象说明颗粒床过滤/催化反应器对飞灰有较好的耐受能力,具有协同处理烟尘中气-固相污染物的潜力。

下载:

下载: