-

含油污水是指含有脂(脂肪酸、皂类、脂肪、蜡等)及各种油类(矿物油、动植物油)的污水,特点是具有一定的气味和色度,BOD和COD较高。工业含油污水量大且面广,在石油化工、煤化工、冶金、机械制造、纺织印染、皮革等工业生产中均会有大量含油污水产生。其中,油污常以悬浮态、乳化态、溶解态多种形式存在,且多伴有表面活性剂、聚合物、细菌、油泥、焦粉等溶解或悬浮的杂质,造成含油污水的处理困难[1-3]。世界上每年至少有近千万吨油类物质通过各种途径进入水体[4],在造成资源浪费的同时,还会对海洋和河流水体环境、土壤环境造成极大危害。因此,含油污水的处理受到广泛关注。

含油污水的处理方法按原理主要分为物理法、物理化学法、化学法、电化学法、微生物法等[5-7]。浮油和分散油(>10 μm)较容易处理,可通过重力沉降、平行板或波纹板强化沉降、旋流分离、常规填料聚结分离等方法完全去除;对于溶解油,可通过吸附、生物处理等方法去除,因其在多数污水中含量极低,对环境影响较小。乳化油(0.1~10 μm)粒径微小,且污水中往往存在表面活性物质并吸附于油滴界面膜,使乳状液趋于稳定状态,油水分离困难,因而成为含油污水处理的重点和难点。乳化油分离的重点在于破乳,目前的破乳方法主要有絮凝气浮法、生物法、离心分离、膜分离、聚结分离、电场分离、超声分离等方法[8-12],这些方法各有其适用范围和优缺点:絮凝气浮法需加破乳剂、絮凝剂,缺点是占地大、药耗高、产生浮渣二次污染;生物法的抗波动性差,对进水水质要求高,需前处理;离心分离的处理量小、效率低、设备维护成本高;膜分离法主要存在成本高、膜污染、寿命短等问题,且对预处理工艺要求苛刻,使其在复杂污水中的应用受限;电场、电化学、超声等分离装置结构复杂、造价高、能耗大,尚难以大规模应用;聚结分离中的常规粗粒化聚结材料易板结,且乳化严重时分离性能差,而聚结滤芯需设置预过滤装置,抗波动性和耐久性差,易堵塞、失效。单一技术无法满足复杂工业含油污水的处理要求,实际处理工艺需根据目标含油污水的特性选择适宜的几种技术进行组合,且随着各行业的快速发展和污水排放标准的日趋严格,对已有技术的深入研究和新型分离技术的开发显得尤为重要。本文对聚结除油技术的发展历程进行了回顾,对国内外学者在聚结除油介质方面的研究和应用进行了梳理和总结,并对该技术的发展方向进行了展望。

全文HTML

-

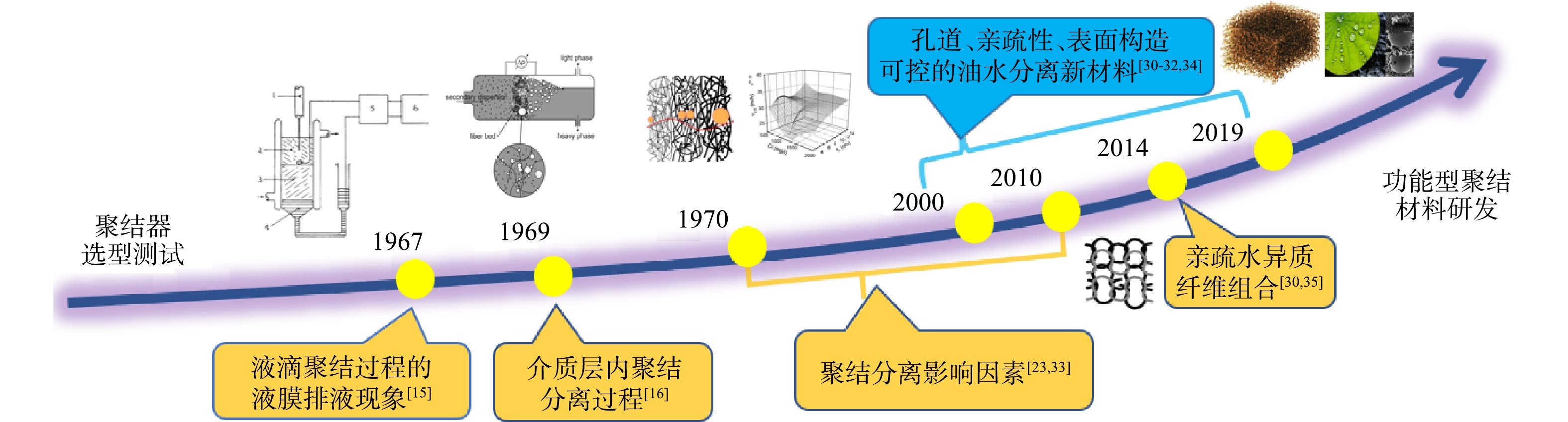

有关液滴聚结现象的研究,早在1897年RAYLEIGH观测小雨滴和池水碰撞时,就发现雨滴和池水表面存在的空气层会阻碍碰撞面的有效接触[13]。1956年GILLRDPIE等[14]和1967年BROWN等[15]较早地研究了油水界面处液滴的聚结行为,发现聚结发生的条件是界面间液膜排液、变薄直至液膜破裂。1969年HAZLETT[16]将纤维床内的液滴聚结分成接近、黏附和脱离3个过程。1978年WASAN等[17]研究了油滴黏度、界面张力等因素对水包油(O/W)乳液中油滴聚结行为的影响规律。近年来,研究者采用高速摄像对液滴碰撞聚结行为进行了研究。KUZNETSOV等[18]发现,随气相中液滴碰撞条件的变化,会出现弹跳、分离、聚结和破碎等碰撞结果。CHRISTOPHER等[19]、JING等[20]、SUBHASISH等[21]研究了微观条件下的液滴碰撞行为,发现低速碰撞更易于液滴聚结的发生。

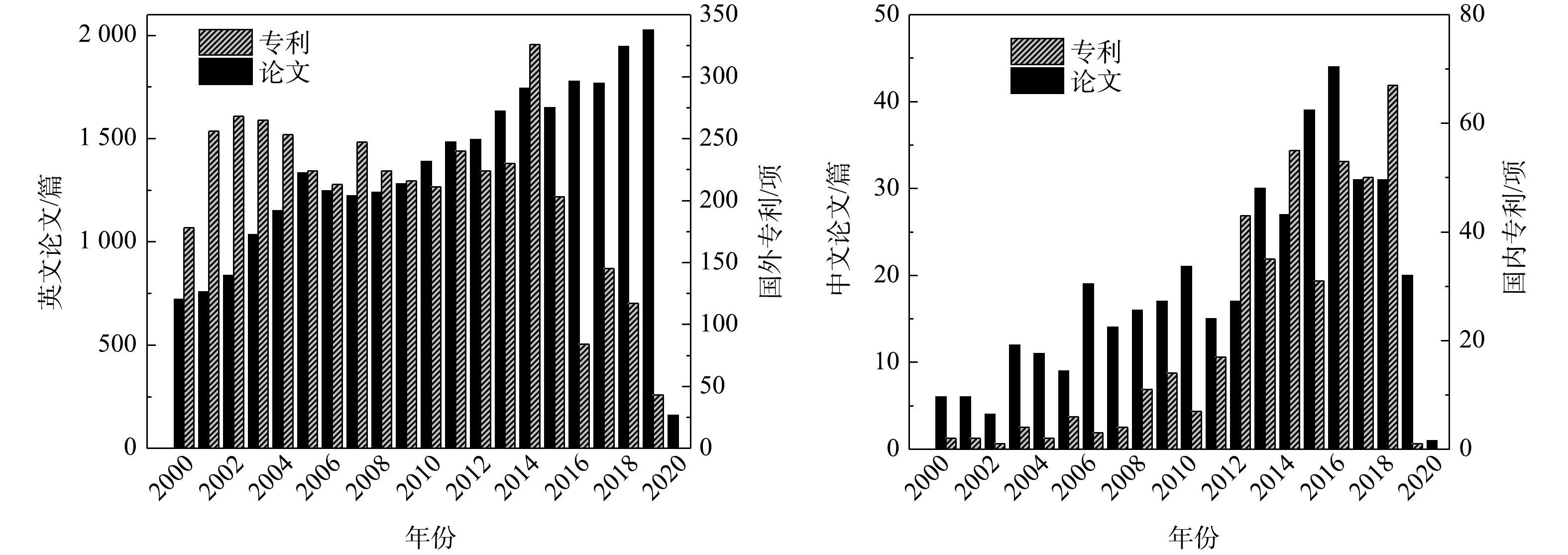

早在1930年左右,聚结分离技术就已开始在工业上应用。20世纪70年代初,随着石油工业的快速发展,含油污水体量大幅增加,从而促进了聚结分离技术的蓬勃发展。以SHERONY等[22]、SOKOLOVIC等[23]研究人员为代表,对聚结材料选型、聚结器构造、操作工况、乳液性质等因素对聚结分离性能的影响规律做了大量的实验研究[24-27]。该阶段主要研究内容在于传统聚结器选型的测试。2000年以后,对传统聚结器的新型设计与应用的研究仍在持续,但随着材料制备技术的发展,整体研究热点逐渐转为以孔道、亲疏改性、表面构造型式可控的功能型油水分离材料的研制[28-29](见图1和图2)。

-

采用物理或化学的方法使小液滴聚并长大的过程称为聚结,如采用化学药剂使乳状液中分散的液滴聚并、采用电场使液滴极化并相互吸引聚并、采用聚结介质捕获并诱导液滴聚结等过程。聚结分离技术一般特指介质聚结分离,其利用聚结介质填充层内流体流动特性和介质表面润湿性,将分散态的微小液滴聚结长大从而实现分离。HAZLETT等[36]将液滴-纤维聚结分为3个步骤:第1步接近过程,液滴在惯性力、范德华力、拦截、扩散等作用下接近纤维或接近附着在纤维上的液滴;第2步黏附过程,液滴接近纤维表面后,接下来希望发生的行为是液滴黏附在纤维上并在纤维上铺展,抵制黏附过程的因素是位于液滴与纤维之间的液膜,液膜必须薄到某一最小厚度才能发生破裂和黏附,液膜排液的阻力与液-液-固界面性质有关;第3步释放过程,流体曳力克服纤维对液滴的黏附力,液滴发生分离。

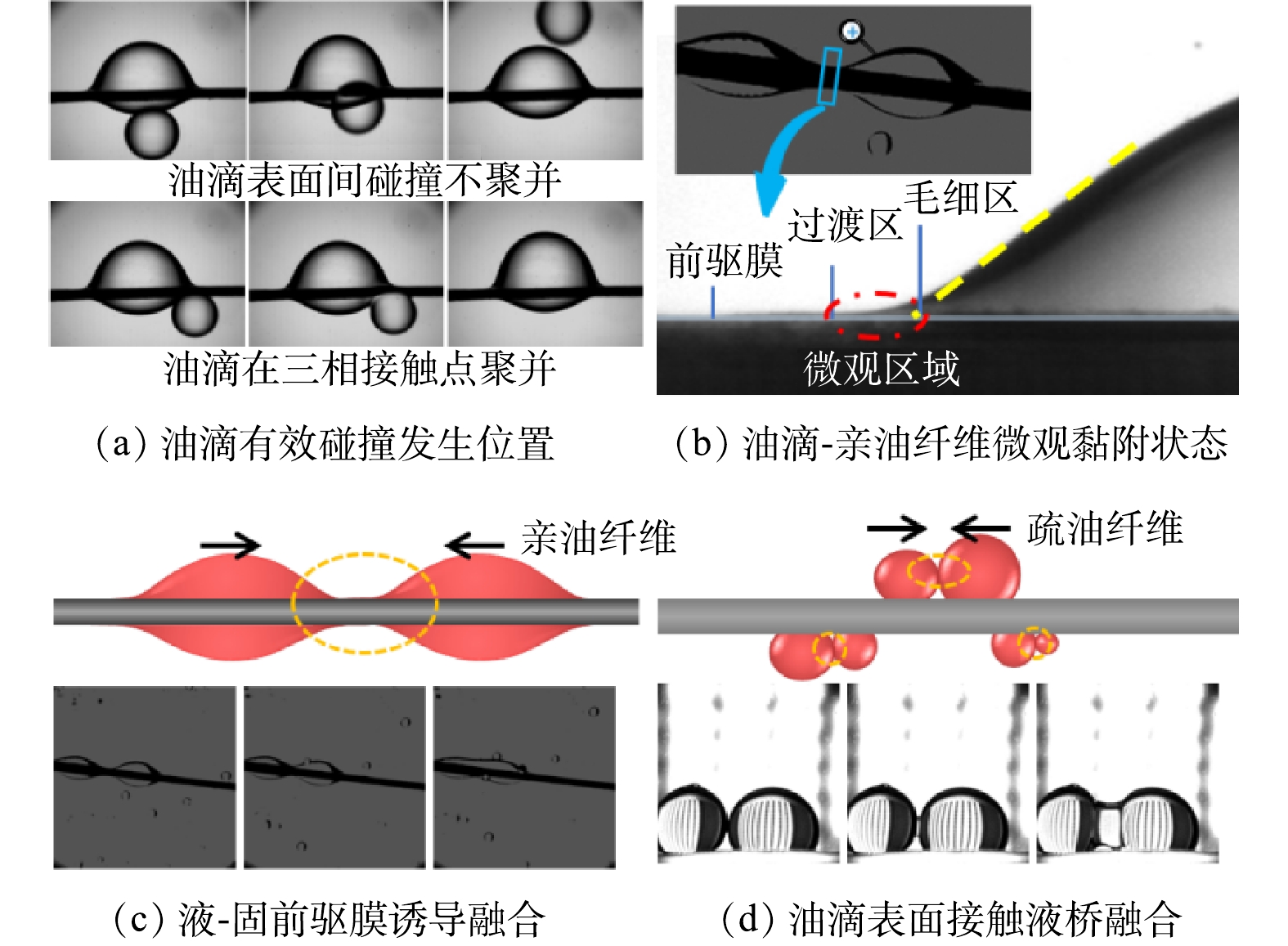

液滴间的碰撞与融合是一个非常复杂的包含多重时间尺度、空间尺度的多相流与界面科学问题[37]。目前已基本建立了气相环境中二元液滴碰撞的5种现象学结果[38-40],包括缓慢聚结、反弹、快速聚结、反射分离、拉伸分离,并且引入了韦伯数和碰撞参数等,绘制出二元液滴的碰撞结果相图。然而,类似的有关液相环境中二元自由液滴的碰撞结果体系尚未建立。近年来,许多研究者基于液滴微流控技术,对微通道内受限液滴的碰撞融合规律进行了研究[41-42]。研究者普遍认为,液滴融合需排出液滴之间的连续相流体并使得液滴界面失稳才能实现,可将液滴融合过程描述为:液滴互相靠近,发生碰撞并挤压变形;碰撞挤压过程中液滴间的连续相流体液膜不断被排出、变薄;液滴界面膜接触,失稳、破裂并发生融合。表面活性剂可抑制液滴的碰撞融合[43-44],即便在液滴间相互挤压变形较大的情况下,仍能保持液滴界面的稳定。其原理为,在液膜排液过程中,液滴界面上的表面活性剂浓度发生改变,并产生阻碍连续相排出的Marangoni对流,延长了排液时间。微流控系统中的液滴碰撞融合多发生在低速碰撞时,碰撞液滴间的液膜排液速度主要由毛细数决定。有研究者定义了临界毛细数,并将其作为判断液滴碰撞融合是否发生的关键参数[45-48]。如WANG等[48]研究了微液滴在不同夹角的Y型通道交叉处的碰撞、挤压、融合、分离的过程(见图3(a)),并通过分析液滴尺寸、流动性质与液膜排液时间、临界毛细数之间的关系,提出了预测液滴碰撞融合临界毛细数的公式。若碰撞液滴的接触时间足够长,液滴间的液膜排液将持续进行,直至液膜薄至分子层厚度时,液滴界面分子间作用力起作用,导致液滴融合。碰撞液滴间的液膜排液时间及碰撞融合的临界毛细数受许多因素影响,如液滴与连续相的黏度比、液滴尺寸、碰撞角度、微通道的结构及润湿性等[41]。目前,对液膜排液的实验研究仍局限于对较大的液滴,对于小于10 μm的乳化液滴,其需要排出的液膜体积将极大减少,且液膜排液的驱动力也会很小,而受拍摄条件的限制,乳化液滴的相关研究尚未见报道。

类似于液滴-纤维诱导聚结过程,DENG等[49]提出一种新颖的微针诱导液滴融合的方法,在一定程度上能够说明润湿性聚结介质对液滴碰撞聚结具有诱导作用。设计思路为:在两液滴碰撞相遇处加入微针,利用微针打破液滴界面膜的平衡状态,液滴通过界面“伤口”处的接触发生融合。微针表面润湿性和尖端形状对其诱导液滴融合的影响如图3(b)所示,具有润湿性表面且尖端锋利的微针可诱导液滴碰撞融合,而具有非润湿性表面的微针无法破坏液滴界面膜的稳定性,液滴相互挤压后分离。

在液滴-介质聚结机理方面,LU等[50]采用微流控和高速摄像技术,在微观尺度及毫秒时间尺度上,对纤维聚结过程中油滴的碰撞、黏附、聚并和迁移等微观行为进行测试,揭示了聚结发生位置、润湿性造成的黏附形态和聚结过程差异等介质聚结的相关机制,如图4所示。其研究发现:在聚结器内的流动碰撞条件下,由于水中油滴界面间的水膜排液速率远小于碰撞油滴之间相对运动的界面滑移速率,自由油滴与已黏附油滴之间的直接碰撞不会导致油滴聚结,油滴有效碰撞的发生位置为三相接触线或裸露纤维表面;在疏油纤维上,相邻黏附油滴由于表面间长时间接触产生的液桥导致融合,油滴特点为站立形、难融合、不迁移;亲油纤维上三相接触区域的前驱膜诱导融合是油滴聚结和纤维表面更新的关键,纤维表面循环发生着油滴的碰撞捕获-融聚长大-迁移聚并以及纤维表面更新的聚结过程;合适比例的亲水纤维与亲油纤维的组合能提高对油水互包液滴的破乳分离性能。

-

在填料式纤维聚结器分离性能的宏观影响因素方面,研究者普遍认为床层特性(如纤维润湿性、纤维尺寸、床层厚度、床层空隙率、床层比表面积)、操作条件(如流速、温度)、处理物料性质(如入口含油量、油滴粒径分布、表面活性剂)等3大因素都能对聚结分离性能产生关键影响[51-52]。

在床层厚度的研究方面,HAZLETT[16]认为床层厚度存在最优值,继续增加床层厚度对聚结无影响;而MAGIERA等[53]则认为,床层厚度越长分离效率越高。SOKOLOVIC等[23]将稳态聚结的最小床层厚度定义为临界床层厚度,指出聚结器中床层厚度的设计值应大于对应体系的临界床层厚度,并对床层厚度、流速、渗透率、入口油含量之间的相互依赖关系进行了研究。其研究表明,临界流速随床层厚度的增加而增加,当厚度超过临界床层厚度时,分离性能主要取决于床层渗透率和入口油含量。LU等[50]的研究表明,聚结器分离效率随床层厚度的增加而增加,但单位床层厚度对分离效率的提升量随床层厚度的增加而下降,特定尺寸液滴的分离效率与床层厚度的定量关系由床层过滤系数决定。

在纤维尺寸的研究方面,普遍认为减小纤维尺寸能提供更大的聚结表面积,从而提高分离性能[54-56]。床层几何特性与纤维尺寸密切相关,纤维尺寸越小则床层空隙率越小、比表面积越大,液滴被纤维捕获的概率越高。SHIN等[57]发现,在微米级纤维层中添加纳米纤维可提高分离效率,纳米纤维可增加介质比表面积并使空隙更小。在分散相液滴尺寸的研究方面,定性来看,液滴尺寸越小分离越困难,大于10 μm的分散液滴很容易被纤维捕获并可能同时与多条纤维接触;但对于小于10 μm特别是小于3 μm的乳化液滴,则较难被纤维捕获。在液滴粒径分布不变时,分散相浓度对纤维聚结器分离性能的影响很小[50]。表面活性剂会吸附在乳化液滴表面,形成稳定的油水界面膜,阻碍液膜排液,抑制液滴的聚结、碰撞捕获,降低分离性能。SHERONY等[22]、LU等[50]基于各自对液滴聚结机理的认知,在适当假设的基础上,建立了计算纤维尺寸、液滴尺寸、床层厚度等宏观参数与纤维床分离效率定量关系的理论预测模型。

在操作条件方面,流速对聚结效果的影响最为关键,研究者普遍认为,分离性能随流速的增加而降低。已有研究[31]中的表观流速范围为0.003~0.03 m·s−1。SOKOLOVIC等[58]将出口分散相浓度超过15 mg·L−1时的流速定义为临界流速,当流速低于此临界值时,出口油含量受流速的影响很小,而一旦流速超过临界值时,出口油含量便会随流速的增大而急剧升高。在入流方向的研究方面,SOKOLOVIC等[59-60]比较了入流方向为垂直向下、垂直向上、水平流动的纤维床分离性能,指出水平流动时具有最佳的分离性能。操作温度通过对流体黏度、界面张力的影响改变聚结效果,一般温度升高,聚结效果可得到一定提升[61]。

在介质润湿性的研究方面,多数研究者认为,采用亲分散相聚结介质更有利于提高分离性能[62-64]。BANSAL等[52]和AGARWAL等[65]建议采用分散相润湿性聚结介质,以及采用粗糙的纤维表面,并使流动方向与纤维层垂直。聚结介质的润湿性一直是备受关注的研究方向之一,尤其是近些年来随着材料制备技术的发展,调控材料润湿性的方法在一定程度上促进了聚结分离技术的发展。

2.1. 液滴聚结机理

2.2. 纤维聚结器分离性能的影响因素

-

聚结材料是聚结分离技术的核心,有天然聚结材料和人造聚结材料2种[66]:天然材料如石英砂、无烟煤、磁铁矿石等;人造材料如聚四氟乙烯、聚丙烯、聚氨酯等高分子材料,以及玻璃纤维、金属纤维、陶粒等无机材料。上述常规聚结材料受限于材料的表面性质,直接使用效果较差。研究者通过在常规聚结材料表面构筑不同的纳微结构或进行超疏水或油水双亲的表面润湿改性,来改善其聚结分离性能。

WAHI等[67]对采用天然纤维材料除油的研究进行了梳理,指出天然纤维在乳化油去除方面表现出高效、环境友好、易实现等特性,而采用一些化学手段对这些纤维改性处理后,能进一步提高其分离性能。在表面亲疏水改性方法方面的相关研究领域已取得进展,如:LIU等[68]以不锈钢网为基底,利用TiO2悬浮液和磷酸铝黏合剂制得水下超疏油不锈钢网;JIANG等[69]将甲基三甲氧基硅烷涂覆到不锈钢网上使其具有良好的亲水疏油性,水下油接触角高达163°;ZHU等[70]以SiO2纳米颗粒分散体为壳纺丝液,PTFE乳液为芯纺丝液,然后原位接枝全氟辛基三甲氧基硅烷,制备了一种分级的、油水双疏的纳米纤维膜,水接触角高达173°,油接触角为134°;YONG等[71]采用飞秒激光技术在聚四氟乙烯表面制造特殊的微观结构,使其能够在强酸、强碱、高温等恶劣环境中表现出持久的超疏水性和超亲油性;PATEL等[72]将不同浓度的聚丙烯溶液电纺成微米和亚微米尺寸的超疏水纤维材料,水接触角超150°。

改性后,聚结材料的油水分离性能得到显著的提高,如:LANGDON等[73]采用甲醛涂层的玻璃纤维对含油污水进行除油,在适宜流速下,除油效率达到100%;张鹏飞等[74]在聚丙烯板的一面覆盖一层氧化薄膜,形成亲水性表面,在另一面保持原有的亲油性,获得的复合聚丙烯板可以提高分离器25%的分离效率;WEI等[75]制备了纳米二氧化硅表面修饰的聚偏氟乙烯膜,表面水接触角达157°,可用于油水混合物和表面活性剂稳定的油包水乳液的分离;JI等[76]采用醇解反应对聚丙烯腈纤维进行改性,醇解反应增强了油滴与纤维之间的黏附力,改性后的聚丙烯腈纤维床具有更加优异的分离性能,其实验体系下的除油效率达到97.3%;HU等[77]用聚氨酯树脂将纤维素纤维黏合在一起,制备的纤维层结构完整性好、油水分离效率高,且抗拉强度是原始纤维层的20倍。

-

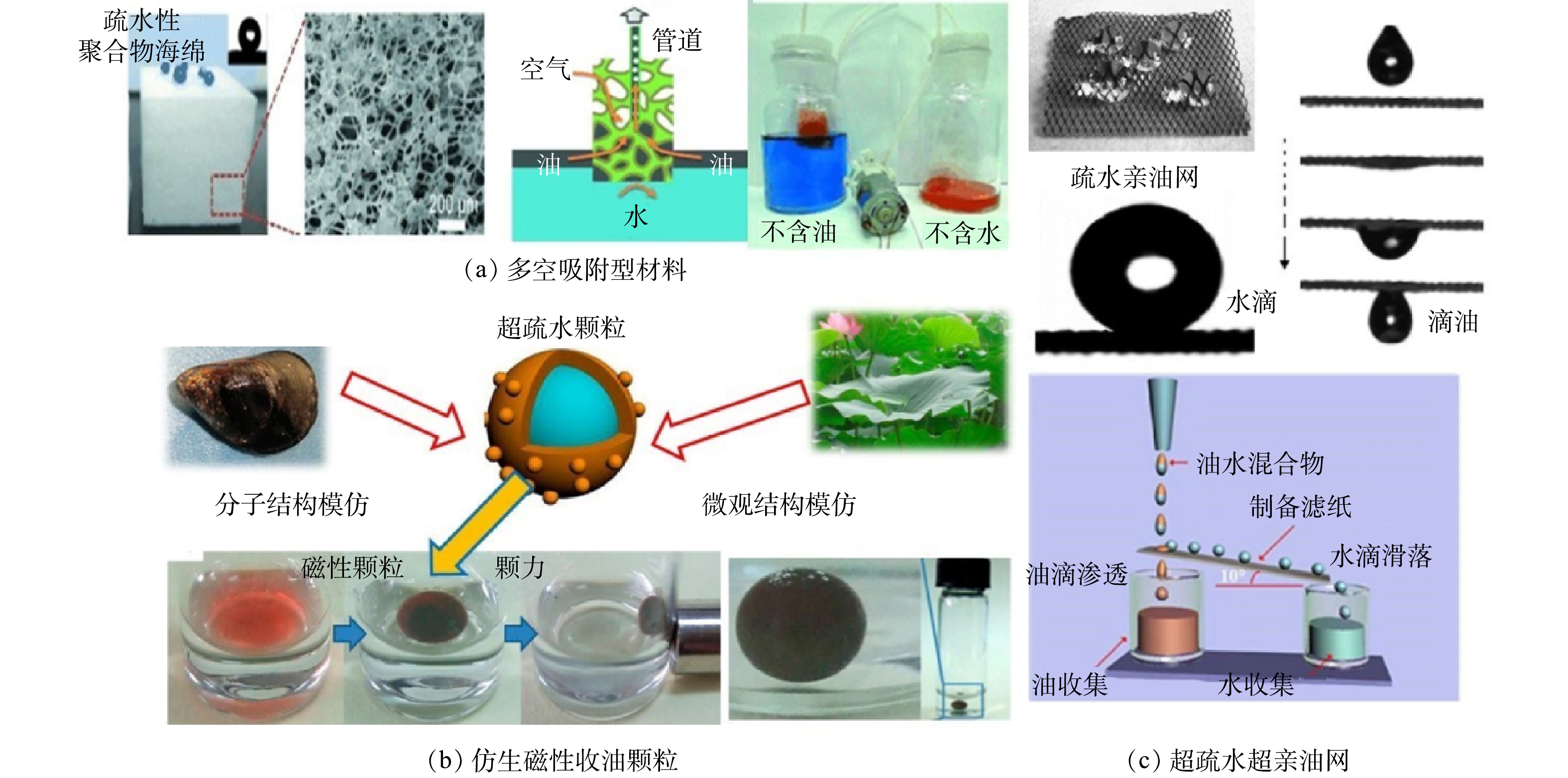

近年来,随着材料科学的发展,以多孔吸附分离为代表的功能型油水分离新材料(图5)的研究成为油水分离领域的研究热点。多孔材料是一种由大量的相互贯通或封闭的孔洞所组成的网状结构材料,其在密度、渗透性、比表面积、质量等特性方面均优于其他吸附材料[78]。研究人员在传统多孔材料的基础上进行改性处理,可获得具有选择性、高吸附能力的多孔材料。如GE等[30]采用浸涂法研制出一种疏水性聚合物海绵,其多孔系统可通过毛细作用将油吸入,达到油水分离的目的(见图5(a))。基于仿生学的油水分离材料也是研究的热点之一,例如,ZHANG等[79]以羰基铁颗粒作为芯材,结合荷叶的超疏水性能和贻贝黏附蛋白的黏附能力,制备了具有类似于荷叶表面微观形态的分层结构的核/壳/卫星复合颗粒,其具有磁性和超疏水性,该颗粒可作为吸油剂和磁控载体,在磁场作用下可将水中的油收集成油丸而分离(见图5(b))。HAN等[34]和PAN等[80]制备了具有超疏水和超亲油特性的改性铜网,当滴上油水混合物时,油滴将穿过网孔,而水滴将沿着倾斜的网面滑落,从而在铜网表面实现油水分离(见图5(c))。诸如此类新材料的开发,扩宽了聚结分离技术的研究方向。

-

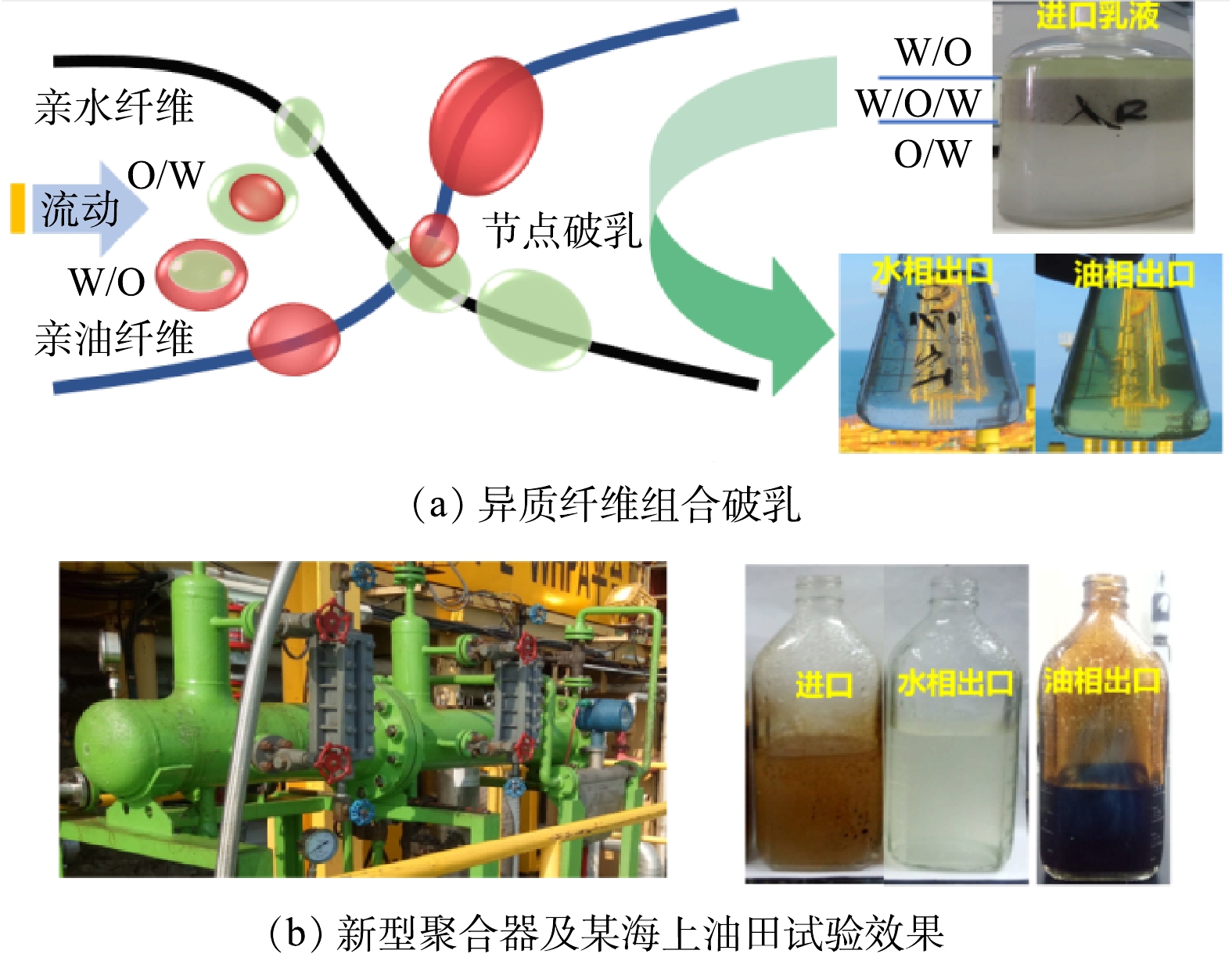

近年来,国内研究者对油水聚结分离过程中液滴与液滴、纤维界面的相互作用关系进行了系统研究,提升了对介质聚结机理的认识[50]。杨强等[35, 81]在液滴破乳、聚结分离微观机理研究的过程中发现,油水乳液流动过程中乳化液滴会在异质纤维交叉节点处因油水极性受力差异而发生破乳分离(见图6(a)),并基于此提出将润湿性不同的亲水、亲油异质纤维进行组合编织的破乳分离方法。异质纤维以特定的比例和几何构型进行组合编织,依据该方法设计的新型纤维聚结器[82],可强化液滴捕获、乳液破乳,提升聚结分离性能;同时,其编织结构还可允许微细颗粒物穿透,从而提升聚结材料的抗污堵性,突破了传统渗透式滤芯聚结分离技术因孔隙小导致易磨损、堵塞失效的难题。新型纤维聚结器实验装置在多个工艺的污水除油过程中表现出优异的分离性能[83-84]:对某延迟焦化放空污水中石油烃的去除率达99%,设备出水油含量约120 mg·L−1,满足进下游汽提装置要求;除溶解性芳香烃外,可完全去除某芳烃装置冲洗水中的乳化态及分散态的石油烃;在某海上油田生产污水处理中,设备入口污水中石油类含量为600~750 mg·L−1,设备出口污水中石油类含量为6~15 mg·L−1,平均除油效率98%;在另一海上油田生产污水处理中,设备入口污水中石油类含量800~1 000 mg·L−1时,设备出口污水中石油类含量降低至30 mg·L−1,平均除油效率96.7%(效果见图6(b))。

3.1. 改性聚结材料

3.2. 功能型油水分离材料

3.3. 亲水和亲油异质纤维组合聚结材料

-

根据聚结材料的不同,聚结分离器的型式主要有板式、填料式和滤芯式3种[66]。

1) 板式聚结分离器。板式聚结器结构及聚结板组(见图7)主要基于浅池原理设计,流体在板组通道内流动过程中,油滴碰撞或上浮到聚结板表面而被分离。板组形式有平行板、错流板、波纹板等,板材可采用聚丙烯、不锈钢、碳钢等[85-88]。

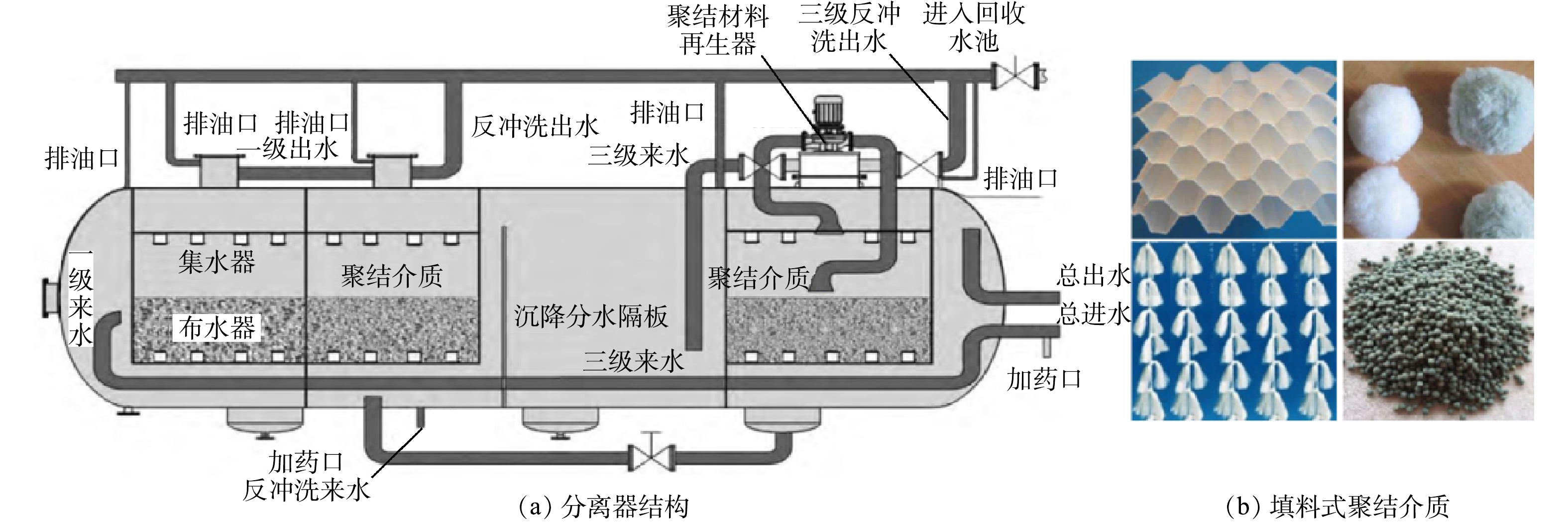

2) 填料式聚结分离器。填料式聚结分离器以规整或散装的各种规格聚结介质作为媒介,流体在介质床层通道内流动时,油滴在介质表面聚结而被分离。聚结介质形式有规整填料式、散堆纤维式、散堆颗粒式、泡沫式等。聚结介质是影响聚结分离效果的关键,根据润湿性的不同可分为亲油介质和亲水介质,常用的亲油介质有聚四氟乙烯、聚丙烯、聚氨酯等高分子材料,常用的亲水介质有玻璃纤维、金属纤维、石英砂、不锈钢板等,其中聚四氟乙烯的亲油性最好、玻璃纤维的亲水性最好[89-90],填料式聚结分离器结构及介质见图8。

聚结器内的填料可采用单一介质或多种介质的组合,如刘丽艳等[91]、潘嘉芬等[92]分别研究了微米级竹炭纤维介质对油包水乳液、多孔陶瓷颗粒介质对水包油乳液的聚结分离性能和因素影响规律。有研究表明,组合介质的分离性能优于单一介质,如KULKARNI等[93-94]发现,合适比例的玻璃纤维和聚丙烯纤维制作的亲水与疏水复合介质,比单一玻璃纤维介质的分离效率更高,并能显著降低床层压降。杨强等[35, 80-81]基于亲油纤维和亲水纤维对油水两相的黏附力不同,提出采用异质纤维组合编织的破乳分离方法。

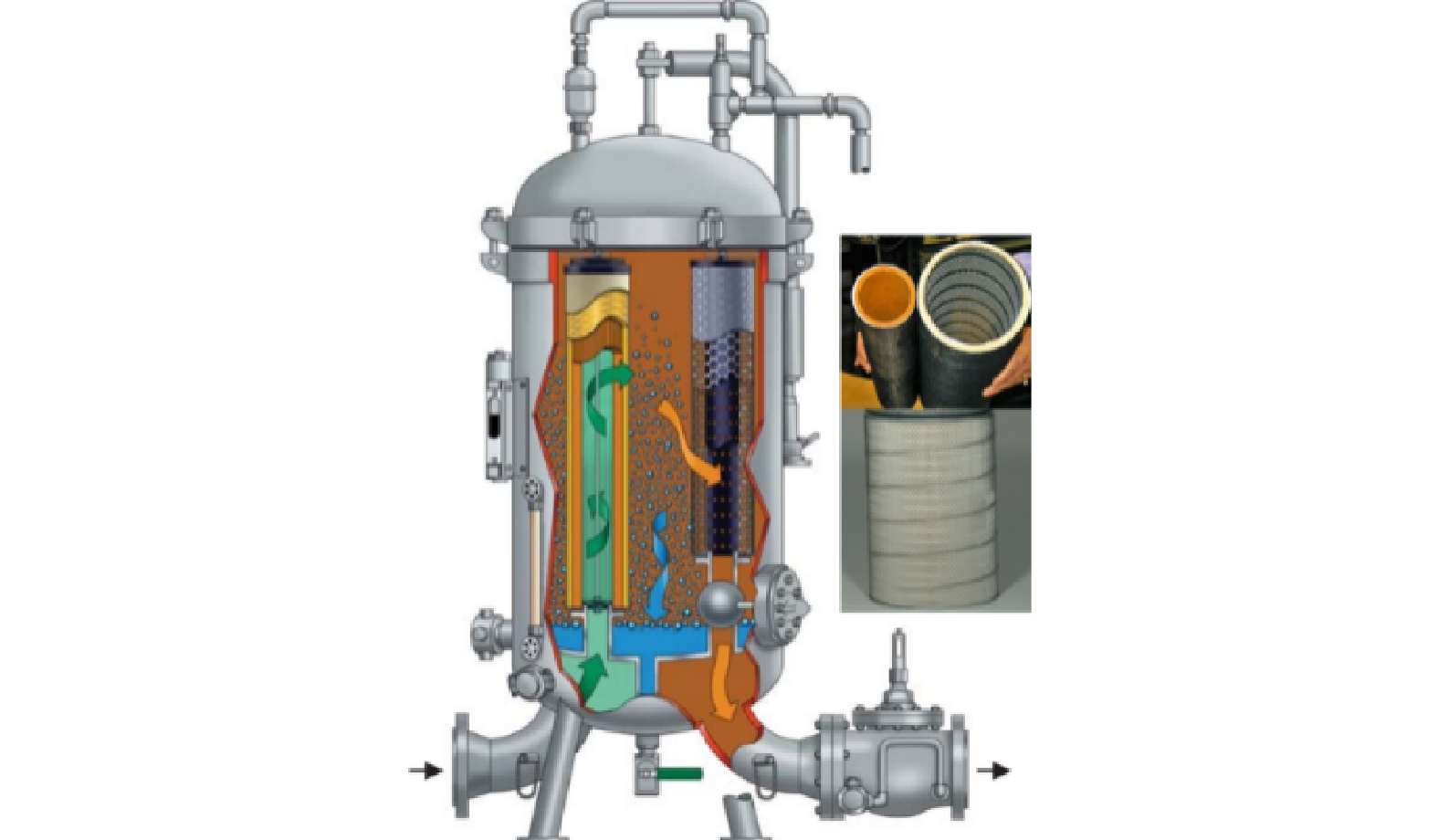

3)滤芯式聚结分离器。滤芯式聚结分离器是将聚结材料加工成滤芯置于分离器内[51, 95-96]。滤芯一般由致密的毡状聚结层、分离层、支撑钢网和钢架组成,由于滤芯聚结介质的填充密度大、孔隙小,可用于乳化油水的精细分离,但处理含固体杂质的物料时存在易堵塞的问题,滤芯式聚结分离器结构见图9。

-

1)油气开采。在油气田开采过程中,井下采出物经三相分离器完成油、水、气的粗分离后,会产生大量的含油生产污水[97]。生产污水体量大、毒性强,排放指标要求严格。在中海油某海上气田平台生产污水处理中,采用了以纤维聚结分离技术为核心的生产污水处理工艺,处理后排海生产污水油含量低于25 mg·L−1,远低于平台所在三级海域的国家排放指标限值45 mg·L−1,解决了该气田开发后期高乳化生产污水的处理难题[98]。

2)石油炼制与化工。在石油炼制与化工中,含油污水来自于多个单元装置[99-100],如在电脱盐装置中,由于原油中环烷酸、沥青质、胶质等天然乳化剂的存在,会造成电脱盐切水油含量高、乳化严重的问题;在常减压蒸馏、催化裂化、延迟焦化等装置的分馏塔顶,油气和水蒸气冷凝后形成含油污水,该部分含油污水含有硫化氢和氨,经除油处理后再进入后续污水汽提装置做净化处理。在某石化电脱盐污水处理中[101],使用了纤维介质和板式介质组合的聚结除油装置,进口污水油含量为150~3 550 mg·L−1,装置出口污水油含量稳定小于50 mg·L−1,且装置具有操作弹性大、低压降的优点;在洛阳石化延迟焦化装置放空含油污水的处理中,亦使用了类似的聚结除油技术,进口污水油含量平均4 500 mg·L−1,除油器出口污水油含量平均418 mg·L−1,除油效果明显[102]。

3)煤化工。甲醇制烯烃装置中,反应产品气中的油类物质在急冷水和水洗水中冷凝,形成含油污水。油类物质以芳烃类为主,在水系统中累积会带来外排净化水COD偏高、水系统换热器堵塞的问题。在某甲醇制烯烃装置的水系统中,增设了以滤芯式聚结器为主要设备的油水分离装置,取得了良好的油水分离效果:外排净化水COD由原来1 500 mg·L−1降低至600 mg·L−1以下,净化水COD含量满足装置外排指标;并且有效控制了油类物质在水系统中的累积,延长了换热器、空冷器等设备的运行周期[103-105]。聚结分离技术还可应用于煤气化污水、煤焦污水、煤制油污水的隔油预处理过程[106-107],为后续物化和生化处理装置的稳定运行提供保障。

4) 船舶含油污水。船舶含油污水的主要来源包括船舶正常操作过程中排放的压载水、洗舱水、舱底水等3类[108]。由于船舶所用油品种类多,且包含大量化学药剂,导致这3类含油污水成分较为复杂、乳化程度较高[109]。随着海上防污法规的日趋完善,对船舶含油污水的处理要求日益严格[110]。在某船舶含油污水处理系统中,在原有一级油水分离装置的基础上,增加了以聚结分离器为主要设备的二级油水分离装置,流入二级油水聚结分离器的污水油含量从100 mg·L−1降至15 mg·L−1以下,满足了国际海事组织的排放标准[111]。

5) 金属工业。金属工业中含油污水的两大来源是钢铁生产及金属机械加工。钢材冷轧厂产生的洗涤水和冷却水油含量高,主要含1%~3%的矿物油、乳化剂,其中25%以上是难分离的乳化油[112-113]。近年来,国家对冷轧污水排放做了严格限制,提高了排放标准[114]。在某冷轧污水的处理过程中[115],改性聚四氟乙烯纤维聚结器的除油效率高达90%以上,出口油含量低于90 mg·L−1。金属机械加工中的含油污水主要来源于金属清洗液、切屑液、润滑液等,一般污水量不大,但污水成分比较复杂,主要含油脂、表面活性剂、悬浮杂质等。污油以浮油、分散油、乳化油多种状态存在[112, 116]。在某柴油机制造厂的中水回用工程改造中[117],增设了高效纤维束聚结过滤器,使得系统出水石油类含量从1 000 mg·L−1降至10 mg·L−1以下。

4.1. 聚结分离器基本形式

4.2. 聚结分离技术在工业含油污水处理中的应用

-

虽然传统介质聚结分离技术的应用研究已较为成熟,但介质聚结的理论体系仍有待完善。目前国内外对聚结机理的认识尚不明晰,聚结过程涉及的油-水-固界面科学问题有待揭示,缺乏指导聚结介质定量设计和选型的理论模型。从聚结分离深度的角度看,仅依靠流体流动和介质床层结构难以实现亚微米级别液滴的聚结分离,施加电场、超声等多物理场辅助的方式强制亚微米液滴的迁移和聚并,可进一步提升介质聚结分离性能。从新材料研制方面看,开发表面改性聚结材料,以及研制超亲疏性、多孔吸附等功能型油水分离材料仍是研究的热点。

下载:

下载: