-

近年来,聚偏氟乙烯(PVDF)因其优异的机械性、耐辐射性、化学稳定性和耐腐蚀性而成为关键的分离膜材料[1]。因此,该材料已被广泛应用于微滤、超滤、膜生物反应器等领域[2]。然而,其低亲水性的特点往往造成严重的膜污染,导致分离过程中能量消耗增加,膜的使用寿命降低,从而造成运行成本增大[3]。等离子体改性技术是改善PVDF超滤膜亲水性的方法之一[4],已有研究[5-8]发现,经等离子体处理后,膜表面的亲水性得到了改善,膜的抗污染性能得到了提高,膜的使用寿命得到了延长。

不同的惰性气体和反应性气体可以结合多种化学基团(如羟基、羰基、羧基、氨基或过氧基),以进一步提高电化学性能。氧等离子体可通过接枝羟基、羰基和羧酸酯基团来修饰表面,但有研究[9]发现,氧具有化学刻蚀特性,氩等离子体在引入表面粗糙度相对较低的含氧基团方面更有效;而氨等离子体不仅可以在材料表面引入含氧基团,还可引入大量含氮基团,从而提高材料表面的亲和性[10]。然而,以往的等离子体表面改性研究均只限于放电区进行,放电过程中生成的等离子体中各种活性物质(如电子、离子、自由基)混合存在[11],并同时作用于材料表面,发生修饰、接枝聚合、交联和刻蚀等综合效应,对材料表面的刻蚀作用较强[12]。在前期研究[13]的基础上,利用等离子体中各种活性粒子存活寿命不同、对材料表面作用不同的特点,通过改变样品距放电中心的距离来控制等离子体中活性粒子的浓度,以获得相对高浓度的自由基环境,增强自由基反应,减少电子、离子刻蚀反应 [11,14]。已有研究 [15-17]表明,与等离子体改性相比,远程等离子体改性在进一步提高材料表面亲水性、抗污染性能的同时,可降低改性过程对材料表面机体性能和膜孔性能的影响。

本研究采用远程氨等离子体处理PVDF超滤膜,通过接触角表征PVDF超滤膜表面的亲水性变化,通过扫描电镜和X-射线光电子能谱表征PVDF超滤膜表面形貌、化学成分变化,通过BSA过滤实验,评价改性前后PVDF超滤膜的过滤性能及抗污染性能变化,为等离子体膜表面改性研究提供参考。

全文HTML

-

PVDF超滤膜(截留分子质量为10 000 Da,深圳市嘉泉膜滤设备有限公司),氩气(高纯,武汉高能达气体有限公司),氨气(高纯,武汉高能达气体有限公司),牛血清蛋白(5 g,分析纯,国药集团化学试剂有限公司)。

1.0 g·L−1 的BSA溶液配制方法:准确称取 1 g BSA,用磷酸盐缓冲溶液 (pH=7.5) 溶解,加入到1 L容量瓶中定容,配成备用。

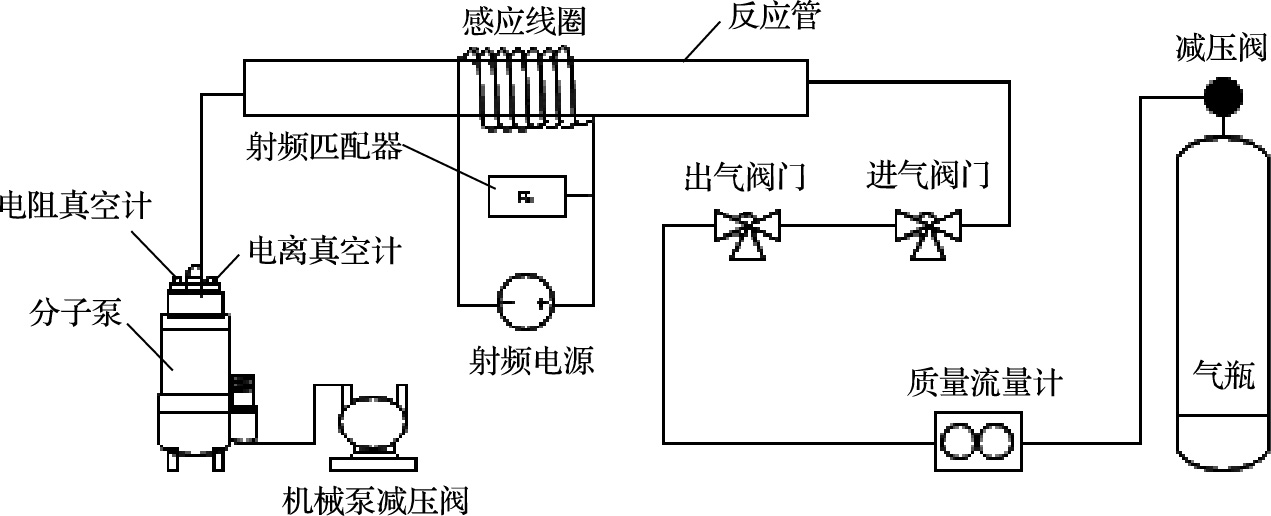

实验仪器包括:接触角测量仪(Sa100,德国德吕士);扫描电镜(GSM5800,日本Jeol电子公司);超滤杯(MSC300型,上海摩速科学器材有限公司);紫外分光光度计(UV-9100,北京瑞利分析仪器公司)。自主研制远程等离子体反应系统如图1所示。其中,反应室为长1 000 mm,直径45 mm的硬质玻璃管,采用电感耦合式放电产生远程等离子体,在理想管式反应器中向远端扩散。

-

PVDF超滤膜长×宽为15 mm×10 mm,表面含有亲水性活性剂。在放电中心处,利用氩等离子体(30 W,20 cm3·min−1,30 s)对其进行预处理,以活化和清洗样品表面。将处理后的样品放置在距放电中心分别为0、20、40、60和80 cm处的5个不同位置的载物板上,通过改变等离子体射频功率、处理时间、气体流量,对样品进行可控氨等离子体处理。

-

采用接触角测量仪测量样品处理前后的水接触角。测量温度为20 ℃,相对湿度为45%,取10次测量结果的平均值。采用扫描电镜观察样品处理前后的表面微观形态。观察前,对样品进行喷金,使其成像,放大倍数为20 000。采用X-射线光电子能谱分析样品处理前后的表面化学成分。体系为美国Perkin-Elmer公司的PHI5400ESCA,X射线源为MgKα(1253.6 eV),功率为250 W,通能为89.45 eV,分析室真空度优于5×10−8 Pa。采用超滤杯测量样品处理前后的纯水(BSA)通量、BSA截留率及总污染率。

1)通量的计算。将剪好的直径为80 mm的超滤膜安装在超滤杯中,往超滤杯中加入300 mL蒸馏水或BSA溶液,密封,用氮气进行加压、调节,使操作压力保持在0.1 MPa,调节搅拌速度为200次·min−1,对透过液计时取样进行实验,取5个测量值的平均值。超滤膜的通量计算方法如式(1)所示。

式中:J为超滤膜的通量,L·(m2·h)−1;Vt为t 时间内透过液体积,L;A为有效膜面积,m2;t为实际操作时间,h。

2)截留率的计算。将操作压力保持在0.1 MPa,用超滤杯测试1.0 g·L−1 的BSA溶液1 h并收集透过液,利用紫外分光光度法分别测定原液与透过液的BSA 浓度(280 nm)。截留率计算方法如式(2)所示。

式中:R为膜对蛋白质的截留率;Cp为透过液中BSA 浓度,g·L−1;Cb为原料液BSA 浓度,g·L−1。

3)总污染率的计算。将操作压力保持在0.1 MPa,测得该压力下膜污染前的纯水通量。然后注入浓度为1.0 g·L−1 的BSA 溶液进行超滤,1 h后,重新用水超滤,并测定污染后的水通量。总污染率计算方法如式(3)所示。

式中:F为超滤膜的总污染率;Jw为过滤BSA 后的纯水通量,L·(m2·h)−1;Jo为过滤BSA 前的纯水通量,L·(m2·h)−1。

1.1. 实验原料、仪器与装置

1.2. 实验方法

1.3. 分析方法

-

图2~图4反映了氨等离子体处理时间、射频功率、气体流量对亲水性的影响。采用水接触角评价超滤膜表面的亲水性,PVDF 超滤膜原始水接触角为95.63°。

图2反映了射频功率30 W,气体流量20 cm3·min−1时,氨等离子体处理时间对膜表面亲水性的影响。由图2可以看出,当处理时间较短(30 s)时,试样的改性效果不明显;而处理时间增至45 s时,接触角迅速减小;随着处理时间的继续增大,接触角变化逐渐平缓。等离子体处理时间过长或过短都不利于对PVDF膜的亲水改性,其原因是随着处理时间的增大,反应腔室内自由基的含量逐渐增加,基团内的活化作用越来越明显,等离子体中的自由基与膜表面的活性基团不断反应而使接触角不断降低;而处理时间过长时,反应将逐渐饱和,再继续延长时间,会使各基团的交联作用成为主导,致使自由基的含量不断减少,不能有效地作用于材料表面。

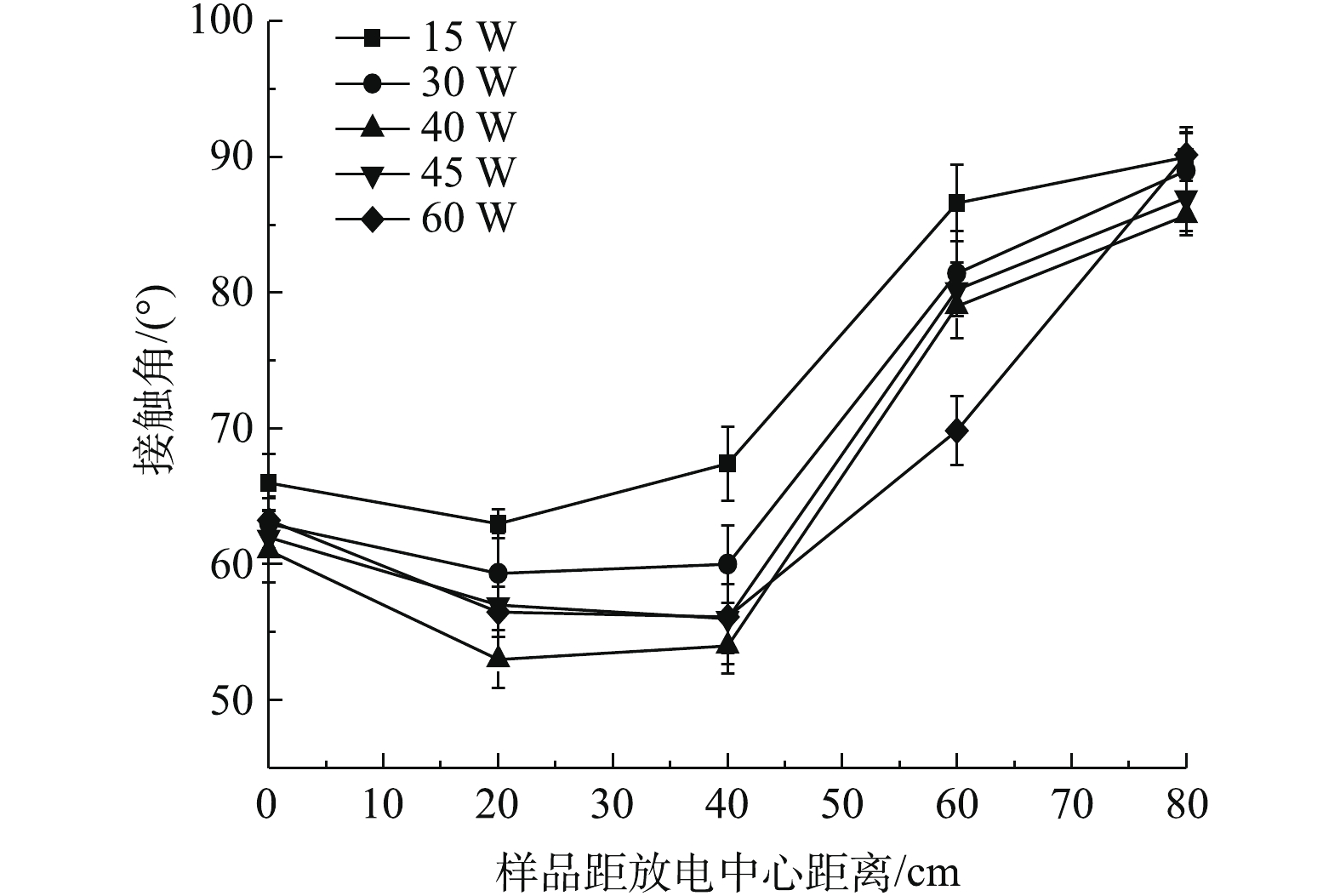

图3反映了处理时间45 s,气体流量20 cm3·min−1时,氨等离子体射频功率对膜表面亲水性的影响。由图3可以看出,随着放电功率的增大,接触角逐渐减小。这是由于功率增大时,定量氨气分子获得的能量增大,则氨气的电离度以及活性粒子的平均能量增高,使得活性粒子对PVDF超滤膜的作用概率和强度增强,从而增强了表面改性效果[18]。当功率达到40 W后,由于离子密度和能量的变化趋于稳定,表面改性反应达到平衡。当功率大于40 W时,电子、离子的生成范围扩大且放电区的电离度及活性粒子的平均能量增加,增强了氨等离子体的刻蚀作用,将膜材料表面涂覆的一部分亲水性物质清洗掉,减弱了材料表面与自由基的相互作用,从而导致材料表面接触角增大。可以看出,PVDF超滤膜接触角随着距放电中心距离的增加,呈先降低然后又增加的趋势,在20 cm和40 cm处达到较低值,在80 cm处接触角基本无变化。这是因为:放电中心处电子、离子、自由基的浓度均较高,与材料表面发生刻蚀与修饰作用;距放电中心40 cm处,电子、离子逐渐消亡,自由基浓度相对较高,与材料表面的相互反应增加了PVDF超滤膜的表面的亲水性[19];而距放电中心80 cm左右时,电子、离子、自由基等活性粒子基本全部消亡,对PVDF超滤膜表面作用微弱。由上述结果可见,氨等离子体的最佳射频功率为40 W。

图4反映了射频功率40 W,处理时间45 s时,氨等离子体气体流量对膜表面亲水性的影响。由图4可以看出:当气体流量为10~50 cm3·min−1时,随着气体流量的增大,接触角的变化幅度相近;当气体流量小于20 cm3·min−1时,反应腔室中的自由基在运动过程中能量损失较大,到达膜表面的自由基含量较低,膜表面的改性效果不明显;当气体流量超过20 cm3·min−1时,腔室内的中性气体分子密度较大,增大了离子与中性粒子的碰撞概率,氨等离子体中的离子密度同步增加,加剧了膜表面等离子体的交联作用从而使自由基含量减少,从而使材料表面接触角增大;当气体流量为20 cm3·min−1时,样品在20~40 cm处接触角出现最小值52.79°,使PVDF超滤膜表面亲水性明显改善。因此,氨等离子体处理PVDF超滤膜的最佳条件为:射频功率40 W,处理时间45 s,气体流量20 cm3·min−1。

-

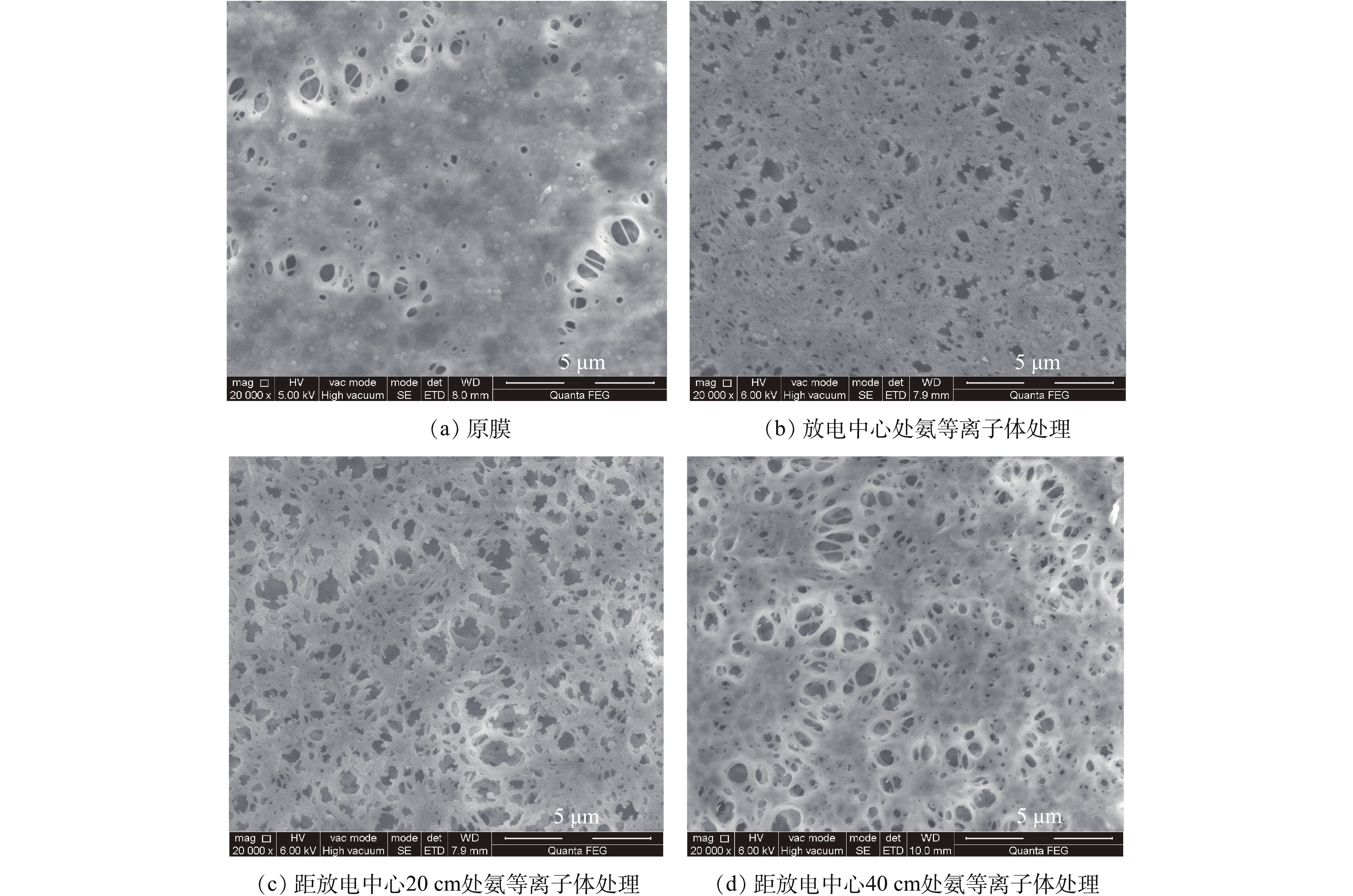

图5为射频功率40 W,处理时间45 s,气体流量20 cm3·min−1条件下PVDF超滤膜处理前后的SEM图。通过SEM观测等离子体处理前后PVDF超滤膜表面的微观形态,判断表面的破坏程度。与原膜相比,经放电中心处氨等离子体处理后的PVDF超滤膜表面粗糙,刻蚀程度很高,孔径有断裂破坏。经距放电中心20 cm处氨等离子体处理后,膜孔增多的同时可以看到膜孔周围呈现撕裂状;而经距放电中心40 cm处氨等离子体处理后,膜表面刻蚀现象轻微,能清晰看见膜孔且膜孔周围未出现撕裂状。由此可见,距放电中心40 cm处,氨等离子体处理抑制了电子、离子对膜表面的刻蚀作用,未破坏膜孔形状。

-

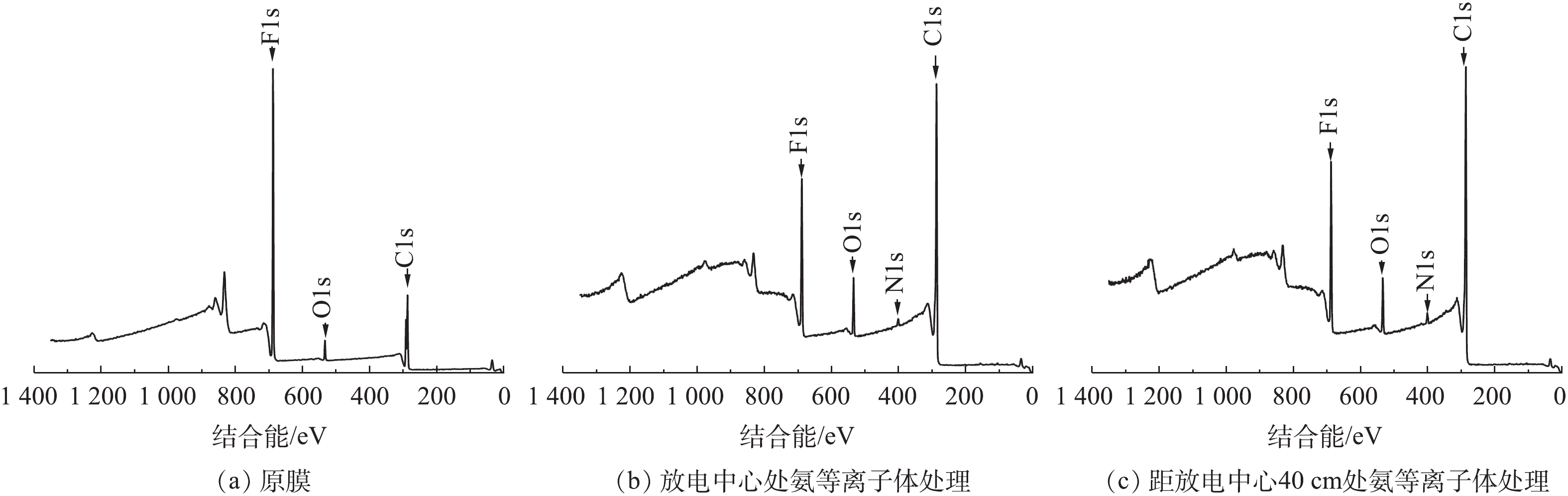

表1和图6分别为40 W、45 s、20 cm3·min−1条件下未处理的、放电中心处氨等离子体及距放电中心40 cm处氨等离子体处理后的PVDF超滤膜的表面元素组成及总谱图。可以看出,经氨等离子体处理后,PVDF表面的(O+N)/C值增加,F/C值降低,且距放电中心40 cm处,(O+N)/C值最大,F/C值最小。这表明,经氨等离子体处理后PVDF表面引入了含氧、含氮基团,膜表面亲水性得到改善,且距放电中心40 cm处改性效果最明显。

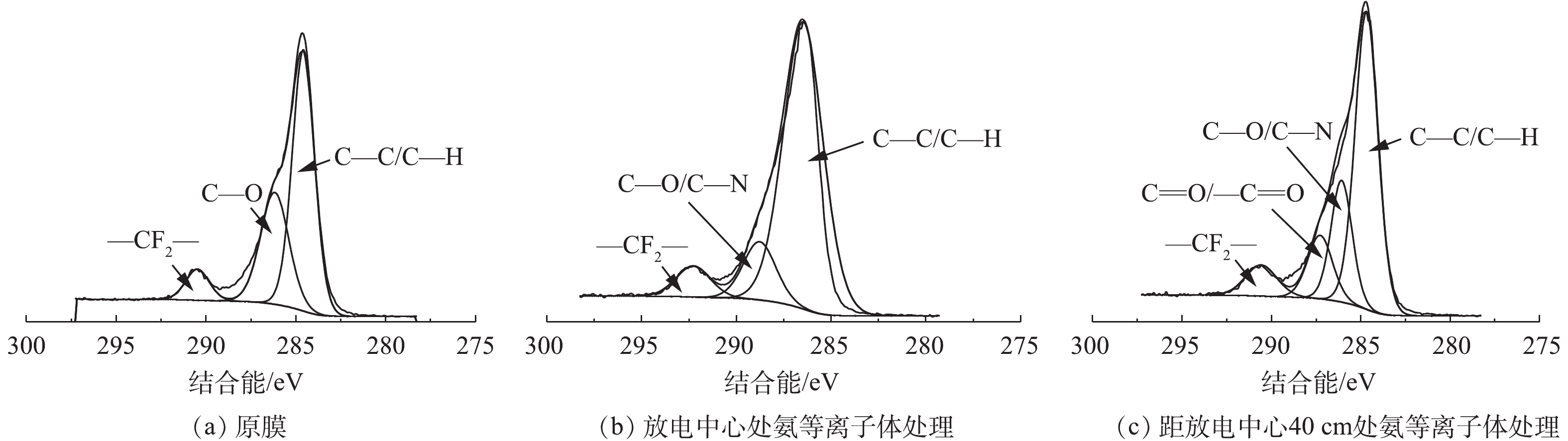

由图7可知,原膜的C1s光谱分别在284.6、286.1和289.5 eV处有3个分离峰[20],分别对应于C—C/C—H、C—O和—CF2—。C—O官能团的出现来自于未清洗掉的添加剂,但是C—O官能团含量极少。经氨等离子体改性后的PVDF超滤膜的光谱图7(b)和图7(c)也显示了这3个峰,同时,C—H、—CF2—官能团含量减少。距放电中心40 cm处氨等离子体处理后,在287.2 eV处出现了少量的C=O/—C=O官能团,且C—H、—CF2—官能团含量进一步减少,C—O/C—N官能团含量增多。膜表面的C—O官能团可能是膜经氨等离子体处理后,表面的碳自由基与空气中的氧元素发生反应产生的。与原膜相比,等离子体处理后的膜降低了C—H、—CF2—的百分比,这种减少与C—O/C—N和C=O/—C=O官能团百分比的增加相抵消[21]。这些结果表明,等离子体处理使C—H、—CF2—键断裂,并在PVDF超滤膜表面的分子链中引入含氧、含氮官能团。这些亲水性基团有助于提高PVDF超滤膜的表面亲水性,这一结论与水接触角分析结果吻合。

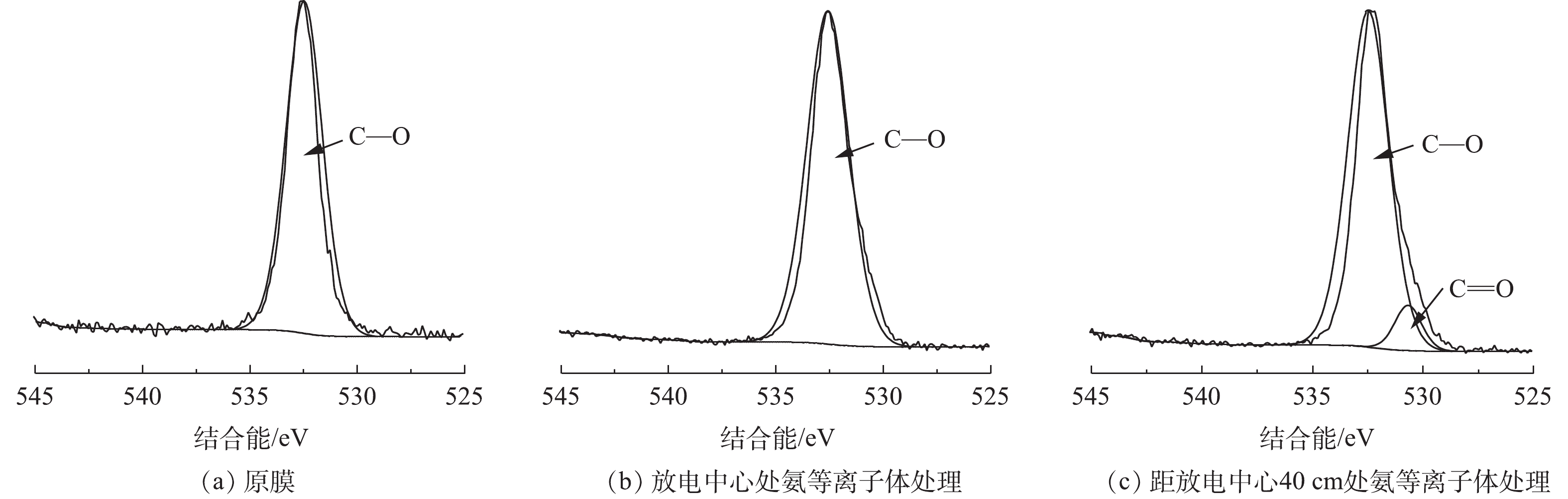

图8为氨等离子体处理后PVDF膜的O1s光谱图。由图8可以看出,原膜的O1s光谱在532.8 eV处出现C—O的分离峰[12]。经氨等离子体处理后的PVDF膜也出现了C—O分离峰,且官能团含量增多。经距放电中心40 cm处氨等离子体处理后,在531.7 eV处出现了少量的C=O官能团[12]。

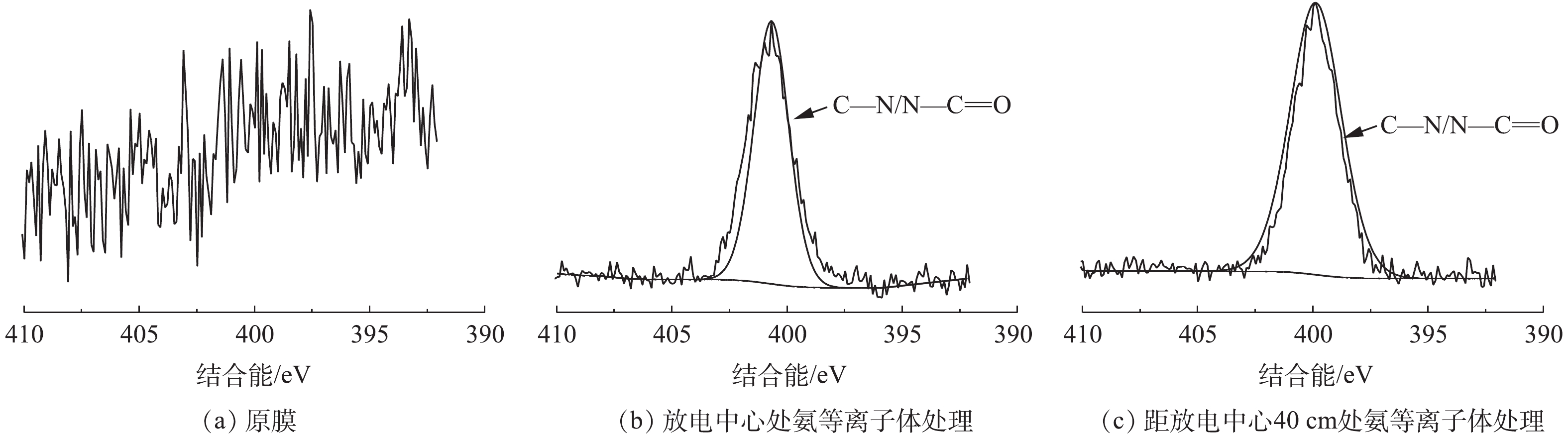

由图9可以看出,原膜的N1s光谱没有分离峰,但经过距放电中心40 cm处和放电中心处氨等离子体处理后在399.08 eV处出现了C—N/N—C=O的分离峰,且距放电中心40 cm处氨等离子体处理后的膜其C—N/N—C=O分离峰强度高于放电中心处氨等离子体处理后的膜。

-

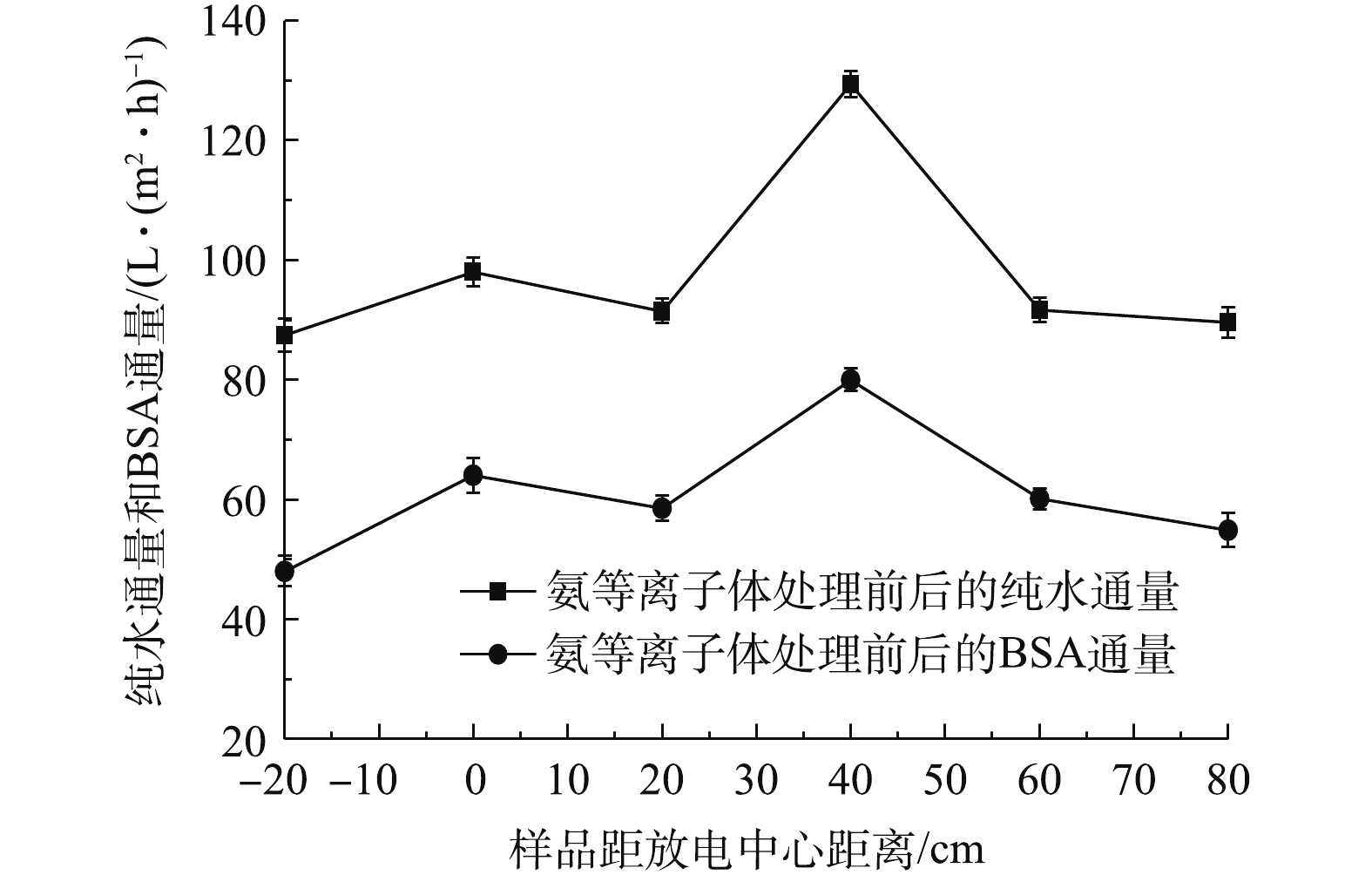

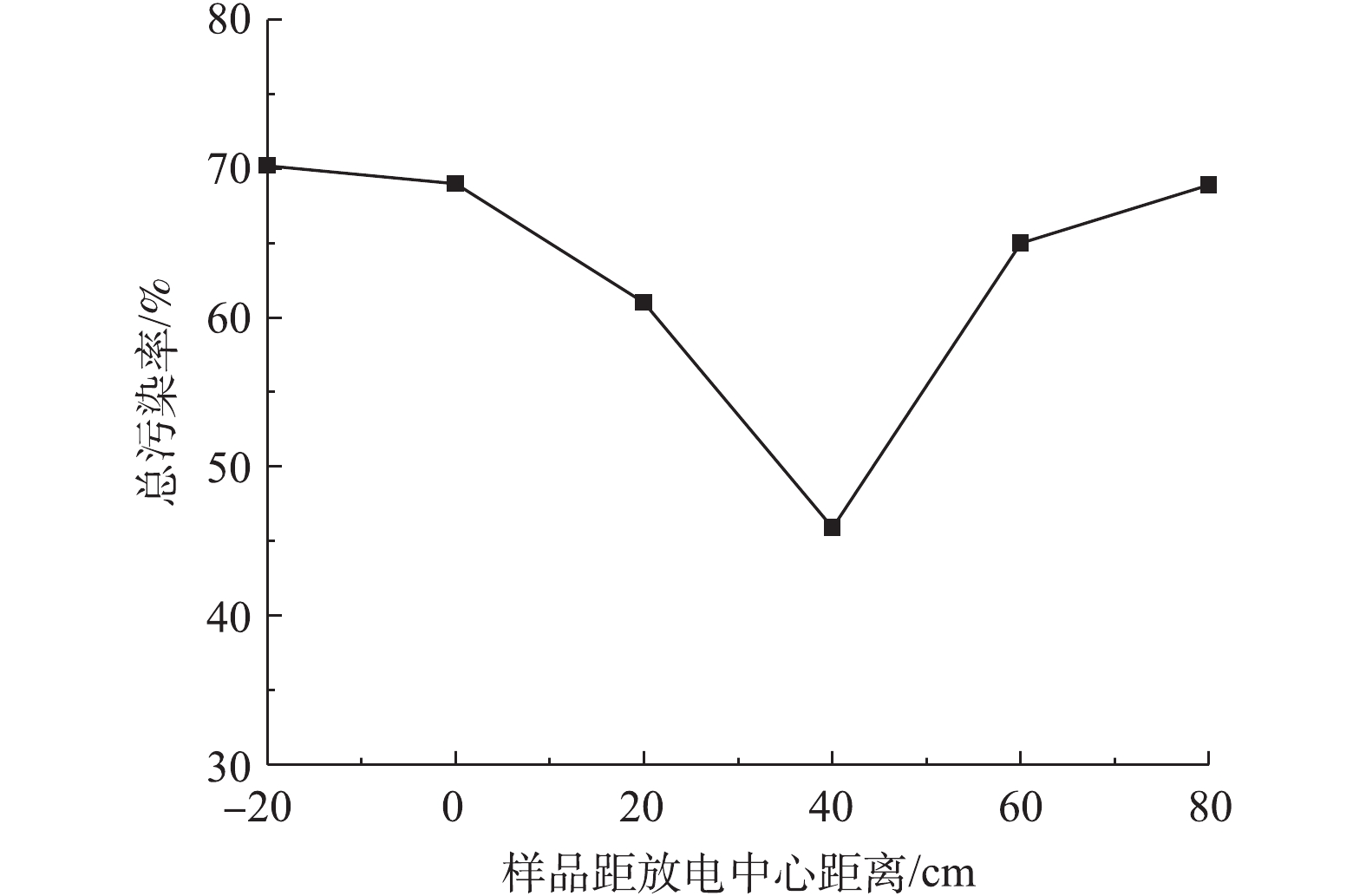

如图10~图12所示,通过BSA分离实验,考察了氨等离子体改性前后PVDF超滤膜在运行中的膜通量(纯水通量、BSA通量)、截留率、总污染率等参数,其中−20 cm处为PVDF超滤膜原始膜的相关数据。

由图10可以看出,经距放电中心40 cm处氨等离子体处理后,PVDF超滤膜的纯水通量及BSA通量均比原膜通量大。在放电中心处通量值较大,但是结合SEM图分析,此处等离子体刻蚀作用最强烈,膜孔性能被严重破坏,在过滤过程中,一部分BSA 蛋白直接通过膜孔无法被截留。经距放电中心20 cm处氨等离子体处理后,结合SEM图分析,此处的刻蚀作用相较于放电中心有所缓解但是膜孔依然能清晰的看到有撕裂现象,此时在过滤过程中,一部分BSA蛋白可能直接通过膜孔,另一部分BSA 蛋白在膜表面堆积阻塞膜孔或嵌入膜孔及孔道内部从而导致水通量及BSA通量下降。距离放电中心60~80 cm处,PVDF超滤膜的纯水通量与BSA通量与原膜相比变化较小,这与上文中水接触角及SEM分析结果一致。

由图11可以看出,经距放电中心40 cm处氨等离子体处理后,PVDF超滤膜对BSA分子的截留率与原膜相比有所提高。这是因为经距放电中心40 cm处氨等离子体处理后,PVDF超滤膜的亲水性增加,膜表面含有的C—O/C=O、N—C=O减少了BSA在膜表面吸附沉积作用,截留率越高的膜截留效果越好[22]。

由图12可以看出,经氨等离子体处理后PVDF膜的总污染率从放电中心至距放电中心40 cm处逐渐下降,在40 cm处降到最低值,60~80 cm处膜的总污染率与原膜相近。PVDF超滤膜膜孔阻塞的主要杂质为蛋白类物质,当膜表面的亲水性降低时,蛋白质的吸附率会上升,从而导致膜污染。由此可见,利用距离放电中心40 cm处氨等离子体改性PVDF超滤膜,可以显著降低蛋白质的吸附和沉淀,从而降低膜的总污染率。

2.1. 氨等离子体处理条件对PVDF 膜表面亲水性的影响

2.2. 氨等离子体改性前后PVDF超滤膜的SEM分析

2.3. 氨等离子体改性前后PVDF超滤膜的XPS分析

2.4. 氨等离子体改性前后PVDF超滤膜的过滤性能和抗污染性能分析

-

1)远程氨等离子体表面改性PVDF超滤膜的最佳条件为:射频功率40 W,处理时间45 s,气体流量20 cm3·min−1,样品距离放电中心40 cm。改性后,PVDF超滤膜的亲水性得到提高,水接触角从95.63°降至52.79°。

2)远程氨等离子体处理后,膜表面的(O+N)/C值增加,F/C值降低,且距放电中心40 cm处,(O+N)/C值最大,F/C值最小。膜表面引入了含氧、含氮基团,膜表面亲水性得到改善,且距放电中心40 cm处改性效果最明显,同时抑制了等离子体中电子、离子对膜表面的刻蚀作用。

3)通过BSA溶液过滤实验,证实了改性后PVDF超滤膜具有良好的过滤性能和抗污染性能,其水通量、BSA通量分别从87.42、48.00 L·(m2·h)−1增至129.36、79.98 L·(m2·h)−1,截留率从81.43%增至87.70%,总污染率从70.25%降至45.96%。

下载:

下载: