-

臭氧的氧化还原电位(2.07 V)较高,具有较强的氧化、杀菌、消毒等能力,是水处理领域公认的一种绿色氧化剂和消毒剂[1-2]。然而,臭氧氧化技术在工程应用过程中普遍存在臭氧利用率低和能耗高的问题[3]。为提高臭氧氧化功效,可采取以下两方面措施:1)增大气液接触面积,提高臭氧与液相间的传质效率;2)通过臭氧分解产生·OH的方法提高臭氧的反应速率和氧化能力。

为提高臭氧气液间的传质效率,研究者将多孔疏水膜应用于臭氧传质,开发了新型的膜接触器。多孔疏水膜既可作为气、液两相的分隔界面,又在膜孔处提供丰富的气液接触界面[4-5]。与填充塔、鼓泡塔和射流负压投加器等传统接触工艺相比,膜接触工艺具有以下优点:1)单位体积内气液接触面积可以提高1~2个量级[6];2)气、液两相独立流动,便于控制;3)气相中分子通过扩散方式直接溶于液相,而不是在压力作用下以气泡形式进入液相,避免了液泛、乳液、雾沫夹带等棘手问题;4)可将膜组件作为模块化组合单元,便于工业应用放大[7-8]。

臭氧在废水处理过程中可与有机污染物直接反应。反应主要通过氧化还原、环加成以及亲电取代等途径进行,具有选择性较强、有机污染物矿化效率低等特点。臭氧间接反应通过臭氧的分解产物(如羟基自由基,·OH)进行,具有反应速率快、无选择性和矿化程度高[9-10]等特点。膜接触臭氧氧化(membrane contact ozonation,MCO)工艺以臭氧直接氧化为主,因而存在反应速率慢、矿化效率低的问题。为了在臭氧高效传质的基础上强化臭氧工艺的氧化能力,有必要将臭氧间接反应与MCO工艺耦合,构建新型的膜接触臭氧氧化工艺。

本研究制备了具有电催化功能的疏水膜,并通过MCO与电化学反应结合构建了膜接触电催化臭氧氧化(electro-catalytic membrane contact ozonation,ECMCO)工艺。电催化疏水膜可将气相中多余的氧气电催化还原为过氧化氢(H2O2);H2O2催化臭氧分解转化为·OH,可明显提升系统的氧化能力。以硝基苯为特征污染物,考察了ECMCO工艺对臭氧难降解污染物的降解效果,明确了高级氧化的反应途径,探究了膜接触传质和电化学反应之间的协同效应。最后,以对酒厂废水的生化出水深度处理为例,评估了ECMCO工艺对实际废水的处理效果,以期为工程应用实践提供参考。

全文HTML

-

本实验所用主要试剂包括:硫酸钠(AR)、二水合草酸钛钾(AR)、硝基苯(AR)、过氧化氢(30%)、甲醇(HPLC)、乙腈(HPLC)等。以上试剂均购自国药试剂公司。以热压法将多孔碳纤维纸负载于聚四氟乙烯疏水膜表面,制得电催化疏水膜。实验所用酒厂废水生化出水来自某酒厂废水处理站。

-

硝基苯浓度采用液相色谱法进行检测,液相色谱仪为1260 Infinity(安捷伦),流动相为超纯水和甲醇,流动相比例30∶70,检测波长262 nm,保留时间7 min。过氧化氢浓度采用草酸钛钾显色法进行检测[11]。应用电子自旋共振波谱(ESR)仪对体系中·OH进行定性分析[12]。应用电化学工作站进行伏安特性扫描,表征体系中的电化学反应。

-

ECMCO工艺的设计原理如图1所示。电催化疏水膜将气、液两相分隔,疏水层与气相接触,可作为氧气和臭氧的传输通道,氧气和臭氧通过扩散方式进入液相,传质过程无泡;电催化层与液相接触,并作为电化学反应的阴极。氧气通过疏水层扩散至电催化层,以2电子途径还原为H2O2(反应式(1));H2O2催化扩散至电催化层的臭氧分解转化为·OH(反应式(2));·OH与有机污染物快速反应,实现污染物的高效去除[13-14]。

各组实验中硝基苯初始浓度均为30 mg·L−1,电解质为50 mmol·L−1 Na2SO4溶液,液量为120 mL。臭氧通过臭氧发生器制备,以氧气为气源;臭氧浓度为40 mg·L−1,气相流量为60 mL·min−1。阳极为钛钌板状电极,阴极为电催化疏水膜;阴阳极有效面积均为5 cm × 5 cm,电流强度为25 mA。

为了考察ECMCO工艺对实际废水的处理效果,对酒厂废水生化出水进行了深度处理。液量为180 mL,臭氧浓度为40 mg·L−1,气相流量为20~80 mL·min−1,槽压为1.9~2.5 V,无电解质添加。COD相对含量为反应过程中某时刻COD与反应前COD之比,其变化表征可反映各工艺对COD的去除效果。

1.1. 实验材料

1.2. 测试方法

1.3. 实验方法

-

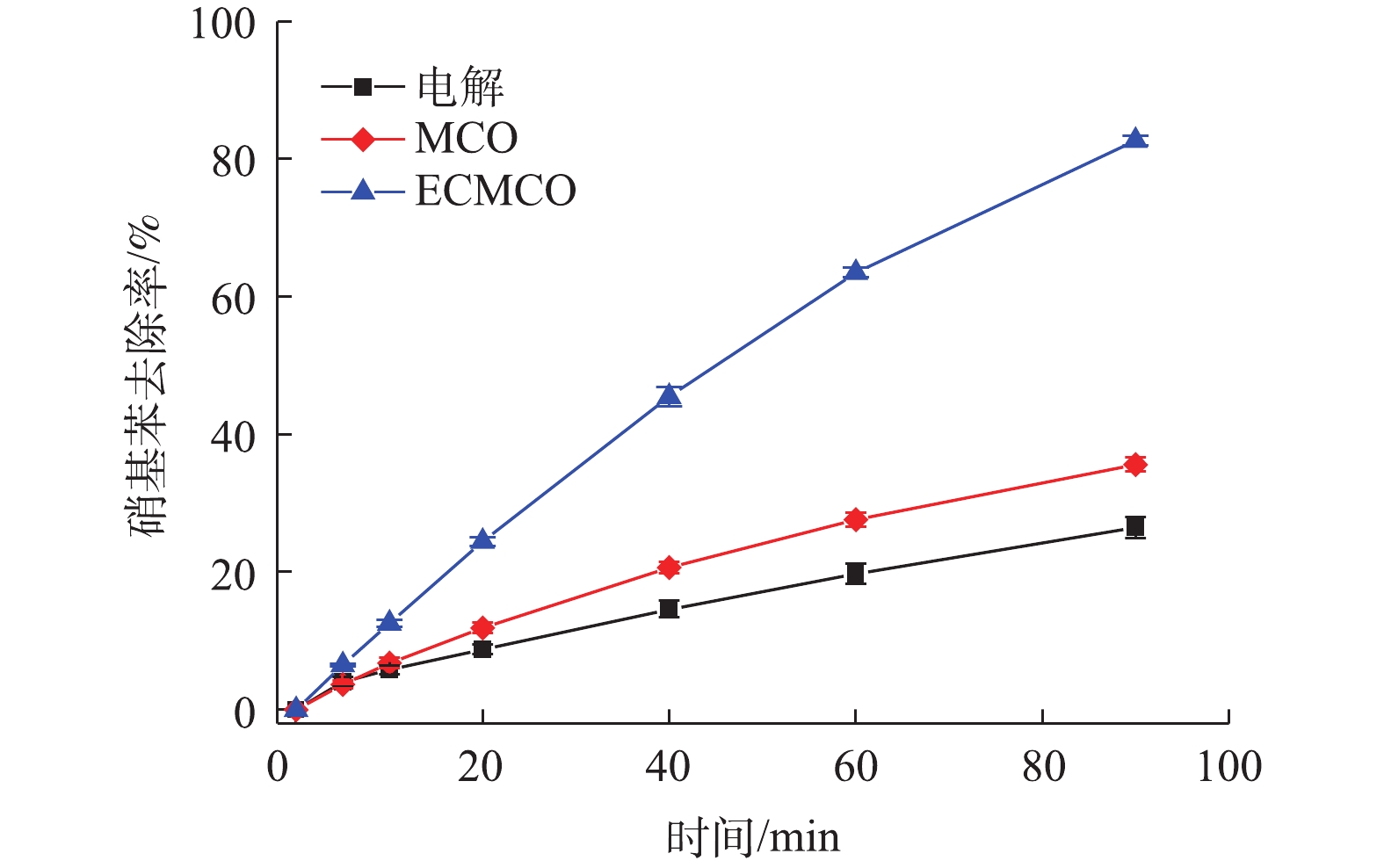

打开电源,关闭臭氧发生器,此时气室内为纯氧气,考察电解作用对硝基苯的去除效果;关闭电源,打开臭氧发生器,此时气室内为氧气和臭氧的混合气体,设定臭氧浓度40 mg·L−1,考察MCO工艺对硝基苯的去除效果;同时打开电源和臭氧发生器,考察ECMCO工艺对硝基苯的去除效果。ECMCO、MCO和电解过程对硝基苯的去除率分别为82.7%、35.6%和26.5%(见图2)。硝基苯与臭氧反应速率较慢,反应速率常数仅为(0.09 ± 0.02) L·(mol·s)−1[15],故臭氧直接氧化对硝基苯的去除效果不佳,MCO工艺对硝基苯去除率较低。电解过程对硝基苯的去除主要为阳极氧化作用,去除率最低。而ECMCO工艺对硝基苯的去除率明显提高,并且超过MCO和电解两者对硝基苯去除率之和,这说明ECMCO工艺处理功效并不是MCO与电解工艺的简单叠加。

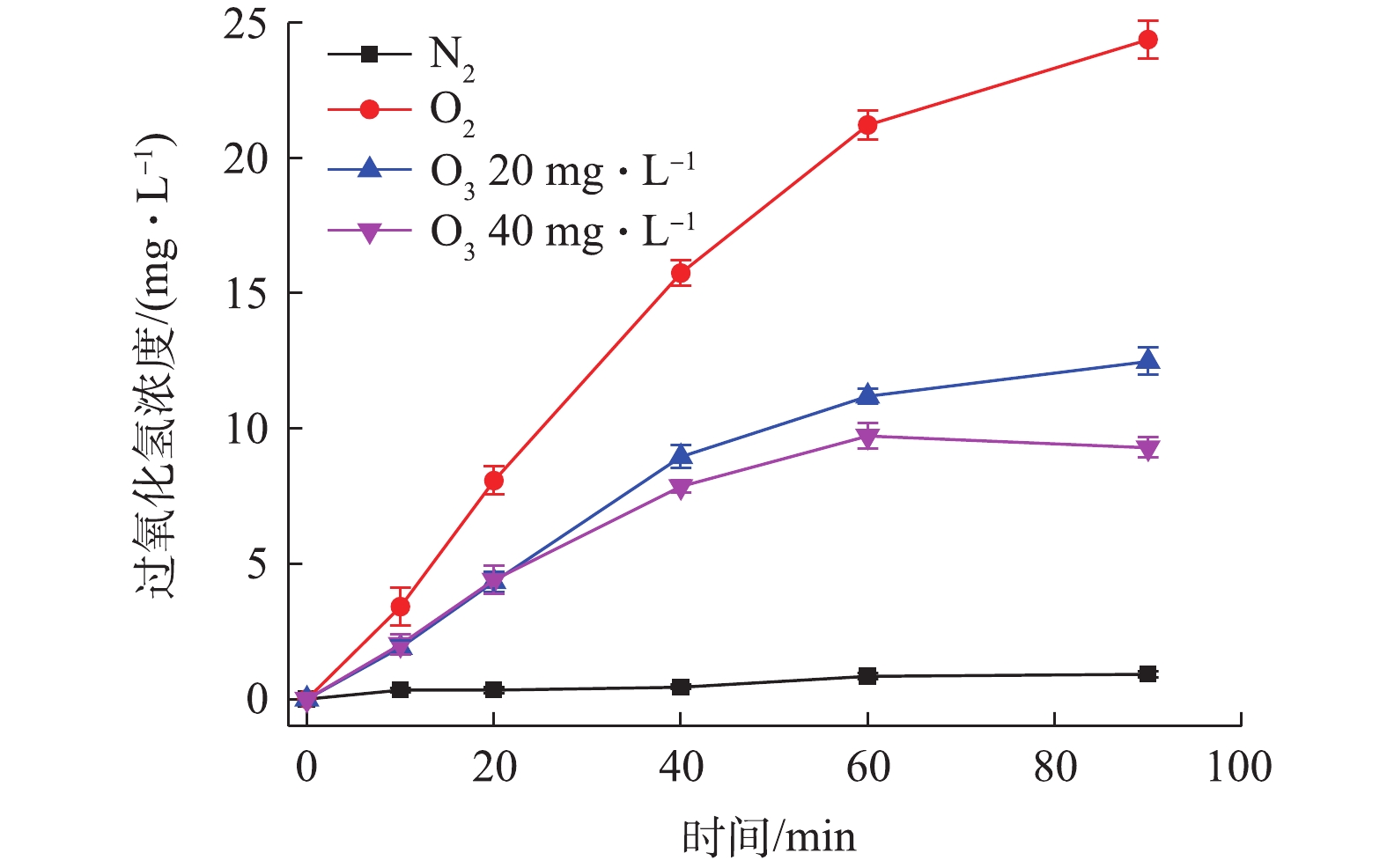

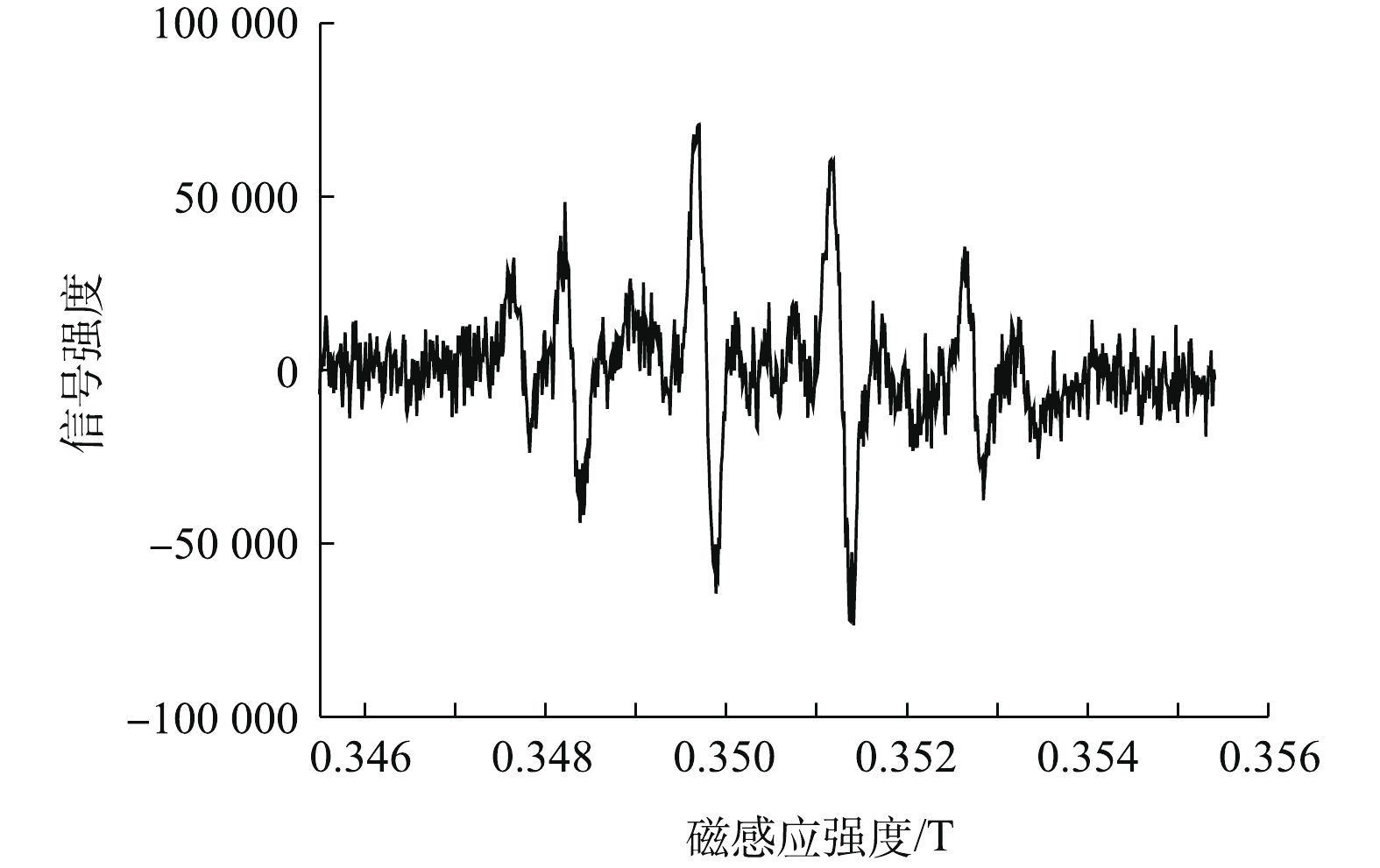

考察了ECMCO工艺体系中H2O2的变化情况,结果如图3所示。当气室中通入氮气时,液相中H2O2含量非常少;当气室中通入氧气时,液相中H2O2浓度急剧升高,可达24.4 mg·L−1。这说明气室中的氧气通过疏水层扩散至电催化层,并以2电子途径还原为H2O2(式(1))。当气室中通入氧气和臭氧的混合气体时,液相中H2O2含量明显下降,并且H2O2浓度随臭氧浓度升高而降低。这说明臭氧已通过电催化疏水膜的疏水层扩散进入液相,并在电催化层内消耗了大量的H2O2。此外,实验还通过ESR检测到了ECMCO体系中·OH的存在(见图4)。以上结果表明,ECMCO工艺中氧气和臭氧已通过电催化疏水膜的疏水层扩散进入电催化层,氧气得电子原位生成H2O2,H2O2催化臭氧分解产生·OH。·OH与硝基苯反应速率较快,反应速率常数为2.2 × 108 L·(mol·s)−1[15],因此ECMCCO工艺对硝基苯的去除效果明显提升。

-

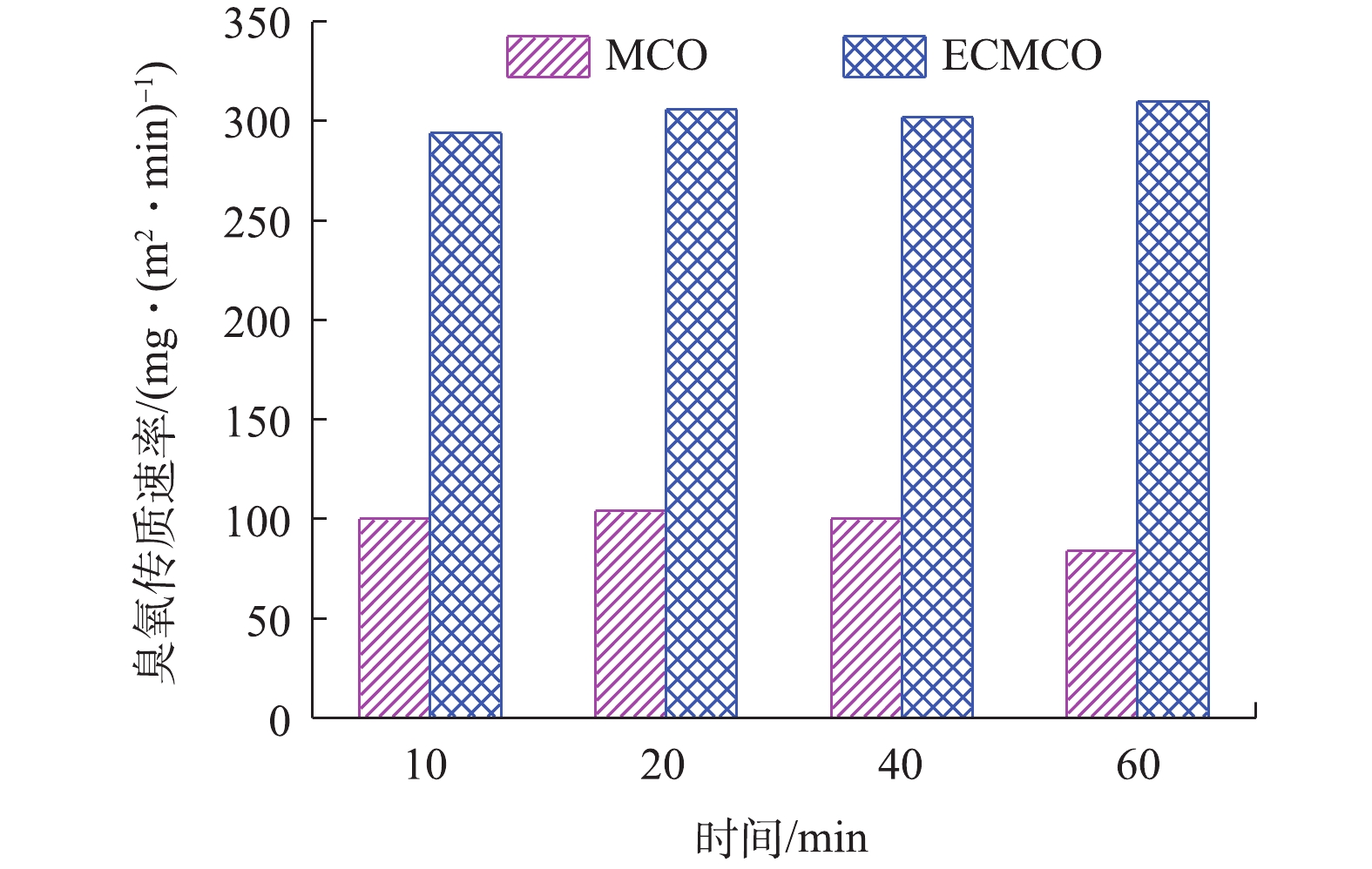

臭氧传质和臭氧反应紧密相关,相互促进。一方面,液相中臭氧快速反应有利于增大臭氧传质的化学势差,促进臭氧传质;另一方面,高效的臭氧传质可以提高液相中臭氧浓度,提升氧化效果。对比了ECMCO和MCO工艺中臭氧传质速率,结果见图5。MCO工艺在各时间点臭氧传质速率均约为100 mg·(m2·min)−1;ECMCO工艺在各时间点均约为300 mg·(m2·min)−1,约为MCO工艺的3倍。在ECMCO工艺中,电催化层内产生的H2O2与臭氧反应较快,可将液相中臭氧快速分解转化,增大臭氧的传质驱动力,因此ECMCO工艺的臭氧传质速率可以达到MCO工艺的3倍。

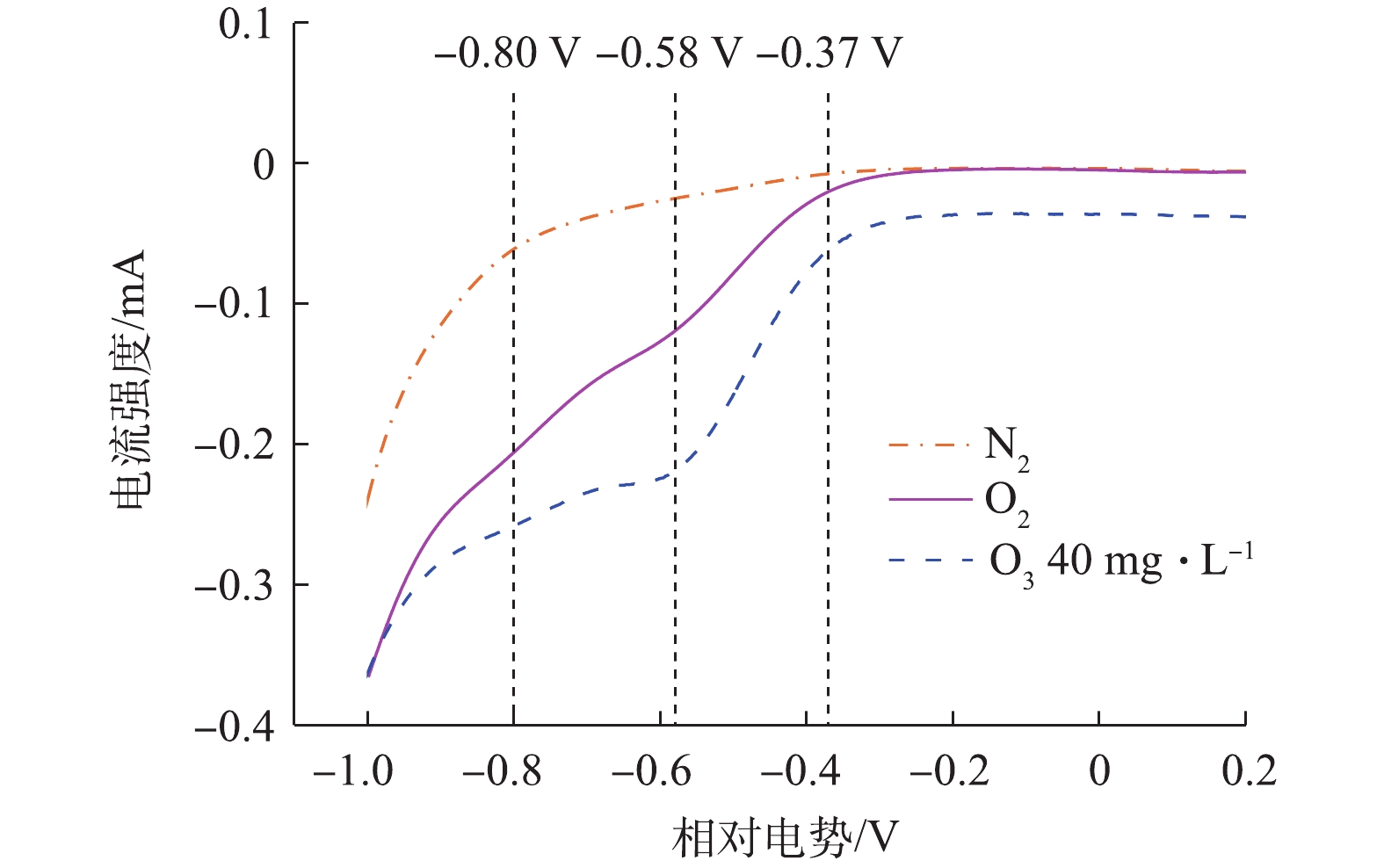

同样,臭氧传质速率的提升,也有利于消耗电催化层内产生的H2O2。当气室内通入氮气,以电势−0.80 V为临界点,相对电势逐渐升高时,几乎无还原电流;相对电势逐渐降低时,开始发生析氢反应。当气室通入纯氧气,电势为−0.37 V时即有较大的还原电流产生,此时氧气以2电子途径原位还原为H2O2(见图6)。当气室通入浓度为40 mg·L−1的臭氧(氧气与臭氧的混合气体),电势为−0.37 V时同样发生了原位产H2O2的反应;随着电势更负,还原电流明显增强。这可能是因为臭氧存在的条件下,电极表面产生的H2O2快速从活性位点脱附,促进了原位产H2O2的电化学过程。

ECMCO工艺中臭氧传质和臭氧分解转化为·OH的过程相互促进,具有明显的协同效应。这表明臭氧快速分解提高了臭氧传质效率,更多的臭氧扩散进入液相产生了更多了·OH,使得硝基苯的去除率获得明显提升。ECMCO工艺中的协同效应是硝基苯高效降解的主要原因。协同效应可以保证臭氧高效利用,并将其转化为·OH,提升系统的氧化能力。因此,ECMCO技术可以同步提高臭氧工艺的经济性和高效性,具有较好的研究价值和应用前景。

-

实际废水中有机污染物和无机离子都可能会影响臭氧氧化反应的氧化效果。为了考察ECMCO工艺对实际废水的处理效果,对某酒厂废水的生化出水进行了深度处理,并对比了ECMCO工艺与传统工艺的运行能耗。

1) 酒厂废水生化出水水质概况。该酒厂原水总COD≤10 000 mg·L−1,色度≤200。目前采用的处理流程为:酒厂混合废水经微滤、调节池后依次通过GF-UASB反应池、A/O反应池和MBR膜池,然后排放。该工艺的出水COD为200 mg·L−1,色度为500,未达到设计出水标准(COD≤50 mg·L−1,色度≤200度)。拟采用ECMCO工艺对该酒厂废水的生化出水进行深度处理,使出水COD和色度达到设计出水标准。

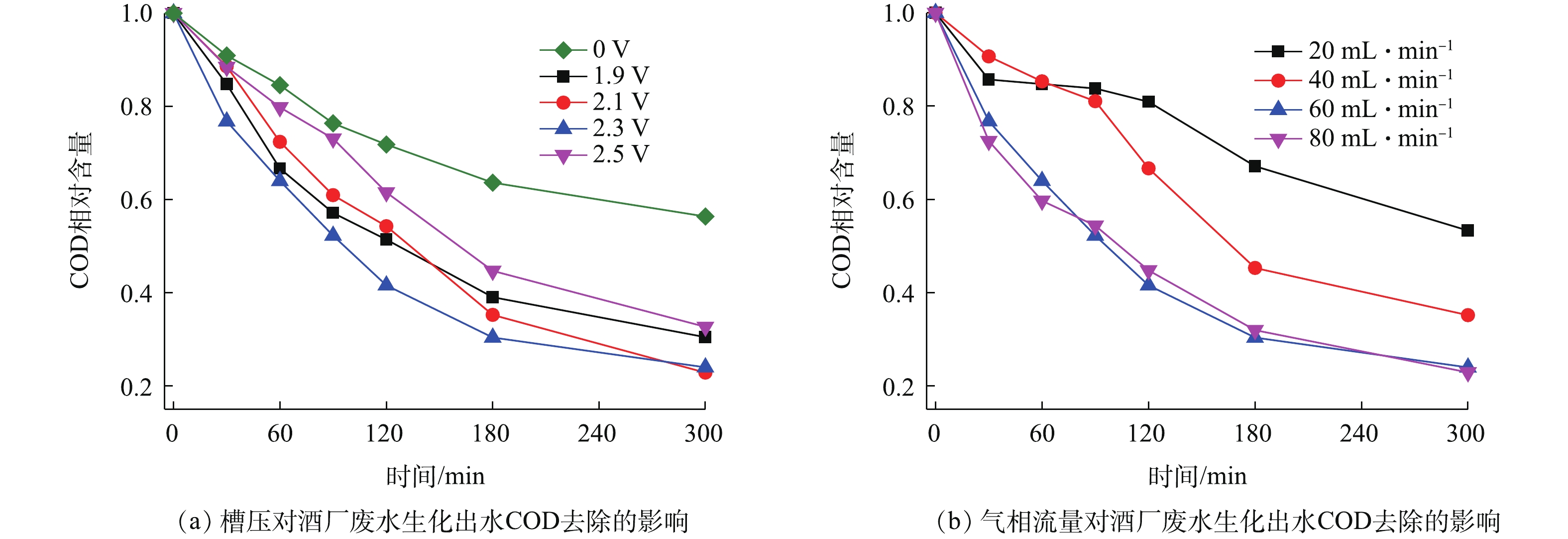

2) 工艺参数对COD去除的影响。考查了槽压对COD去除的影响(见图7(a)),施加电压为0时,为MCO工艺对COD去除效果,300 min时体系中COD相对含量为0.56。施加电压1.9~2.5 V、反应300 min时COD相对含量明显减少。当槽压为2.3 V时,COD相对含量为0.24,去除效果最佳,可以达到设计出水标准;槽压为1.9 V时,电流强度较小,电催化层内H2O2产量较低,因此体系中产生的·OH量较少,COD去除较少;槽压为2.5 V时,可能发生了较多的析氢反应(图6),导致产H2O2的电流效率较低,COD去除率也较低。

考查了气相流量对COD去除的影响(见图7(b))。气相流量从20增大到60 mL·min−1时,反应300 min后,COD相对含量逐渐减少。这是由于臭氧浓度的增加增大了臭氧传质驱动力,更多的臭氧通过电催化疏水膜扩散进入液相,分解转化为·OH,体系的氧化能力增强,故COD去除量逐渐升高。当气相流量增大至80 mL·min−1时,COD相对含量与气相流量为60 mL·min−1时无明显变化。这说明臭氧传质可能受到膜内部和液相边界传质阻力的制约,继续增大气相流量并不能提高体系的氧化能力。当槽压为2.3 V,气相流量为60 mL·min−1时,酒厂废水的生化出水在反应120 min时可实现完全脱色,反应300 min时出水COD低于50 mg·L−1,可以达到设计出水标准。

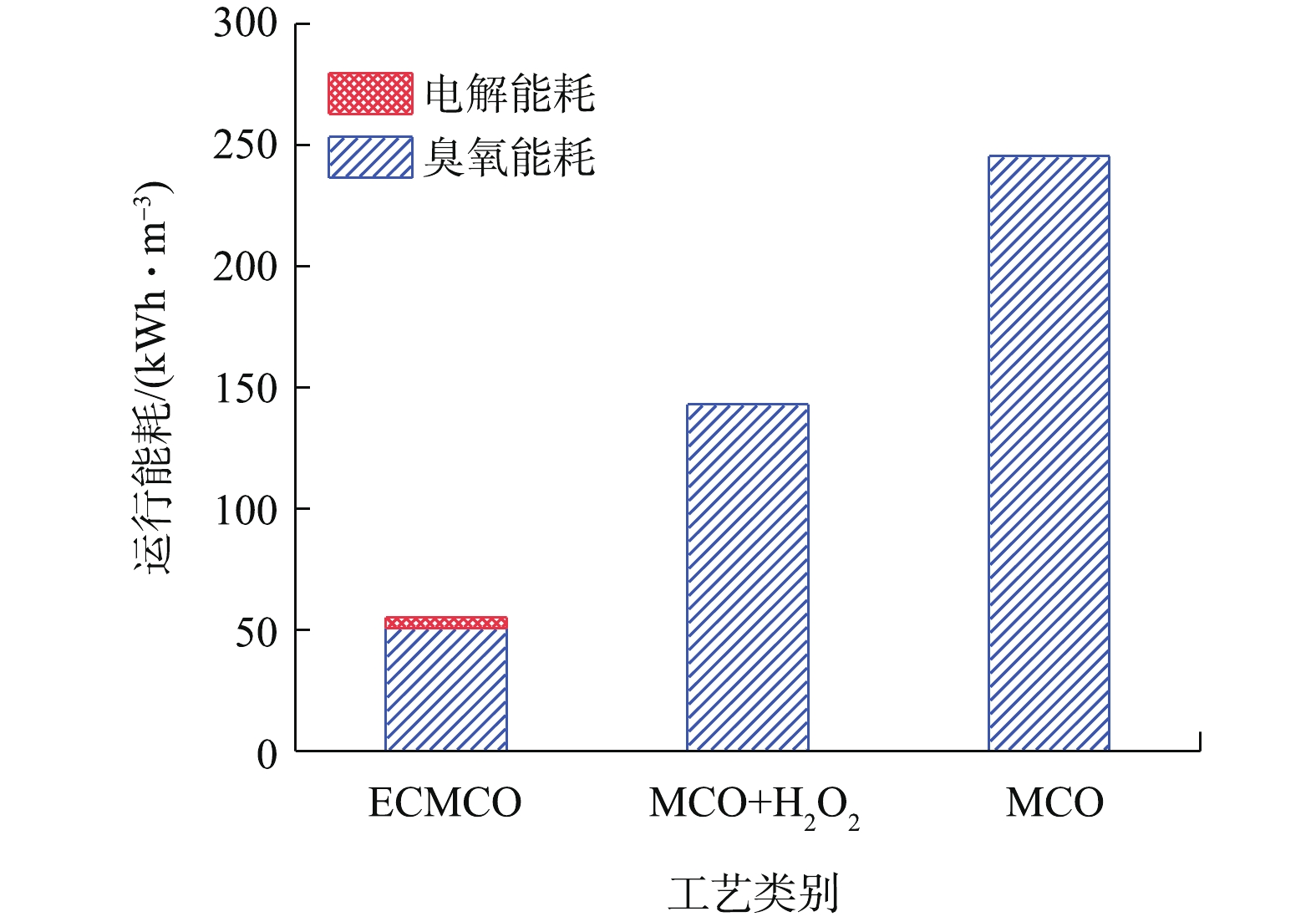

3)运行能耗对比。为了评估ECMCO工艺的应用前景,将其与MCO工艺进行了运行能耗对比;同时,为了考察气液界面原位产H2O2对体系氧化能力的影响,将其与MCO+H2O2(H2O2为外部投加,而非电化学过程原位产生)工艺也一并进行了对比(见图8)。对比发现,外加H2O2浓度为30 mg·L−1时,COD去除效果最佳;继续增加H2O2投加量,COD去除量无明显变化。因此,MCO+H2O2工艺选定H2O2投加量为30 mg·L−1进行对比。此外,各工艺条件采用气相流量60 mL·min−1,臭氧浓度40 mg·L−1,运行能耗为COD降至50 mg·L−1时的电解能耗和产臭氧能耗。

MCO工艺运行能耗最高,为245.3 kWh·m−3。MCO工艺以臭氧直接氧化为主,反应速率较慢,具有较强的选择性,同时臭氧传质驱动力较弱,臭氧利用率较低。故将COD降至50 mg·L−1时需要较长的反应时间,臭氧投加量明显高于ECMCO和MCO+H2O2过程。由于产臭氧过程能耗较高,所以MCO工艺需消耗更多的电能。H2O2的投加可以促进液相中臭氧的分解,从而增大臭氧传质驱动力,并将臭氧转化为氧化能力更强的·OH,从而使COD降解速率有较高提升,因而MCO+H2O2工艺对臭氧的能耗明显较少;通过计算同时发现,外加H2O2所需消耗仅为0.3 kWh·m−3。ECMCO工艺中,H2O2可以在气液界面处持续产生,将界面处臭氧快速分解转化为·OH,比外加H2O2方式产生更强的传质驱动力,产生更多的·OH,因此ECMCO工艺的臭氧能耗最低。该工艺的电解过程能耗为4.5 kWh·m−3,是臭氧能耗的8.9%。故ECMCO工艺以较低的电解能耗大大削减了臭氧的能耗,总能耗为55.1 kWh·m−3。ECMCO工艺电解产H2O2所需费用虽然高于MCO+H2O2工艺中外加H2O2的费用,但气液界面处H2O2可以更多地促进臭氧传质,从而提高体系的氧化能力,使总运行能耗低于MCO+H2O2工艺的能耗。

2.1. 膜接触电催化臭氧氧化工艺构建

2.2. ECMCO工艺中的协同效应

2.3. 酒厂废水深度处理

-

1)与MCO和电解过程相比,ECMCO对硝基苯的去除率大幅提高。氧气和臭氧通过疏水层扩散至电催化层,氧气在电催化层内电催化还原为H2O2。H2O2催化臭氧分解产生·OH,而·OH促进了硝基苯的氧化降解。

2)电催化层内产生的H2O2可将气液界面处臭氧快速分解,增大臭氧传质驱动力,臭氧传质为传统工艺的3倍。臭氧存在的条件下,电催化产H2O2的还原电流明显增强,可能是因为臭氧消耗部分H2O2,促进了氧气的电化学还原过程。ECMCO工艺中,臭氧传质和电化学还原过程相互促进,并以硝基苯的高级氧化为降解途径,是其氧化能力大大提升的重要原因。

3) ECMCO工艺对酒厂废水生化出水的深度处理有明显的效果,色度全部脱除,COD降至50 mg·L−1L以下。电化学反应消耗的电能仅为臭氧能耗的8.9%,并未消耗大量能源,并且可以使臭氧用量明显减少,故ECMCO与MCO和MCO+H2O2工艺相比,具有明显的经济性。

下载:

下载: