-

落地油泥是石油开采过程中产生的一种固体废弃物,因其环境危害大,已被列入国家危险固体废弃物名录[1-4]。对其进行有效处理,无疑具有重要的环境保护效益。目前,常用的油泥处理技术有焚烧、萃取、热解、氧化、热洗、生物修复、固化/稳定化等[5-12]。其中,焚烧、热解等技术虽然除油效果很好,但无法回收其中的石油资源;而萃取、热洗等技术存在处理成本高、原油回收效率低等问题[13-20]。

近年来,利用超声波处理油泥技术受到广泛关注。研究发现,超声波的“空化效应”可弱化土壤对原油的黏附作用,提高原油的清洗效率[21-24]。与现有的其他技术相比较,超声波处理技术具有分离效果好、成本低、操作简单等优点[21-26]。然而,研究中也发现,利用超声波处理不同来源油泥时存在效果不稳定、原油回收效率差异大等问题[27-30],具体原因仍然不清楚,但怀疑与油泥中土壤的性质有关。

本研究选取了3种具有代表性的油田落地油泥,在分析土壤颗粒级配、化学组成的基础上,着重考察了土壤性质对超声处理除油效果的影响。同时,利用脱油后的油田油泥土壤进行了原油吸附和超声除油模拟实验,以期为油田落地油泥超声处理技术的开发及规模化应用提供指导。

全文HTML

-

实验所用油泥样品取自冀东、大庆、大港3个油田生产作业所产生的新鲜落地油泥。现场去除落地油泥中的杂草、树枝、生活垃圾及大块岩石后,将样品密封于黑色取样袋内,运回实验室4 ℃保存。

实验试剂为三氯甲烷、无水硫酸钠、四氯化碳、30%双氧水、盐酸等试剂,均为分析纯,购自国药化学试剂集团。

实验仪器:红外测油仪(126+,吉林北光,中国);X射线衍射(X’Pert PRO MPD,荷兰PANalytical分析仪器有限公司,荷兰);激光粒度仪(Mastersizer 3000,马尔文,英国);X射线荧光光谱(ARL Perform’X4200,赛默飞世尔科技(中国)有限公司,中国)。

-

取100 g新鲜油泥样品,加水400 g,在60 ℃恒温水浴、50 r·min−1搅拌的条件下,用0.33 W·cm−2、25 kHz的超声波进行超声处理30 min,处理结束,静置沉淀或离心分离后,取下层土壤烘干,测定土壤中残余原油含量,每组实验重复3次。

-

以三氯甲烷为萃取剂,采用索氏提取法去除冀东及大港落地油泥中的原油,风干后研磨过筛,取0.25~0.50 mm(35~60目)的土壤为模拟用土。将模拟土壤搅拌均匀后,称取10.0 g土壤、2.0 g蒸馏水,分别加入冀东原油1.0、2.0、3.0、5.0、7.0 g,充分搅拌均匀后,密封于45 ℃,恒温老化24 h,每组重复3次。恒温老化结束后,加40 mL热水(45 ℃)并在45 ℃恒温搅拌10 min(50 r·min−1),搅拌结束后,静置沉淀,除去上层水及未吸附的原油,取下层土壤约2.0 g,烘干后测定原油的吸附量。然后再加40 mL 温度为60 ℃的热水,按照与上述油泥超声处理同样的操作进行处理后,测定土壤中的剩余含油量。

-

1)油泥组分分析。用烘干至恒重的玻璃培养皿,取50 g左右经过搅拌混匀的新鲜油泥样品3份进行称重,然后在65 ℃下烘24 h,转移至干燥器中冷却至室温再称重,计算油泥含水量。

将烘干后的油泥样品原样磨碎,混匀后随机取样1.00 g,转移至100 mL的分液漏斗中,加入红外测油专用的四氯化碳50.0 mL,在200 r·min−1下振荡30 min,静置10 min后,将萃取液通过装填有无水硫酸钠的层析柱,去掉最先流出的滤液35 mL,取后续滤液1.0 mL转移至25 mL比色管中,用测油专用四氯化碳定容,按照《水质 石油类和动植物油类的测定 红外分光光度法》(HJ 637-2012)使用红外测油仪测定油泥含油量。含固量为原样与含油、含水量之差。

2)土壤颗粒分析。将烘干的油泥原样用三氯甲烷萃取除去原油,研磨后去掉石块和杂物,按四分法,取5.0 g土壤于100 mL烧杯中,加入20 mL H2O2(10%)溶液、加热至沸腾,使其充分反应,自然冷却后,再加入20 mL HCl(10%)溶液,加热至沸腾;自然冷却后,加蒸馏水至80 mL,置于超声波清洗机中超声15 min后静置24 h[31]。预处理结束,抽去上层蒸馏水,搅拌均匀后用激光粒度仪测试土壤颗粒粒径。

3)土壤元素及矿物种类分析。将用三氯甲烷萃取后的土壤研磨后过200目土壤筛,取筛下混合均匀的土壤样品约10 g左右,置于200 ℃下恒温2 h,然后转移至干燥器中冷却,用于X射线荧光光谱分析和X射线衍射仪分析,并按照RIR因子法计算土壤中矿物的相对含量[32-34]。

1.1. 试剂和仪器

1.2. 油泥超声处理

1.3. 模拟油泥制备及处理

1.4. 分析及表征

-

3个油田落地油泥中的水分、石油类和固体含量见表1。由表1可知,落地油泥中含有3%~10%的石油类、68%~90%的土壤、9%~22%的水分。其中,冀东落地油泥的固相含量最高,含油率、含水率最低;大庆落地油泥中的固相含量最低,含油率和含水率均为最高;大港落地油泥的3项含量处于冀东和大庆落地油泥之间。

-

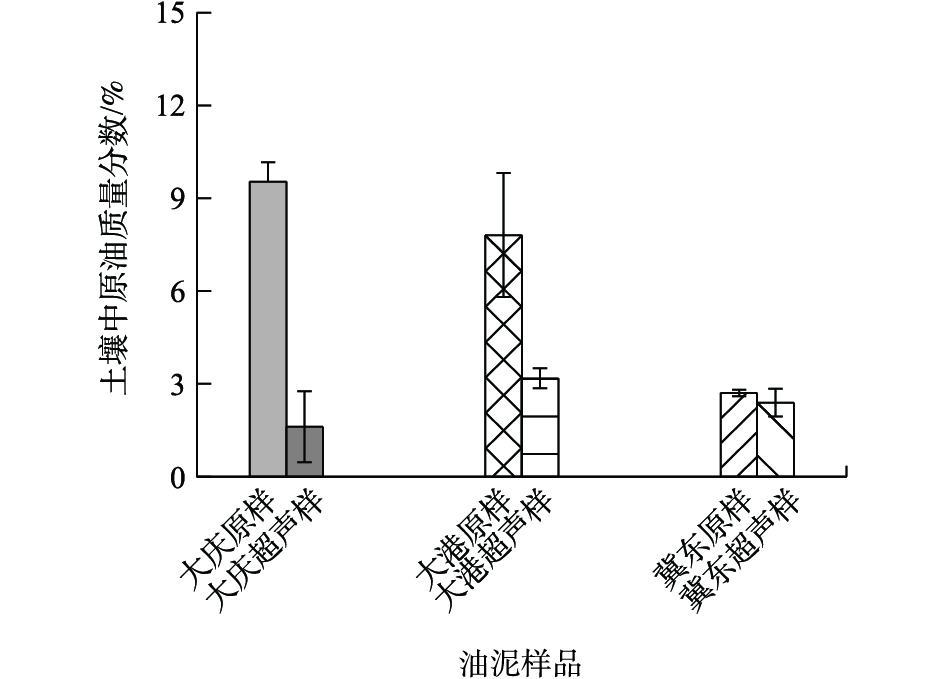

已有研究[27-30]表明, 在使用超声处理技术处理油田油泥时,不同地域来源油泥的原油去除率差异较大。本研究所选取的3种代表性的落地油泥也来自于不同地域的油田,超声处理前后土壤中原油含量如图1所示。超声处理后,大庆、大港、冀东落地油泥土壤固相中残余原油含量分别为(1.62±1.15)%、(3.18±0.32)%、(2.4±0.45)%,原油去除率分别为83.10%、59.33%、11.22%,与已有研究结果一致。其中,大庆落地油泥的处理效果最好,处理后的土壤含油量基本可以达到标准(<2%);大港落地油泥次之,冀东落地油泥的处理效果最差。

-

图2为3种落地油泥土壤的粒径分布情况。落地油泥中土壤颗粒粒径分布极不均匀,均表现出双峰分布的特征。大庆落地油泥土壤颗粒粒径分布分别在100 μm和500 μm左右出现极值,其中100 μm附近的土壤颗粒所占比重最大。大港油泥土壤颗粒的第1个峰出现在300~400 μm处,第2个则出现在2 000 μm处。而冀东落地油泥颗粒在2~60 μm处出第1个扁平峰,在500~700 μm处出现第2个陡峭峰。通过比较3种土壤颗粒粒径和比表面积(表2)发现,冀东油田落地油泥土壤粒径最小、比表面积最大,这可能是造成冀东落地油泥超声处理效果较差的重要原因。此外,采用不同粒径的河沙为模拟土壤、冀东原油为模拟油的模拟实验结果也验证了土壤颗粒越大,超声处理效果越好,土壤颗粒粒径越小,超声处理效果越差。

-

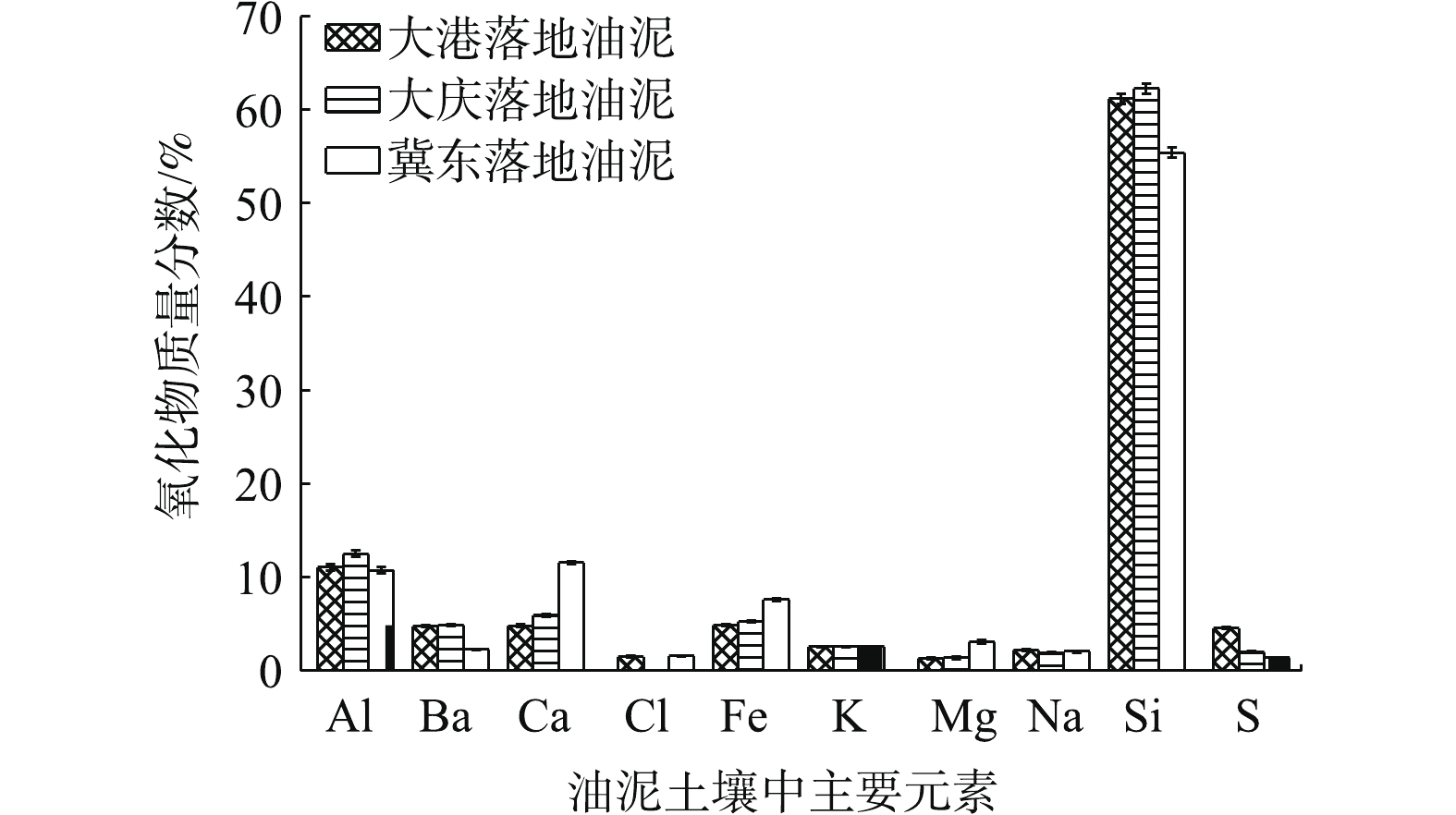

落地油泥土壤中化学氧化物质量分数大于0.5%的元素含量如图3所示。由图3可知,硅、铝、铁、钙等含量相对较高,其中,硅氧化物含量最高。不同来源的油泥中铁和铝氧化物含量基本相同,而硅氧化物和钙氧化物有较大差异。在大港、大庆、冀东落地油泥土壤中,硅氧化物的含量分别为61.17%、62.27%、55.42%;钙氧化物含量分别为4.84%、5.94%、11.57%。大庆和大港落地油泥中的硅氧化物含量显著高于冀东落地油泥,而冀东落地油泥中钙氧化物含量比大庆、大港落地油泥高出1倍左右。超声处理后,大庆、大港落地油泥的除油效果较好,冀东落地油泥的效果最差,这表明油泥土壤中的硅氧化物及钙氧化物含量可能与除油效果有关。

进一步对油泥土壤中的矿物组成进行分析,XRD结果表明,落地油泥土壤中矿物的结晶度较低,钙、铁等氧化物全部以非晶态形式存在,只有小部分的硅氧化物和铝氧化物以晶体形式存在(见表3)。晶体矿物主要有二氧化硅、硅酸铝钾、硅酸铝钠、磷酸铝等,其中,二氧化硅和硅酸铝钠是油泥土壤中共有的晶体矿物,占晶体矿物总量的50%以上。因此,很难从油泥土壤中晶体矿物的种类和结晶度来评价油泥的超声处理效果。

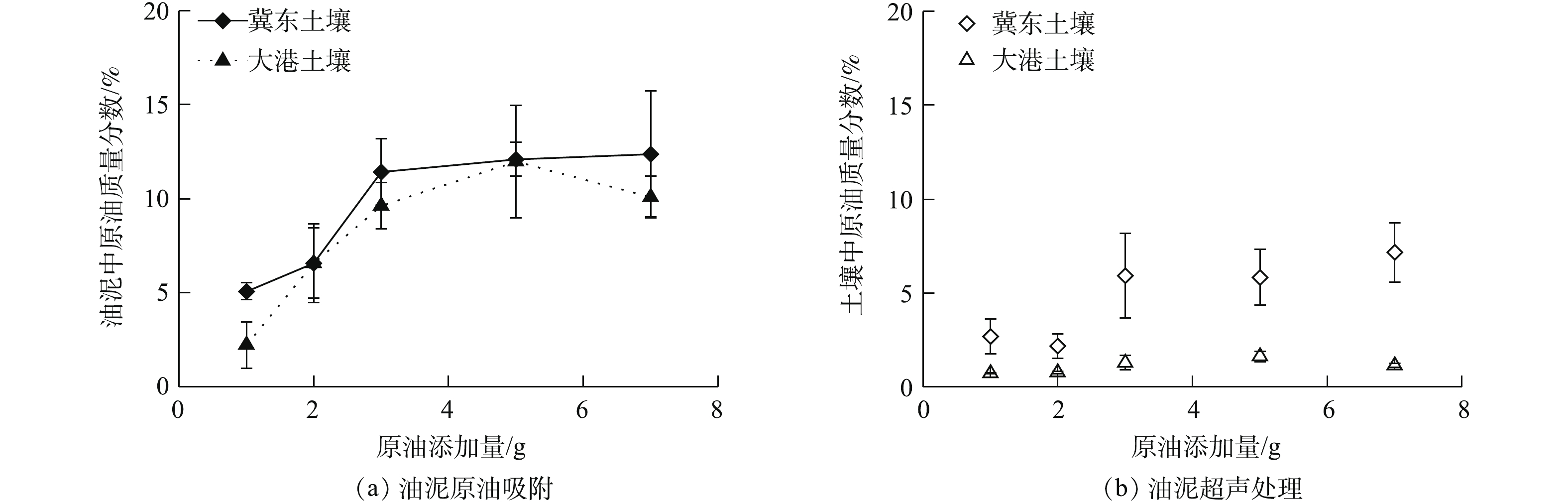

在冀东落地油泥和大港落地油泥的土壤中,钙氧化物和硅氧化物含量差异较大。选择这2种组成不同的脱油后油泥土壤,以冀东原油为模拟油开展原油吸附和超声除油模拟实验,结果如图4所示。

模拟油泥的原油吸附量随原油添加量的增加而增大,当添加量增加到3.0 g,即原油质量占土壤质量的30%时,吸附基本达到平衡。采用Langmuir模型和多分子层吸附的BET模型拟合分析,拟合效果较差。而用Logistic模型处理,修正后的R2均大于0.9,拟合效果好。Logistic模型的计算方法如式(1)所示。

式中:y为土壤中原油质量比;x为原油添加量,g;回归参数y1、y2、x0、p分别为y的最小值、y的最大值、曲线拐点及与拐点处斜率相关的参数。由拟合结果(表4)可知,Logistic方程可以很好地反映原油在土壤中的吸附过程,冀东落地油泥土壤的最大吸附量为12.12%,大港落地油泥土壤的最大吸附量为10.31%。由此可见,钙氧化物含量高的冀东落地油泥土壤对原油的吸附量大于钙氧化物含量低的大港落地油泥土壤。

在经过超声处理后,冀东土壤配制的油泥的残余含油量随着原油吸附量的增加而增加,吸附平衡后土壤中原油的去除率为(47.3±4.0)%。而大港土壤配制的模拟油泥残余含油量并未随吸附量的增加而增加,吸附平衡后土壤中原油的去除率为(87.3±1.0)%。这表明钙氧化物含量高的土壤与冀东原油的吸附作用强,超声处理后油泥中原油的去除率低。

2.1. 落地油泥组分

2.2. 不同来源的油泥超声除油效果对比

2.3. 土壤颗粒级配对超声除油效果的影响

2.4. 土壤组成对超声除油效果的影响

-

1)油泥土壤颗粒级配分布宽为0.5~2 000 μm,且不同土壤级配的油泥超声除油效果不同。粒径大的土壤颗粒超声除油效果较好,粒径小的土壤颗粒超声除油效果差。

2)原油在土壤中的吸附符合Logistic模型。钙氧化物含量高的土壤对原油的吸附量大、吸附强度高、超声处理效果较差;而钙氧化物含量低的吸附量小、吸附强度弱、超声处理效果较好。

3)模拟油泥的超声处理效果均优于实际油泥,除实际油泥的土壤颗粒级配分布宽以外,油泥的老化时间也可能是影响油泥超声处理效果的重要因子,其具体机理有待进一步的研究。

下载:

下载: