-

我国畜牧养殖业的快速发展加剧了其与环境保护之间的矛盾[1-2]。畜牧养殖业产生的污染已经成为关键性的农业面源污染之一[3]。此外,磺胺类和β-内酰胺类抗生素因其具有使用方便、杀菌效果好、适用范围广等优点而被广泛应用于防治动物疾病[4-6]。2013年,我国使用了大约8.4×104 t以上的兽用抗生素[7]。抗生素仅少部分蓄存在动物体内或被完全分解,剩下的约30%~90%随粪便和尿液排出[8-10]。我国不同的畜禽养殖场的粪便及废水共检出28种不同种类抗生素[11],但养殖场中现有的废水处理设施对抗生素的去除效果极差[12]。近年来,细菌耐药性的传播对公众健康产生不良影响,引起了人们的广泛关注[13]。因此,亟需研发畜禽废水中的抗生素高效去除技术。

畜禽废水处理工艺大致可分为物理化学法、生物处理法以及兼顾不同技术的组合工艺。吸附[14-15]和Fenton氧化[16]等物理化学法对废水中的有机物及氮磷的去除效果较好,但成本较高。生物处理法具有处理效果好、运行成本低等优点。HUANG等[17]利用好氧生物反应器降解磺胺二甲嘧啶,最高可以得到80%的去除率;CHEN等[18]利用曝气生物滤池处理养猪场废水中的抗生素,部分抗生素的去除率高达70%~100%。因单一的厌氧或好氧工艺不能很好地去除废水中有机污染物和氨氮[19-21]。还有研究者采用组合工艺处理畜禽废水,如温飞[22]采用厌氧-好氧组合工艺处理畜禽废水,COD去除率大于85%,出水氨氮低于20 mg·L−1。

缺氧/好氧(A/O)系统运行经验丰富,且可通过反硝化补充部分碱度。本研究采用小试规模的A/O系统处理了低C/N奶牛场废水,详细考察了系统中常规污染物以及磺胺类和β-内酰胺类抗生素的处理效果,为奶牛场废水的处理提供有益的参考。

全文HTML

-

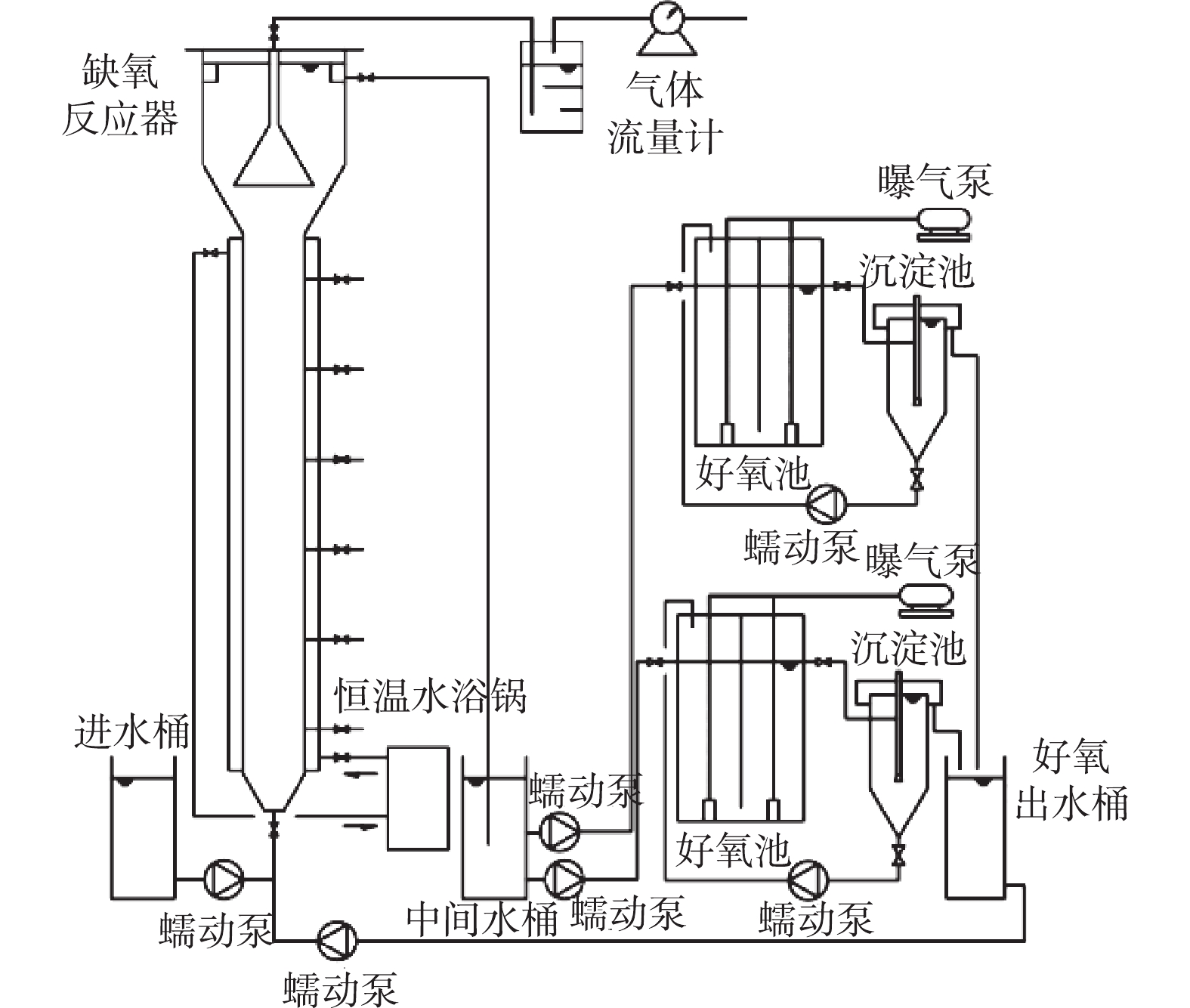

小试实验装置主体部分由缺氧反应器(A池)、好氧池(O池)和沉淀池组成,如图1所示。考虑到某些奶牛场废水处理采用UASB-接触氧化工艺[23],本实验装置的A池采用UASB反应器的形式。实验装置主要材料与设备参见表1。

-

实验用水采用上海某奶牛养殖厂固液分离后的原水,每次取水后将水置于冷库(0~4 ℃)储存备用,为避免原水中固体堵塞管路采用80目筛网过滤后使用。UASB反应器和O池内的接种污泥分别取自处理该奶牛场废水的UASB反应器(中温厌氧)和好氧反应器。接种后,UASB反应器内MLSS和MLVSS分别为28.37 g·L−1和22.13 g·L−1,O池内MLSS和MLVSS分别3.24 g·L−1和2.46 g·L−1。

-

驯化阶段(1~20 d)。为使污泥适应新的进水水质,首先按UASB(33~37 ℃)-好氧工艺运行。该阶段UASB反应器和O池的水力停留时间(HRT)分别为4 d和5.4 d。该阶段的UASB反应器的回流为中间水桶到UASB反应器的回流,回流比为3∶1,即回流水量为UASB反应器进水水量的3倍,而污泥回流比为1∶1。该阶段O池溶解氧控制在4~5 mg·L−1,同时需添加碳酸氢钠调节O池内的pH。21~53 d,适逢春节期间,装置停止运行,将UASB反应器和O池内的污泥分别放入冷库中(0~4 ℃)存储。

A/O系统运行阶段(54~227 d)。该阶段按图1的工艺流程运行,O池溶解氧控制在4~5 mg·L−1,污泥回流比为1∶1,硝化液回流比R(硝化液回流量:进水量)等其他运行参数见表2。外加碳源投加在进水中,表2中的碳源投加量均为500 mg·L−1。

-

对水样COD、总氮(TN)、总磷(TP)的分析采用哈希试剂测定;氨氮(

$ {\rm{NH}}_4^ + $ -N)采用纳氏试剂分光光度法测定;硝酸盐氮(${\rm{NO}}_3^ - $ -N)采用紫外分光光度法测定;溶解氧使用便携式溶解氧仪测定;pH使用梅特勒酸度计测定;污泥浓度(MLSS)和挥发性污泥浓度(MLVSS)使用标准称量法测定;抗生素采用LC-MS/MS测定,采用文献的测定方法[24]。当2个O池并联运行时,O池出水的水质指标为2个O池出水水质指标的平均值。

1.1. 实验装置

1.2. 实验用水及实验污泥

1.3. 实验方法

1.4. 分析方法

-

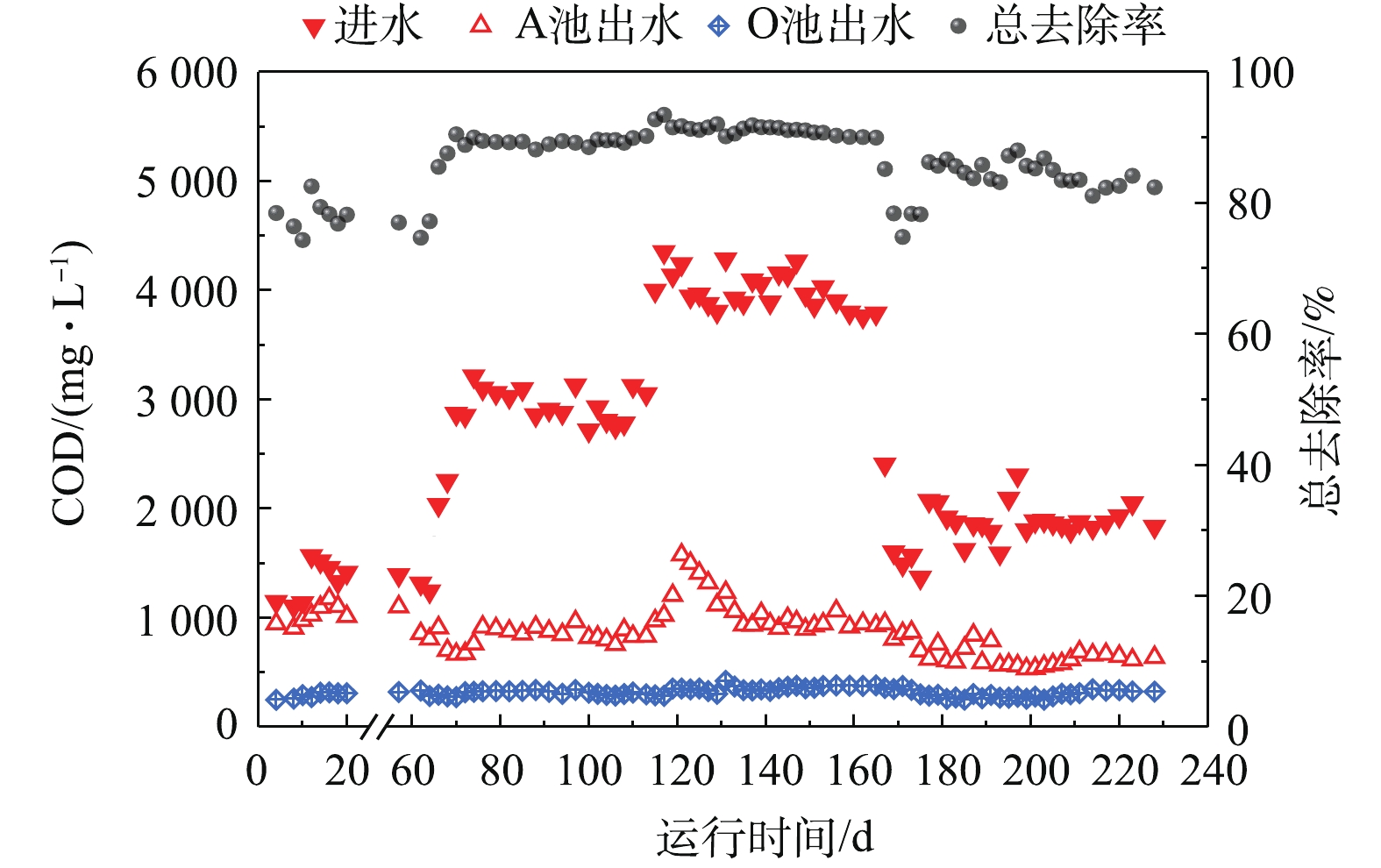

A/O系统COD变化如图2所示。由图2可知,奶牛场废水水质变化较大,进水COD为1 242~4 350 mg·L−1。A/O系统对废水中COD的总去除率为76%~93%。A池对COD的去除与反硝化消耗碳源有关,O池对COD的去除效果较为稳定,可以将A池出水中COD降低至400 mg·L−1以下。

在驯化阶段(1~20 d),进水COD较低,UASB反应器基本不能去除COD,O池对COD的去除效果较好,总去除率高于76%。第54天,将中间水桶到UASB反应器的回流改为O池出水桶到UASB反应器的回流后,A池出水COD有所降低,总的COD去除率基本不变,稳定在76%~80%。当进水COD升高至3 000 mg·L−1左右时,总COD去除率升高至88%~90%,出水COD为300~330 mg·L−1。第98天,加大进水量以提高进水负荷,A池和O池对COD的去除效果基本不变,显示该系统具有较强的抗冲击负荷能力。当进水COD升高至4 000 mg·L−1左右时,总COD去除率为90%~93%,出水COD为340~400 mg·L−1。第131天,将硝化液回流比由1.0∶1改为1.3∶1后,总COD去除率基本没有变化,系统运行稳定。当进水COD降为1 800 mg·L−1左右时,总COD去除率下降至80%~86%,出水COD为250~330 mg·L−1。第206天,将硝化液回流比改为1∶1,同时,将O池的HRT缩短为原来50%(即停止运行一个O池,所有A池出水均进入另外一个O池),O池对COD的去除效率略有所下降,但出水COD仍低于330 mg·L−1。

-

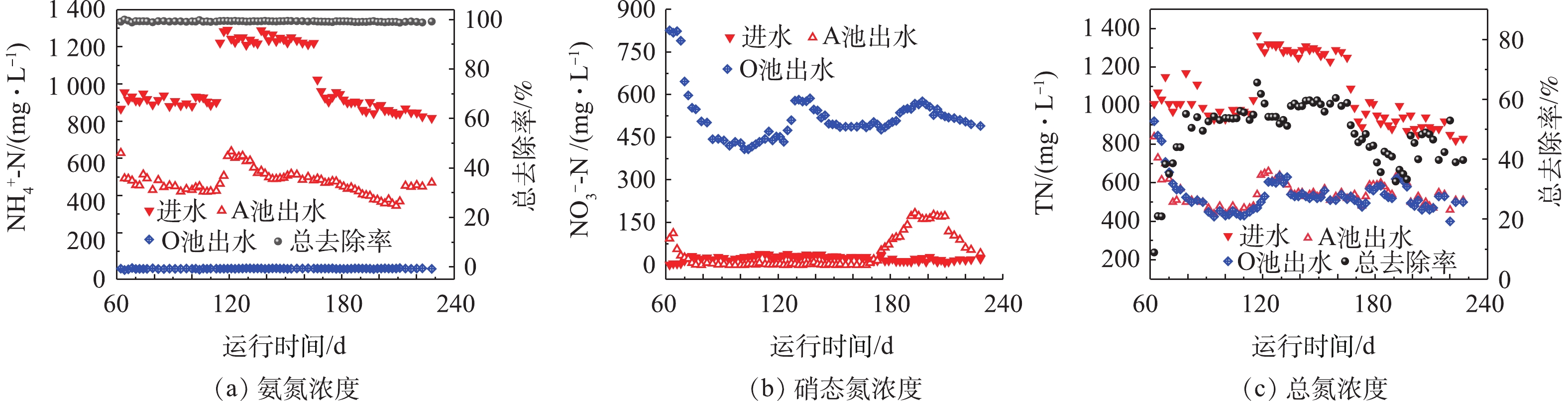

在实验期间,奶牛场废水中氨氮含量特别高(800~1 290 mg·L−1),假如不设置A池,原水中碱度无法满足O池硝化所需碱度,而设置A池后,A池反硝化产生碱度可以在一定程度上补充硝化所需的碱度,从而可降低外加碱度的成本。

原水pH在8左右。在第54天增加O池出水至A池的回流后,无需额外添加碳酸氢钠补充碱度,O池出水pH稳定在7.5左右(C/N=3.1~3.5)。第114天进水水质发生变化(C/N=3.1~3.5),原来1.0∶1的硝化液回流比无法满足碱度需求,故需要添加碳酸氢钠调节O池中pH。第131天将回流比提高至1.3∶1后,O池出水pH稳定在7.8左右,此时无需额外添加碱度。可见,当反硝化碳源充足时,增加硝化液回流比可增加反硝化产生的碱度。166~179 d,进水水质再一次改变(C/N=1.5~1.7),因反硝化碳源不足,此时改变回流比无法取得良好效果。第180天,往进水中投加蔗糖,进水pH反而有所下降,可能是进水中有水解酸化现象造成,效果不佳。第193天,在不添加碱度的前提下改变碳源投加,于进水中添加500 mg·L−1醋酸钠,O池出水pH再一次稳定在7.8左右。

图3显示了A/O系统运行期间氮素变化情况。奶牛场废水中的TN为820~1 360 mg·L−1,氨氮为800~1 290 mg·L−1,硝态氮低于40 mg·L−1,氨氮占TN的绝大部分。由图3(a)可知,O池几乎可以完全去除进水中的氨氮,出水氨氮浓度低于10 mg·L−1。将O池HRT从5.4 d降低至2.05 d后,反应器对氨氮的去除效果依旧良好。图3(b)显示了系统硝态氮变化情况,在开启硝化液回流后,A池出水的硝态氮浓度逐渐下降直到接近检测不到硝态氮,这表明在碳源足够的条件下(C/N≥3.1),可以将回流水中的硝态氮完全反硝化去除。从第166天开始,由于碳源的不足(C/N=1.5~1.7)导致反硝化无法彻底进行,A池出水硝态氮浓度逐渐上升至170 mg·L−1左右。第193天,投加碳源醋酸钠并降低回流比后,A池出水硝态氮浓度逐渐下降。图3(c)显示了系统TN的变化,TN的去除率与进水水质及硝化液回流比有关,在碳源充足的条件下(C/N≥3.1),回流比越高,总氮去除率越高;在不添加碳酸氢钠的条件下,总氮的去除率为40%~60%。

-

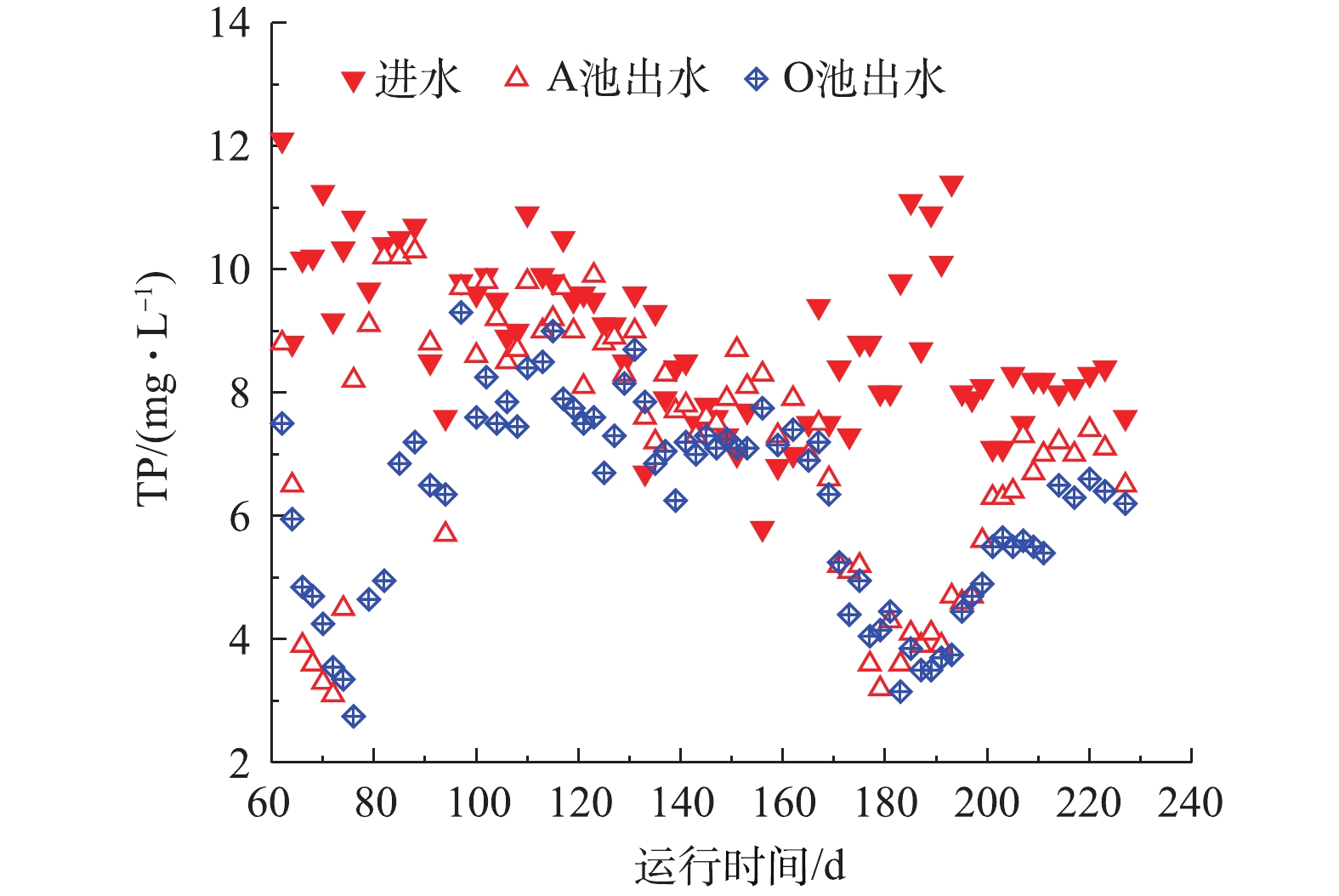

使用A/O系统处理奶牛场废水时,其中的TP的变化如图4所示。在每次更换进水水质后,进水TP浓度的变化为先上升后下降的趋势,应该是由于部分P以不溶性固体形式存在,随着放置时间的延长,固体下沉至水桶底部,造成分析误差。由图4可知,进水TP浓度为6~12 mg·L−1时,出水TP浓度为3~9 mg·L−1,在进水水质发生改变后,进出水TP浓度相差较大,但经过一段时间稳定后,进水TP浓度与出水TP浓度相近,整套系统最大程度地保留了废水中的磷,利于出水还田。

-

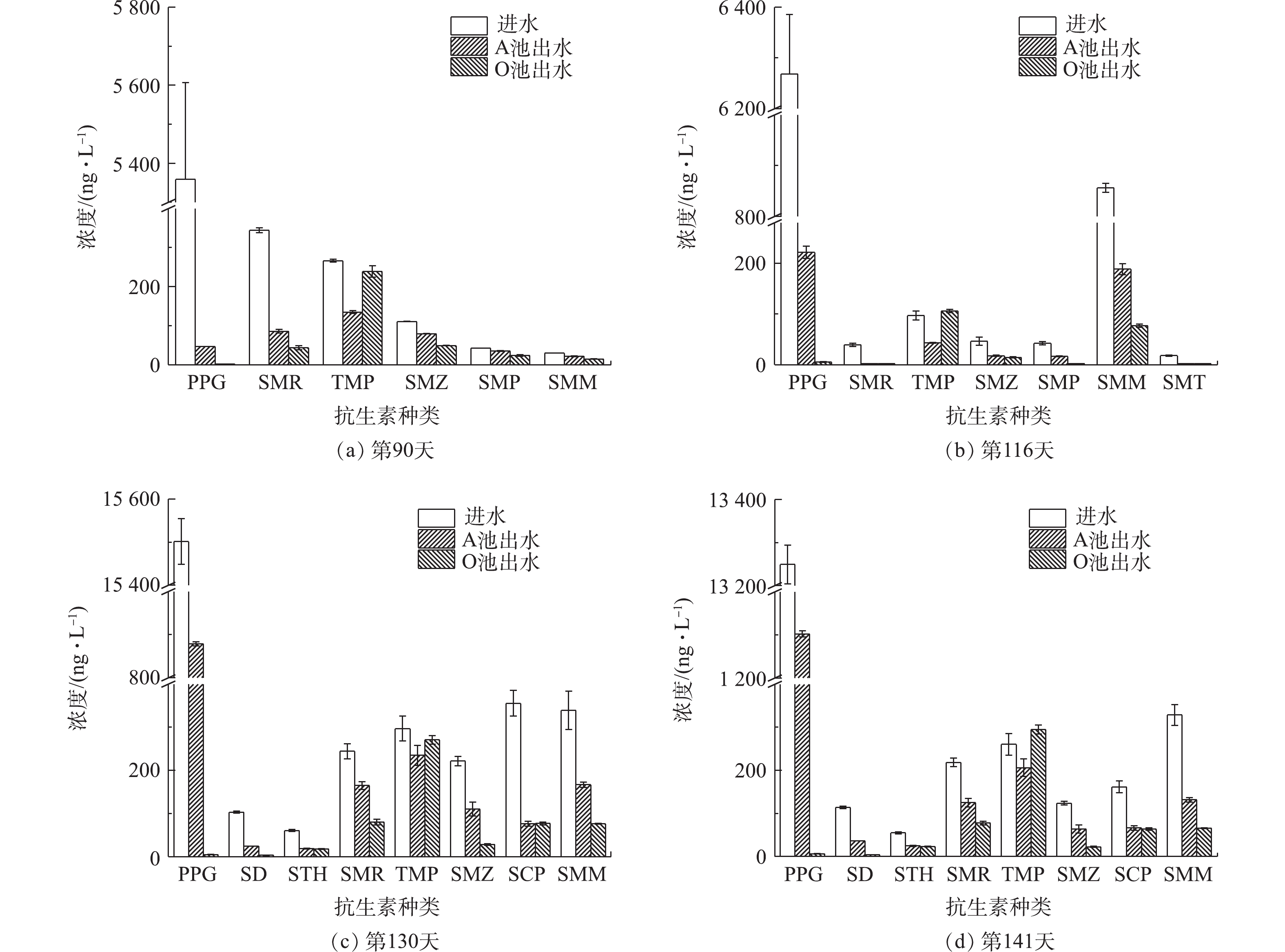

在第90、116、130和141天,对A/O系统中11种磺胺类抗生素(磺胺噻唑(STH)、磺胺二甲嘧啶(SMZ)、磺胺甲恶唑(SMX)、磺胺氯哒嗪(SCP)、磺胺甲氧基哒嗪(SMP)、磺胺嘧啶(SD)、磺胺甲基嘧啶(SMR)、磺胺甲噻二唑(STZ)、甲氧苄啶(TMP)、磺胺间二甲氧嘧啶(SMT)、磺胺间甲氧嘧啶(SMM))和8种β-内酰胺类抗生素(阿莫西林(AMX)、头孢喹肟(CFQ)、普鲁卡因青霉素G(PPG)、氨苄西林(AMP)、头孢噻呋(CEF)、苄基青霉素钾(PCG)、氯唑西林钠(CLX)、苄星青霉素G(BPG))进行分析测定,结果如图5所示。由图5可知,A/O系统中共检测出10种抗生素,包括1种β-内酰胺类抗生素(PPG 5.11~15.55 μg·L−1)和9种磺胺类抗生素(SD 100.49~116.84 ng·L−1、STH 52.80~62.77 ng·L−1、SMR 36.01~350.48 ng·L−1、TMP 87.64~325.25 ng·L−1、SMZ 38.32~232.25 ng·L−1、SMP 39.39~45.98 ng·L−1、SCP 148.04~384.91 ng·L−1、SMM 294.70~860.12 ng·L−1、SMT 16.72~30.14 ng·L−1),这10种抗生素的总浓度为5.89~17.31 μg·L−1。所检测到的抗生素种类及浓度与水质有关,不同时间段所检测到的抗生素种类有所不同。系统对所检测抗生素有良好的去除效果,总去除率为93.7%~97.2%。其中,PPG占所测抗生素总量的85%以上,而PPG是一种容易被生物降解的物质[25],大部分在A池中就已经被降解,系统对其总去除率超过99%。系统对磺胺类抗生素也具有良好的去除率。除TMP外,其余抗生素都有不同程度的去除,去除率分别为96.4%~97.2%(SD)、54.7%~78.7%(STH)、60.5%~95.3%(SMR)、55.3%~88.7%(SMZ)、62.4%~94.9%(SMP)、55.2%~80.9%(SCP)、73.9%~91.5%(SMM)、49.8%~89.7%(SMT),其中大部分磺胺类抗生素在O池中得到去除,而A池对磺胺类抗生素去除效率较低。值得注意的是,系统对TMP基本没有去除,在A池出水中TMP浓度有所下降,而O池出水TMP浓度又有所上升,可能是由于抗生素代谢产物造成[26]。

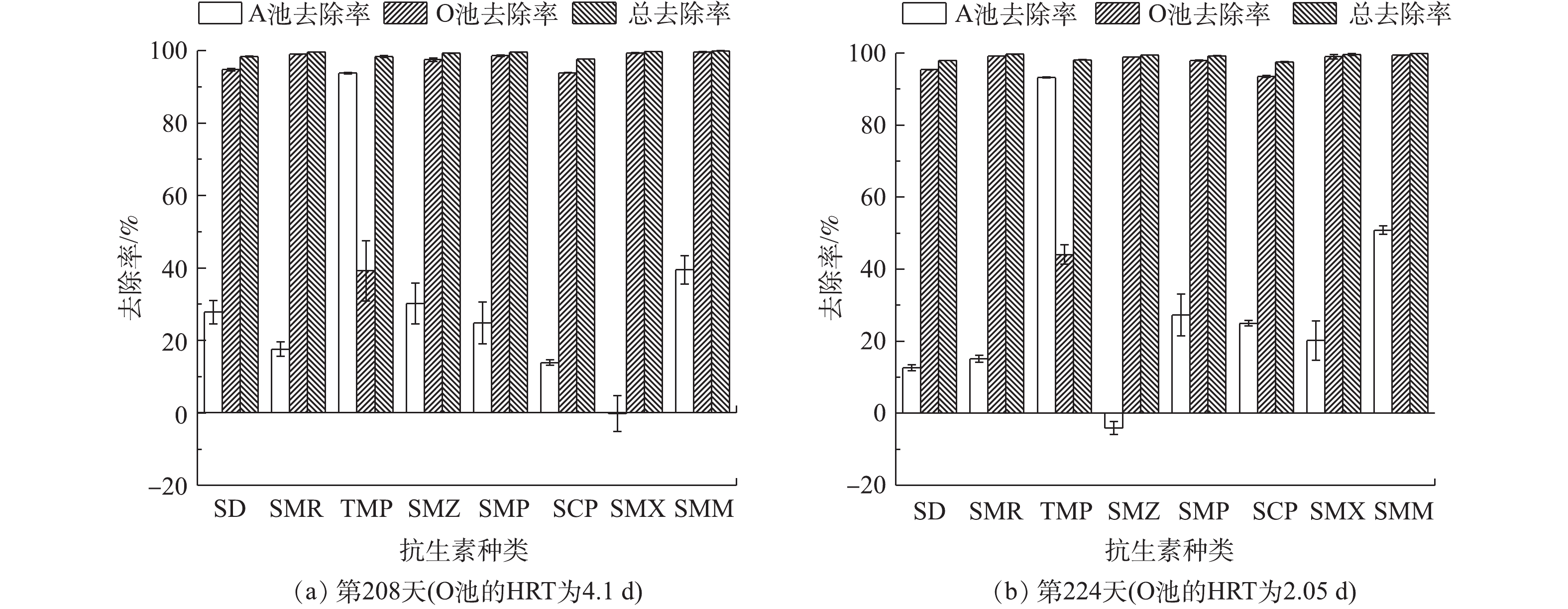

由于原水中磺胺类抗生素浓度较低,为了研究A/O系统对较高浓度磺胺类抗生素是否同样有良好的去除效果,在第141天,于进水中投加8种磺胺类抗生素(SD、SMR、TMP、SMZ、SMP、SCP、SMX、SMM),每种的投加浓度均为50 μg·L−1,去除情况如图6所示。

由图6可知,系统对8种磺胺类抗生素去除效果十分良好,总去除率为91.77%~97.08%,其中,A池的去除率为15.02%~33.76%,O池的去除率为69.1%~90.3%。投加抗生素10 d后,总去除效率就高达(92.32±0.55)%,说明系统对中等浓度的抗生素适应性好;24 d后总去除率有所升高,达到(96.16±0.30)%,之后去除率维持在这附近。总体来看,O池对8种磺胺类抗生素的去除效果比A池要好。A池仅对TMP去除效率较高,对其他7种磺胺类抗生素去除效率低于50%。A池出现一些去除率为负值的情况,可能是与抗生素代谢产物[26]和污泥吸附及解吸[27]造成分析误差有关。磺胺类抗生素主要在O池内得到去除,这一点与之前的研究[28]结果相符。大部分磺胺类抗生素通过生物降解去除,仅有少部分通过生物吸附去除[29]。除TMP外,其余7种磺胺类抗生素的分子结构中都含有磺酰胺基团。有相关研究[24, 30]发现,磺胺类抗生素的部分降解产物的形成与磺酰胺基团中S—N键断裂有关。在增加碳源或氮源的情况下,磺胺类抗生素的降解效率随之上升[31]。TMP中不含有S—N键,其结构中的双环由—C—连接。由图6可知,A池和O池对TMP均有一定的降解能力。在第165天时,O池还未展现对TMP良好的降解能力;在第179天时,A池对TMP的去除效果变低,而O池对TMP有一定降解效果。这可能与进水COD变低有关,A池中微生物由于碳源不足生长受到抑制导致降解TMP能力变弱。而O池一直有着良好的COD和氨氮去除率,微生物生长未受到影响。BATT等[31]认为TMP的降解与硝化活性污泥中的硝化细菌有关;而有研究[32]发现TMP的降解与硝化活性污泥中的硝化细菌和异养细菌均没有关系。从实验结果来看,TMP的降解效果与异养细菌的生长有很大的关系。

为进一步探究抗生素进水浓度及HRT对其去除率的影响,在第194天加大了进水中8种磺胺类抗生素的投加量(每种的投加浓度均为200 μg·L−1),并于第208天减少其中一个O池的使用,具体去除情况如图7所示。由图7(a)可知,系统对8种磺胺类抗生素的去除效果依旧良好,抗生素总去除率为(99.03±0.08)%,其中A池和O池的去除率分别为(30.92±3.31)%和(90.22±1.21)%。图7(b)表明,当O池HRT减少50%后,系统对抗生素的总去除率略有降低,为(98.91±0.07)%,其中A池和O池的去除率分别为(30.03±2.12)%和(89.45±0.91)%。

2.1. COD去除情况

2.2. pH及氮素变化情况

2.3. 总磷变化情况

2.4. 抗生素去除情况

-

1)采用A/O系统处理COD/TN≤3.5的奶牛场废水,出水COD<400 mg·L−1、氨氮<10 mg·L−1、TN去除率为40%~60%(无外加碳源)、总磷基本没有去除,这利于出水的还田处理。

2)当进水COD/TN为3.1~3.5时,通过调节硝化液回流比(1.0∶1~1.3∶1)可实现碱度自给自足,从而降低了运行成本。

3)对奶牛场废水中11种磺胺类和8种β-内酰胺类抗生素研究发现,共检测出9种磺胺类和1种β-内酰胺类抗生素,其总浓度为5.89~17.31 μg·L−1,此时A/O系统对抗生素的总去除率大于93%。先后2次向进水中人为添加8种磺胺类抗生素(每种浓度先后为50 μg·L−1和200 μg·L−1)不影响系统运行的稳定性,且抗生素总的去除率大于90%。除甲氧苄啶外,其余7种磺胺类抗生素主要在O池中得到去除,这与其分子结构中的S—N键有关,具体的生物降解机理和生物降解产物尚需深入研究。

4)A/O系统对高、中、低浓度磺胺类抗生素均具有良好的去除效果。当O池的HRT减少至50%后,系统对抗生素的总去除率基本不变。关于HRT对抗生素去除率的影响尚需进一步的研究。

下载:

下载: