-

近年来,我国大力推进生活垃圾源头分类工作,初步构建了以“四分法”为基础的城市生活垃圾分类体系。生活垃圾可以分为厨余垃圾、可回收物、有害垃圾和其他垃圾。厨余垃圾包括家庭厨余垃圾、餐厨垃圾和果蔬垃圾等,占中国城市生活垃圾总量的40%~60%,是生活垃圾分类工作的重点和难点[1]。目前,各城市收集到的厨余垃圾主要是餐厨垃圾,一些重点城市也开始了家庭厨余垃圾和果蔬垃圾的分类收运。分出的厨余垃圾大多进行厌氧消化处理,少量采用好氧堆肥、转化饲料等模式,但大部分厨余垃圾仍未分出,与其他垃圾混合,最终进入到焚烧厂或填埋场进行处理[2-3]。

为了构建完整的生活垃圾分类体系,提高厨余垃圾源头分类率和建设厨余垃圾处理设施已成为许多城市的重点工作。然而,厨余垃圾分类,特别是家庭厨余垃圾分类,虽然提高了生活垃圾分类率,但也存在着管理成本增加和增加终端设施建设的难题。针对厨余垃圾管理策略,许多研究者从不同角度进行了分析。YU等[4]认为,两相厌氧消化相比单相厌氧消化更适于厨余垃圾处理;厨余垃圾分类后,厌氧消化会比混合焚烧具有更好的环境效益[5]。然而,厨余垃圾分类也推高了社会成本,为了实现社会成本和环境效益的平衡,家庭厨余垃圾应适度分类[6]。GUO等[7]比较了厨余垃圾生物精炼与厌氧消化的环境效应,发现生物精炼可以固定75%的碳,但也会产生大量废液。EDWARDS等[8]的研究结果表明,厌氧消化的碳排放明显小于好氧堆肥和填埋。GUVEN等[9]对比分析了厨余垃圾焚烧、厌氧消化和破碎后进入下水管网3种处理模式,发现厨余垃圾焚烧的能源回收效率最高,具有最好的环境效益。这些已有研究主要关注厨余垃圾处理技术本身的环境影响,还缺少对中国城市生活垃圾分类体系中厨余垃圾处理模式的系统性分析。

针对上述问题,本研究从回收利用率、环境效益和全周期费用等角度分析了厨余垃圾不分类(与其他垃圾混合焚烧)和分类处理(加工饲料、厌氧消化和好氧堆肥)的优劣。其中,回收利用率是评估垃圾分类工作成效的关键指标,而环境效益和全周期费用是垃圾分类工作需要考量的2个最重要因素。在环境效益方面,碳排放是目前广受关注的焦点。食品生产全链条的碳排放占全球碳排放的26%[10],而厨余垃圾导致的碳排放占全球碳排放的6%左右[11]。因此,本研究重点评估了不同处理模式的碳排放情况。在这些研究的基础上,本研究希望能够给出厨余垃圾处理模式的优先级排序。

全文HTML

-

不同区域经济发展水平和居民生活习惯差异较大,厨余垃圾性质也有所不同。根据本研究对北京、上海、厦门、深圳等地厨余垃圾处理设施的调查,进场垃圾中一般含有10%~25%的杂质(如木筷、橡塑、纸杯、玻璃、大骨等)。杂质含量和成分对评估结果有直接影响,但基于杂质的分析不能反映中国生活垃圾分类的趋势和厨余垃圾处理模式本身的优劣。因此,本研究以1 t厨余垃圾(不含杂质)作为比较单元,其性质参考本研究实地调查数据和文献数据[12-14]。1 t厨余垃圾含干固体200 kg,包括有机质190 kg和无机质10 kg,干基热值为15 000 kJ·kg−1。干固体中,糖类占(50.9±10.9)%、蛋白质占(15.6±3.1)%、脂类占(22.4±5.2)%[7]。以此推算,干固体中可生物降解的有机质约为170 kg,而难生物降解部分(木质纤维素类)约为20 kg[15]。不同文献报道的厨余垃圾元素组成如表1所示,本研究取平均值,即碳49.3%、氢7.3%、氧31.0%、氮3.0%。

-

1)混合收集+焚烧处理。厨余垃圾和其他垃圾混合收集处理,这是目前大多数城市采用的模式。根据原生垃圾零填埋的趋势,本研究以焚烧厂作为终端处理设施。进场垃圾在储坑暂存数天后进入焚烧炉焚烧发电,焚烧飞灰稳定化后和炉渣进行填埋处置。在储坑暂存期间,厨余垃圾含水率从80%降至70%,排出渗滤液230 kg·t−1,COD约为60 g·L−1[22-23],渗滤液经污水处理系统净化后排放。

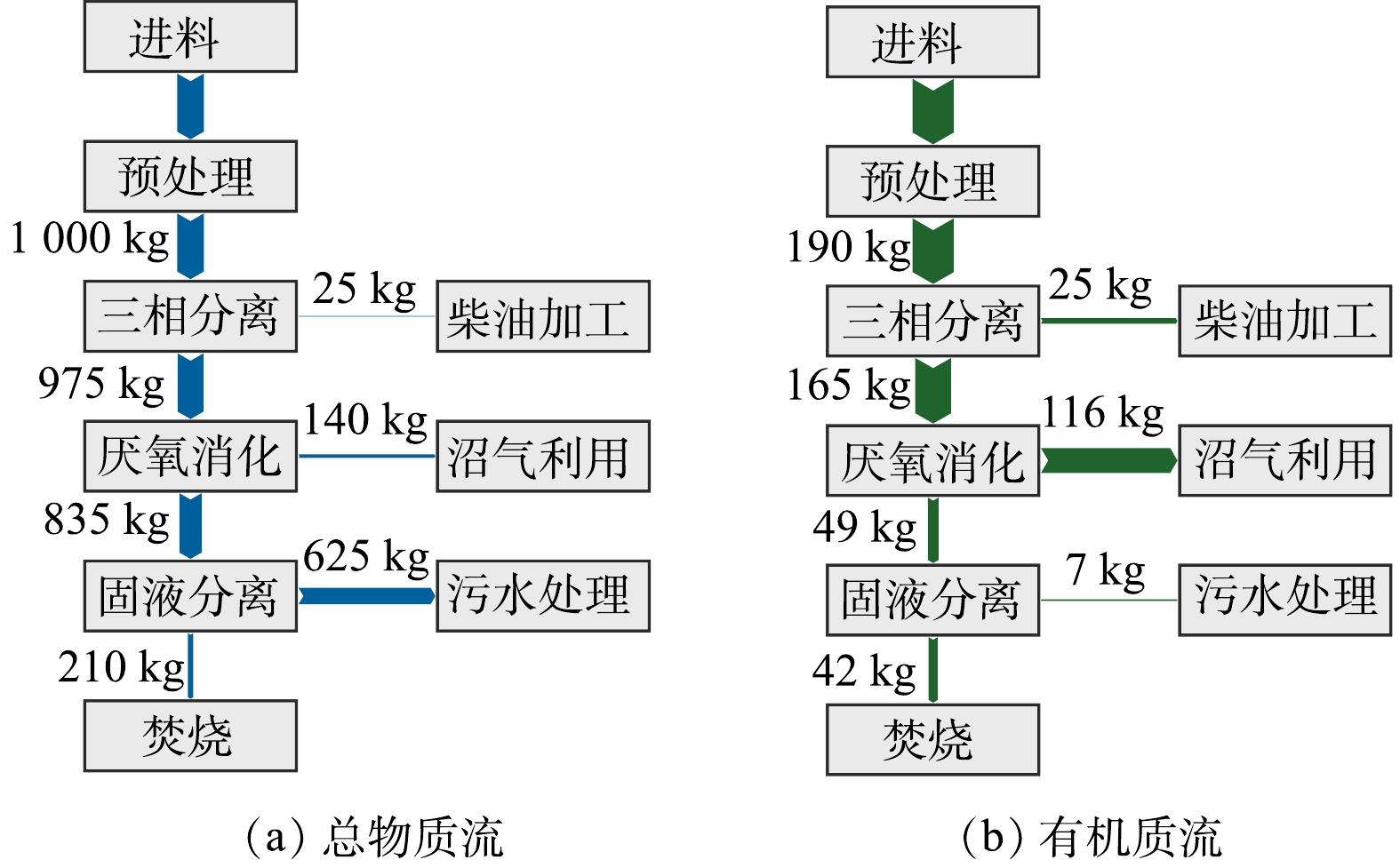

2)分类收集+厌氧消化。厌氧消化是厨余垃圾资源化的主要途径,产生的沼气可以用于发电,具有较强的适用性[14]。厨余垃圾厌氧消化可以采用单相工艺或两相工艺,后者可以承受更高的有机负荷,耐冲击能力更好[24],因此,近期项目多采用两相工艺。厨余垃圾经预处理后进入三相分离系统,分离得到粗油脂、固渣和液体。其中,粗油脂用于加工生物柴油,而固渣和液体进行厌氧消化,产生的沼气用于发电。厌氧消化后的沼液进入污水厂处理,而沼渣进入焚烧厂焚烧。

3)分类收集+好氧堆肥。好氧堆肥也是厨余垃圾资源化的常用方法,技术成熟,堆肥产品可进行土地利用,但需要考虑周边地区的用肥需求[25]。厨余垃圾含水率较高,所以堆肥前通常要加热蒸发水分,或加入其他低含水率的有机废物,或返混低含水率的腐熟成品。本研究主要分析集中式堆肥系统,采用加入辅料和熟料返混的方式进行水分调控。

4)分类收集+饲料化。厨余垃圾本身可以直接饲喂动物,但其储存收运过程中可能滋生病原体,必须经过处理以满足饲料安全和营养要求[15]。处理方法主要有干热法、微生物发酵[26]和昆虫饲养[27]等。微生物发酵目前处于实验室研发阶段,黑水虻幼虫饲养适用于中小规模处理,而干热法技术成熟,可大规模应用,但其产物的饲喂对象受限[28]。干热处理步骤包括除杂破碎、脱水脱油、高温干燥、制粒膨化等。

-

1)回收利用率。在厨余垃圾处理过程中,有机质可以部分转化为肥料、饲料或能量,为了便于对不同技术进行比较,本研究按照式(1)定义计算回收利用率,其包括了物质回收和能量回收。

式中:R为回收利用率,%;MR为回收产物中来自于厨余垃圾的质量,kg·t−1;MFW为厨余垃圾干固体总质量,kg·t−1;ER为从厨余垃圾中回收的能量,kJ·t−1;EFW为厨余垃圾干固体的生物质能,kJ·t−1。根据式(1),可以计算4种厨余垃圾处理模式的回收利用率。

混合焚烧。厨余垃圾焚烧处理主要回收电能,参考式(1),混合焚烧的回收利用率如式(2)所示,经简化后,可以转化为式(3)。

式中:RIN为混合焚烧的回收利用率,%;HS为干固体热值,HW为水分蒸发所需热量,分别为15 000和2 257 kJ·kg−1;RTS为厨余垃圾干固体比例,%;γIN为焚烧发电系统的热效率,一般为14%~22.5%,典型值为19%(锅炉热效率76%,汽轮机热效率25%)[29],如果通过热电联产回收低品位热能,则效率可达60%[30];β为能量自用率,一般为20%~25%[31],参考深圳某焚烧企业,典型值设为25%。

厌氧消化。厨余垃圾经三相分离后可回收粗油脂,剩余的有机质部分转化为沼气并燃烧发电,部分进入沼渣并焚烧发电。根据式(1),厌氧消化系统的回收利用率计算方法见式(4)。

式中:RAD为厌氧消化系统回收利用率,%;Moil为粗油脂分出量,约25 kg[32];α为粗油脂转化生物柴油的效率,80%;mVS为有机质质量,kg·t−1;RDD为有机质降解率,文献[5]中2个厨余垃圾处理企业的有机质降解率分别为66.8%和72.6%,本研究取值范围为65%~75%,典型值取平均值70%;RSBP为降解单位有机质产生沼气的产率,根据1.1节中厨余垃圾元素组成,RSBP为1 m3·kg−1,甲烷含量为60%;Hbiogas为沼气热值,21.5 MJ·m−3;γAD为沼气利用的热效率,大多数处理厂采用沼气内燃发电机,利用余热进行消化系统保温(不外输蒸汽和热水),按气耗率0.5 m3·(kWh)−1计,热效率为33.5%[4],即厨余垃圾发电量为155~250 kWh·t−1;β为能量自用率,文献[33]中厨余垃圾厂内部耗电量为25~38 kWh·t−1,文献[5]中为18~47 kWh·t−1,取中位数32 kWh·t−1计算,与厨余垃圾发电量相比,β值取15%;Mresidue为沼渣干固体质量,kg·t−1。

好氧堆肥:厨余垃圾经好氧堆肥后变为肥料,根据式(1),其回收利用率计算方法见式(5)。

式中:RCOM为好氧堆肥的回收利用率,%;RDD为有机质降解率,%。张园等[34]研究发现,水溶性有机质在堆肥过程中降解了85%,而纤维素和半纤维素的降解率为32%~36%。任连海等[35]研究发现,厨余垃圾堆肥时有机质降解率达到了90%以上。绳以健等[36]研究发现,厨余垃圾有机质含量从90%降低至70%,降解率实际上达到了74%。周营等[37]研究发现,厨余垃圾经堆肥后,有机质含量从85%降至50%,即有机质降解率为65%。根据这些报道,本文RDD取值范围为65%~75%,典型值取平均数70%。

饲料化。厨余垃圾经干热处理后加工为饲料,根据式(1),其回收利用率计算方法见式(6)。

式中:RFEED为饲料化的回收利用率,%;VSloss为干热过程中随渗滤液、水分蒸发而损失的有机质,约为干固体的5%~20%[15]。因此,每t厨余垃圾可产生饲料产品160~190 kg。

2)碳排放。厨余垃圾中的碳均为生物源碳,其转化生成的CO2不计入碳排放。厨余垃圾处理的碳排放来自于收运处理过程中消耗外部能量、物质引起的间接碳排放,而碳减排效应来自于系统输出的产品或能量产生的替代效应。同时,处理过程中温室气体甲烷(CH4)和氧化亚氮(N2O)的泄漏也会导致碳排放。本研究所述碳排放均以二氧化碳当量计,参考政府间气候变化专门委员会(IPCC)报告,CH4和N2O的百年温室气体效应分别按CO2的28倍和310倍计算[38]。系统总碳排放可以按式(7)计算。

式中:EC为系统总碳排放,kg·t−1;ECextra为处理过程中消耗能源、药剂等带来的附加碳排放,kg·t−1;ECleak为处理过程中泄漏的温室气体的碳排放当量,kg·t−1;Poutput为系统产物,fp为系统产物所替代的能量或产品的单位碳排放。

混合焚烧。焚烧过程中的附加碳排放取决于工艺条件和管理水平,文献[39]报道为20.3 kg·t−1、文献[5]报道为深圳某焚烧厂为47 kg·t−1、文献[40]报道上海某焚烧厂为27~45 kg·t−1等;考虑到深圳、上海焚烧厂运行水平相对较好,本研究典型值取45 kg·t−1。厨余垃圾在储坑产生渗滤液,其处理过程会泄漏CH4和N2O并消耗电能和絮凝剂,按每去除1 kg COD引起碳排放0.63 kg计[41],则产生碳排放8.7 kg。系统外输电力的碳减排效应按0.88 kg·(kWh)−1计[42]。

厌氧消化。厌氧消化过程中的附加碳排放约为34.3~82.8 kg·t−1[4,33],本研究取中间值60 kg·t−1作为典型值;1 t厨余垃圾产生沼液约0.9 t,COD浓度为9 g·L−1[4],按每去除1 kg COD引起碳排放0.63 kg计[41],对应碳排放5 kg;厌氧消化系统的CH4泄漏率一般在2%~5%,而澳大利亚厌氧消化系统的CH4泄漏率仅为0.4%[43]。本研究参考IPCC,甲烷泄漏率取5%,而N2O可以忽略[38],则厨余垃圾厌氧消化的甲烷泄漏量为2.6 kg·t−1,对应碳排放73 kg·t−1。碳减排效应来自于上网电力和生物柴油,后者可以替代柴油,柴油全生命周期(含使用)的碳排放系数为3.1 kg·kg−1[44]。

好氧堆肥。堆肥产物可以替代化肥,并通过腐殖化和土地施用固定有机碳。堆肥产物含氮元素3.08%[33],考虑堆肥有效利用率70%,其可以替代尿素5.1 kg,按尿素单位碳排放0.35 kg·kg−1计[45],则每kg堆肥产物因替代尿素引起的碳减排量为0.016 kg。堆肥产物本身还实现了碳固定[46],假设厨余垃圾中的碳30%转化为堆肥产品,堆肥产物含水率为40%,则含碳量约为25%,堆肥产物固定的二氧化碳当量为0.917 kg·kg−1堆肥产物。因此,每kg堆肥产物因替代化肥和固碳的总碳减排量为0.93 kg。好氧堆肥的附加碳排放主要来自于耗电,一般为40~80 kWh·t−1[33],取中位数60 kWh·t−1计算,则碳排放为53 kg·t−1。此外,堆肥过程泄漏的CH4为初始碳含量的1%~10%,N2O为初始氮含量的0.5%到5%[43],本研究典型值取CH4泄漏4 kg·t−1和N2O泄漏0.3 kg·t−1[33],则温室气体泄漏引起的碳排放为205 kg·t−1。

饲料化。首先利用干燥机将厨余垃圾含水率从80%降至30%,水分蒸发量为714 kg·t−1。按干燥机单位水蒸发能耗(含热耗、电耗)1.0 kWh·kg−1计,单位厨余垃圾加热蒸发能耗为714 kWh·t−1。如以天然气供热,则需天然气73 m3(锅炉热效率90%),按天然气排放系数2.2 kg·m−3计算[47],则干燥过程碳排放为160.6 kg·t−1。其他附加碳排放约为7.3 kg·t−1[48]。饲料化产物可以替代同类产品,以替代燕麦饲料和黄豆饲料计,分别减少碳排放0.38和2.70 kg·kg−1饲料产品[48],本研究以平均值1.5 kg·kg −1计算。

收运过程。厨余垃圾收运过程也会产生碳排放。深圳市厨余垃圾收运全程柴油消耗约2.88 L·t−1,当收集率提高时,可能需要一次中转,中转站的柴油消耗量为0.4 L·t−1、耗电量为1 kWh·t−1[6]。边潇等[33]对南方某县级市的分析表明,收运油耗为3.91 L·t−1。何品晶等[39]对上海的分析表明,收运碳排放为13.7~21.0 kg·t−1。这3者中,深圳最低,南方某县居中,而上海最高,这与深圳面积较小、厨余垃圾收运距离短有关。本研究取居中值,按收运过程油耗3.9 L·t−1计算,而柴油全生命周期(含使用)的碳排放系数为3.1 kg·kg−1[44],这样厨余垃圾收运过程的碳排放约为12.1 kg·t−1。

3)全周期费用。厨余垃圾分类系统涉及投放、收运、处理处置和监管等环节,不同区域、不同设施、不同运行水平的厨余垃圾全周期费用会有较大差异。对于管理部门,财政支出是其制定厨余垃圾管理策略的重要依据。因此,该部分不对各个环节企业的运营成本进行财务分析,而是直接参考多个城市管理部门的调研数据,对厨余垃圾处理模式进行全周期费用的比较。

1.1. 厨余垃圾性质

1.2. 处理模式

1.3. 评估方法

-

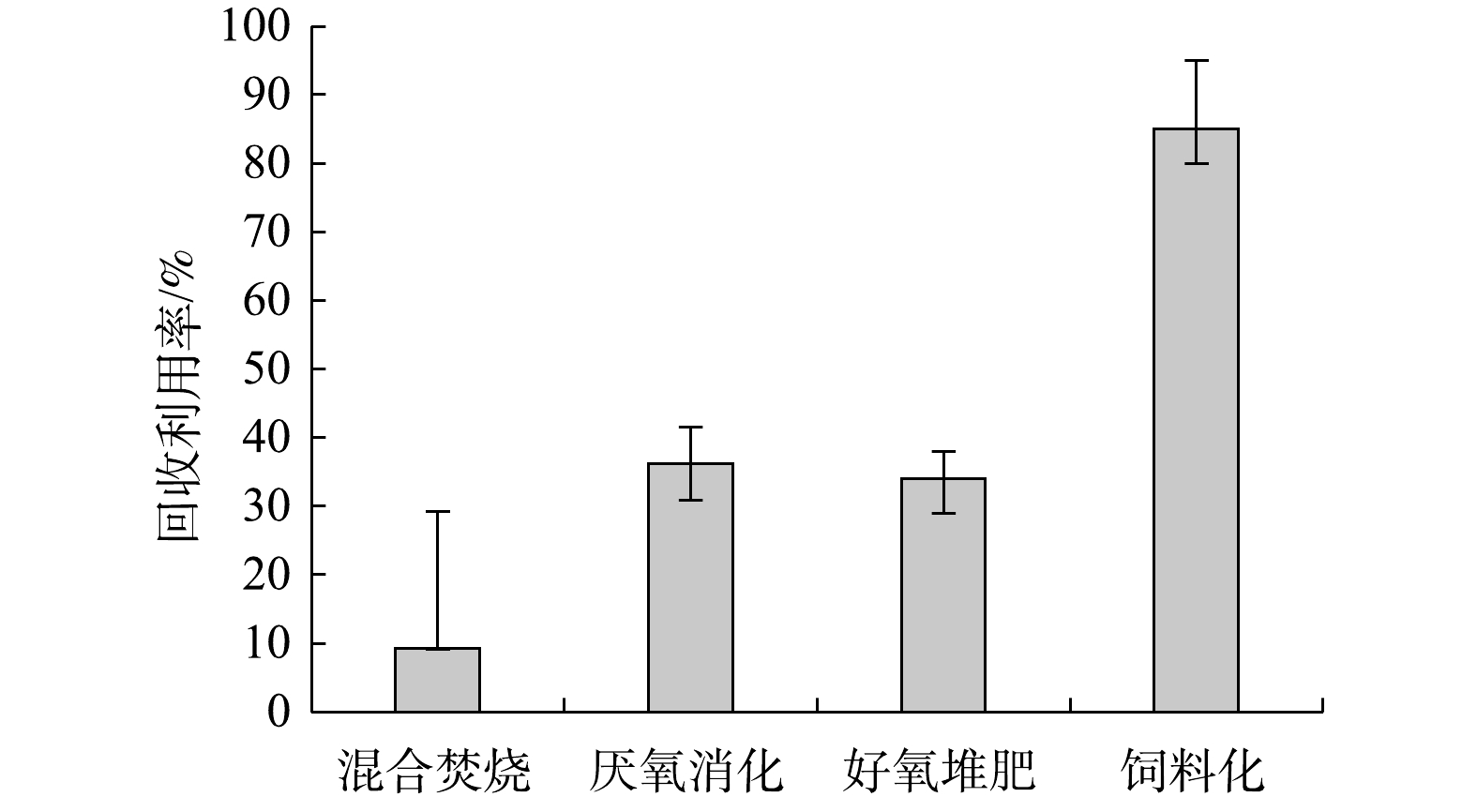

1)混合焚烧。对于混合焚烧处理,根据式(3),回收利用率主要受厨余垃圾含固率和系统热效率的影响。厨余垃圾进入焚烧厂后,在储坑排出部分水分,含水率从80%降至70%,该条件下的回收利用率仅为9%。这是因为,厨余垃圾干基热值远低于橡塑、纸类等,而且含有大量水分。实际上,厨余垃圾焚烧的外输电量仅76 kWh·t−1。即使厨余垃圾含水率进一步降低至60%,回收利用率也仅提升至11%。根据式(3)可知,要提升回收利用率,还必须提升焚烧系统的热效率;如果热效率为60%,则厨余垃圾焚烧处理的回收利用率可以达到29%,但这需要焚烧厂周边有稳定的热需求。

2)厌氧消化。对于厌氧消化处理,油脂回收量取决于厨余垃圾特性,而整个处理系统的回收利用率主要受有机质降解率和沼气发电热效率的影响。如厨余垃圾有机质降解率为70%,则沼气产率为115 m3·t−1。每t厨余垃圾产生废液(含沼液和厂区其他外排废水)约0.92 t,含有机质7 kg;产生沼渣210 kg,含有机质为42 kg,其余为水分。假设无机质10 kg全部进入沼液,而工艺消耗的药剂不计入质量平衡,则系统物质流如图1所示。根据式(4),厨余垃圾厌氧消化厂的上网电量为204 kWh·t−1,沼渣在焚烧厂外输电量为14 kWh·t−1,共外输电力218 kWh·t−1,整个系统的回收利用率为36%,显著高于焚烧处理。当厨余垃圾有机质降解率为65%~75%、综合热效率为30%~40%、CH4泄漏率为0.5%~5%,则系统的回收利用率在31%~42%之间波动。

厨余垃圾好氧堆肥时,大部分有机质矿化为二氧化碳和水,少部分腐殖化进入堆肥产物。典型条件下,厨余垃圾中70%的有机质降解,同时含水率从80%降低至40%(以满足堆肥产品要求),这样得到的堆肥产物为112 kg·t−1(其中干固体为67 kg·t−1),即产率为11%,略高于文献[33]中的5%。在这种条件下,根据式(5),好氧堆肥的回收利用率为34%。当厨余垃圾有机质降解率为65%~75%时,回收利用率为29%~38%。

厨余垃圾干热处理时,有少量有机质损失,而大部分干固体进入到饲料产品中。根据式(6),干热处理的回收利用率为80%~95%。因此,干热处理这种短流程的物理加工方式可以最大限度的利用有机质。当采用微生物或昆虫幼体处理厨余垃圾时,微生物和昆虫幼体本身会消耗有机质,同时在产物分离过程中会有一定的质量损失,所以回收利用率会有所下降。

不同厨余垃圾处理模式的回收利用率总结在图2中。饲料化具有最高的回收利用率,这是由于干热处理最大限度地利用了厨余垃圾有机质。厌氧消化的回收利用率略高于好氧堆肥,这是由于厌氧条件下有机质转化为甲烷,但甲烷利用率较低;而好氧条件下大量有机质被矿化为二氧化碳。与焚烧处理相比,厌氧消化系统转化有机质的效率略高,同时无需蒸发水分,而且自用电比例更低,因此具有更高的回收利用率。如果厌氧消化系统有机质降解率降低,则进入到沼渣的有机质变多,由于焚烧发电的效率较低,则系统的回收利用率会下降。如果厌氧消化系统不进行沼气发电,而是直接外输沼气或甲烷,则可以避免沼气发电环节的损耗,提高系统的回收利用率。

-

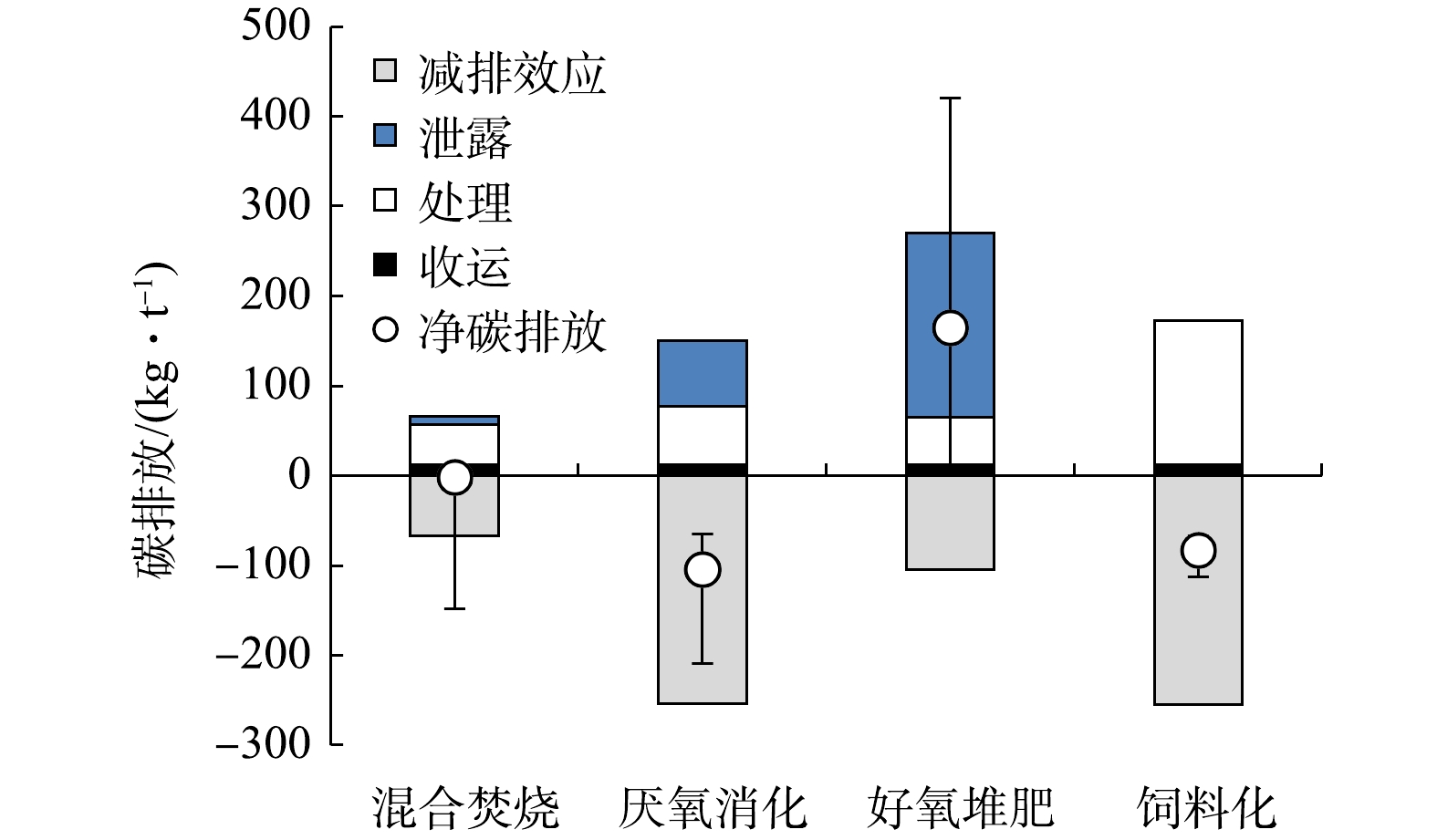

厨余垃圾焚烧后可以向外输电,同时焚烧系统(包括运输、渗滤液处理、飞灰处理、炉渣处理、烟气治理等)中输入的材料、能量和水等会带来附加碳排放。在典型条件下,餐厨垃圾焚烧处理后外输电力的效率仅14%,即76 kWh·t−1,对应碳减排量为67 kg·t−1;扣除收运过程、自身消耗能量与材料、渗滤液处理产生的碳排放后,厨余垃圾焚烧处理的碳排放为−1.2 kg·t−1,碳减排效应可忽略不计。如通过热电联产提高热效率至60%,则厨余垃圾焚烧处理的碳排放为−148 kg·t−1,具有显著的碳减排效应。

厨余垃圾厌氧消化时,参考2.1节的典型值,系统总的外输电力为218 kWh·t−1,生物柴油产量为20 kg·t−1,前者通过替代效应实现碳减排192 kg·t−1,后者实现碳减排62 kg·t−1。上述效应加和,同时考虑收运过程碳排放、系统附加碳排放和泄漏引起的碳排放,系统总的碳排放为−104 kg·t−1。当厨余垃圾有机质降解率为60%~90%、综合热效率为30%~40%、CH4泄漏率为0.5%~5%时,系统的碳排放为−65~−209 kg·t−1。

与焚烧和厌氧消化相比,好氧堆肥不仅可以替代化肥,还可以通过有机碳腐殖化实现固碳,总的碳减排效应为105 kg·t−1。然而,好氧堆肥过程中温室气体泄漏较多,叠加收运过程的碳排放,厨余垃圾好氧堆肥的净碳排放为165 kg·t−1,文献[49]也报道了类似结果。当有机质降解率为65%~75%、CH4泄漏率为碳含量的1%~5%、N2O泄漏率为氮的0.5%~5%时,系统的碳排放为10~420 kg·t−1。相对于集中式堆肥,分散式的厨余垃圾处理机电耗较高,有的可达到200 kWh·t−1[33],但分散式处理可以减少收运过程的碳排放,而且处理机通过充分搅动可以减少温室气体的生成和泄露,因此分散式好氧堆肥的碳排放相对较低。需要注意的是,处理机应保证足够的堆肥时间,以满足有机质充分降解和腐殖化的要求,否则不稳定的堆肥产物在施用过程中不仅无法作为肥料,还会导致显著的温室气体排放。

厨余垃圾干热处理加工饲料时,碳排放主要来自于加热能耗,不同能源的碳排放差异较大。当采用天然气供热,饲料产率为80%~95%时,系统的碳排放为−67~−112 kg·t−1,具有显著的碳减排效应。如果采用电加热,则碳排放将大幅增加;反之,如果可以利用余热加工厨余垃圾,或者利用相对干燥的食品废弃物作为原料,则可以进一步减少碳排放。

根据上述分析,不同厨余垃圾处理模式的碳排放如图3所示。在厨余垃圾处理过程中,附加碳排放一般不到50 kg·t−1,收运过程的碳排放也相对较小,因此系统热效率、有机质降解率和温室气体泄漏率是影响不同处理模式碳排放的主要因素。饲料化和厌氧消化具有最好的碳减排效应,而混合焚烧的碳减排效应可忽略不计。好氧堆肥受到温室气体泄漏的影响,会产生较多的碳排放,当堆肥工艺运行良好,无CH4和N2O排放时,好氧堆肥可产生碳减排效应。

-

1)投放费用。根据深圳市主管部门提供的数据,深圳市建设了集中投放点16 000个,每个投放点(含垃圾桶、地基、洗手池、雨棚围挡、宣传栏等)建设费用为3.7×104元,平均垃圾投放量1.25 t·d−1。这样,按5 a折旧,垃圾投放点建设引起的垃圾投放费用为16元·t−1。同时,参考《深圳市环卫工程消耗量定额》[50],每个投放点物业清扫保洁服务费用平均为10 106元·a−1,即22元·t−1。当厨余垃圾分类量较大时,无论是分类还是混合投放,垃圾总量和垃圾桶总数不变,因此投放费用均为38元·t−1。为了保证垃圾分类效果,深圳市每个投放点设督导员1名,人工费为60元·d−1,则督导费用为48元·t−1;根据北京市西城区某街道垃圾分类全覆盖服务项目中标公告,每月每户督导费用为5.7~6.9元,按每户6.3元、每户3.5人和人均垃圾产生量1.2 kg·d−1计,督导费用为49元·t−1,与深圳市结果相近。因此,分类投放的总费用为86元·t−1。

2)收运费用。深圳市大多数转运站规模为20 t·d−1,物业单位收集垃圾运至转运站,经压缩后采用勾臂式自卸车转运,参考《深圳市环卫工程消耗量定额》[50],综合收运费用为233元·t−1。对于分类后的厨余垃圾,由特定企业根据收运合同进行收运,餐厨垃圾的收运费用为180元·t−1,而家庭厨余垃圾的直运费用为299元·t−1,考虑餐厨垃圾产量约为家庭厨余垃圾产量的1/4,则厨余垃圾的收运费用按275元·t−1计。上海的收运费用约为290元·t−1[51],而杭州农村地区的平均收运费用为284元·t−1[52],均与深圳接近。

3)处理费用。不同城市给不同处理设施的补贴标准不同。深圳市生活垃圾混合焚烧补贴(含垃圾处理费和发电补贴)平均为280元·t−1,与上海市补贴费用类似[51],但一些三四线城市的补贴较低。深圳市厨余垃圾处理补贴(包括厌氧消化、好氧堆肥等)均为284元·t−1,而上海为270元·t−1[51]。根据各地招标文件和定价通知,杭州市厨余垃圾处理补贴为207元·t−1,太原为220元·t−1,北京丰台项目为308元·t−1(含收运)。本文按284元·t−1计算,但需要强调的是,企业的实际运行费用会不同程度地低于该值。

4)宣教监管费用。为推动垃圾分类,各级政府广泛开展宣传、教育、培训和激励工作,不同地区的投入差别较大。以深圳市为例,宣教费用约25元·t−1,分类监管费用约6元·t−1,处理监管费用约1元·t−1,合计32元·t−1。当采用混合收运模式时,仅有处理过程的监管费用,即1元·t−1。

不同厨余垃圾处理模式的政府支出汇总如图4所示。可以看出,混合焚烧的全周期费用最低,而分类处理的全周期费用高出125元·t−1。这主要是由于垃圾分类增加了前端投放督导和宣教监管费用,此外收运费用也略高于混合焚烧。除上述费用外,垃圾收运处理设施也会占用一定的土地,由于占地面积和工艺路线、设计方案有关,同时土地费用差别很大,这里不计入比较。

-

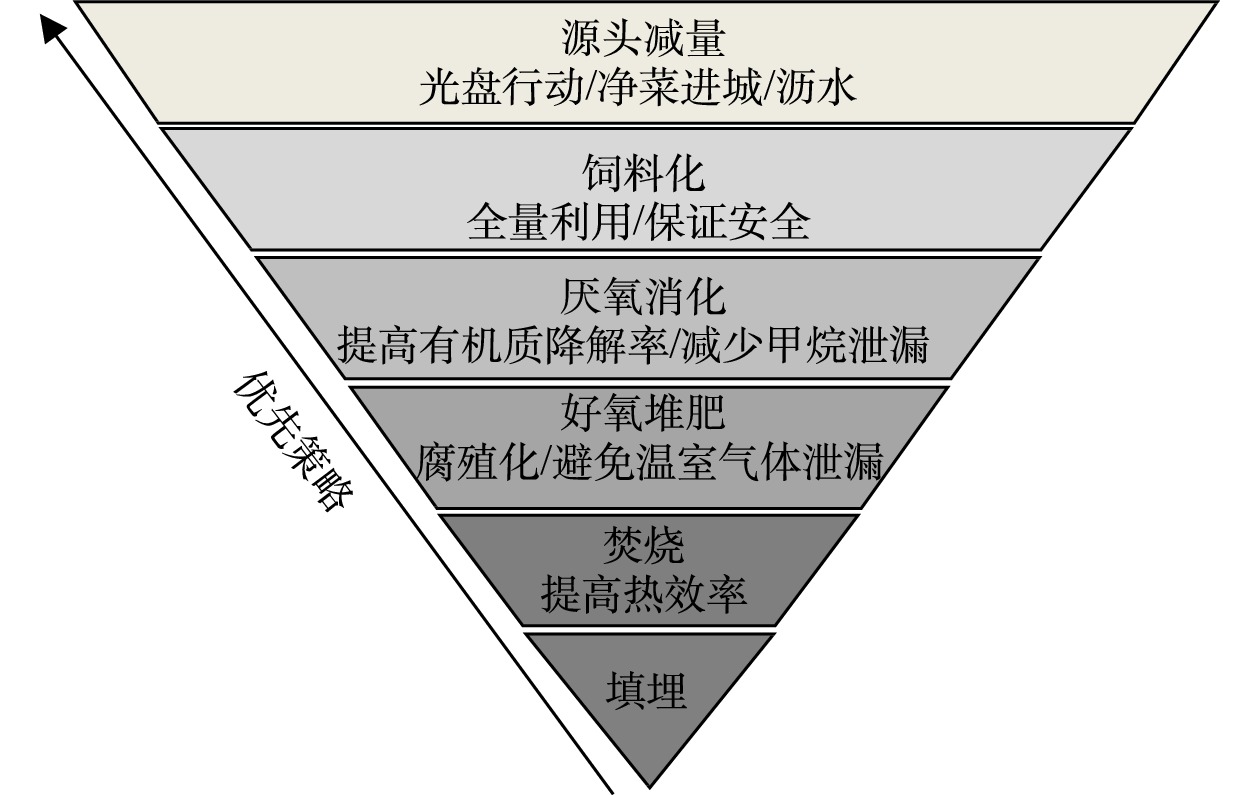

根据前述分析,虽然分类收集处理的全周期费用较高,但这些费用主要来自于垃圾分类工作开始阶段的宣教、监管支出,一旦分类体系成熟,这部分费用可以降低乃至取消;另一方面,厨余垃圾分类具有显著的环境效益,因此厨余垃圾适宜分类处理。在分类体系下,源头减量如光盘行动、源头沥水等措施不需要额外的费用、能耗和材料,也可以显著提升整个系统的表现[6],因此是最优策略。对于产出的厨余垃圾,在各类处理模式中,饲料化的回收利用率最高且碳减排效应显著。厌氧消化具有较高的回收利用率和最大的碳减排效应,但厌氧消化设施应稳定运行,以保证较高的有机质降解率,否则系统表现会显著下降。好氧堆肥的回收利用率与厌氧消化相当,但在无法确保充分好氧的条件下,会形成CH4和N2O排放,造成较高的碳排放。相对而言,混合焚烧比好氧堆肥更易控制,可以避免温室气体泄漏。虽然垃圾焚烧余热发电的回收利用率较差,但如果采用热电联产,则可以实现更多的碳减排。对于厨余垃圾厌氧消化和其他垃圾焚烧构成的综合处理体系,厨余垃圾分出可以提高其他垃圾的焚烧效率。这符合高含水率、低热值垃圾进行厌氧消化,而低含水率、高热值垃圾进行焚烧处理的理想情形。厨余垃圾分类率每提高20%,生活垃圾全系统的碳减排量可以增加5%~7%[6]。因此,当新建焚烧设施时,应充分考虑厨余垃圾分出后其他垃圾水分减少、热值上升的情况;而对于已有的焚烧设施,为了保证进炉垃圾热值处于最优范围,进炉垃圾中厨余垃圾含量在30%左右为宜[53]。这样,厨余垃圾的管理策略如图5所示。

2.1. 回收利用率分析

2.2. 碳排放分析

2.3. 费用分析

2.4. 综合比较

-

1) 厨余垃圾饲料化具有最高的回收利用率和显著的碳减排效应;厌氧消化回收利用率较高,碳减排效应最大;好氧堆肥的回收利用率与厌氧消化相当,但温室气体泄露会导致较高的碳排放;混合焚烧可以避免温室气体泄漏,但余热发电的回收利用率较低,基本无碳减排效应。

2)相对于混合收运处理,分类收运处理的全周期费用较高,但增量主要来自于前期督导和监管的费用,一旦分类体系成熟,这部分费用可以降低乃至取消。

3)厨余垃圾管理的优先策略依次为:源头减量>饲料化>厌氧消化>好氧堆肥>混合焚烧。

下载:

下载: