-

NOx是造成城市灰霾天气、光化学烟雾、大气酸沉降等一系列环境问题的根源之一[1]。SCR技术是工业上应用最为广泛的烟气脱硝技术[2]。低温SCR装置可置于除尘或脱硫装置之后而不加热烟气,使脱硝系统具有较低能耗且易于改装到锅炉烟气净化系统中[3]。另外,由于非电力行业工业窑炉排烟温度低,难以直接使用电力行业成熟的高温SCR脱硝工艺控制NOx的排放,而选择性非催化还原(selective non-catalytic reduction ,SNCR)氮氧化物净化效率较低,难以满足排放标准。因此,低温SCR脱硝技术将成为该领域主要脱硝工艺[4]。催化剂是制约低温SCR脱硝技术发展的核心问题,其活性直接影响SCR系统的整体效果[5]。锰铈系催化剂表现出Mn、Ce两种金属的性质,具有良好的低温SCR脱硝活性[6-7],是低温SCR催化剂领域热点,如催Mn-Ce/ASC[8]、Mn-Ce/ATP[9]、MnOx-CeO2 -Al2O3[10]和Ce-Mn/TiO2[11]等。

不同制备方法对催化剂的物理性质和化学性质均有不同影响。贺丽芳等[12]采用浸渍法、氨水共沉淀法和机械混合法制备了Mn-Ce/ZSM-5催化剂,并测试其脱硝性能。结果表明,采用氨水共沉淀法制备的Mn-Ce/ZSM-5催化剂显示出优越的SCR催化活性,不仅低温催化活性好、反应温度窗口宽,且热稳定性好。廖伟平等[13]采用浸渍法、沉淀沉积法及新型共沉淀法制得Mn-Ce/TiO2脱硝催化剂。结果表明,新型共沉淀法制备的Mn-Ce/TiO2催化剂有更高的低温活性。因此,催化剂制备方法不仅影响催化剂性能,且影响催化剂成本。

基于此,拟采用常用的3种催化剂制备方法——共沉淀法、浸渍法、溶胶凝胶法来制备Mn-Ce/TiO2,对比3种方法制备出催化剂的结构特点和活性,并分析制备过程和成本,以对比出催化剂的最佳制备方法,以期为锰基低温脱硝催化剂的制备提供参考。

-

1)共沉淀法。将一定质量的TiOSO4·XH2SO4·8H2O完全溶解于水中,在60 ℃下水浴加热,然后加入一定比例的Mn(NO3)2和Ce(NO3)3·6H2O,搅拌0.5 h,混合均匀。将NH4OH缓慢滴加到上述溶液中,至pH=9~10为止。搅拌2 h、老化3 h,过滤收集沉淀物,并用去离子水洗涤至中性,在105 ℃烘箱中干燥12 h,在马沸炉中500 ℃下焙烧3 h后,研磨、筛分。选择40~60目颗粒备用,记作Mn-Ce/TiO2(C)。

2)浸渍法。将一定比例的Mn(NO3)2和Ce(NO3)3·6H2O溶于去离子水中,取一定质量钛白粉置于活性组分溶液中,搅拌均匀,浸渍12 h,然后放入烘箱内在105 ℃干燥12 h,置于马弗炉中500 ℃下焙烧3 h后,研磨、筛分。选择40~60目颗粒备用,记作Mn-Ce/TiO2(I)。

3)溶胶凝胶法。A液的配制:取适量的钛酸丁酯与一定比例的无水乙醇混合,加入适量冰乙酸抑制钛酸丁酯水解,待溶液充分混合后加入适量CTAB。B液的配制:取适量六水合硝酸铈晶体溶于适量的蒸馏水及相应比例的无水乙醇中,按一定比例加入适量50%硝酸锰溶液,并调节pH至1~2。催化剂的制备:将B液倒入酸式滴定管,匀速滴加到A液中,滴定过程中将A液置于磁力搅拌器上持续搅拌,滴定完成后放置一定时间老化后形成凝胶,然后将其放置于烘箱内在105 ℃下干燥12 h,最后放置马弗炉中于500 ℃下煅烧5 h,研磨、筛分,选择40~60目颗粒备用,记作Mn-Ce/TiO2(S)。

-

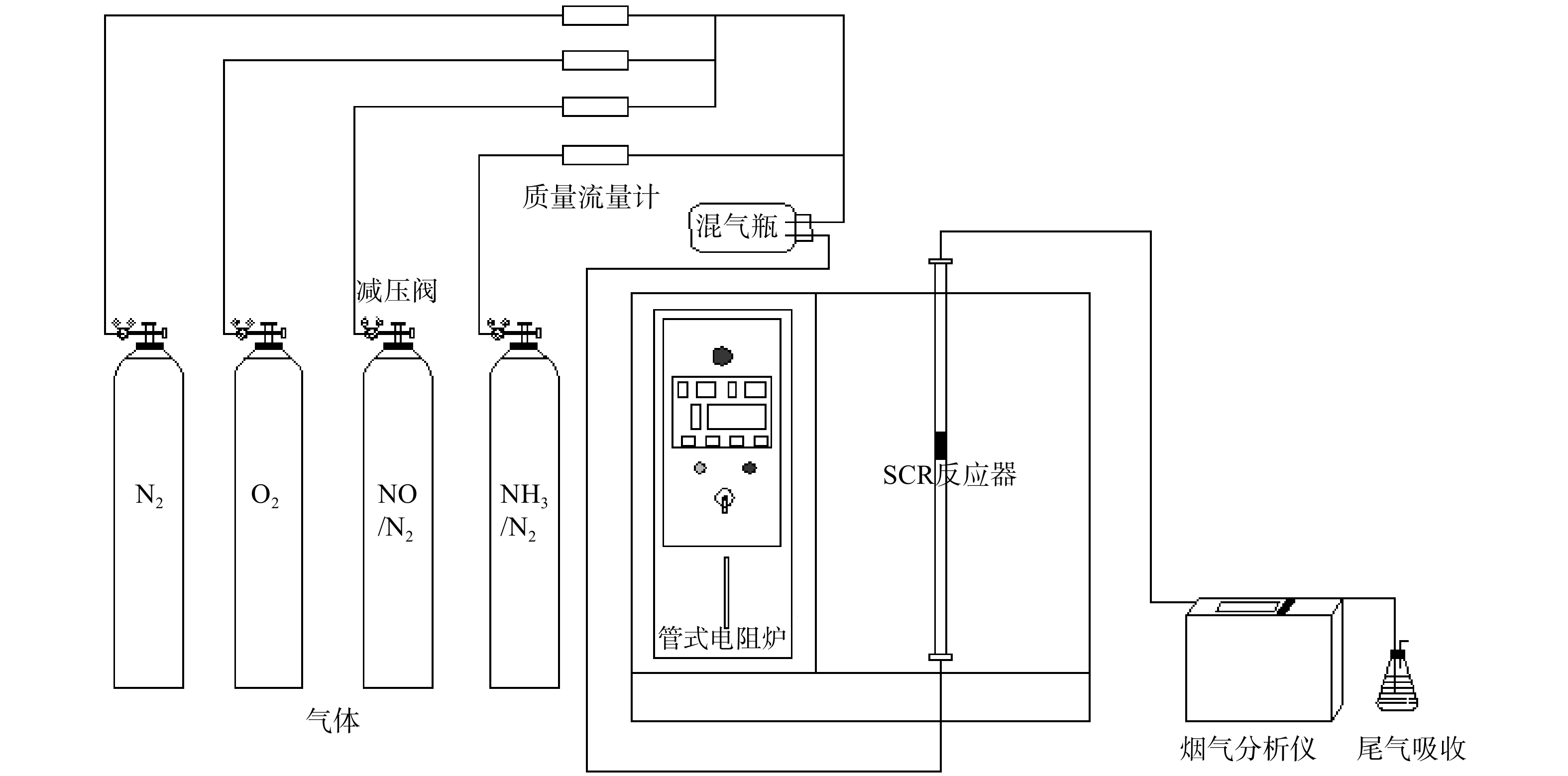

催化剂的SCR活性评价在固定床反应器中进行(图1),空速(GHSV)20 000 h−1,气体流量1 000 mL·min−1。其中NO体积分数为600×10−6,NH3体积分数为600×10−6,[NH3]/[NO]为1,O2为5%,N2作为平衡气。通过德国MGA5 VARIO PLUS烟气分析仪持续监测NO、NO2的浓度。 NOx转化率、N2选择性和N2O生成率分别通过(1)、(2)和(3)式计算得到。

NOx转化率、N2选择性和N2O生成率分别通过(1)、(2)和(3)式计算得到。

-

催化剂样品表面形貌采用日本日立S-570型电子扫描电镜进行分析。首先对样品进行喷金,工作电流10 mA,时间100 s。SEM表征实验时,扫描电镜选用SEI模式,加速电压15 kV。催化剂进BET表征采用北京金埃谱V-SorbX800型比表面积仪测定。先取一定质量的样品,在120 ℃下预处理2 h,再进行测试。

样品的晶型结构采用日本理学UltimanIV型X-射线衍射仪对催化剂进行测定。测试条件为:聚焦光Kα射线与Cu靶,角速度4°·min−1,步长0.02,扫描角5~90°,操作电流40 mA,电压40 V,功率为1.6 kW。

样品官能团采用Nicolet iS50傅立叶变换红外光谱仪(FT-IR) 进行分析。首先将催化剂与适量KBr混合研磨,压片后测定。测定条件:扫描范围4 000~400 cm−1,以分辨率4 cm−1,扫描64次。

采用ChemSorb 2 720对样品进行程序升温还原及程序升温脱附。H2-TPR实验时,首先进行预处理:样品质量100 mg、温度为300 ℃、He气氛围下预处理时间30 min。然后冷却至室温并通入H2-He,待基线稳定后,以10℃·min−1的速率升温至900 ℃。NH3-TPD实验时,对样品进行预处理后,通入吸附气NH3 30 min,并用He气吹扫至基线稳定后,以10℃·min−1的速率升温至1 000 ℃。

-

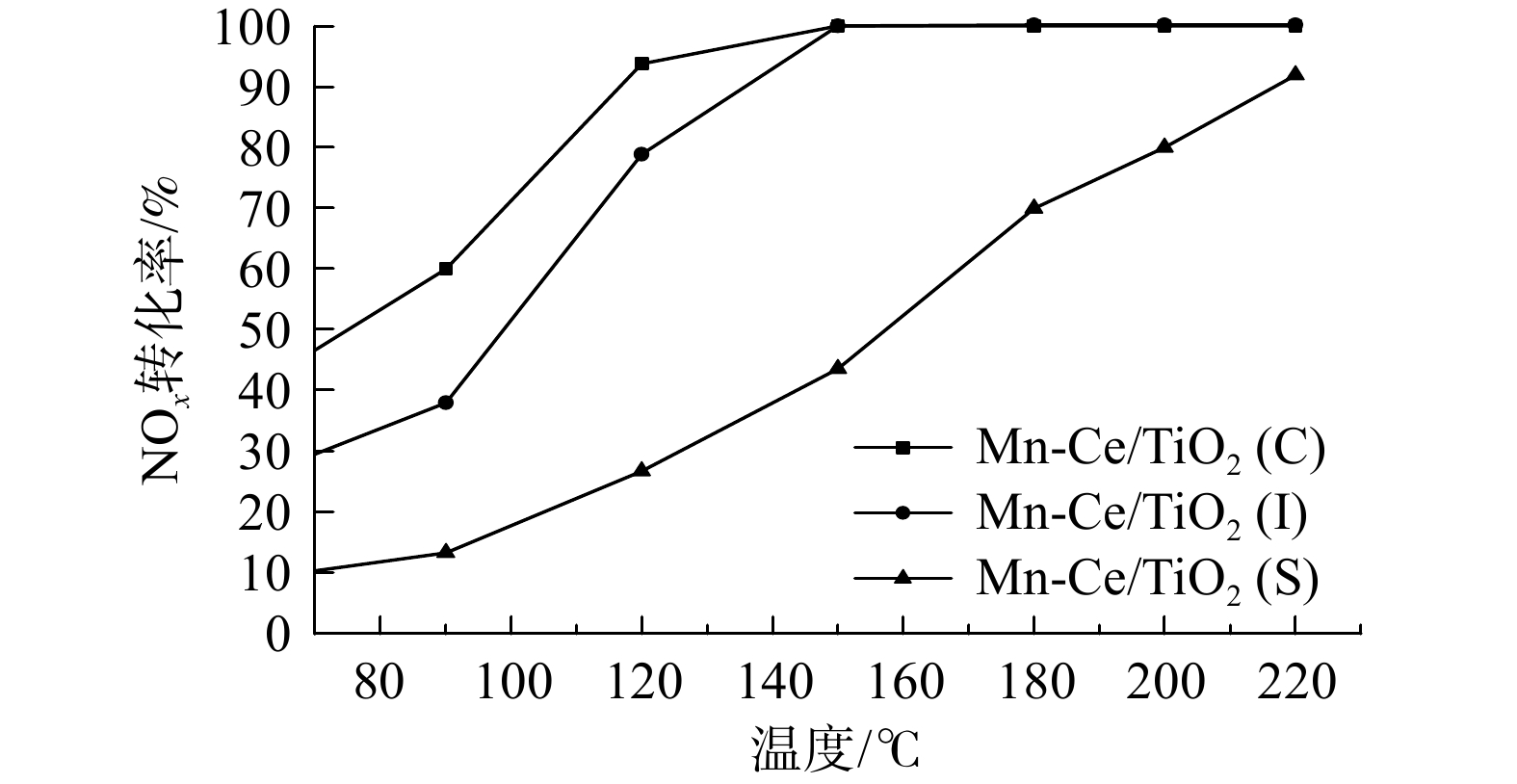

图2是不同制备方法的催化剂90~220℃时NO转化率的变化。催化剂的低温SCR活性顺序依次为:共沉淀法>浸渍法>溶胶凝胶法。其中,共沉淀法制备的催化剂脱硝效果最好,在120℃时共沉淀法制备的催化剂的NO转化率达到90%,浸渍法制备的催化剂的NO转化率约为75%,溶胶凝胶法制备的催化剂NO转化率仅为约25%;温度升至150℃以上时,共沉淀法和浸渍法制备的催化剂NO转化率都保持在100%,而溶胶凝胶法制备的催化剂转化率不到50%,在温度继续升高到200℃时,NO转化率才达到90%。这说明3种催化剂的制备方法中,共沉淀法与浸渍法制备的催化剂都有着良好的低温SCR性能。

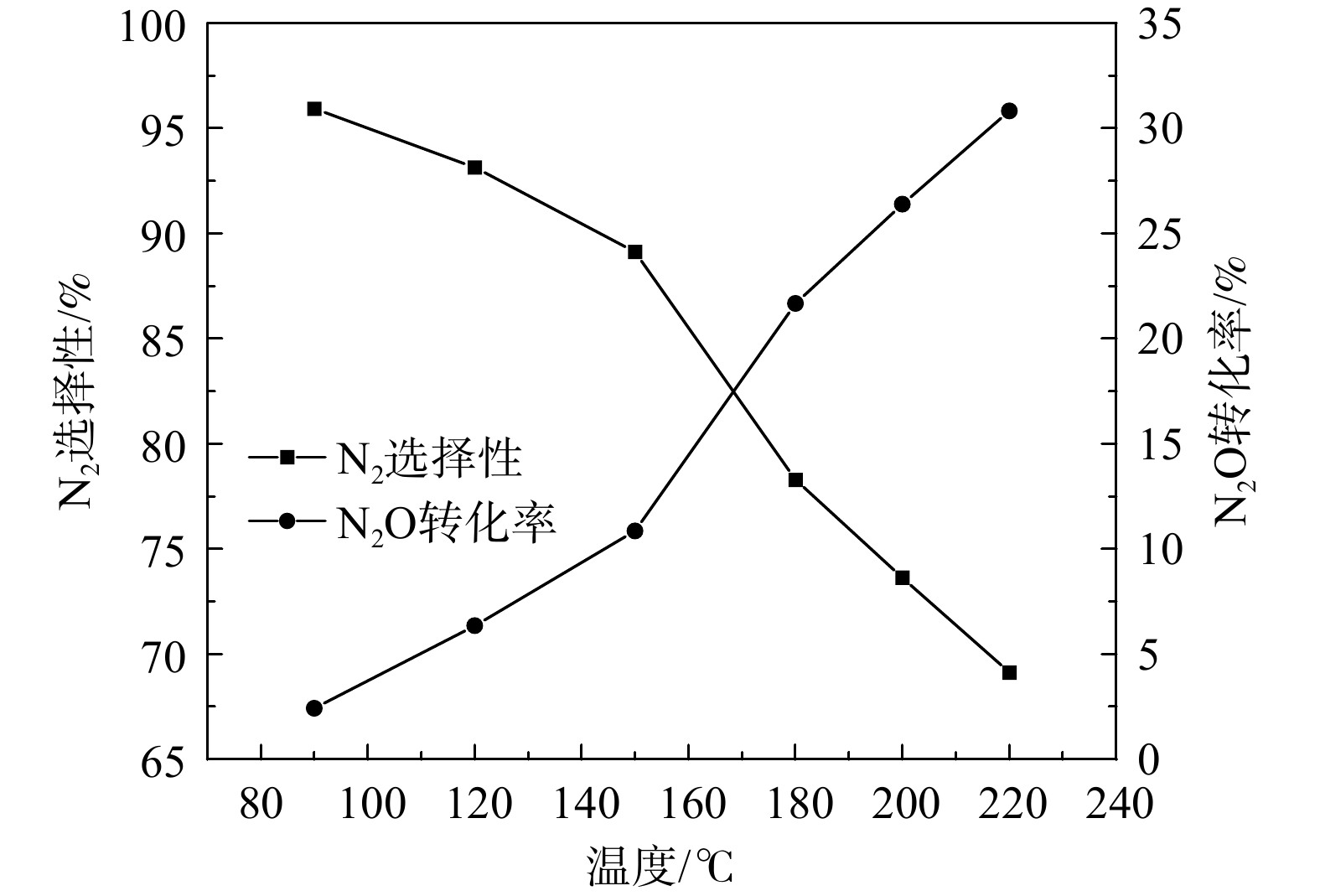

图3为Mn-Ce/TiO2催化剂低温环境下温度对N2选择性和副产物N2O的生成率的影响。在90~220℃时,随温度增加Mn-Ce/TiO2催化剂的N2选择性逐渐下降,而副产物N2O随温度增加生成量增加。反应温度为150℃时,NO转化率为100%,N2选择性大于90%,副产物N2O的生成率小于10%。

-

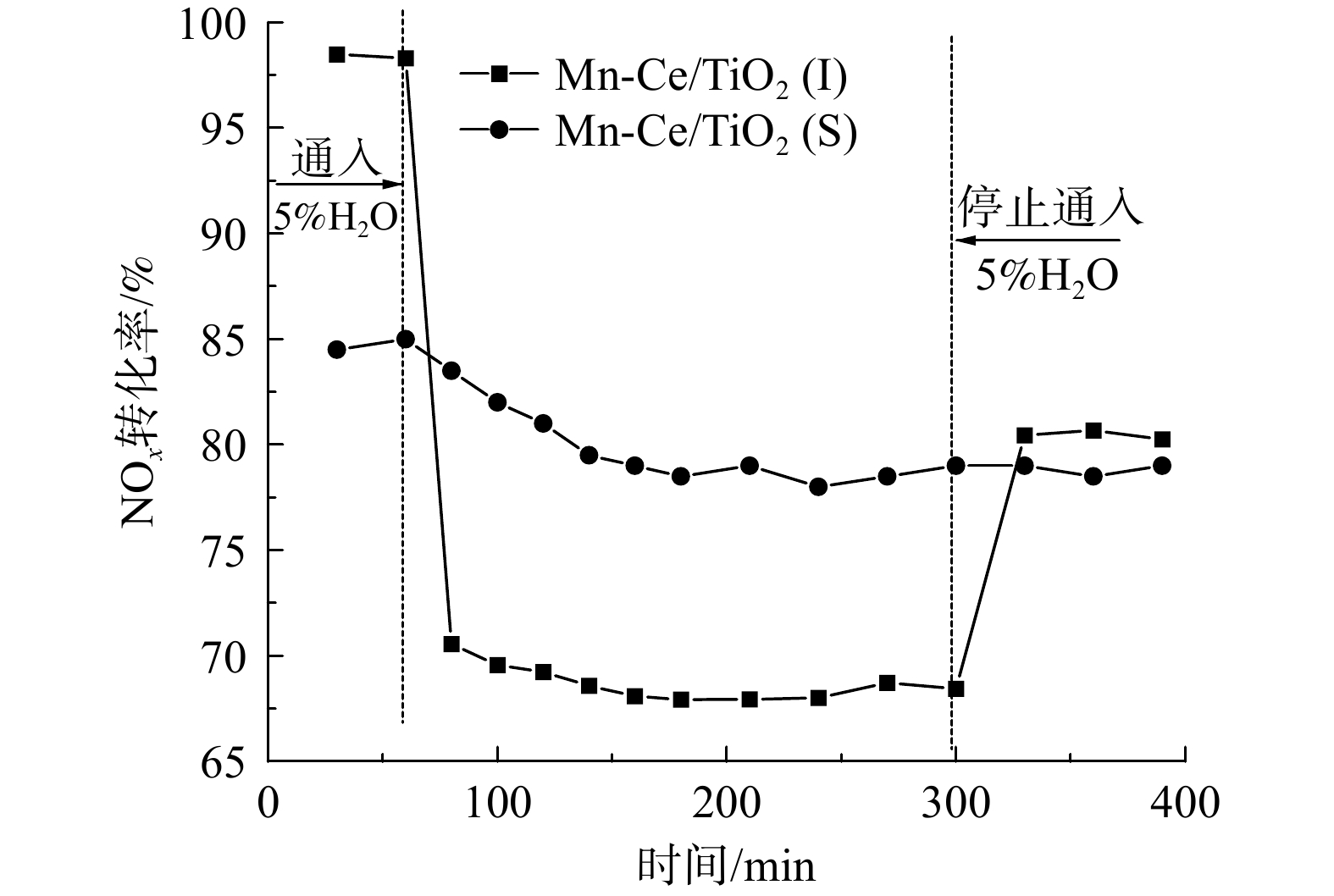

水蒸气是烟气中的固有成分之一,一般烟气中水含量为5%~20%。在反应条件为NH3、NO的体积分数为0.06%、O2体积分数为5%、GHSV为20 000 h−1、平衡气为N2、反应温度150℃时,通入5%水蒸气观察水对不同制备方法下Mn-Ce/TiO2催化剂脱硝效率的影响,结果如图4所示。结果表明水对催化剂活性表现出一定抑制作用。

在150℃下通入5%水后,浸渍法制备Mn-Ce/TiO2的NOx去除率降至约68%,停止通入水后活性恢复到80%,表明催化剂对水有一定的抗中毒能力。溶胶凝胶法制备Mn-Ce/TiO2的NOx去除率基本维持在约85%,但当通入H2O后,催化剂的NOx去除率便有所下降,并最终稳定在约80%。当停止通入H2O后,催化剂活性基本可以恢复到H2O通入前的水平。这表明H2O引起的催化剂失活是可逆的。H2O对催化剂的抑制作用,可能主要是由于在催化剂表面H2O与弱吸附态的NO产生了竞争吸附,并使得H2O最终占据了NO的弱吸附位,使NO在催化剂活性位点上的吸附减少,进而使催化剂脱硝活性得到抑制[14]。另外,H2O本身即为SCR催化还原反应产物之一,H2O的存在自然不利于SCR催化还原反应向NOx去除方向(即H2O生成方向)进行。当反应温度为150℃时,停止通入H2O,吸附在催化剂上的H2O很快就因蒸发而除去, H2O对催化剂活性产生的抑制作用便得到解除。

-

研究当温度为150℃、SO2为0.08%时,不同制备方法下Mn-Ce/TiO2的抗硫性能,结果见图5。实验1 h后,向反应环境中通入0.08%SO2,2种不同催化剂的活性均迅速下降,但反应一段时间后达到稳定。浸渍法制备Mn-Ce/TiO2去除率从98%降至63%;SO2使催化剂失活的主要原因可能是由于SO2和氨气反应生成硫酸盐遮挡催化剂的活性位,使催化剂表面变得粗糙,阻碍NH3与NOx反应从而使得脱硝效率降低。而且,通入SO2会使催化剂在低温下的氧化还原性变差,这也是其活性变差的原因之一。

向溶胶凝胶法制备催化剂通入SO2后,该催化剂活性显著降低,NOx去除率由约85%降至约42%。而且,在停止通入SO2后,经过一段时间,催化剂脱硝活性仍不能自行恢复。这说明在此反应条件下,SO2对催化剂的毒化作用明显,并且引起的催化剂失活不可自行恢复。

-

1) BET表征。表1为3种不同方法制备催化剂的比表面积、孔容及平均孔径。共沉淀法制备的催化剂比表面积最大,为80.12m2·g−1,依次是溶胶凝胶法和浸渍法,分别为77.68和73.95m2·g−1。对比催化剂的活性顺序:共沉淀法>浸渍法>溶胶凝胶法,这与活性顺序基本一致。在通常情况下,当催化剂表面活性组分分布均匀时,催化剂的比表面积越大,其活性越高。溶胶凝胶法比表面积大于浸渍法,活性却比浸渍法差,可能是由于其表面活性组分分布较为不均匀,这点可从SEM表征分析中观察到。同时,这也说明BET比表面积不是催化剂高SCR活性的决定性因素[15]。另外,从催化剂样品的平均孔径数据可见,共沉淀法和浸渍法制备的催化剂平均孔径较小,催化剂内部含有的中孔较多,这更有利于气体在催化剂表面的传质。

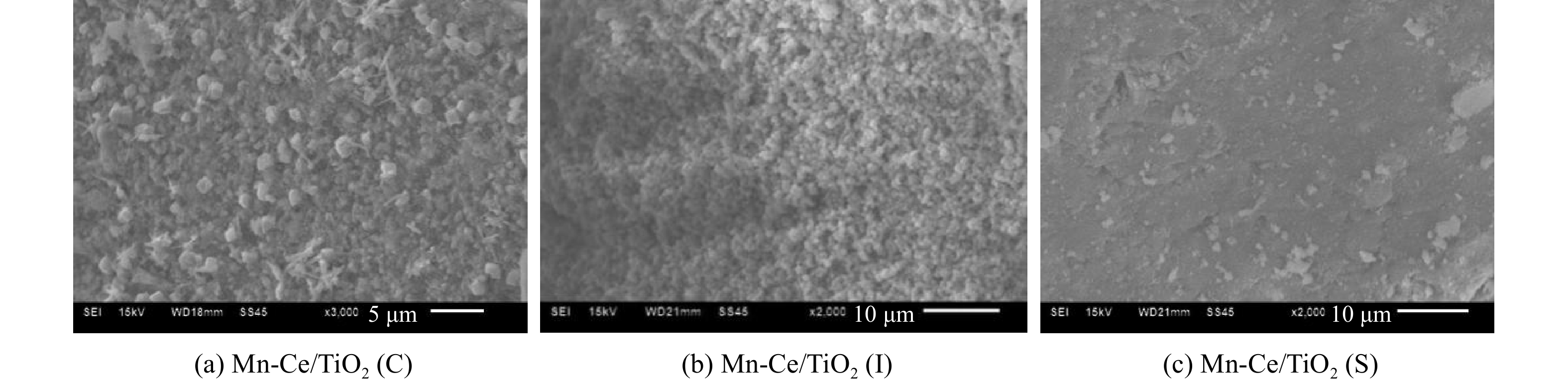

2) SEM分析。通过扫描电镜可得到催化剂样品的表面形貌特征,图6是3种催化剂样品的SEM图。共沉淀法制备催化剂样品的表面平整光滑,无烧结团聚现象;浸渍法制备的催化剂样品,活性组分在催化剂表面分散均匀,呈现球状分布;溶胶凝胶法制备的催化剂表面活性组分分布不均匀,局部有团聚现象,这会影响催化剂的脱硝性能。因此,共沉淀法及浸渍法制得催化剂的脱硝效果优于溶胶凝胶法制得的催化剂。

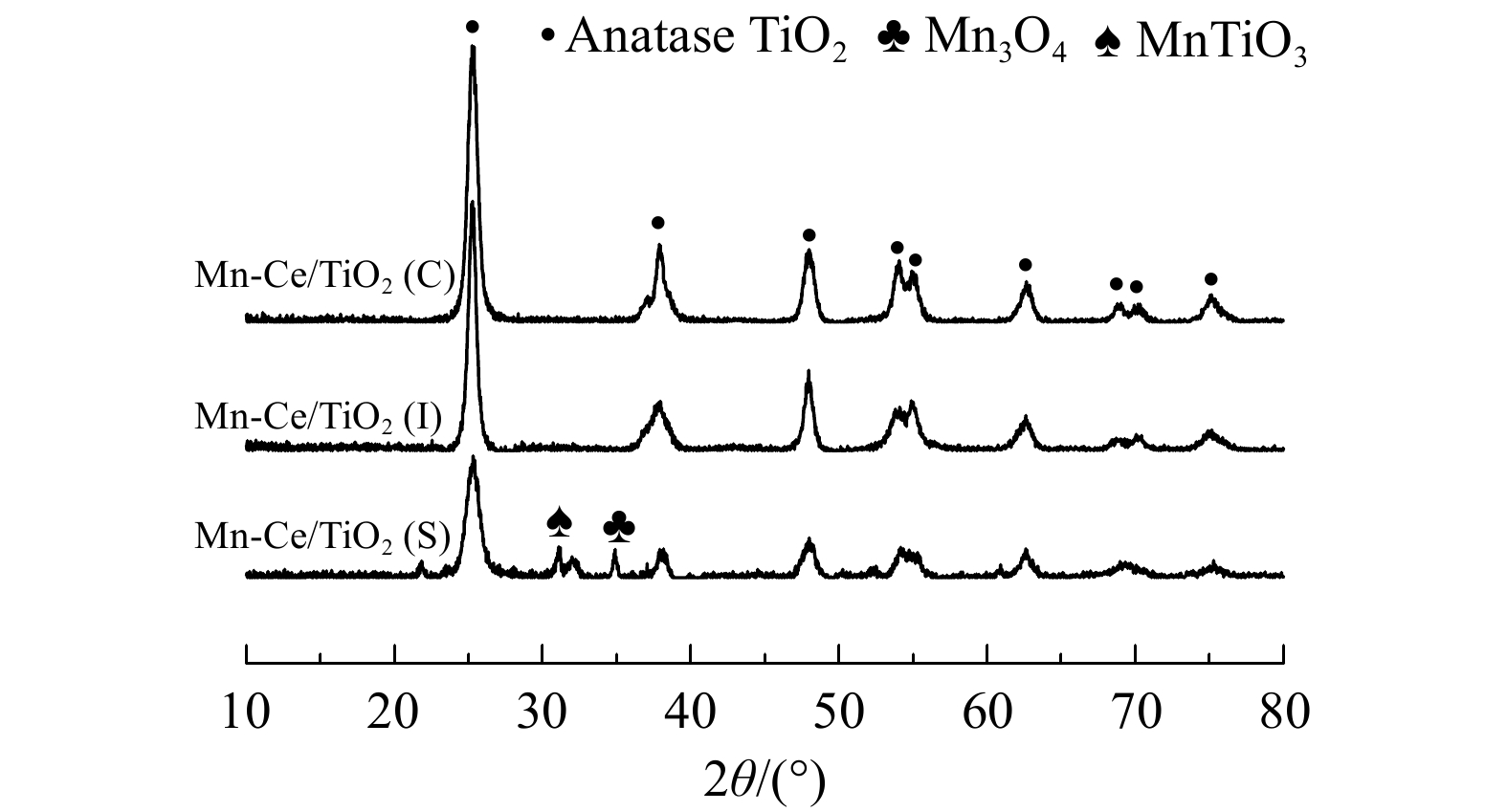

3) XRD分析。为研究不同方法制备Mn-Ce/TiO2催化剂的晶型结构,对样品进行了XRD表征,表征结果见图7。3种催化剂对应的XRD衍射图谱上均未见金红石TiO2的相关特征峰。另外,观察催化剂表面的活性物质形态,在共沉淀法和浸渍法制备催化剂表面没有观察到锰氧化物衍射峰。其原因可能是,Mn在载体TiO2分散度高或以无定型形态分布。在溶胶凝胶法制备催化剂表面观察到Mn3O4和MnTiO3的衍射峰,这说明活性物质Mn在载体上以晶体结构分布。MnTiO3的出现表明Mn与Ti的相互作用较差[16],因此,其脱硝效果比其他2种方法制得催化剂差。

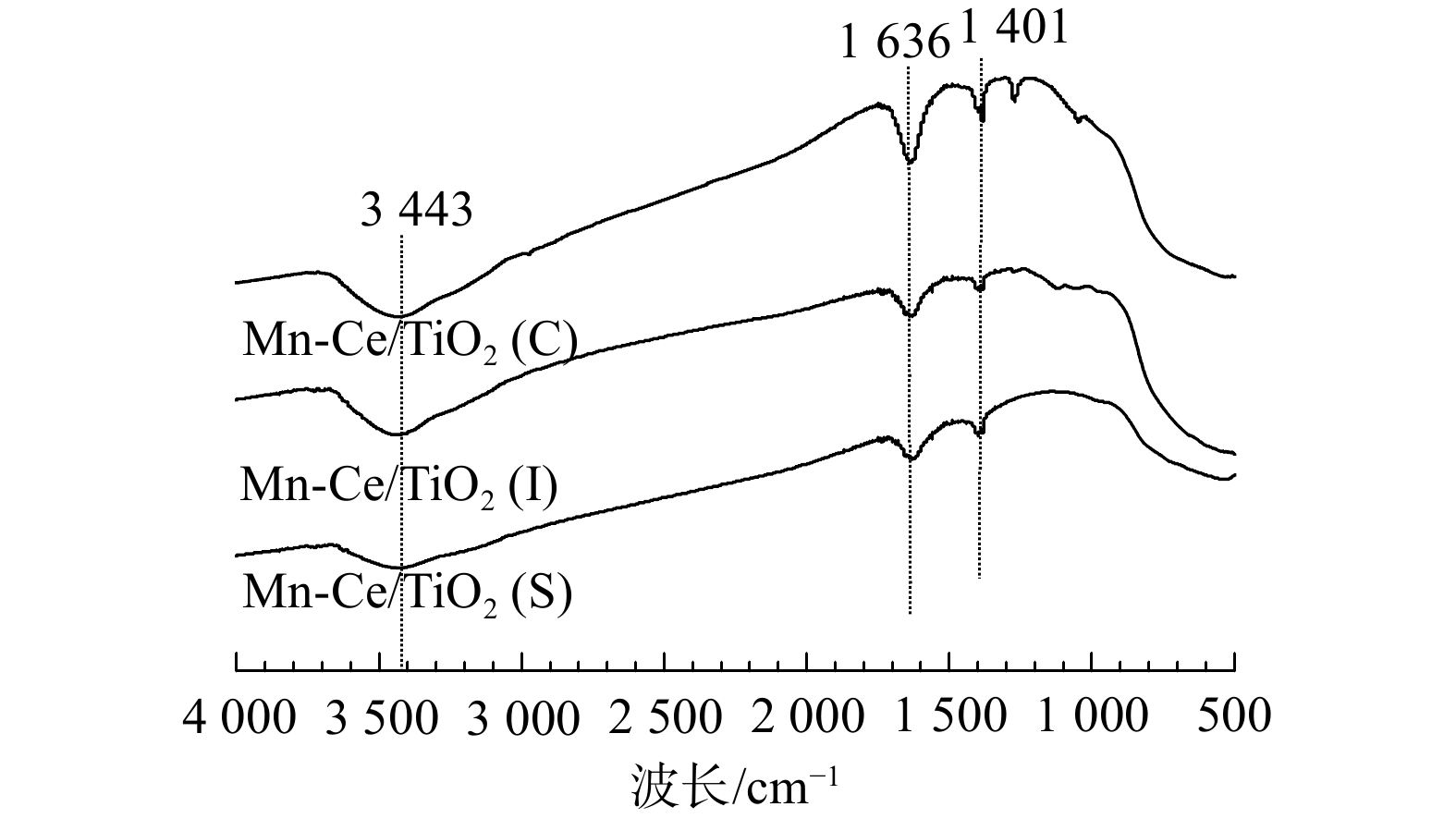

4) FT-IR。催化剂样品的FT-IR谱图见图8。3组样品在3 443cm−1、1 636cm−1和1 401cm−1三处均出现了特征峰。3 443cm−1 和1 636cm−1 两处出现的特征峰分别对应H2O中的H—O的弯曲振动峰与伸缩振动峰[17]。波长1 401cm−1处出现的特征峰为NH4+的弯曲振动峰,其生成应该来自于SCR反应过程中吸附于催化剂表面酸性位上的反应气体NH3[18]。共沉淀法制备的催化剂特征峰最强,这也与催化剂的活性顺序一致。FT-IR表征分析说明活催化剂的制备方法对催化剂的官能团特征峰的强度有影响,但是对催化剂特征峰的种类没有影响。

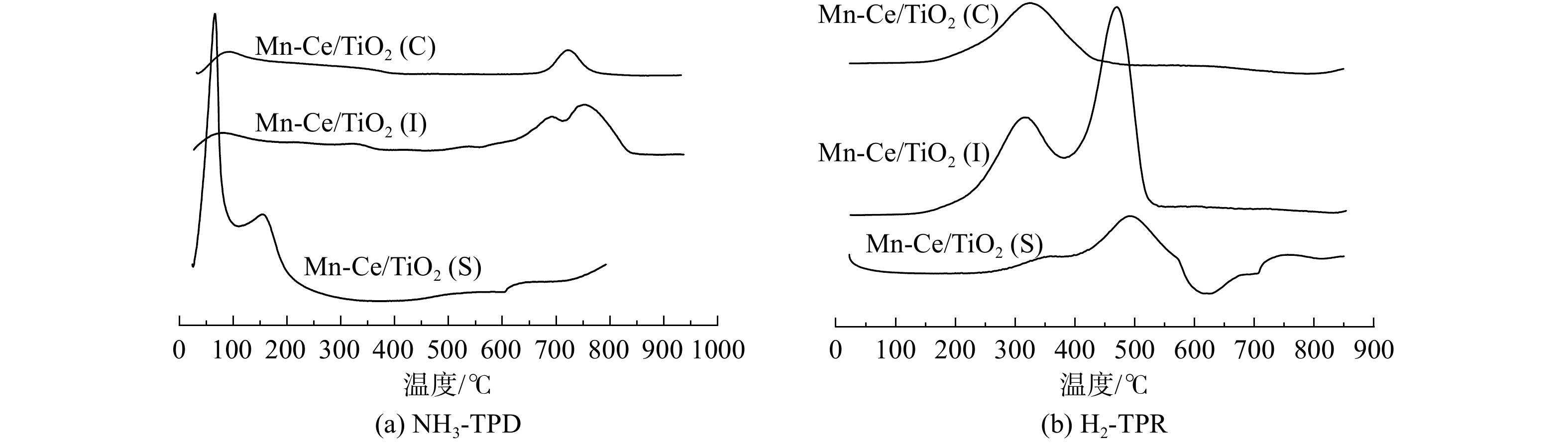

5) NH3-TPD和H2-TPR分析。为进一步研究制备方法对催化剂的氧化还原能力和酸性位点的影响,对催化剂样品进行了NH3-TPD和H2-TPR表征分析。由图9(a)可见,溶胶凝胶法在100~300℃有2个明显的NH3的脱附峰。此温度段的峰属于催化剂表面弱酸性位对NH3吸附产生的脱附峰。观察共沉淀法和浸渍法制备催化剂,其样品在约730℃出现了脱附峰,对应的是催化剂强化学吸附的NH3分解而成的N2脱附峰[19],属于催化剂表面的强酸性位。通常,催化剂表面酸性位点的强弱对催化剂氧化还原能力有较大影响,3种催化剂的NH3-TPD分析结果也与其脱硝效率一致。

图9(b)是催化剂H2-TPR图谱。对于不同方法制备的Mn-Ce/TiO2,在温度为200~600℃时有2个重叠的氧化还原峰[20],较低温度处的还原峰是锰氧化物的还原峰,主要来自于为MnO2和Mn2O3向Mn3O4的转变或Mn3O4向MnO转变[21],较高温度处的还原峰为铈氧化物的还原峰,为CeO2向Ce2O3的转化[22]。共沉淀法制备催化剂表面的氧化还原峰,属于锰氧化物还原峰;浸渍法制备催化剂表面有2种还原峰;而溶胶凝胶法制备催化剂表面仅观察到铈氧化物的还原峰。对比共沉淀法和浸渍法,明显看出溶胶凝胶法制备催化剂的锰氧化物还原峰对应高温较高。这是由于MnO2和Mn2O3→Mn3O4的还原[23],这说明催化剂中MnO2的量减少,从XRD分析中可看到同样结果。参考文献[24]得知,MnOx的低温SCR活性遵循以下规律MnO2>Mn2O3>Mn3O4>MnO。因此,催化剂的氧化还原能力顺序为共沉淀法>浸渍法>溶胶凝胶法。

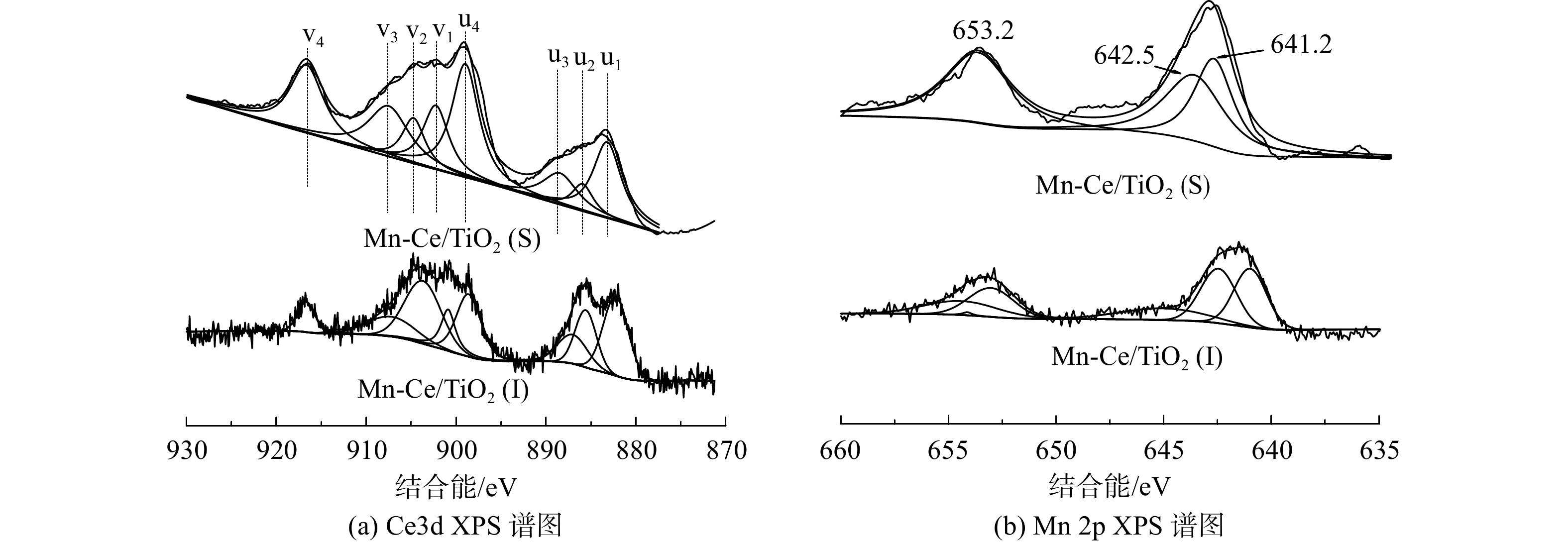

6) XPS分析。催化剂XPS表征分析结果见图10。图10(a)、(b)分别表示了Ce 3d和Mn 2p的XPS谱图。Ce 3d XPS图谱较为复杂,对其能谱峰分峰拟合后可得到Ce 3d5/2和Ce 3d5/2两类峰, u1(882.9 eV)、u2(885.6 eV)、u3(888.3 eV)和u4(898.9 eV)为Ce 3d5/2能谱峰,而v1(901.8 eV)、v2(904.6 eV)、v3(907.5 eV)和v4(916.8 eV)为Ce 3d3/2能谱峰。其中,u1、u3、u4和v1、v3、v4的能谱峰主要对应Ce4+化合物,而u2和v2的能谱峰主要对应Ce3+化合物[25]。因此,CeOx主要以CeO2和Ce2O3的氧化态存在。估算得到催化剂CeO2峰面积所占比例约为88.4%,说明在CeOx中CeO2占绝大部分。CeO2作为催化剂级的活性助剂,在催化过程中主要起到储存氧的作用,可加强MnO2与Mn2O3之间的转化。而两者在价态转化和电子传递过程中形成表面空穴氧,有利于配位态NH3与NO反应形成的中间产物彻底降解为无害产物[26-27]。

图10(b)为不同方法制备Mn-Ce/TiO2的Mn 2p XPS谱图。浸渍法制备的Mn-Ce/TiO2催化剂位于约653.3 eV和641.5 eV的2个主峰分别是Mn 2p1/2和Mn 2p3/2[28-29]。对Mn 2p3/2进行分峰拟合,即得到644.3 eV Mn4+,642.4 eV Mn3+,640 eV Mn2+。Mn-Ce/TiO2催化剂的Mn4+/Mn比值约为20.70%。锰铈钛催化剂中由MnOx作为活性物质,NO去除率由高到低依次为:MnO2> Mn5O8> Mn2O3> Mn3O4。因此,Mn-Ce-Sb0.2/TiO2催化剂在低温下具有更高的NOx去除率。溶胶凝胶法制备的催化剂Mn 2p XPS图谱表明Mn的2p轨道都出现了2个主要能谱峰,分别为641.5eV处的Mn 2p3/2能谱峰和653.2eV处的Mn 2p1/2能谱峰。其中,Mn 2p3/2峰为可分峰拟合为2个峰,分别是641.2~641.8 eV处Mn2O3(Mn3+)的能谱峰,以及642.0~642.6 eV处MnO2(Mn4+)的能谱峰[25]。KAPTEIJN等[27]研究了MnOx与脱硝催化剂活性关系的实验,发现Mn的价态对催化剂的活性影响较大,即主要几种MnOx活性为MnO2>Mn5O8>Mn2O3> Mn3O4。

-

1)药剂成本。3种方法制备10 g的Mn-Ce/TiO2催化剂的药剂成本依次为9.78元、2.70元和32.11元。其中,浸渍法制备催化剂使用的药剂成本最低,依次是溶胶凝胶法,共沉淀法(表2)。从3种制备方法过程使用的药剂可见,活性组分锰、铈元素的前驱体都一样,都是使用硝酸锰和硝酸铈。主要区别在于载体二氧化钛的前驱体不同,分别是酞酸丁酯,钛白粉,硫酸氧钛。这3种前驱体的单价由高到低依次是:硫酸氧钛>酞酸丁酯>钛白粉,硫酸氧钛的成本最高,因此,共沉淀法制备的催化剂药剂成本较高。另外,制备同样质量的催化剂成品,所使用的药品量不一样,也是3种方法制备催化剂成本不同的原因。

2)综合分析。浸渍法制备催化剂成本较另外2种方法明显较低.共沉淀法催化剂成本较高,溶胶凝胶法次之。另外,从制备过程可见,制备过程中的能耗:共沉淀法>溶胶凝胶法>浸渍法,制备过程时长:溶胶凝胶法>浸渍法>共沉淀法。浸渍法制备催化剂过程简单,且耗时较短。共沉淀法和溶胶凝胶法在制备催化剂原液过程中,均需关注液体状态。这2种方法不仅历时较长,且考虑到商业化生产,在生产过程中无法做到大批量快速生产。结合催化剂的脱硝性能,共沉淀法和浸渍法制备催化剂都具有优异低温SCR性能。因此,3种制备方法中,浸渍法成本最低,所制得的催化剂有着良好的SCR性能。

-

1)制备方法对催化剂有较大影响,不仅体现在对催化剂脱硝性能的影响,还影响着催化剂的物理化学性质。采用共沉淀法、浸渍法、溶胶凝胶法制备的催化剂,其SCR活性顺序为共沉淀法>浸渍法>溶胶凝胶法。其中,共沉淀法和浸渍法制备催化剂都有着优异的低温SCR性能,在温度高于150℃时,其NO转化率能达到100%。

2) BET及SEM表征表明,共沉淀法比表面积最大,且活性组分分布均匀。溶胶凝胶法虽然比表面积比浸渍法大,但其活性组分分布不均匀。溶胶凝胶法制备的催化剂表明锰氧化物以MnTiO3和Mn3O4形式存在,说明活性组分Mn与在载体Ti的相互作用较差。共沉淀法和浸渍法催化剂其氧化还原峰温度更低,因此,低温SCR活性较高。共沉淀法和浸渍法制备催化剂表面呈强酸性位,而溶胶凝胶法制备的催化剂表面仅观察到弱酸位点,所以其对NH3的吸附能力较差。

3)对3种方法进行成本分析,成本由低到高依次是浸渍法<溶胶凝胶法<共沉淀法。浸渍法制备过程历时较短,且操作简单,制备同样质量的催化剂所消耗的药剂最少,是一种较为经济的制备方法。

3种制备方法对Mn-Ce/TiO2催化剂的性能影响及成本分析

Performance comparison and cost analysis of Mn-Ce/TiO2 catalyst made by different preparation methods

-

摘要: 制备方法对催化剂的性能和成本有重要影响。选择共沉淀法、浸渍法和溶胶凝胶法制备Mn-Ce/TiO2催化剂,在90~220 ℃对比测试不同方法制得催化剂样品的低温SCR性能,利用BET、SEM、XRD、FT-IR、H2-TPR和NH3-TPD分析样品的物理化学性质,并对3种方法的实验室制备过程进行成本分析。结果表明:共沉淀法和浸渍法制备的催化剂低温SCR性能均较好,在反应温度为150 ℃的条件下,催化剂的脱硝效率达到100%;制备方法不仅会影响催化剂的比表面积、表面形貌,还会对催化剂的氧化还原能力和表面酸性位产生影响;成本由低到高依次为浸渍法、溶胶凝胶法、共沉淀法。3种方法制得同样质量的催化剂时,采用浸渍法所消耗的药剂最少,而且浸渍法制备过程最短,操作最简单。本研究可为锰基低温脱硝催化剂的制备提供参考。

-

关键词:

- 低温SCR /

- Mn-Ce/TiO2 /

- 制备方法 /

- 催化剂性能 /

- 成本分析

Abstract: The preparation method has important influence on the performance and cost of the catalyst. Mn-Ce/TiO2 catalysts were prepared by co-precipitation method, impregnation method and sol-gel method, and the low-temperature SCR performances of the catalysts were tested at 90~220 ℃. The physical and chemical properties of the catalyst samples were analyzed by BET, SEM, XRD, FT-IR, H2-TPR and NH3-TPD. And the cost analysis of the catalysts prepared by the three methods was carried out. The results showed that the performances of the catalysts prepared by the co-precipitation method and the impregnation method both were better, and the dnirification efficiencies of the catalysts reached 100% at the reaction temperature of 150 ℃. The preparation method would not only affect the specific surface area and surface morphology of the catalyst, but also affect the redox capacity and surface acidity of the catalyst. The cost of the three methods from low to high was impregnation method, sol-gel method, coprecipitation method. When the three methods were used to prepare catalysts of the same quality , the impregnation method consumed the least amount of reagents, the impregnation method took the shortest time and the operation of which was the simplest.-

Key words:

- low-temperature SCR /

- Mn-Ce/TiO2 /

- preparation method /

- catalyst performance /

- cost analysis

-

-

表 1 不同制备方法的催化剂的比表面积、孔容及平均孔径

Table 1. Specific surface area, pore volume and average pore size of the catalysts prepared by different methods

催化剂种类 比表面积/

(m2·g−1)微孔体积/

(cm3·g−1)平均孔径/

nmMn-Ce/TiO2(C) 80 0.44 22.19 Mn-Ce/TiO2(I) 74 0.85 46.19 Mn-Ce/TiO2(S) 78 1.58 81.40 表 2 不同制备方法的综合对比

Table 2. Comprehensive comparison of different preparation methods

制备方法 成本/元 制备过程 NO 转化率(90~220℃) 浸渍法 2.70 常温浸渍12 h+烘干12 h+焙烧500 ℃ 3 h 90℃,其NO转化率45%;120 ℃,NO转化率83%;

150 ℃以上,NO转化率100%。共沉淀法 32.11 水浴加热搅拌0.5 h+老化3 h+过滤洗涤2 h+

烘干12 h+焙烧500℃ 3 h。90 ℃,其NO转化率60%;120 ℃,NO转化率93%;

150 ℃以上,NO转化率100%。最优溶胶凝胶法 9.78 磁力搅拌器3 h+老化12~24 h+烘干12 h+焙烧500℃ 5 h 180 ℃,NO转化率69%;220 ℃,NO转化率91%。 -

[1] 郝吉明, 马广大, 王书肖. 大气污染控制工程[J]. 北京:高等教育出版社, 2010: 389-404. [2] 唐晓龙, 郝吉明, 徐文国, 等. 固定源低温选择性催化还原NOx技术研究进展[J]. 环境科学学报, 2005, 25(10): 1297-1305. doi: 10.3321/j.issn:0253-2468.2005.10.002 [3] BUSCA G, LARRUBIA M A, ARRIGHI L, et al. Catalytic abatement of NOx: Chemical and mechanistic aspects[J]. Catalysis Today, 2005, 107/108: 139-148. doi: 10.1016/j.cattod.2005.07.077 [4] 梁海龙, 吴彦霞, 霍艳丽. 低温SCR脱硝催化剂实现需求”量身定制”[J]. 中国建材, 2018, 426(06): 125-126. [5] 张文伯,苏伟,邢奕. 工业烟气选择性催化氧化脱硝催化剂研究进展[C]//.《环境工程》2019年全国学术年会论文集,2019:219-224. [6] JIN R B, LIU Y, WU Z B, et al. Low-temperature selective catalytic reduction of NO with NH3 over Mn-Ce oxides supported on TiO2 and Al2O3: A comparative study[J]. Chemosphere, 2010, 78(9): 1160-1166. doi: 10.1016/j.chemosphere.2009.11.049 [7] STANCIULESCU M, CARAVAGGIO G, DOBRI A, et al. Low-temperature selective catalytic reduction of NOx with NH3 over Mn-containing catalysts[J]. Applied Catalysis B Environmental, 2012, 123/124(23): 229-240. [8] REN S, YANG J, ZHANG T S, et al. Role of cerium in improving NO reduction with NH3, over Mn–Ce/ASC catalyst in low-temperature flue gas[J]. Chemical Engineering Research and Design, 2018, 133: 1-10. doi: 10.1016/j.cherd.2018.02.041 [9] QI N Y, DAN H J, LI X H. Effect of Cu Doping on the SCR Activity of Mn‒Ce/ATP Catalyst[J]. Russian Journal of Applied Chemistry, 2018, 91(1): 136-142. doi: 10.1134/S1070427218010214 [10] WANG C, YU F, ZHU M Y, et al. Highly selective catalytic reduction of NOx by MnOx–CeO2–Al2O3 catalysts prepared by self-propagating high-temperature synthesis[J]. Journal of Environmental Sciences, 2019, 75(01): 127-138. [11] XU Q, YANG W J, CUI S T, et al. Sulfur resistance of Ce-Mn/TiO2 catalysts for low-temperature NH3-SCR[J]. Royal Society Open Science, 2018, 5(3): 171846. doi: 10.1098/rsos.171846 [12] 贺丽芳, 刘建东, 黄伟, 等. 制备方法对Mn-Ce/ZSM-5催化剂低温选择性催化还原NO性能的影响[J]. 高等学校化学学报, 2012, 33(11): 2532-2536. doi: 10.7503/cjcu20120079 [13] 廖伟平, 杨柳, 王飞, 等. 不同制备方法的Mn-Ce催化剂低温SCR性能研究[J]. 化学学报, 2011, 69(22): 2723-2728. [14] SHEN B X, ZHANG X P, Ma H Q, et al. A comparative study of Mn/CeO2, Mn/ZrO2 and Mn/Ce-ZrO2 for low temperature selective catalytic reduction of NO with NH3 in the presence of SO2 and H2O[J]. Journal of Environmental Sciences, 2013, 25(4): 791-800. [15] LI X, LI Y. Selective catalytic reduction of NO with NH3 over Ce-Mo-Ox catalyst[J]. Catalysis Letters, 2014, 144(1): 165-171. doi: 10.1007/s10562-013-1103-6 [16] 闫东杰, 李亚静, 玉亚, 等. 碱金属沉积对Mn-Ce/TiO2低温SCR催化剂性能影响[J]. 燃料化学学报, 2018, 46(12): 116-122. [17] YAMAMOTO A, TERAMURA K, HOSOKAWA S, et al. Effects of SO2 on selective catalytic reduction of NO with NH3 over a TiO2 photocatalyst[J]. Science & Technology of Advanced Materials, 2015, 16(2): 1-7. [18] CENTENO M A, CARRIZOSA I, ODIRIOZOLA J A. NO-NH3 coad sorption on vanadia titania catalysts: determination of the reduction degree of vanadium[J]. Applied Catalysis B:Environmental, 2001, 29(4): 307-314. doi: 10.1016/S0926-3373(00)00214-9 [19] 汪洋. NO气体在TiO2表面的吸附行为[J]. 化学学报, 2006, 64(15): 1611-1614. doi: 10.3321/j.issn:0567-7351.2006.15.017 [20] ANDREOLI S, DEORSOLA F A, PIRONE R. MnOx-CeO2 catalysts synthesized by solution combustion synthesis for the low-temperature NH3-SCR[J]. Catalysis Today, 2015, 253: 199-206. doi: 10.1016/j.cattod.2015.03.036 [21] WAN Y P, ZHAO W R, TANG Y, et al. Ni-Mn bi-metal oxide catalysts for the low temperature SCR removal of NO with NH3[J]. Applied Catalysis B Environmental, 2014, s 148/149(6): 114-122. [22] 黄继辉, 童华, 童志权, 等. H2O和SO2对Mn-Fe/MPS催化剂用于NH3低温还原NO的影响[J]. 过程工程学报, 2008, 8(16): 517-522. [23] WANG X, ZHENG Y Y, XU Z, et al. Amorphous MnO2 supported on carbon nanotubes as a superior catalyst for low temperature NO reduction with NH3[J]. RSC Advances, 2013, 3(29): 11539-11542. doi: 10.1039/c3ra41512k [24] POURKHALIL M, MOGHADDAM A Z, RASHIDI A, et al. Preparation of highly active manganese oxides supported on functionalized MWNTs for low temperature NOx reduction with NH3[J]. Applied Surface Science, 2013, 279(Complete): 250-259. [25] PAPARAZZO E. Some notes on XPS Mn2p and Ce3d spectra of MnOx-Ceria catalysts[J]. Catalysis Today, 2012, 185(1): 319-321. doi: 10.1016/j.cattod.2012.02.014 [26] WU Z B, JIN R B, LIU Y, et al. Ceria modified MnO2/TiO2 as a superior catalyst for NO reduction with NH3 at low-temperature[J]. Catalysis Communications, 2008, 9: 2217-2220. doi: 10.1016/j.catcom.2008.05.001 [27] KAPTEIJN F, SINGOREDJO L, ANDREINI A. Activity and selectivity of pure manganese oxides in the selective catalytic reduction of nitric oxide with ammonia[J]. Appl Cazal B, 1994, 3(2-3): 173. doi: 10.1016/0926-3373(93)E0034-9 [28] YE Q, ZHAO J S, HUO F F, et al. Nanosized Ag/α-MnO2 catalysts highly active for the low-temperature oxidation of carbon monoxide and benzene[J]. Catalysis Today, 2011, 175(1): 603-609. doi: 10.1016/j.cattod.2011.04.008 [29] JARRIGE. J, Vervisch. P. Plasma-enhanced catalysis of propane and isopropy l alcohol at ambient temperature on a MnO2-based catalyst[J]. Applied Catalysis B:Environmental, 2009, 90(1): 74-82. -

下载:

下载: