-

肉类屠宰厂产生的废水包含圈栏内粪便冲洗水、屠宰车间内的含血废水及褪毛高温废水,主要含有大分子有机物、动物油脂等,以及类大肠杆菌等细菌,且伴有腥臭味[1-2]。屠宰废水中COD、氨氮和总氮分别约为600~3 000 mg·L−1、50~320 mg·L−1、 80~354 mg·L−1[3-4]。屠宰废水生化处理技术比较成熟,多采用“水解酸化+生物接触氧化”[3-4]或“UASB+SBR”[5]等组合工艺。然而,UASB等工艺的基建难度较大、成本较高,并不适用于小型污水处理厂。传统生物法基建难度小、成本低,但其脱氮效率不理想且存在脱氮除磷过程中聚磷菌和硝化细菌污泥龄矛盾的问题。以传统A2/O工艺为基础的UCT工艺对COD、总氮和总磷的去除率较高,还可解决SBR、UASB、A2/O等传统工艺在脱氮除磷时存在的问题[6]。

将UCT工艺进行回流模式的改良,可提高除磷效果,并解决传统活性污泥法中污泥易流失的问题[7]。改良方法为将二沉池污泥直接回流至接触好氧池前端。其中,硝化细菌污泥龄较短,在进入好氧池后曝气量充足的情况下,会较快地适应好氧环境,然后快速增长繁殖,并降解水体中有机物及氨氮;而反硝化细菌污泥龄较长,好氧污泥进入厌氧环境后,适应期较长,优势菌种难在短时间内增长繁殖。因此,将二沉池污泥直接回流至好氧系统前端,在一定程度上可减少好氧污泥和厌氧污泥间的更替,使大部分硝化菌和反硝化细菌处于适宜生长环境下,从而解决硝化菌与反硝化菌在污泥龄上的矛盾问题,更有利于菌种培养。另一方面,聚磷菌厌氧释磷条件是绝对厌氧状态,污泥回流混合液中含有大量硝态氮及游离氧,若回流至厌氧池会破坏厌氧环境,使得厌氧池内优先发生反硝化作用,且厌氧段磷释放的有效容积减少而硝态氮也会抑制磷的释放,导致除磷效果较差。因此,通过将二沉池污泥直接回流至接触好氧池前端,可从源头上减少厌氧段内游离氧及硝态氮含量,从而提高除磷效果。

本案例以《屠宰与肉类加工工业水污染物排放标准 (征求意见稿) 》的间接排放标准为废水处理目标,基于传统生化工艺设计出一套基建难度小且能满足生产需求的改良回流模式UCT工艺。根据出水水质情况及污泥挂膜情况,调整曝气量、硝化混合液回流比、缺氧混合液回流比及污泥回流比,以完成现场运行调试,并核算改造成本与运行成本,以期为同类小型高氮屠宰废水的处理工程的设计或运行改造提供参考。

-

废水主要由屠宰生产过程中产生的各类废水组成。由于每日屠宰量随市场需求变化,故屠宰废水产生量不同。夏秋两季屠宰废水产生量为40~50 m3·d−1,春冬两季屠宰废水产生量则高达180~200 m3·d−1。原有污水处理设施采用传统A2/O工艺,其日处理量仅为60 m3,且原污水处理设施厌氧池与缺氧池内无搅拌装置,极易造成污泥沉积与池体堵塞。同时,接触好氧池内曝气管道腐蚀穿孔,曝气不均匀,处理效果不佳,故需建造新污水处理设施以保证屠宰场正常生产运行。由于屠宰废水属于间歇式用水且用水量的时变化系数较大,因此峰值排放量按照200 m3·d−1设计。目前,该屠宰厂所在区域乡镇污水管网已覆盖,利用原有污水处理设施的污水管道进行新设施的修建,设计规模为200 m3·d−1。出水水质执行《屠宰与肉类加工工业水污染物排放标准 (征求意见稿) 》标准。设计进、出水水质如表1所示。

-

1) 预处理设计。该处理系统原水B/C为0.75>0.3,可生化性好。由于废水中含有大量动物油脂、动物毛发及屠宰过程中产生的肉类碎屑,故保留原有前端预处理设备。在预处理阶段,废水会经过固液分离、隔油池和格栅去除掉大宗杂物和浮渣,然后进入混凝气浮,使动植物油、悬浮物和部分有机物得到有效去除。预处理后的废水进入改造后的调节池,并利用成一体化溶气式气浮机,去除其中的小粒径悬浮物。

2) 生化工艺设计。考虑到该屠宰废水氨氮指标较高,而在碱性条件下,曝气量对氨氮去除效果的影响较大,故选用风量为1 000 m3·h−1的变频风机,为理论曝气量的134%。由于生化系统进水COD较高,直接采用接触氧化等工艺,所需生化池容积较大,基建成本过高,故先利用水解酸化对有机物进行预降解[7],利用厌氧微生物去除废水中的有机物并使含氮有机物氨化,以提高污水的可生化性。然后设置缺氧池使厌氧池出水与富含硝态氮的好氧池回流液混合,并在缺氧池内进行反硝化反应。反硝化反应过程中产生的碱度可为好氧池中硝化反应创造有利条件。缺氧池出水经过絮凝沉淀后,厌氧污泥一部分回流至厌氧池,以加强厌氧—缺氧的交替,另一部分排入污泥池,上清液进入接触好氧池,并在好氧池前端主要进行碳化反应以去除好氧有机物 (以COD计) ;后端主要进行硝化反应,使氨态氮变为硝态氮。最后,混合液在二沉池进行泥水分离后,污泥部分回流至接触好氧池前端,部分排入污泥池,上清液达标排放。

3) 回流工艺设计。为避免好氧系统内溶解氧会对厌氧环境造成破坏,将二沉池污泥直接回流至好氧系统前端,好氧系统内仅设置硝化混合液回流至缺氧段。由于缺氧段布设潜流推进器会导致缺氧段污泥部分流失,故缺氧段后设置混凝沉淀池并将污泥部分回流至厌氧段,以加强脱氮效果并保证整个生化系统内的厌氧菌和好氧菌在绝大程度上处于各自适应的生长环境条件下,从而减少其转换周期,有利于污泥培养。

4) 固废的处理。预处理阶段的残渣产生量较多,再加上生化系统所产生性质稳定的活性污泥,可将该处理系统产生的固废直接进行收集、贮存,再通过叠螺机进行压滤处理。

-

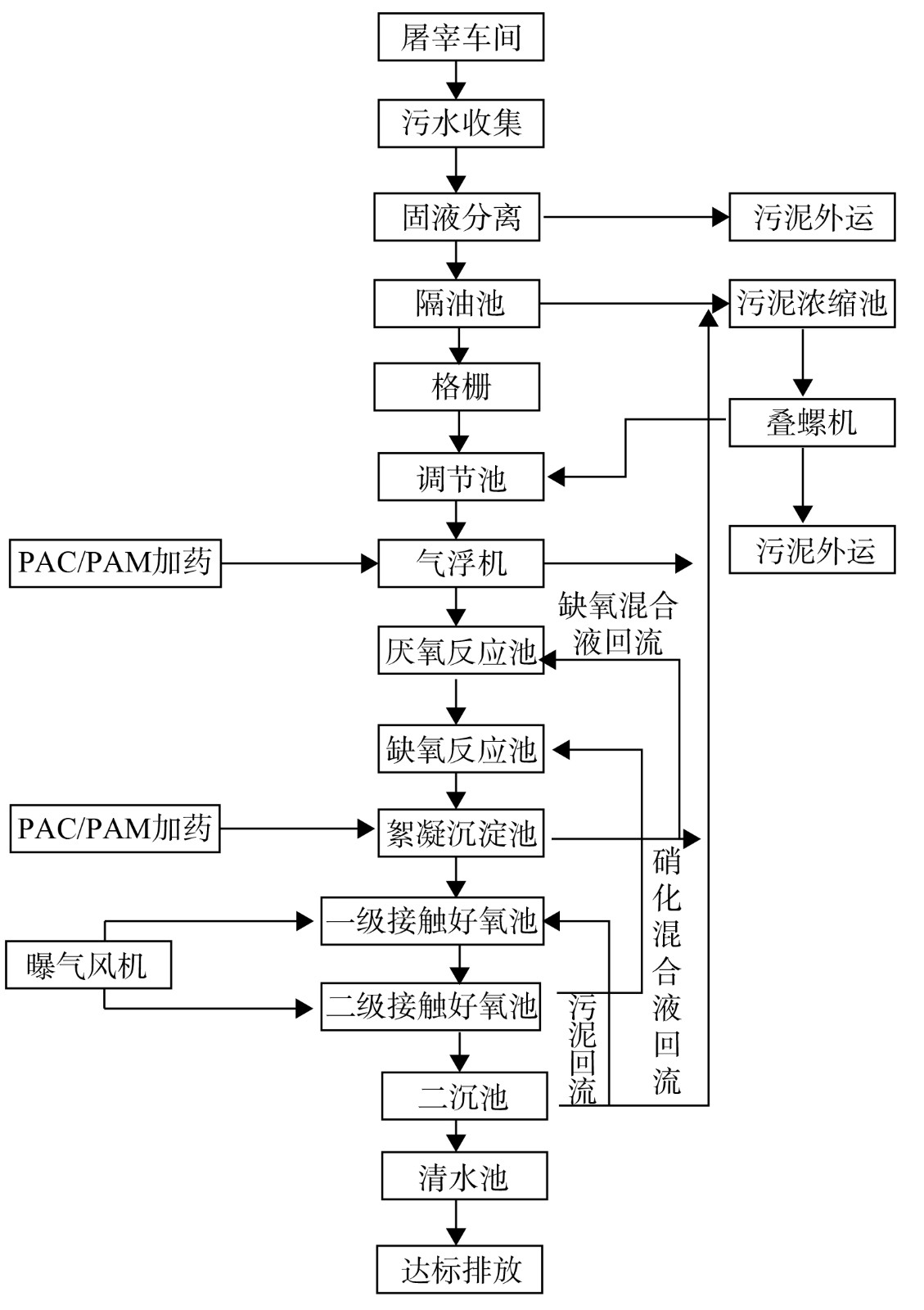

综合考虑该厂原有污水处理设施的实际运行情况、处理成本、进水水质及出水要求确定了废水处理工艺流程 (图1) 。

1) 预处理系统。预处理系统利用该厂原有设施,如斜筛式干湿分离机、隔油池及格栅等。在运行过程中,为避免残渣在调节池内沉积,先利用斜筛式干湿分离机将废水中残渣分离,而后通过隔油池和格栅去除动物油脂及部分悬浮物。出水含渣量较少可减少对管道及提升泵的磨损,预处理后的污水进入新处理系统调节池内,再泵入溶气式气浮机内去除剩余悬浮物及部分总磷。预处理系统出水较清澈但有异味。

2) 生化处理系统。该系统为新建设施,主要包括厌氧池、缺氧池、絮凝沉淀池、生物接触氧化池及二沉池。为保证该系统容积得到充分利用,其水流采用下进上出式。絮凝沉淀池与二沉池均为浇筑后砖砌泥斗。由于泥斗坡度较小,在正常运行过程中,沉淀池内泥层较厚,但不影响出水浊度。而厌氧池、缺氧池及生物接触池内均装有组合生物填料,为细菌生长提供附着物,可有效避免污泥流失。

3) 污泥处理系统。该系统亦为新建设施,主要包括污泥浓缩池和叠螺机。由于气浮机前期运行出现故障产渣量较多,二沉池泥斗建造坡度较小、水力冲击负荷较大,在运行过程中需要经常性排泥,故该系统前期运行较为频繁。当气浮机和生化系统运行稳定后,产渣量和产泥量大幅度减少,运行时间也随之减少。浓缩污泥在叠螺机前端絮凝反应池内与阳离子型聚丙烯酰胺絮凝成大颗粒絮体,并通过叠螺机进行泥水分离。脱水后污泥进行集中处理,压滤液排至调节池内进行再处理。

-

1) 调节池。半地下式钢筋混凝土结构,厚混凝土侧壁为250 mm,有效容积500 m3。配套污水提升泵2台 (Q=12 m³·h−1,H=20 m,P=1.1 kW,单价350 元·台−1,一备一用) 。电磁流量计1台。

2) 混凝气浮机。一体式设备,处理能力为10 m3·h−1 (单价13 600 元·台−1) ,容量水量为2~3 m3·h−1。外形尺寸为5 000 mm×2 500 mm×2 300 mm,有效容积9 m3。主机、刮抹机、空压机功率分别为3 kW、0.37 kW和1.10 kW。

3) 厌氧池。半地下式钢筋混凝土结构,进水方式采用上进下出式。出水处设置混凝土溢流堰,有效容积为50 m3,水力停留时间6.25 h。池内装有组合生物填料。

4) 缺氧池。半地下式钢筋混凝土结构,池内设有钢筋混凝土折板,末端设置钢筋混凝土溢流堰,其有效容积为83 m3,水力停留时间为10 h。池体对角设置2台潜水搅拌机 (P=2.2 kW,单价2 500 元·台−1) ,并装有组合生物填料。

5) 絮凝沉淀池。半地下式钢筋混凝土结构,混凝池有效容积14.72 m3,混凝反应池中间隔墙距池底1 m处开孔,设计混凝停留时间为1.70 h,沉淀池有效容积为45 m3,浇筑后砖砌泥斗,设计停留时间为5.40 h。混凝池内设有减速搅拌机2台 (其搅拌杆2.0 m,P=1.1 kW,单价1 060 元·台−1)。PAC、PAM加药设备各1套 (10~50 L·h−1,PE桶为1 000 L,单价890 元·套−1) 。沉淀池内设有提升泵1台 (Q=8 m³·h−1,H=10 m,P=1.5 kW,单价200 元·台−1) 。

6) 两段式生物接触氧化池。半地下钢筋混凝土结构,池体两端预埋管径200 mm UPVC管,氧化池前端设置宽为1 m的预混合区。预混合区末端墙体下端距池体底部0.40 m,以保证水流方向在整个池体处于下进上出状态。好氧池末端设置宽为0.92 m的沉淀区,总有效容积195 m3,水力停留时间为24 h。池内装有组合生物填料、曝气盘。配套风量为1 000 m3·h−1变频风机2台 ( Q=1 000 m³·h−1,p=100 kPa,P=48 kW,单价13 000 元·台−1,一备一用) ,提升泵2台 (Q=30 m³·h−1,H=10 m,P=2.5 kW,单价700 元·台−1,一备一用) ,溶解氧仪1台 (单价1 400 元·台−1) 。

7) 二沉池。半地下式钢筋混凝土结构,有效容积为45 m3,采用中心进水周边出水式辐流沉淀池,周边溢流堰采用砖砌结构,末端预埋管径200 mm UPVC管。池体浇筑后砖砌泥斗并布置斜板,池内设有提升泵2台 (Q=15 m³·h−1,H=10 m,P=2.2 kW,单价426 元·台−1,一备一用) 。

8) 污泥池。半地下钢筋混凝土结构,总有效容积为60 m3,池内设有污泥提升泵1台,末端设置混凝池,方便后续叠螺机压泥,其有效容积为9 m3。混凝池内设有减速搅拌机2台 (搅拌杆长为2.0 m,P=1.1 kW,单价1 060元·台−1) ,加药系统1套 (流量10~50 L·h−1,PE桶容积1 000 L,单价890 元·套−1) ,污泥提升泵1台 (Q=8 m³·h−1,H=10 m,P=1.5 kW,单价200 元·台−1) 。

-

化学需氧量采用快速消解分光光度法;氨氮采用纳氏试剂分光光度法;总氮采用碱性过硫酸钾消解紫外分光光度法;总磷采用钼酸铵分光光度法;SS采用重量法;pH (无量纲) 采用玻璃电极法;动植物油采用红外分光光度法;溶解性有机质 (dissolved organic matter,DOM) 采用荧光光谱法[16]。

为避免因屠宰废水中的悬浮物和动物油脂影响COD测定结果,在测定前先用絮凝剂进行混凝沉淀预处理,然后取其上清液进行检测。

-

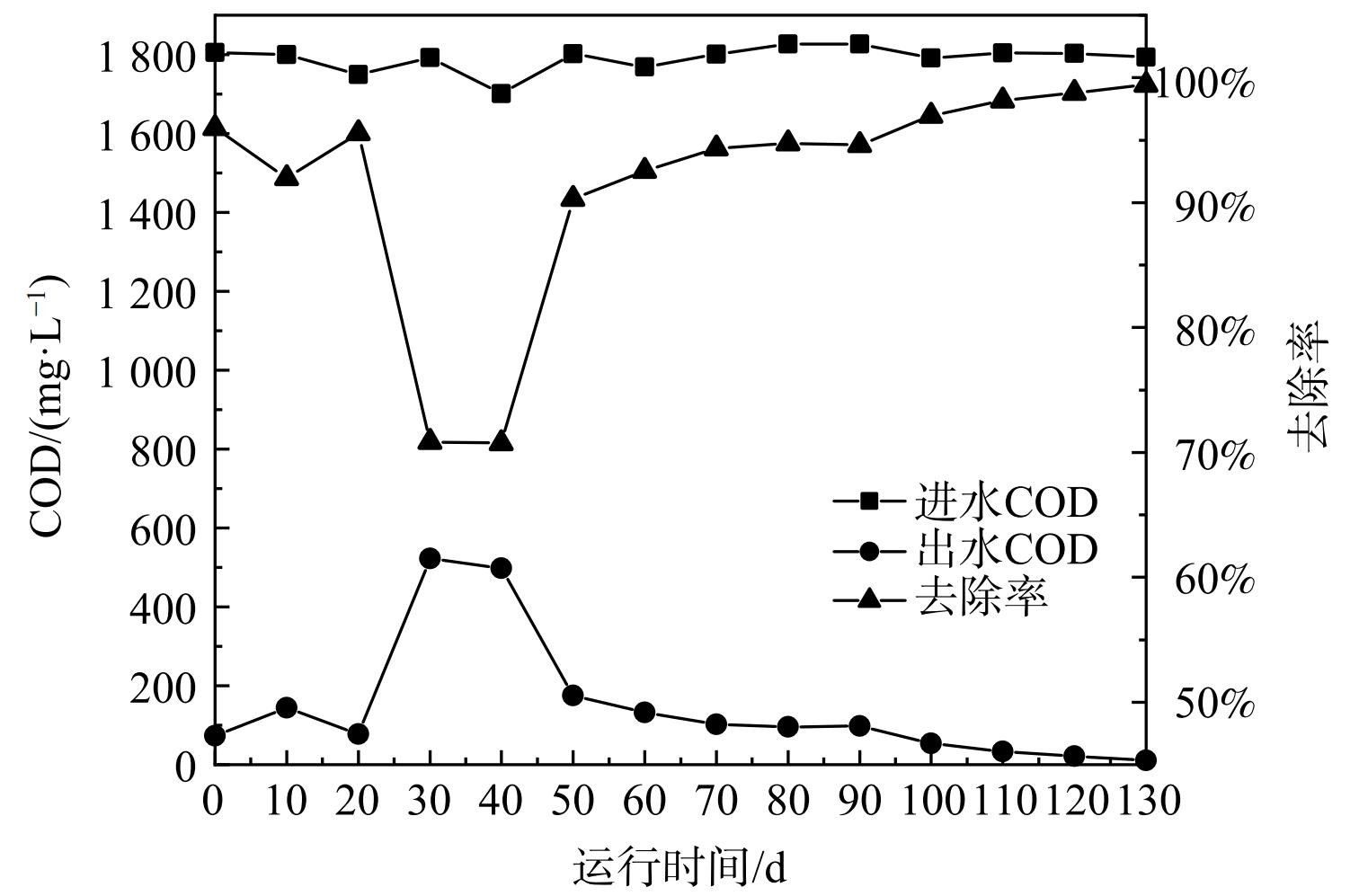

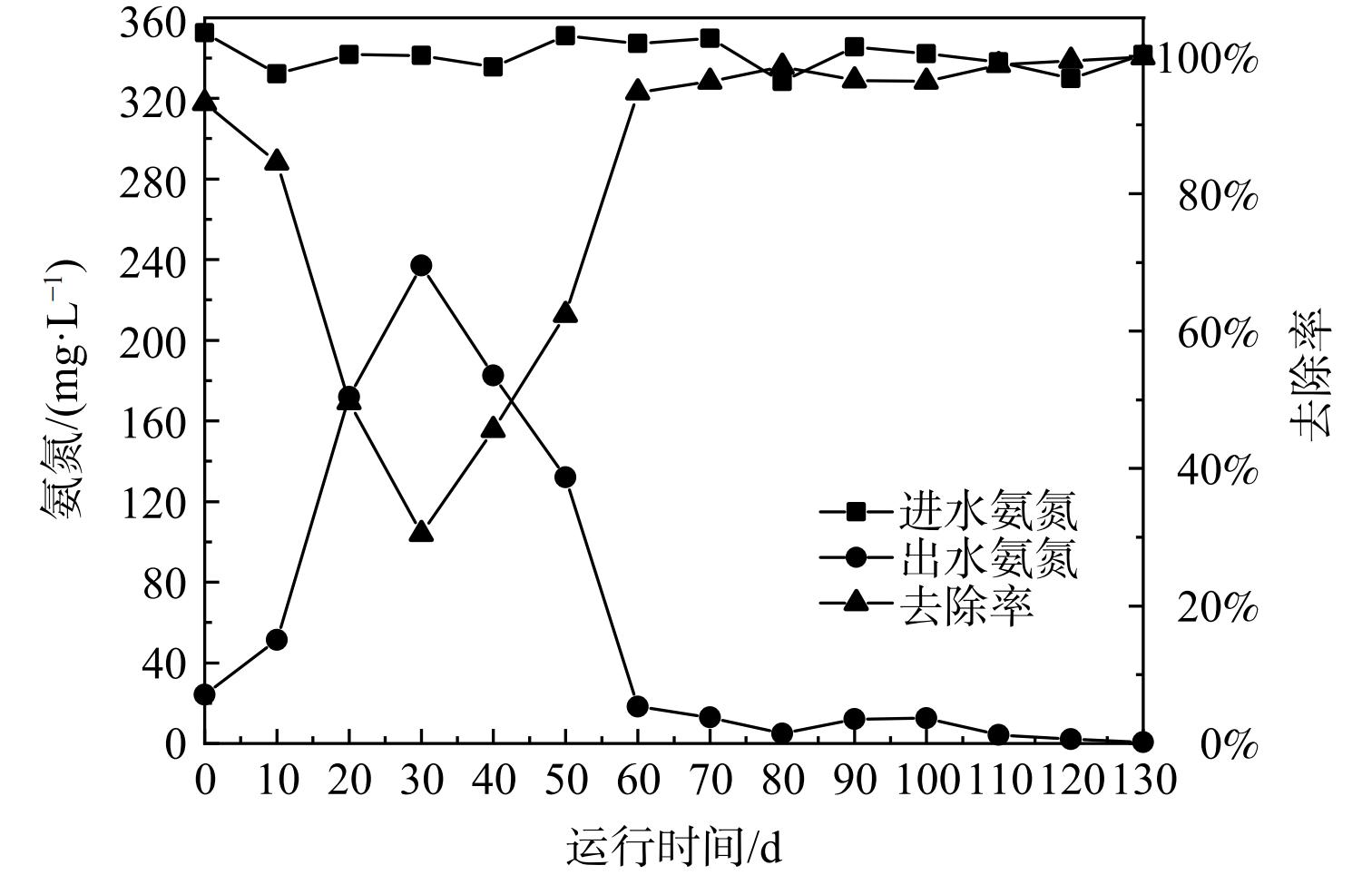

该污水处理设施建成后,在调试运行过程中对进出水中各项指标进行了连续130 d的监测。图2表明,初期生物填料上生物挂膜量较少,此时的污泥质量浓度为2 500 mg·L−1;中期生物填料生物挂膜量多,测得污泥质量浓度为6 000~7 000 mg·L−1。这说明污泥浓度与生物挂膜量有明显增加。

结合各项污染物指标分析处理效果发现:在系统初期,微生物主要处于适应期,未出现明显的增长繁殖,生物填料上的挂膜量较少,COD、氨氮、总氮和总磷去除率较低;在系统初期运行时每日投加25 kg葡萄糖并每隔2 d投加30 g磷酸二氢钾,以补充碳源与微量元素,有利于微生物增长繁殖;由于沉淀池上清液较混浊,将曝气量由1 000 m3·h−1调整至700 m3·h−1,使得好氧系统内溶解氧保持在2~3 mg·L−1,并使污泥回流比由50%提升至70%,以延长好氧污泥在好氧系统的停留时间,为微生物生长创造有利条件;在系统运行中期,污泥浓度与生物挂膜量大大增加,COD、氨氮、总氮和总磷的去除率也随之提高,并趋于稳定。

-

1) COD。在工艺运行过程中,系统对好氧有机物 (以COD计) 的去除效果见图3。在运行前期,由于系统内进水量不大,存在稀释作用,出水COD较低。随着进水量的增加,出水COD升高。经过污泥培养驯化及运行参数调整阶段后,出水COD逐渐降低,好氧有机物 (以COD计) 去除率逐渐提高,最终实现出水COD稳定达标。当系统运行到第10天时,初期的低负荷污水已排出系统外,随着进水量的增加,出水COD逐渐增高。通过增强厌氧—缺氧段循环,将缺氧混合液回流比由60%提升至82%,从而延长厌氧污泥在厌氧系统的停留时间[8-9];连续运行一段时间后,厌氧/缺氧池污泥浓度有所增加,水解酸化能力增强,好氧有机物 (以COD计) 去除效率明显提高,二沉池出水COD逐渐降低。在系统连续运行90 d后,出水COD稳定在70~130 mg·L−1,平均值为107 mg·L−1,好氧有机物 (以COD计) 去除率稳定在94%~97%。

2) 氨氮。在运行过程中对氨氮的去除效果见图4。在运行初期,由于废水进水量不大存在稀释作用,二沉池出水NH3-N较低。随着进水量增加,系统NH3-N去除率降低,出水中NH3-N逐渐升高。分析其主要过程为:在运行初期,系统内污泥质量浓度较低,硝化菌数量较少且生物填料上的挂膜量较少 (见图2 (a) ) ;系统运行至第10天时,好氧池负荷较低且C:N:P比例失衡,由于硝化细菌污泥龄较短,好氧污泥在好氧系统停留时间过长,好氧污泥自身氧化解体,从而导致二沉池出水浑浊且NH3-N升高;通过减小污泥回流比、增加硝化混合液回流比,减小好氧污泥在好氧池的停留时间,同时在系统运行前期定时向系统中补充适量碳源和微量元素 (通常投加磷酸二氢钾) ,以增加负荷和调整碳氮磷比例,使得整个系统更有利于细菌的生长繁殖 (在培养污泥过程中可采用此类方法,以减少培养周期) ;在运行一段时间后,出水NH3-N逐渐降低,生化系统中的污泥絮体变大且生物填料上挂膜量明显增加 (见图2 (b) ) ,测得污泥质量浓度为6 000~7 000 mg·L−1;在连续运行90 d后,出水NH3-N稳定在2~18 mg·L−1,平均值为10.16 mg·L−1,其去除率稳定在96%~99%。

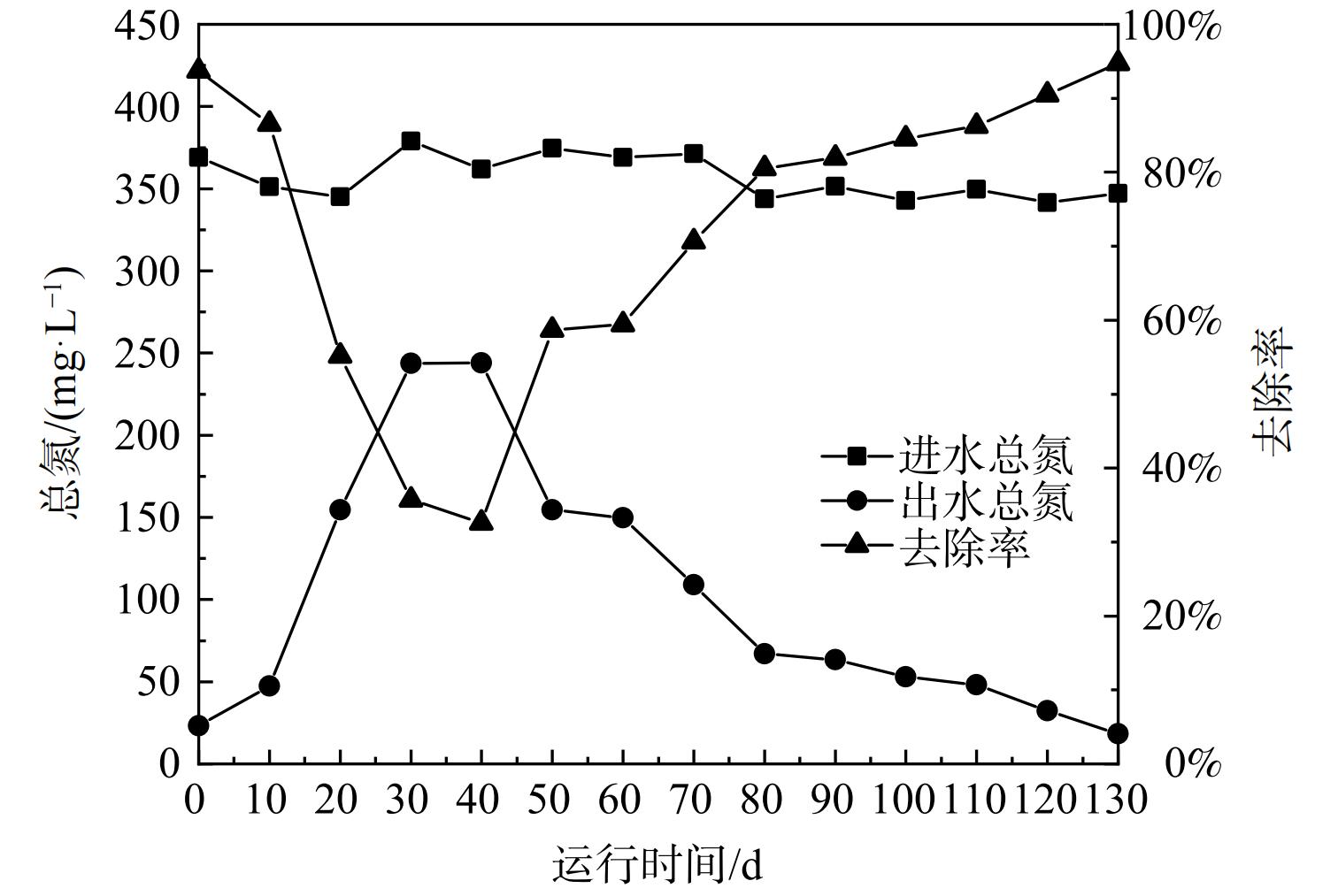

3) 总氮。运行过程中总氮 (TN) 去除效果见图5。在系统运行前30 d,出水TN波动较大。初期出水TN较低,随着总进水量的增加,运行至第10天时,出水TN逐渐升高。分析其主要过程为:进水NH3-N较高,NH3-N经过硝化反应后产生大量NO−3-N,随硝化混合液回流至缺氧段,缺氧段的反硝化压力过大[10],同时反硝化细菌较难培养,数量有限,会导致运行前期出水TN缓慢增加;缺氧池出水NO−3-N为12.63 mg·L−1 > 8 mg·L−1,NO−3-N回流至厌氧池会抑制厌氧池内含氮有机物的氨化过程;在好氧系统过度曝气,二级接触好氧池内保持较高DO,硝化回流混合液中携带了大量氧气进入缺氧段,过高DO又会抑制反硝化作用的进行。通过调整风机运行时间将曝气量由400 m3·h−1提升至750 m3·h−1,并逐级调整硝化混合液回流泵运行时间,将硝化混合液回流比由210%提升至267%。在连续运行30 d后,二级接触好氧池末端DO为2~3.50 mg·L−1,缺氧段出水NO−3-N保持在0.12~0.41 mg·L−1 (< 2 mg·L−1) ,能保证缺氧池内反硝化反应进行[11]及厌氧池中含氮有机物的有效氨化;连续运行90 d后,出水TN稳定18~70 mg·L−1,平均值为44 mg·L−1,TN去除率稳定在89%~95%。林康理等[15]对广州某屠宰场的旧污水处理设施进行升级,将传统A/O工艺改造为厌氧—缺氧—接触氧化工艺,效果明显,但氨氮去除率仅为84.6%。这表明本工艺对高氮屠宰废水的处理效果优势明显。

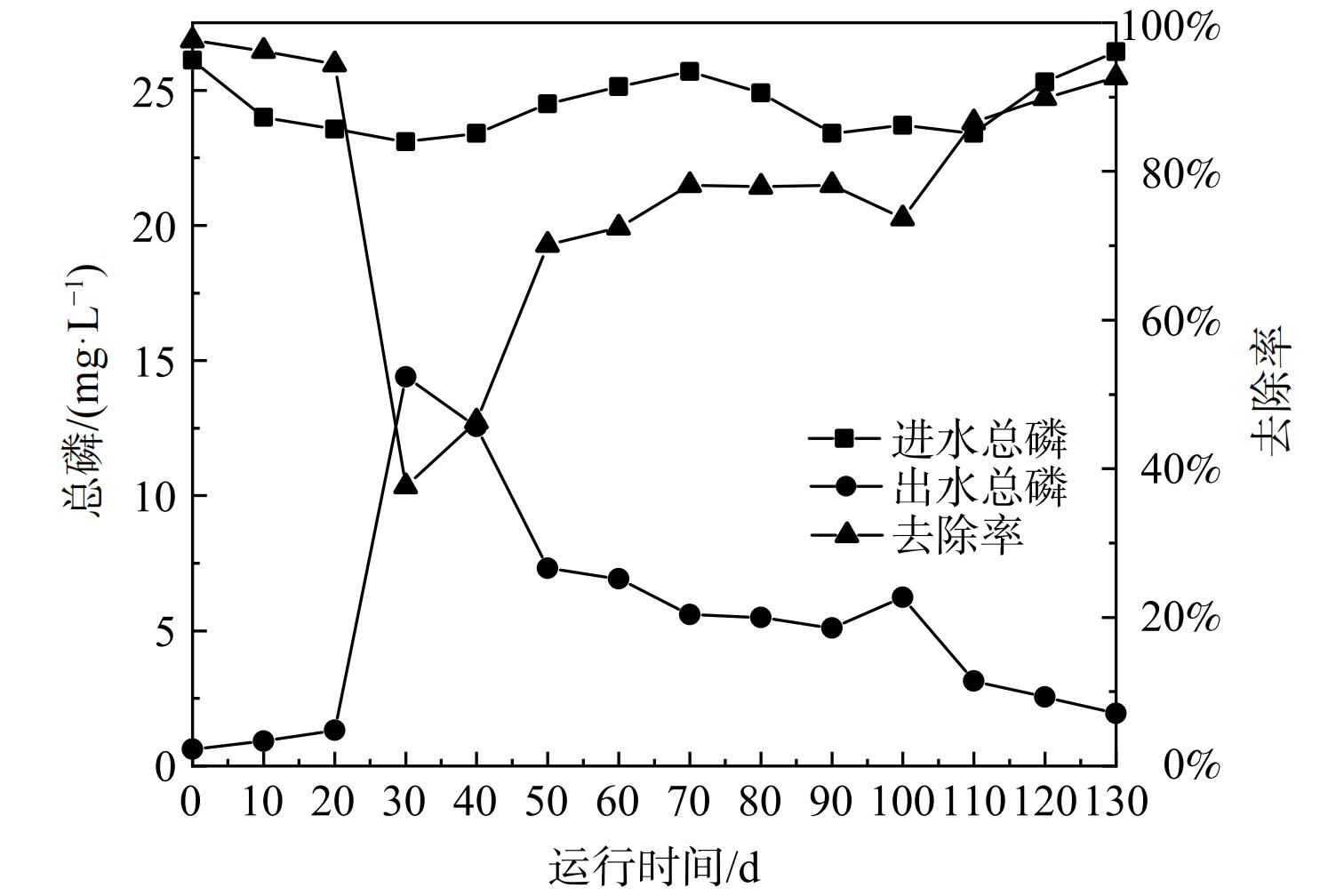

4) 总磷。运行过程中对总磷 (TP) 的去除效果见图6。在运行前期,出水TP较低,运行至第20天时,出水TP逐渐增加。分析其中的过程为:在运行至第10天时,增大了硝化混合液回流比与缺氧混合液回流比,过量NO−3-N进入缺氧段;由于反硝化细菌培养困难,反硝化效果不理想,故缺氧段出水NO−3-N较高,导致过多NO−3-N通过缺氧混合液回流被带入厌氧段抑制厌氧释磷[12],从而使得厌氧释磷效果较差;通过逐级调整硝化混合液回流比,使得缺氧段出水硝酸盐低于2 mg·L−1,以保证泥缺氧混合液回流中的NO−3-N不会抑制厌氧段的释磷性能[13];同时,缺氧混合液回流增强了厌氧—缺氧的交替[14],加强了系统的反硝化除磷性能,除磷效率随之提高。在连续运行90 d后,出水TP稳定在3~6 mg·L−1,平均值为4.50 mg·L−1,去除率稳定在85%~92%。

-

取115 d内的各工艺段的水样,用30 μm滤膜过滤后,将滤液稀释至在254 nm下吸光度小于0.05 A,然后用日立F-7000 荧光分光光度计进行检测。检测中的参数分别为:激发波长200~450 nm;发射波长200~550 nm;激发/发射狭缝5 nm;光电倍增管负高压500 V;扫描速度1 200 nm·min−1。共检测到4个荧光特征峰 (图7) ,其具体信息如表2所示。

图7中荧光峰A所代表的色氨酸类蛋白质和荧光峰B所代表的可溶性微生物副产物均为易降解有机物,荧光峰C代表的富里酸类腐殖质为可生物降解有机物,荧光峰D所代表的腐殖酸类腐殖质为难生物降解有机物[16]。其中,色氨酸类蛋白质和可溶性微生物副产物在经过水解酸化后其特征峰荧光强度明显降低。再经过好氧处理后,图7 (c) 中荧光峰A和荧光峰B的特征峰已消失,这说明该工艺对此类有机物具有较好处理效果,且出水中C峰和D峰的荧光强度明显降低说明该工艺对难生物降解有机物具有一定降解效果。这与图3中进出水COD变化一致。图7中荧光峰A的荧光强度变化与图5进出水TN一致,这表明该工艺对有机氮化合物的降解效果也较为明显。该工艺稳定出水COD约20 mg·L−1,氨氮约2 mg·L−1,总氮约18 mg·L−1,总磷约2 mg·L−1,可达到《屠宰与肉类加工工业水污染物排放标准 (征求意见稿) 》的间接排放标准。

-

该系统的调试及运行重点在于污泥的驯化培养。该工艺的生化系统水力停留时间为2~3 d。系统运行主要问题有:1) 在系统运行初期,生化系统后端负荷较低且碳氮磷比易失衡,每日投加25 kg葡萄糖并每隔2 d投加30 g磷酸二氢钾来补充碳源和微量元素,使得碳氮磷比例约为100∶5∶1;2) 二级接触好氧池末端的溶解氧探测仪与2台变频风机联用,以此控制风机启停时间,当气温低时,溶解氧设定为1.50~2.50 mg·L−1,当气温高时设定为2~3 mg·L−1,以保证好氧系统溶解氧含量充足;3) 厌氧系统要安装潜流推进器保证污水和污泥处于完全混合流动状态,使细菌与待降解物质充分接触;4) 在污泥的驯化培养完成后,根据出水水质,在硝化液混合液回流泵、污泥回流泵及缺氧混合液泵流量分别为30、8和 15 m3·h−1的条件下,通过调整其对应时间控制开关中运行时间来逐级调整硝化混合液回流比、污泥回流比和缺氧混合液回流比分别为267%、70%和82%,以保证出水稳定达标。

-

1)工程改造费用。本工程总费用为201.50万元,包括建筑工程费用153万元、设备购置费及安装费用45万元,其他费用3.50万元。该处理设施由甲方自建,乙方负责设备采购、安装调试、设备运输、方案设计和运行维护。主要设备采购价格总计7 0152元,管道及配套阀门等共计2.7万元,PLC自动化控制柜费用为3.5万元。此外,设备运输费为3 000元,运行调试费用为5 000元,方案设计费为1.7万元。

2) 运行成本。运行费用主要包括药剂费和电费,该系统的运行维护主要由厂里工人兼任,无需考虑人工费用。实际核算结果如下:1) 药剂费用为 0.47 元·m−3,其中26%聚合氯化铝每吨2 400 元,其用量为33.30 kg·d−1,60万分子量阴离子型聚丙烯酰胺每吨5 840 元,其用量为2.50 kg·d−1;2) 电费为1.11 元·m−3,变频风机、减速搅拌机等设备运行总功率为19 kW,当地电价为0.6507 元·(kW·h)−1计,夜间电价按白天电价一半计。因此,运行费用总计为1.58 元·m−3,仅为厌氧折流板反应器+A/O处理屠宰废水运行费用的1/3[1],且低于采用固液分离/涡凹气浮/水解酸化/接触氧化工艺处理屠宰废水运行费用[4]。

-

1) 采用改良回流模式的UCT工艺处理屠宰废水,连续130 d的调试运行结果表明,该系统运行稳定且出水水质达到《屠宰与肉类加工工业水污染物排放标准 (征求意见稿) 》的间接排放标准。好氧有机物 (以COD计) 、氨氮、总氮和总磷的去除率分别达到 97%、98%、95%和92%。

2) 该系统运行初期出现污泥老化问题,通过投加25 kg·d−1葡萄糖和15 g·d−1磷酸二氢钾补充碳源、微量元素,并根据污泥生长情况,调整风机曝气量,可有效解决初期污泥老化的问题。

3) 在系统运行过程中,出水氨氮过高时,可在曝气量充足的条件下,将污泥回流比由50%调整为70%,增加水力停留时间,从而提高氨氮去除率;同时,出水中总氮逐渐升高,将硝化混合液回流比由210%逐级调整为267%,并缺氧池混合液回流比由60%提升至82%,可保证回流混合液中硝态氮进行的反硝化反应,以提高脱氮效率;逐级增加进水水量,由4 m3·h−1 增至9 m3·h−1,系统仍能保证运行稳定。

4) 改良回流模式的UCT工艺对高氮屠宰废水处理效果较好,其改造、调试和运行经验可为同类废水处理工程提供参考。工艺改造易实现,改造费用较低,且运行成本较传统工艺较低。

改良回流模式的UCT工艺处理高氮屠宰废水的工程案例

Engineering case of UCT process with improved reflux mode for treating high-nitrogen slaughtering wastewater

-

摘要: 采用改良回流模式的UCT工艺处理高氮屠宰废水,该系统处理能力为200 m3·d−1。连续130 d的调试运行结果表明,在进水水质较稳定的情况下,该工艺对COD、氨氮、总氮和总磷的去除率分别达到97%、98%、94%和92%,出水水质达到《屠宰与肉类加工工业水污染物排放标准 (征求意见稿) 》的间接排放标准。该工艺调试运行初期,通过投加碳源以及微量元素,有效避免污泥老化问题;在稳定运行过程中,调整硝化混合液回流比、缺氧混合液回流比以及污泥回流比分别至267%、82%和70%,使得工艺处于最佳条件下运行;结合各工艺段荧光图谱分析结果显示,改良回流模式的UCT工艺有效降解色氨酸类物质及可溶性微生物副产物,具有较好的脱氮效果;工程改造成本中涉及设备和调试费用不高,且与传统屠宰废水处理流程比,吨水处理费下降了约30%。该工程案例的改造、调试及运行经验可为同类高氮废水处理工程提供参考。Abstract: The UCT process with a modified reflux mode was used to treat high-nitrogen slaughter wastewater with a treatment capacity of 200 m3·d-1. Under the condition of relatively stable quality of the inlet water, the results of 130 consecutive days of the commissioning and operation showed that the removal rate of COD, ammonia nitrogen, total nitrogen and total phosphorus could reach 97%, 98%, 94% and 92% respectively, and the effluent water quality reached the indirect discharge standard of the"Discharge Standard of Water Pollutants for Slaughtering and Meat Processing Industry (Draft for Comments)". In the early stage of commissioning and operation of the process, the problem of sludge aging was effectively avoided by adding carbon sources and trace elements. In the process of stable operation, the reflux ratio of nitrifying mixture, the reflux ratio of anoxic mixture and the sludge reflux ratio were adjusted to 267%, 82% and 70%, respectively,to make the process run under the best conditions. Combined with the fluorescence spectrum analysis results of each process section, it was shown that the modified reflux mode UCT process had a good nitrogen removal effect and the tryptophan substances and soluble microbial by-products were effectively degraded during the process. The equipment and commissioning costs involved in the engineering renovation were not high, the cost of treating tons of water was about 30% lower than the traditional slaughter wasterwater treatment process. The debugging and operation experience could provide reference for the commissioning and operation of similar wastewater treatment projects.

-

-

表 1 进水水质和排放标准

Table 1. The influent quality and discharge standard

水质指标 质量浓度/(mg·L−1) 设计进水指标 进水指标 排放标准 COD 2 500 1 700~2 000 ≤500 BOD5 1 700 1 200~1 500 ≤300 氨氮 200 300~350 ≤45 总氮 230 320~370 ≤70 总磷 20 15~20 ≤8 SS 2 000 1 700~2 000 ≤400 pH (无量纲) 6~9 6~9 6~9 动植物油 300 350~400 ≤50 表 2 各工段三维荧光光谱参数表

Table 2. Three dimensional excitation-emission fluorescence spectrum parameter table of each section

荧光峰类别 λex/λem 组分 荧光强度 A 225 nm/335 nm 色氨酸类蛋白质 图8(a):412 a.u

图8(b):82 a.uB 280 nm/336 nm 可溶性微生物副产物 图8(a):327.5 a.u

图8(b);72 a.uC 225 nm/402 nm 富里酸类腐殖质 图8(b):98 a.u

图8(c):73 a.u

图8(d):57 a.uD 290 nm/402 nm 腐殖酸类腐殖质 图8(b):88.5 a.u

图8(c):65 a.u

图8(d):56 a.u -

[1] 郑伟波, 郑卉, 余敏露. 气浮+厌氧折流板反应器+A/O处理屠宰废水工程[J]. 水处理技术, 2021, 47(5): 137-140. [2] KANAFIN Y N. , MAKHATOVA A, MEIRAMKULOVA K, et al. Treatment of a poultry slaughterhouse wastewater using advanced oxidation processes[J]. Journal of Water Process Engineering, 2022, 47. [3] 程永伟, 孙春波, 武彦生, 等. 水解酸化+生物接触氧化法处理屠宰厂废水[J]. 中国给水排水, 2017, 33(12): 116-118. doi: 10.19853/j.zgjsps.1000-4602.2017.12.027 [4] 白王军, 倪军. 固液分离/涡凹气浮/水解酸化/接触氧化处理屠宰废水[J]. 中国给水排水, 2020, 36(4): 106-109. doi: 10.19853/j.zgjsps.1000-4602.2020.04.021 [5] 周明俊, 于鹏飞, 傅金祥, 等. 混凝气浮-UASB-SBR耦合工艺处理屠宰废水[J]. 水处理技术, 2016, 42(3): 116-120. [6] 李桂荣, 王立军, 杜春山, 等. UCT工艺处理低C/N值城市污水的试验研究[J]. 中国给水排水, 2012, 28(9): 101-104. doi: 10.3969/j.issn.1000-4602.2012.09.026 [7] 戴捷, 马玉宝, 陈丽雯, 等. 厌氧水解-二段生物接触氧化处理生活污水试验研究[J]. 水处理技术, 2013, 39(4): 90-92. doi: 10.3969/j.issn.1000-3770.2013.04.022 [8] 朱开贞, 许新海. 改良UCT-A/MBR工艺启动特性研究[J]. 环境科学与技术, 2019, 42(8): 189-194. [9] 贾军峰, 吴俊奇, 王真杰, 等. 改良UCT工艺处理高氨氮生活污水的实验研究[J]. 应用化工, 2020, 49(3): 661-664. doi: 10.3969/j.issn.1671-3206.2020.03.029 [10] 尤立, 刘平, 胡春明. 改良型UCT工艺在农村生活污水处理中的应用[J]. 环境工程学报, 2022, 16(2): 651-658. doi: 10.12030/j.cjee.202012075 [11] 宋文哲, 林甲, 刘杰, 等. 缺氧混合液回流对改良UCT工艺影响研究[J]. 给水排水, 2022, 58(6): 55-61. doi: 10.13789/j.cnki.wwe1964.2021.09.02.0002 [12] 张园, 罗固源, 许晓毅, 等. UCT工艺进水COD浓度与C/N对除磷效果的影响[J]. 环境科学, 2010, 31(8): 1846-1850. doi: 10.13227/j.hjkx.2010.08.011 [13] 郭珊珊, 杨云龙. UCT工艺处理生活污水的启动运行[J]. 水处理技术, 2011, 37(10): 109-112. [14] 乔宏儒, 孙力平, 吴振华, 等. 倒置A~2/O工艺和UCT工艺脱氮除磷效能比较[J]. 水处理技术, 2015, 41(12): 118-121. [15] 林康理. 屠宰废水处理设施改造工程实例[J]. 广东化工, 2021, 48(7): 115-117. doi: 10.3969/j.issn.1007-1865.2021.07.045 [16] SUN M X, WU M, DAI J, et al. 3DEEM spectroscopy analysis to assess the EPS composition in HMBR systems[J]. Water Science and Technology, 2016, 72(11): 2708-2716. -

下载:

下载: