-

焚烧处理已成为我国城市生活垃圾和危险固体废物无害化处理的主要方式[1−3]。然而,固体废物焚烧过程中不可避免会产生新的污染物,对人类健康及大气环境造成影响。目前,固体废物焚烧产生的污染物研究主要集中在二噁英等持久性有机污染物和重金属等方面[4−6],对挥发性有机物(VOCs)的研究非常有限。VOCs不但有较高的急性毒性和致癌性,而且可参与大气中一些自由基反应,促进臭氧和二次有机气溶胶生成,造成大气污染[7−9]。2019年,我国生态环境部和国家卫生健康委员会发布的《有毒有害大气污染物名录(2018年)》中共包含11种污染物,其中有机污染物有6种,全部属于VOCs。

固体废物焚烧是大气VOCs的一个不可忽视的排放源。Liu等[10]研究发现,某垃圾焚烧发电厂在运行状态下,烟囱排放VOCs的总浓度为(270.6 ± 2.8)μg·m−3,是垃圾存放车间VOCs总浓度的近5倍。Beylot等[3]对法国90个城市垃圾焚烧发电厂的研究发现,VOCs的排放因子是4.68 g·t−1垃圾,而二噁英的排放因子只有7.78×10−8 g ·t−1垃圾。目前,我国尚未对固体废物焚烧行业的VOCs排放进行管控。

现代化的大型固体废物焚烧系统普遍采取严格的污染排放管控措施,通常安装脱硫脱硝设备、活性炭喷射装置和布袋除尘器,重点控制氮氧化物、二氧化硫、二噁英、重金属和烟尘的排放。为将氮氧化物的大气排放浓度控制在100 mg·Nm−3以下,大部分新建的大型固体废物焚烧系统在布袋除尘器后安装了选择性催化还原(SCR)装置。SCR催化剂同时具有较高的催化氧化还原活性,可改变焚烧烟气中有机污染物的浓度和分布[11]。有研究表明,SCR装置也可有效去除烟气中的二噁英[12-13]。但尚未有研究报道安装SCR装置对固体废物焚烧过程VOCs排放的影响。

本文在一安装于医疗废弃物焚烧系统布袋除尘器后的SCR侧线装置上,研究了不同温度条件下SCR催化对VOCs排放的影响,分别采集SCR装置进口和出口烟气,对烟气中的VOCs进行广谱筛查和定量分析;通过调控SCR装置的运行温度,研究了SCR装置运行状态对焚烧烟气中VOCs浓度和分布的影响。相关研究结果可为固体废物焚烧行业VOCs的排放管控提供参考。

-

7890B/5977A气相色谱-质谱联用仪和DB-624毛细管色谱柱(60 m × 0.32 mm × 1.80 mm)购自美国Agilent公司;TD-100热脱附仪及吸附管C2-AAXX-5032均购自英国Markes公司。

色谱级甲醇、22种VOCs混标(Custom Volatile Mix,22-1172,包括:丙酮、异丙醇、正己烷、乙酸乙酯、六甲基二硅氧烷、苯、正庚烷、3-戊酮、甲苯、乙酸丁酯、环戊酮、乳酸乙酯、乙苯、间-二甲苯、对-二甲苯、丙二醇单甲醚乙酸酯、邻-二甲苯、苯乙烯、2-庚酮、苯甲醚、1-癸烯、苯甲醛、2-壬酮、1-十二烯)及苯甲醛和乳酸乙酯混标(2-1173)均购自上海安谱有限公司。内标M-8260A/B-IS购自北京百灵威公司;Micro-reaction vessel VOCs 储备液专用瓶购自美国Supelco公司。

-

吸附管在使用前进行活化,首次使用前的活化条件为:高纯氦气100 mL·min−1,320 ℃活化2 h,再以335 ℃活化30 min;再次使用前的活化条件为:高纯氦气100 mL·min−1,335 ℃活化15 min。活化后立即用密封帽密封吸附管两端,并用密封袋密封,放入装有硅胶和活性炭的干燥器内,于4 ℃冰箱中保存,7 d内使用。

-

在某一医疗废物焚烧系统开展试验研究,该焚烧系统采用热解焚烧工艺,日处理医疗废物30 T,烟气净化系统由除酸反应塔、活性炭喷射装置和布袋除尘器组成。布袋除尘器后一部分气体进入SCR侧线装置,经SCR反应器后气体汇入烟尘气。引入SCR装置的烟气流速为57 Nm3·h−1,操作空速为8444 h−1。SCR催化剂为商用钒钛钨催化剂。采用电加热方式将SCR装置的运行温度分别控制在200、250、300 、350 ℃,分别在SCR装置的进口和出口处采集烟气样品。在SCR装置运行温度达到预设温度稳定运行4h后开始采集烟气样品,每个温度条件下3次重复采样。参照HJ 732进行采样,用3升聚氟乙烯(Tedlar)气袋采样,采烟气约2 L。采气结束后立即将气袋与吸附采样管连接,并以36 mL·min−1的恒定流速对VOCs进行富集,采样体积为1 L。

-

热脱附:以高纯氮气为载气,流速为50 mL·min−1;传输线温度为180 ℃;吸附管预脱附时间为1 min;一级热脱附温度为300 ℃,一级热脱附时间为3 min;冷阱(U-T11GPC-2S,Markes)温度为−20 ℃,升温速率为40 ℃·min−1,二级热脱附温度为320 ℃,二级热脱附时间为3 min;分流比为5∶1。

气相色谱-质谱:以高纯氦气为载气;柱流速为2.0 mL·min−1;进样口温度为180 ℃。色谱柱升温程序为:起始温度为35 ℃,保持5 min,以6 ℃·min−1的速率升温至100 ℃,再以20 ℃·min−1的速率升温至220 ℃,保持6 min。质谱电离源为:电子轰击(EI)源,温度为250 ℃;传输线温度为250 ℃;四极杆温度为150 ℃。扫描模式:全扫描;扫描范围:m/z35~300。

-

采用固相吸附-热脱附/气相色谱-质谱法对采集烟气中的VOCs进行分析。对在24种VOCs混合标样(混标22-1172和2-1173)范围内的目标VOCs,通过与标样保留时间和质谱图比较来实现定性,以内标法进行定量。由于间二甲苯和对二甲苯在色谱柱上分不开,因此这两种物质浓度以总和的形式给出。非目标化合物的定性主要依靠对样品总离子流色谱图中的未知峰进行人工谱图处理、解卷积和谱图库检索来实现,检索匹配度限值设定为80%。非目标化合物的定量则通过参照同种类已知目标VOCs的相对响应因子来进行估算。

检出的VOCs种类及其在烟气中的平均含量如表1所示。在15个烟气样品中共鉴定出46种VOCs,其中包括9种烷烃、1种烯烃、4种卤代烃、5种芳烃、3种醇、5种酮、2种醛、3种醚、2种酚、2种脂肪酸、5种脂肪酸酯、1种酰胺、1种硅氧烷和3种腈类化合物。在15个烟气样品中共监测到72个色谱峰,鉴定出VOCs的总色谱峰面积占所有色谱峰总面积的73.5%—99.6%,其平均值为84.8%,这意味着绝大多数烟气中VOCs成分被鉴定出。

-

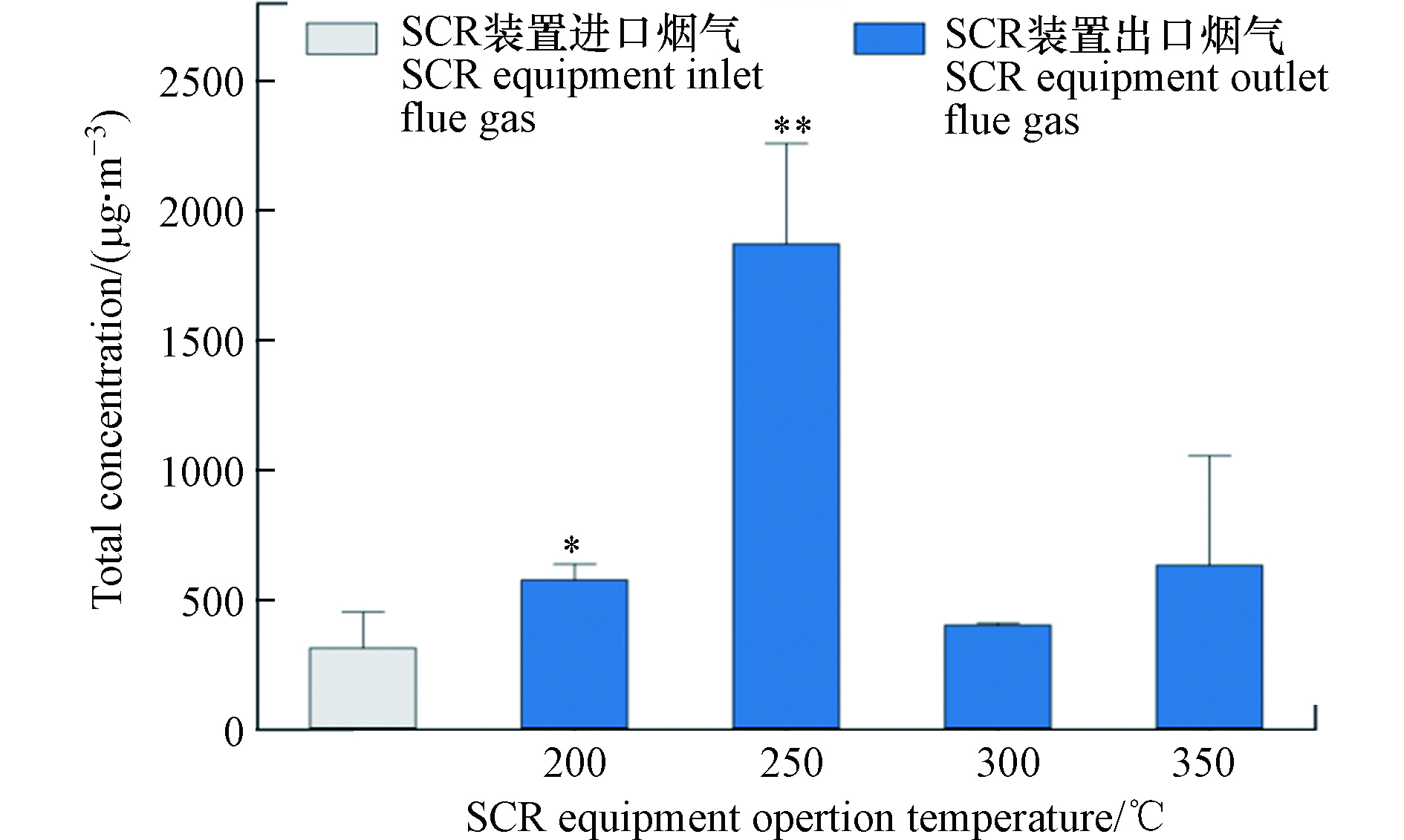

通过计算烟气中鉴定出VOCs的总浓度,研究了SCR装置运行温度对烟气VOCs排放水平的影响。在SCR装置进口烟气中鉴定出VOCs的总浓度变化范围为210.5–473.2 μg·m−3,平均值为313.3 μg·m−3。此浓度水平与Liu等报道的某垃圾焚烧发电厂烟囱气中VOCs的总浓度比较接近(平均值270.6 μg·m−3)[10]。

如图1所示,SCR装置的运行不但没有导致焚烧烟气中VOCs总量下降,反而增加了VOCs的排放。当SCR装置运行温度为200 ℃和250 ℃时,在其出口烟气中鉴定出VOCs的总浓度变化范围分别为518.0–641.8 μg m−3和1463.3–2233.4 μg m−3,显著高于SCR装置进口烟气中VOCs总浓度。烟气通过运行温度为200 ℃和250 ℃的SCR装置后,其VOCs总浓度的均值分别增加了0.8倍和5.0倍。当SCR运行温度增加到300 ℃和350 ℃时,其出口烟气中鉴定出VOCs的总浓度与运行温度为250 ℃时相比大幅降低,但其均值仍明显高于SCR装置进口烟气中VOCs总浓度的均值。

固体废物焚烧烟气中有机污染物组成复杂,除VOCs外还含有较多的二噁英、多环芳烃(PAHs)等半挥发性有机物(SVOCs)。固体废物焚烧烟气经SCR装置后VOCs浓度升高有可能主要是因为:①VOCs没有被完全降解;②SVOCs经SCR催化剂催化后形成分子量更小的VOCs。陈进生等[14]的研究发现,SCR装置会促进PAHs的生成,尤其是导致低环PAHs含量的增加。Busca等[15]和Finocchio等[16]的研究发现,商用钒钛钨催化剂对碳氢化合物和氧化物具有较低的催化活性,并产生大量的部分氧化产物,也就是不能实现对VOCs的完全降解,而只是使一种VOCs转化成另外一种VOCs。另外,Setyan等的研究中指出,温度是驱动VOCs在气体和颗粒物中分配转移的重要参数,即温度越高就会有越多原本吸附在颗粒物上的VOCs转移至气相中[2]。在本研究中,SCR装置进口烟气的温度为120 ℃,而SCR装置的运行温度为200–350 ℃;较高的运行温度可促进有机物从颗粒相向气相中迁移,从而造成SCR装置出口烟气中VOCs浓度增加。SCR装置运行温度为250 ℃时出口烟气中VOCs的浓度达到最高值。随着运行温度增加到300 ℃和350 ℃,出口烟气中VOCs的浓度与250 ℃时相比大幅降低,这应该是因为,在较高的温度下,SCR催化剂更好地发挥了催化降解VOCs的效果。

-

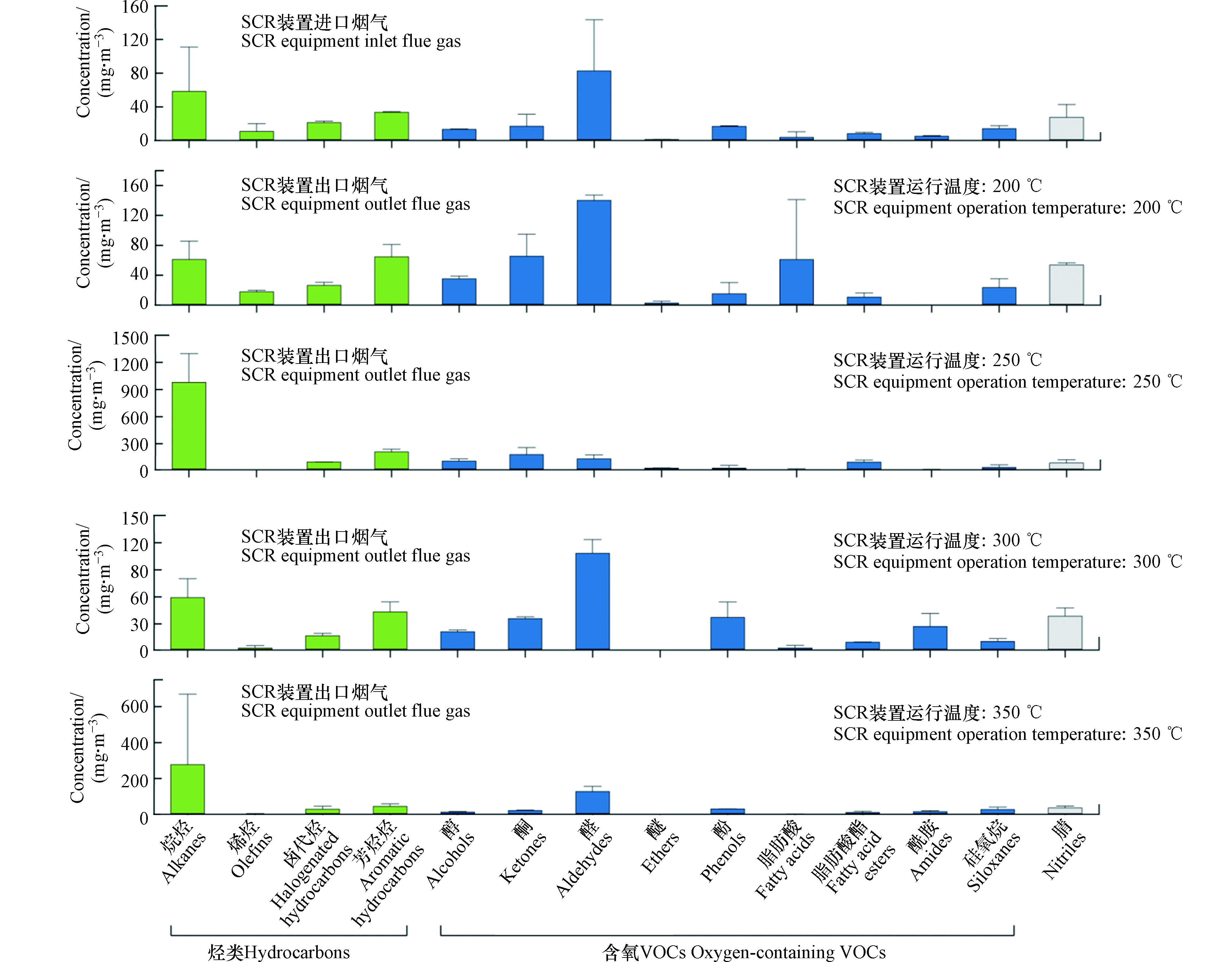

焚烧烟气中不同种类VOCs的浓度水平及分布如表1和图2所示。在SCR装置进口烟气中共检出32种VOCs,排放量相对较高的种类包括:烷烃、醛、芳烃、腈和卤代烃,其浓度所占VOCs总浓度比例分别为18.7%、26.4%、10.7%、8.8%和6.8%。Setyan等对瑞士两个垃圾焚烧发电厂排放烟气中VOCs的监测结果表明,排放的VOCs主要为烷烃和芳烃[2]。在我们之前的研究工作中也发现,烷烃类化合物在垃圾焚烧排放VOCs中占有较高的比例[16]。本研究中,固体废物焚烧排放的芳烃主要是苯系物,即苯、甲苯、二甲苯以及乙苯(表1)。Chagger等[17]和Chen等[18]的研究发现,甲苯是垃圾焚烧的一种主要产物。苯系物也是煤燃烧排放VOCs的主要组成[19-20]。苯系物广泛存在于环境空气中,具有较强的毒性和致癌性,可对人体健康造成严重危害。固体废物焚烧排放的腈类化合物主要是乙腈和苯甲腈(表1),均具有较强的环境毒性;醛类化合物主要是苯甲醛,该物质在固定源废气中较为常见[21-22]。排放的卤代烃类化合物浓度为(21.2 ± 1.8)μg m−3,与Liu等在广州某垃圾焚烧发电厂烟气中检出的卤代烃类化合物的浓度较为接近((31.1 ± 3.0)μg m−3)[10]

SCR装置的运行显著改变了焚烧烟气中VOCs的组成分布。在通过SCR装置后,所有鉴定出的VOCs中,壬醛和苯乙酮的浓度大幅降低,其他化合物的浓度或升高或无明显改变(表1)。SCR的运行温度也会显著影响不同种类VOCs在烟气中的含量。当200 ℃时,出口烟气中含氧VOCs的浓度明显增加,尤其是酮和脂肪酸的相对含量增加较大(图2)。而当SCR装置运行温度为250 ℃时,出口烟气中烃类VOCs的浓度大幅增加,尤其是烷烃;出口烟气中烷烃的平均浓度高达973.6 μg m−3,与SCR装置进口烟气中烷烃平均浓度相比增加了15.6倍。可能是由于在200 ℃时,酮和脂肪酸会从颗粒物脱附,而酮和脂肪酸容易氧化,250 ℃时在V-W-Ti催化剂表面能够催化分解;而通常烷烃类容易脱附,烷烃类增多可能是由于其他VOCs的不完全降解或半挥发性有机物的催化分解;但烷烃在该催化剂上较低的温度条件下,难以转化。当SCR装置运行温度为300 ℃时,出口烟气中N,N-二甲基乙酰胺和苯酚的相对含量增加明显,可能是由于它们高的沸点需要较高的温度才能从颗粒物脱附。而当SCR装置运行温度为350 ℃时,由于V-W-Ti催化剂对于长链有机物以及容易降解的有机物具有一定的催化活性,但其低的低碳烷烃降解活性,导致出口烟气中烷烃的浓度又大幅增加;出口烟气中烷烃的平均浓度为276.6 μg m−3,与SCR装置进口烟气中烷烃平均浓度相比增加了3.7倍。

-

医疗废物焚烧过程产生的VOCs成分比较复杂,包括烷烃、烯烃、卤代烃、芳烃、醇、酮、醚、醛、酚、脂肪酸、脂肪酸酯、酰胺、硅氧烷和腈类化合物。在医疗废物焚烧系统的布袋除尘器后安装SCR脱硝装置导致了VOCs的大气排放浓度明显增加。当SCR装置运行温度为200 ℃和250 ℃时,排放烟气中鉴定出VOCs的总浓度均值分别增加了0.8倍和5.0倍。通常,200—250 ℃是固体废物焚烧系统烟气SCR装置的正常运行温度。因此,在后续的商业催化剂研制过程中应兼顾SCR装置运行导致VOCs排放增加的风险。

选择性催化还原装置对固体废物焚烧过程挥发性有机物排放的影响

Influence of selective catalytic reduction equipment on the emission of volatile organic compounds from the incineration of solid waste

-

摘要: 在某一大型医疗废物焚烧系统研究了选择性催化还原(SCR)装置的运行温度(200—350 ℃)对挥发性有机物(VOCs)大气排放的影响。采用固相吸附-热脱附/气相色谱-质谱法对SCR装置进口和出口处烟气中的VOCs进行分析。在焚烧烟气中共鉴定出46种VOCs,包括烷烃、烯烃、卤代烃、芳烃、醇、酮、醚、醛、酚、脂肪酸、脂肪酸酯、酰胺、硅氧烷和腈类化合物。在SCR装置进口烟气中鉴定出VOCs的总浓度均值为313.3 μg·m−3。SCR装置的运行导致VOCs的大气排放浓度明显增加。当SCR装置运行温度为200 ℃和250 ℃时,排放烟气中鉴定出VOCs的总浓度均值分别增加了0.8倍和5.0倍。SCR装置的运行也显著改变了焚烧烟气中VOCs的组成分布。当SCR装置运行温度为200 ℃时,出口烟气中含氧VOCs的浓度大幅增加,尤其是酮和脂肪酸。当SCR装置运行温度为250 ℃和350 ℃时,排放烟气中鉴定出烷烃的平均浓度分别增加了15.6倍和3.7倍。导致SCR装置出口烟气中VOCs增加的主要原因可能为:VOCs没有被完全降解,半挥发性有机物经SCR催化剂催化后形成分子量更小的VOCs,较高的运行温度促进了VOCs从颗粒相向气相中迁移。Abstract: The effect of the operation temperature of selective catalytic reduction (SCR) equipment on the atmospheric emission of volatile organic compounds (VOCs) was investigated on a full-scale medical waste incineration system. Sorbent adsorption-thermal desorption/gas chromatography-mass spectrometry method was adopted to analyze the composition of VOCs in flue gases at the inlet and outlet of SCR equipment. A total of 46 VOCs were identified, including alkanes, olefins, halogenated hydrocarbons, aromatic hydrocarbons, alcohols, ketones, ethers, aldehydes, phenols, fatty acids, fatty acid esters, amides, siloxanes and nitriles. The average total concentration of identified VOCs in the inlet of SCR equipment was measured to be 313.3 μg·m−3. The operation of SCR equipment induced an obvious increase in the emission concentration of VOCs. When the SCR equipment was operated at 200 ℃ and 250 ℃, the average emission concentrations of total identified VOCs were increased by 0.8-fold and 5.0-fold, respectively. The operation of SCR equipment also induced a remarkable variation in the compositional distribution of VOCs in the flue gas. When the SCR equipment was operated at 200 ℃, the concentrations of oxygen-containing VOCs especially ketones and fatty acids in the flue gas at the outlet of SCR equipment were increased largely. When the SCR equipment was operated at 250 ℃ and 350 ℃, the average emission concentrations of total identified alkanes were increased by 15.6-fold and 3.7-fold, respectively. The possible main reasons for the increase in the concentration of VOCs in the flue gas at the outlet of SCR equipment were speculated as: incomplete degradation of VOCs, transformation of semi-volatile organic compounds to VOCs with smaller molecular weight, temperature-induced transfer of VOCs from the particle phase into the gas phase.

-

-

表 1 SCR装置进口和出口处烟气中鉴定出的VOCs种类及其平均浓度

Table 1. Species and average concentrations of identified VOCs in combustion flue gases at the inlet and outlet of SCR equipment

序号

No.化合物

Compounds保留时间/min

Retention timeSCR装置进口烟气浓度/(μg·m−3)

SCR equipment inlet Flue gasSCR装置出口处烟气浓度/(μg·m−3)

SCR equipment outlet flue gasSCR装置运行温度

SCR equipment operation temperature200 ℃ 250 ℃ 300 ℃ 350 ℃ 1 1-异氰基丁烷b 4.49 0.7 1.2 7.7 1.6 2.1 2 2-甲基丁烷b 5.96 26.4 28.0 511.8 32.6 169.0 3 正戊烷b 6.68 14.0 13.1 338.5 12.2 81.9 4 乙醇b 7.05 6.4 16.4 28.6 8.7 6.5 5 丙酮a 8.01 10.6 32.4 116.3 23.4 10.6 6 异丙醇a 8.37 5.3 15.6 66.7 8.7 5.6 7 乙腈b 8.72 14.5 23.1 51.5 18.1 14.5 8 乙酸甲酯b 8.82 n.d. n.d. 7.1 0.3 n.d. 9 二氯甲烷b 9.04 20.8 26.4 75.4 16.0 28.5 10 环戊烷b 9.18 n.d. n.d. n.d. n.d. 3.1 11 3-甲基戊烷b 9.65 0.4 6.8 41.1 1.7 0.6 12 正己烷a 10.27 17.7 12.6 40.2 22.0 22.0 13 丙基环丙烷b 11.67 n.d. 0.5 7.8 0.9 n.d. 14 2-丁酮b 11.99 0.4 1.0 14.4 1.0 0.3 15 乙酸乙酯a 12.12 3.4 6.5 50.8 3.0 12.8 16 四氢呋喃b 12.57 1.2 2.7 2.2 n.d. n.d. 17 三氯甲烷b 12.65 n.d. n.d. 1.1 n.d. n.d. 18 2,4-二甲基戊烷b 13.02 n.d. n.d. 5.1 n.d. n.d. 19 环己烷b 13.13 n.d. n.d. 17.6 n.d. n.d. 20 3-甲基己烷b 13.41 n.d. n.d. 11.6 n.d. n.d. 21 苯a 13.82 6.1 15.1 21.3 5.6 6.4 22 1,2-二氯乙烷b 13.89 0.4 n.d. 6.2 n.d. n.d. 23 乙酸b 14.04 1.0 57.3 n.d. 0.3 1.0 24 3-己酮b 14.35 n.d. 17.2 3.6 n.d. n.d. 25 1-丁酮b 15.05 n.d. 4.2 25.9 2.3 0.4 26 过氧化二叔丁基b 16.34 n.d. n.d. 12.4 n.d. n.d. 27 乙酸仲丁酯b 17.42 n.d. n.d. 9.9 n.d. n.d. 28 甲苯a 17.65 11.1 21.1 96.5 19.9 22.4 29 六甲基环三硅氧烷b 18.18 14.1 23.5 24.9 9.5 26.8 30 1,1,2-三氯乙烷b 18.27 n.d. n.d. 4.4 n.d. n.d. 31 乙酸丁酯a 18.76 5.9 6.1 7.5 5.3 6.0 32 正丁醚b 19.70 n.d. n.d. 3.5 n.d. n.d. 33 乙苯a 19.76 4.2 6.3 16.7 4.1 4.2 34 间,对-二甲苯a 19.89 7.1 14.7 48.2 7.8 6.8 35 2-丙烯酸丁酯b 20.28 n.d. n.d. 10.0 n.d. n.d. 36 邻-二甲苯a 20.38 4.9 7.3 15.9 4.9 5.0 37 N,N-二甲基乙酰胺b 20.80 5.0 n.d. 1.7 26.3 15.0 38 苯甲醛a 21.84 76.7 139.3 118.4 106.7 124.4 39 D-柠檬烯b 22.04 10.8 17.8 n.d. 2.2 2.2 40 2-乙基-1-己醇b 22.28 1.4 3.1 1.3 2.9 1.2 41 苯甲腈b 22.32 12.4 29.3 18.3 18.4 18.7 42 苯酚b 22.53 15.3 4.3 17.5 31.9 29.6 43 壬醛b 23.14 6.1 0.8 3.9 1.1 3.2 44 苯乙酮b 23.18 17.9 10.5 12.4 8.2 10.4 45 2-乙基己酸b 23.47 8.3 3.8 13.9 2.9 n.d. 46 2-硝基酚b 24.14 4.3 10.7 nd 6.7 1.6 注:a,用标准品准确定量;b,通过同类化合物相对响应因子估算含量;n.d.,未检出.

Note: a, quantified with standard substance; b, contents estimated with relative response factor of similar compounds; n.d., not detected. -

[1] 俞明锋, 付建英, 詹明秀, 等. 生活废弃物焚烧处置烟气中二(口恶)英排放特性研究 [J]. 环境科学学报, 2018, 38(5): 1983-1988. YU M F, FU J Y, ZHAN M X, et al. The research of PCDD/Fs emission characteristics in flue gas from municipal solid waste incinerations [J]. Acta Scientiae Circumstantiae, 2018, 38(5): 1983-1988(in Chinese).

[2] SETYAN A, PATRICK M, WANG J. Very low emissions of airborne particulate pollutants measured from two municipal solid waste incineration plants in Switzerland [J]. Atmospheric Environment, 2017, 166(octa): 99-109. [3] BEYLOT A, HOCHAR A, MICHEL P, et al. Municipal solid waste incineration in France: an overview of air pollution control techniques, emissions, and energy efficiency [J]. Journal of Industrial Ecology, 2018, 22(5): 1016-1026. doi: 10.1111/jiec.12701 [4] TIAN H Z, GAO J J, LU L, et al. Temporal trends and spatial variation characteristics of hazardous air pollutant emission inventory from municipal solid waste incineration in China [J]. Environmental Science & Technology, 2012, 46(18): 10364-10371. [5] ZHOU Q, YANG J X, LIU M M, et al. Toxicological risk by inhalation exposure of air pollution emitted from China's municipal solid waste incineration [J]. Environmental Science & Technology, 2018, 52(20): 11490-11499. [6] YANG L L, ZHENG M H, ZHU Q Q, et al. Inventory of polychlorinated naphthalene emissions from waste incineration and metallurgical sources in China [J]. Environmental Science & Technology, 2020, 54(2): 842-850. [7] HUANG B B, LEI C, WEI C H, et al. Chlorinated volatile organic compounds (Cl-VOCs) in environment - sources, potential human health impacts, and current remediation technologies [J]. Environment International, 2014, 71: 118-138. doi: 10.1016/j.envint.2014.06.013 [8] 付昱萌, 杨红刚, 卢民瑜, 等. 鄂州市大气VOCs污染特征及来源解析 [J]. 环境科学, 2020, 41(3): 1085-1092. FU Y M, YANG H G, LU M Y, et al. Analysis of pollution characteristics and sources of atmospheric VOCs in Ezhou city [J]. Environmental Science, 2020, 41(3): 1085-1092(in Chinese).

[9] VARUTBANGKUL V, BRECHTEL F J, BAHREINI R, et al. Hygroscopicity of secondary organic aerosols formed by oxidation of cycloalkenes, monoterpenes, sesquiterpenes, and Related Compounds[J]. Atmospheric Chemistry and Physics 2006, 6: 2367–2388. [10] LIU S L, WANG B G, HE J, et al. Source fingerprints of volatile organic compounds emitted from a municipal solid waste incineration power plant in Guangzhou, China [J]. 2011 International Conference of Environmental Science and Engineering. Procedia Environmental Sciences, 2012, 12: 103-115. [11] 任美慧, 樊芸, 王胜, 等. SCR装置对焦炉煤气燃烧废气中PCDD/Fs、PCBs和PCNs的协同脱除 [J]. 环境科学, 2019, 40(1): 143-148. REN M H, FAN Y, WANG S, et al. Simultaneous removal of polychlorinated dibenzo-p-dioxins/dibenzofurans, polychlorinated biphenyls, and polychlorinated naphthalenes from flues gases from coke gas burning using selective catalytic reduction equipment [J]. Environmental Science, 2019, 40(1): 143-148(in Chinese).

[12] LIU X L, WANG J, WANG X, et al. Simultaneous removal of PCDD/Fs and NOx from the flue gas of a municipal solid waste incinerator with a pilot plant [J]. Chemosphere, 2015, 133: 90-96. doi: 10.1016/j.chemosphere.2015.04.009 [13] GALLASTEGI-VILLA M, ARANZABAL A, GONZALEZ-MARCOS J A, et al. Tailoring dual redox-acid functionalities in VOx/TiO2/ZSM5 catalyst for simultaneous abatement of PCDD/Fs and NOx from municipal solid waste incineration [J]. Applied Catalysis B:Environmental, 2017, 205: 310-318. doi: 10.1016/j.apcatb.2016.12.020 [14] 陈进生, 袁东星, 洪有为, 等. 烟气催化脱硝装置对多环芳烃排放特性的影响 [J]. 燃料化学学报, 2007, 35(6): 722-726. doi: 10.1016/S1872-5813(08)60006-7 CHEN J S, YUAN D X, HONG Y W, et al. Effect of catalytic de-Nox device on the emission characteristics of polycyclic aromatic hydrocarbon in flue gas [J]. Journal of Fuel Chemistry and Technology, 2007, 35(6): 722-726(in Chinese). doi: 10.1016/S1872-5813(08)60006-7

[15] BUSCA G, BALDI M, PISTARINO C, et al. Evaluation of V2O5-WO3-TiO2 and alternative SCR catalysts in the abatement of VOCs [J]. Catalysis Today, 1999, 53(4): 525-533. doi: 10.1016/S0920-5861(99)00140-6 [16] FINOCCHIO E, BALDI M, BUSCA G, et al. Study of the abatement of VOC over V2O5-WO3-TiO2 and alternative SCR catalysts [J]. Catalysis Today, 2000, 59(3): 261-268. [17] CHAGGER H K, JONES J M, POURKASHANIAN M, et al. The formation of VOC, PAH and dioxins during incineration [J]. Process Safety and Environmental Protection, 2000, 78: 53-59. doi: 10.1205/095758200530457 [18] CHEN J C, HUANG J S, CHEN C M, et al. Emission characteristics of PAHs, benzene and phenol group hydrocarbons in O2/RFG waste incineration processes [J]. Fuel, 2008, 87: 2787-2797. doi: 10.1016/j.fuel.2008.02.012 [19] LIU J, WANG J W, CHENG J, et al. Distribution and emission of speciated volatile organic compounds from a coal-fired power plant with ultra-low emission technologies [J]. Journal of Cleaner Production, 2020, 264: 121686. doi: 10.1016/j.jclepro.2020.121686 [20] CHENG J, ZHANG Y S, WANG T, et al. Emission of volatile organic compounds (VOCs) during coal combustion at different heating rates [J]. Fuel, 2018, 225: 554-562. doi: 10.1016/j.fuel.2018.03.185 [21] JAY K, STIEGLITZ L. Identification and quantification of volatile organic components in emissions of waste incineration plants [J]. Chemosphere, 1995, 30(7): 1249-1260. doi: 10.1016/0045-6535(95)00021-Y [22] 陈海秀, 李军, 李冠华. 固体吸附-热脱附/气相色谱-质谱法测定固定污染源废气中50种挥发性有机物 [J]. 环境监控与预警, 2020, 12(1): 36-40. CHEN H X, LI J, LI G H. Determination of 50 volatile organic compounds in stationary source emission [J]. Environmental Monitoring and Forewarning, 2020, 12(1): 36-40(in Chinese).

-

下载:

下载: