-

机动车(包括汽车、低速汽车、摩托车、挂车和拖拉机等)尾气排放的污染物,如一氧化碳(CO)、未完全燃烧的碳氢化合物(HC)、氮氧化物(NO和NO2,统称NOx)和颗粒物PM(由碳黑Soot内核及其表面吸附的可溶性有机物构成)等,是大气污染的重要来源,也是造成细颗粒物(PM2.5)、臭氧(O3)和光化学烟雾等污染的重要原因。作为汽车尾气污染的典型案例,发生于1940年至1960年间的美国洛杉矶光化学烟雾事件推动了1970年版美国《Clean Air Act(清洁空气法)》的出台,以及1975年将催化净化器引入到汽车尾气处理中[1]。

自2009年以来,我国已连续十一年成为世界机动车产销第一大国,汽车是机动车污染物排放总量的主要贡献者,其排放的CO、HC、NOx和PM等4项主要污染物均超过机动车排放的90%[2]。济南市2017年大气污染源解析结果表明,机动车排放对济南市PM2.5的分担率为32.6%,居各项来源之首,排放的NOx占济南市总排放的65.5%,是第一大贡献源,汽车尾气污染对我国大中城市环境空气质量的影响尤为严重,已直接威胁人民群众的健康和生活[3]。汽油车(燃料为汽油)在机动车中占比较高,是我国乘用车的主要形式,由中国汽车工业协会、社会科学文献出版社等共同发布的《汽车工业蓝皮书:中国汽车工业发展报告(2020)》表明,2019年乘用车占我国该年汽车销量的83.2%,已连续8年超过80%,抓好汽油车尾气污染治理是城市机动车尾气污染控制的关键环节[4]。

面对汽车尾气污染的严峻形势及国家的紧迫要求,本文首先简要介绍了汽油车划时代技术—三效催化剂(three way catalysts,简称TWC)的基本原理,接着回顾了世界(美国为代表)治理汽车尾气45年的发展历史,特别是近20年来我国在TWC方面的技术进步和实践,然后重点介绍了稀土储氧材料、载体和涂覆技术、密偶催化剂和四效催化剂等方面的进展,最后对TWC技术的未来和更环保节能的汽油车尾气后处理技术,进行了展望和畅想。

-

目前,汽油车和天然气车尾气治理的商业化技术是使用TWC控制污染物的排放,即通过ECU电控系统(Electronic control unit, ECU)、采用闭环的方式,控制发动机在化学当量空燃比(约14.7)附近运转,催化剂将尾气中的3种污染物,即CO、HC和NOx同时转化为二氧化碳(CO2)、氮气(N2)和水(H2O),实现3种主要污染在一个催化剂上同时消除,因此称为三效催化剂。主反应为公式(1—3):

其它化学反应还有公式(4—5)

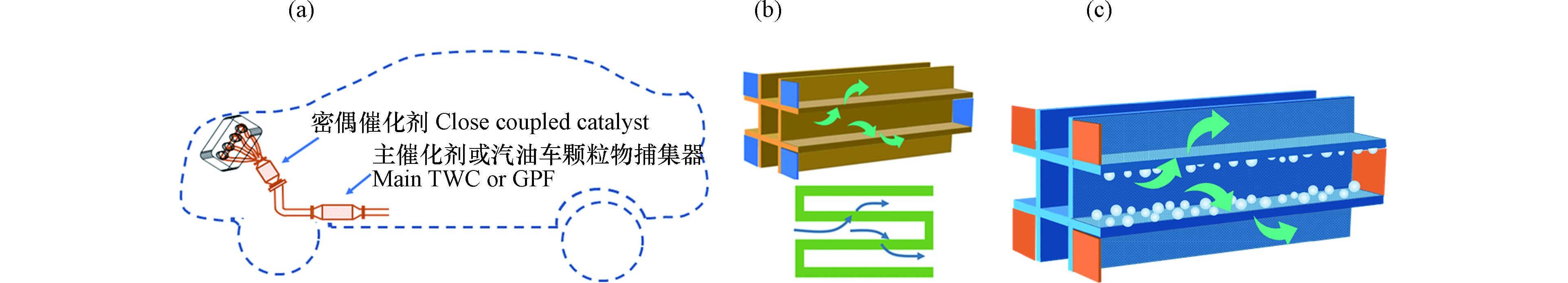

TWC主要组成包括Pt、Pd和Rh贵金属活性成分,稀土储氧材料(助剂),氧化铝(γ-Al2O3)涂层和蜂窝载体(图1)。其中,稀土储氧材料为铈(Ce)基固溶体或复合氧化物,γ-Al2O3为贵金属和铈基复合氧化物的第二载体,又称水洗层,为提高其热稳定性,通常添加镧(La)或钡(Ba)等结构稳定剂,再将贵金属-储氧材料-氧化铝制成的浆料涂覆到蜂窝载体上。

TWC是在公众产品市场上使用催化技术的最显著成就之一,也是最为公众所熟知的一种催化剂,对环境保护和污染物减排具有划时代的重大意义。

-

Farrauto等[1]以美国为代表,将国外的汽油车尾气催化剂发展分成了下列几个阶段,如图2。

1975—1980年:第一代氧化型催化剂,由美国Engerlhard公司(2006年被美国BASF公司收购)开发,主要活性成分为Pt和Pd,用来消除CO和HC,而NOx则通过废气再循环(exhaust gas recirculation,EGR)来降低,满足了美国1975年的排放标准。但是由于当时的汽油中普遍添加含铅(Pb)的添加剂用来提高汽油辛烷值,催化剂一直受到Pb毒化的困扰,直到九十年代取消含铅添加剂才使得后来的技术突破成为可能。

1980—现在:随着对NOx排放限值的加严,起还原作用的Rh作为催化活性成分加入到TWC中,形成Pt/Pd/Rh活性成分。发动机则通过氧传感器闭环控制空燃比(空气质量/汽油质量)在理论值(即14.7)附近,实现了CO、HC和NOx的同时催化净化,即汽油车尾气治理迎来了TWC时代。

1995—2018年:由于Pt和Rh的价格较高,美国Engerlhard公司(现为BASF)开发了与Pt-Rh体系性能相当的全Pd催化剂,并被Ford等公司投入商用。其中,在2007—2008年,由于Rh的价格急剧上涨,曾掀起过降低Rh含量的热潮。

2018—现在:全Pd催化剂推动了Pd的价格大涨,同时为满足排放法规对NOx更严格的限值要求,Pd基TWC中添加了少量Rh,形成Pd/Rh活性成分,并主要在密偶催化剂中使用,而在常规的主催化剂中则是Pt/Rh体系。

目前巴斯夫(BASF),庄信(Johnson Matthey)和优美科(Umicore)等三大外资公司占据世界TWC市场主要份额,但是经过40多年的研发、特别是近20年的产业化实践,我国TWC技术的发展进步明显,生产规模随着国产汽车产业的快速发展也迅速扩大。

我国的汽车尾气催化剂研究起源于上世纪七十年代末,以华东理工大学[5]、中国科学技术大学[6-7]、中科院长春应化所[8]和北京工业大学[9]等单位为主要代表。1990年北京亚运会后,在我国曾掀起汽车尾气催化剂研究和产业化的热潮,但是直到上世纪九十年代后期,都没有形成规模化的产业,而且还经历了氧化型催化剂(化油器车辆)和抗铅催化剂等弯路。上世纪九十年代中后期,即1999年无铅汽油和电喷技术在全国推行,我国才迎来汽车尾气催化剂的春天。清华大学[10]、浙江大学[11]、天津大学[12]、中国科学院生态环境研究中心[13]、四川大学[14]、南昌大学[15]、昆明贵金属研究所[16]、福州大学[17]、北京理工大学[18]和济南大学[19]等一批研究力量如雨后春笋般涌现,无锡威孚力达催化净化器有限公司、昆明贵研催化剂有限责任公司、海南六合环保催化剂有限公司[20-21]、重庆海特汽车排气系统有限公司等TWC企业也应运而生,为2001年国家发布的GB18352.1—2001《轻型汽车污染物排放限值及测量方法(Ⅰ)》(即国Ⅰ标准)顺利实施提供了技术和产品支撑。随着国家标准的逐步加严,2005年后又催生了中自环保科技股份有限公司、宁波科森净化器制造有限公司、山东艾泰克环保科技股份有限公司等一批TWC生产企业。2009年由清华大学翁端教授、华东理工大学卢冠忠教授和天津大学沈美庆教授等完成的“稀土催化材料及在机动车尾气净化中应用”获国家科技进步奖二等奖。特别值得一提的是,2015年无锡威孚力达催化净化器有限公司获得GM国Ⅴ平台120万台轿车催化剂配套订单,开创自主品牌催化剂进入国际主流汽车品牌先河,具有里程碑意义。但是,合资品牌汽车的催化器市场仍主要由巴斯夫、庄信万丰和优美科等外资品牌占据,国内企业则主要为国产品牌汽车配套。

我国汽油车新车国家排放标准基本遵循欧洲路线,比如欧Ⅰ与国Ⅰ相当,虽然我国国Ⅰ标准在2000年才开始实施,比欧Ⅰ实施时间1993年晚了7年,但是在2020年我国就开始执行与欧Ⅵ相当的国Ⅵ标准(图2),而欧洲目前实施的正是欧Ⅵ标准,我国仅用20年基本赶上排放限值的国际水平。

在新的国内外形势下,2019年由天津大学牵头、联合稀土汽车催化行业产业链上下游领军企业成立了国家级稀土催化研究院。2014年以来,在济南大学支持山东艾泰克环保科技股份有限公司进军后处理市场取得显著发展的基础上,2020年双方又联合成立了“济大-艾泰克催化剂研究院”,致力于原创催化剂研发。这些新型研发机构为TWC相关产品的创新发展提供了新机会。

-

铈(Ce)基氧化物存储和释放氧气的化学原理如下:

为提高CeO2的热稳定性,一般在CeO2中掺杂锆(Zr),形成所谓的CeO2-ZrO2固溶体或复合氧化物。根据CeO2所占的摩尔百分数,一般有下列结晶相(图3a)。为提高CeO2-ZrO2的热稳定性和储氧量及氧移动性,通常加入三价稳定剂La和促进剂Y、Pr、Nd、Sm等。稀土储氧材料的发展是与排放标准的逐步提高密切相关的,历经CeO2、CeO2-ZrO2、CeZr(La/Y/Pr/Nd)四元和五元复合氧化物等4个阶段,满足从国Ⅰ/Ⅱ、国Ⅲ/Ⅳ、国Ⅴ到国Ⅵ排放标准(图3b)[22]。稀土储氧材料调节TWC空燃比性能的原理如图3c所示,一旦储/放氧量下降,不能调节尾气中的氧含量,车载诊断系统(OBD)则判断TWC失效,因此储氧材料在TWC技术中具有不可或缺的重要作用。

比利时Solvay、日本DKKK、加拿大AMR等三家企业占据国际稀土储氧材料70%以上的市场份额,国内著名的铈锆固溶体生产企业,如淄博加华新材料资源有限公司系加拿大AMR独资企业。近年来,国内稀土储氧材料企业正逐步成长,并正在突破国外专利封锁,抢占铈锆固溶体制高点和部分市场份额。

-

除了上述催化材料取得的巨大进展,在蜂窝载体、氧化铝、浆料制备、分层和分区涂覆技术、以及真空和定量涂覆等方面的提高,也是TWC性能强化的有效组成部分。

蜂窝载体一般分为堇青石(Cordierite,成分为 2MgO-5SiO2-2Al2O3)陶瓷蜂窝和金属(FeCrAl)蜂窝两种。从表1可以看出,堇青石陶瓷蜂窝载体随蜂窝的目数(cpsi:cells per square inch)增加,几何表面积依次增加,而壁厚逐渐降低至0.051 mm,制造难度也逐步增加。高端的堇青石陶瓷蜂窝载体制备技术主要被美国康宁(Corning)公司和日本NGK公司控制,山东奥福环保科技股份有限公司是国内掌握薄壁、低热膨胀系数蜂窝陶瓷技术的代表性企业(2019年11月在科创版上市)。金属蜂窝的背压低,但催化剂与载体的表面结合强度较差,主要用于高端轿车和摩托车,以及电加热辅助快速起燃的情况,比如在新兴的油电混动汽车的密偶催化剂中[23]。

高比表面积和热稳定的γ-Al2O3是TWC活性成分的载体,起到分散活性成分、防止烧结和提高利用率等作用。国外用于TWC制造的高纯纳米γ-Al2O3生产企业有日本住友、SOSAL等。我国是氧化铝生产大国,TWC用γ-Al2O3生产企业众多,如山东国瓷功能材料股份有限公司、山东晶鑫晶体科技有限公司、宣城晶瑞新材料有限公司等,其中山东国瓷功能材料股份有限公司制定了“纳米技术-汽车尾气处理用催化剂载体纳米氧化铝-特性和测量方法”材料规范ISO国际标准(ISO/TS 23362),已于2021年1月实施,表明我国在该领域的领先地位。

将催化剂活性成分涂覆到蜂窝陶瓷载体上是汽车尾气催化剂生产的关键技术,经历了手动提拉法、机器喷涂法等阶段,目前主要由定量真空涂覆机完成,并分为上给料和下给料两种,它们的特点如表2。

一般对催化剂浆液的要求为:(i)具有良好的流动性,确保涂覆厚度均匀度;(ii)具有良好的抗沉降稳定性,避免涂覆过程中发生分层或颗粒凝聚。因此,为提高涂覆效果,可将催化剂研磨到合适的粒径分布,或者添加粘结剂比如拟薄水铝石和/或硅胶,并在一定时间内完成。当前产品不仅是简单的涂覆,还包括分层、分区等技术,比如(i)将Pd放置在最外层或入口处,既能有效地催化HC氧化,又快速提高了催化剂床层温度;(ii)高含量贵金属成分在前/上,低含量贵金属成分在后/下;(iii)与HC和NOx吸附剂组合;等等。

-

为提高汽车冷启动阶段的净化效果,将通常放置在脚踏板下的TWC安装在紧靠发动机排气歧管的排气总管中,称为密偶催化剂(close coupled catalyst,简称CCC),CCC可以在发动机启动后的10—15 s起燃,显著降低了冷启动排放(图4a)。为应对国VI排放标准,特别是对PM质量及其数量(particulate number,简称PN)的限值,将CCC体积扩大,添加稀土储氧材料并提高贵金属的含量,起到主TWC作用,而原来脚踏板下的主TWC则被替换为涂覆有TWC活性成分的GPF(图4b),称为cGPF(catalytic GPF)或FWC(four way catalyst,即四效催化剂),如图4c。该cGPF的贵金属含量一般比较低,主要功能是捕集PM、降低PN,同时密偶TWC没有转化的污染物也在cGPF上三效去除,达到国VI及以上超低排放的目标。

-

受排放法规随人类对美好环境需求逐步提升的驱动,汽车尾气催化是十分活跃的研发领域,也是公众关注的焦点,下面几点将会是未来亟待解决的关键问题。

(1)低/无贵金属技术。在满足日益严格的排放限值情况下,追求贵金属的减量化是TWC的永恒主题,比如用于天然气发动机的TWC,目前的贵金属含量高达每立方英尺100 g,近期该含量将会降到50 g,甚至30 g,由此带来的经济效益将非常显著。随着排放标准的加严,TWC中贵金属含量不升反降,五元稀土储氧材料及其与贵金属的协同作用功不可没。因此,贵金属纳米颗粒、纳米团簇、直到单原子技术,甚至非贵金属活性成分,都是未来TWC的发展方向,也是应对资源枯竭的有力举措。

(3)低温和油电混动催化技术。低温催化活性的提高是发动机节能减排的需求,美国早在2012年即提出了150 ℃起燃的挑战问题,即要求催化剂在150 ℃达到90%的污染物转化效率。另一方面,油电混动汽油车具有良好的燃油经济性,但是,与常规汽油车存在冷启动排放问题相比,在市区油电交替运行会频繁出现类冷启动现象,很容易造成更多的污染物排放,应给予足够重视。解决低温问题的途径有三个,一是增加贵金属含量,使TWC更快起燃,但成本会大幅增加;二是研发更低起燃温度的TWC,或者添加HC和NOx吸附剂,但这要依靠创新的高效TWC和吸附材料;三是利用车载电加热TWC,但受限于电池的电压和电加热效率,实用化还有一段路要走。

(4)稀燃汽油机催化技术。汽油发动机节能减排技术螺旋上升式发展,从稀燃到化学计量空燃比燃烧再回到稀燃,这时TWC对NOx的净化效率大幅降低,难以满足法规限值,而且尾气温度更低,因此选择性催化还原(selective catalytic reduction of NOx,即SCR)和NOx存储-还原(NOx storage-reduction,即NSR)或稀燃NOx捕集(lean NOx traps, 即LNT)等技术将彰显巨大的威力,这种情况同样适用于稀燃天然气发动机,因此对这些TWC替代技术的研究不但不能停止反而必须加强,才能迎接未来发动机技术转向的革命性挑战。

汽车尾气三效催化剂研究和应用40年

40 years of research and application of three-way catalysts for gasoline automobiles

-

摘要:

汽车尾气污染已成为我国大气污染的重要来源,是大气污染防治的重中之重。三效催化剂(TWC)是汽油车和天然气车尾气治理的商业化技术,也是在公众产品市场上使用催化技术的最显著成就之一,对汽车尾气污染物减排具有划时代的重大意义。本文首先简要介绍了TWC的基本原理,回顾了世界(美国为代表)治理汽车尾气40多年的发展历史,特别是近20年来我国在TWC方面的技术进步和实践,然后重点介绍了稀土储氧材料、载体和涂覆技术、密偶催化剂和四效催化剂等进展,最后针对未来低油耗和低CO2排放的汽车需求,展望了未来的TWC和稀燃发动机尾气催化净化技术。

Abstract:Automobile exhaust has become an important source of air pollution in China, which is the key point for air pollution control. The commercial technology for treatment of automobile exhaust from gasoline and natural gas engines is three-way catalyst (TWC), the most remarkable achievement of catalysis application in the public market, implying an unprecedented significance for pollutant removal. Herein, the basic theory of TWC is first introduced followed with a chronological review of forty-years development of TWC in the world, and especially twenty-years R&D in China. Then, recent progresses on oxygen storage materials based on rare-earth oxides, honeycomb supports, coating techniques, close-coupled catalysts and four-way catalysts are highlighted. Finally, the prospective TWCs and catalytic technologies for lean-burn engines with low gasoline consumption and CO2 emission are proposed.

-

-

表 1 蜂窝陶瓷的物理性能

Table 1. Physical properties of honeycomb substrates

目数/cpsi

Mesh number壁厚/mm

Wall thickness壁厚/ mil

Wall thickness几何表面积/(m2·L−1)

Geometric surface area开口面积率/%

Open facial area200 0.305 12 1.8 68.9 300 0.125 5 2.5 83.4 400(Ceramic) 0.101 4 2.9 84.6 400(FeCrAl) 0.04 1.6 3.2 92 600 0.076 3 3.6 85.8 750 0.063 2.5 4.0 86.8 900 0.051 2 4.4 88.4 蜂窝陶瓷数据来自山东奥福环保科技股份有限公司. 表 2 上、下给料涂覆适用性对比

Table 2. Comparison of applicability for upper- and down-feed coating

上给料涂覆Upper-feed coating 下给料涂覆Down-feed coating 每次涂覆量 高涂覆量15%—30%、精度高 低涂覆量3%—15%、精度较高 涂覆工艺 定量给料、真空抽吸 喷射给料、蜂窝反转、真空抽吸 对浆液要求 含固量高的粘稠浆料、流动性好 含固量低的稀薄浆料、流动性好 适合加工的催化剂 TWC、SCR等 GPF、DPF等 -

[1] FARRAUTO R J, DEEBA M, ALERASOOL S. Gasoline automobile catalysis and its historical journey to cleaner air [J]. Nature Catalysis, 2019, 2(7): 603-613. doi: 10.1038/s41929-019-0312-9 [2] 中华人民共和国生态环境部. 中国移动源环境管理年报[R/OL]. 北京: 中华人民共和国生态环境部, 2020 [2020-03-10]. http://www.mee.gov.cn/hjzl/sthjzk/ydyhjgl/202008/P020200811521365906550.pdf. Ministry of Ecology and Environment, PRC. China Mobile Source Environmental Management Annual Report[R/OL]. Beijing: Ministry of Ecology and Environment, PRC, 2020 [2020-03-10]. http://www.mee.gov.cn/hjzl/sthjzk/ydyhjgl/202008/P020200811521365906550.pdf (in Chinese).

[3] 源头防治, 严控“老车”换蓝天[N]. 济南: 济南日报, 2019. [2021-03-10]. http://news.bandao.cn/a/178446.html. Source control, strict control of “old car” for blue sky[N]. Jinan: Jinan Daily Newspapering, 2019. [2021-03-10]. http://news.bandao.cn/a/178446.html (in Chinese).

[4] 中国汽车工业协会, 中国汽车技术研究中心有限公司, 丰田汽车公司. 汽车工业蓝皮书: 中国汽车工业发展报告(2020)[M]. 北京: 社会科学文献出版社, 2020: 404 China Association of Automobile Manufacturers, China Automotive Technology and Research Center, Toyota Motor Corporation. Blue book of automotive industry: Annual report on the development of China automotive industry (2020)[M]. Beijing: Social Sciences Academic Press, 2020: 404 (in Chinese).

[5] 汪仁, 郭养浩. 钙钛矿型稀土催化剂及其氧化性能的研究 [J]. 燃料化学学报, 1982, 10(3): 193-202. WANG R, GUO Y H. Rare earth catalysts of perovskite-type structure for catalytic oxidation [J]. Journal of Fuel Chemistry and Technology, 1982, 10(3): 193-202(in Chinese).

[6] 王其武, 林培琰, 戎晶芳, 等. 钙钛矿型稀土复合氧化物催化剂净化内燃机尾气试验 [J]. 催化学报, 1980, 1(2): 154-156. WANG Q W, LIN P Y, RONG J F, et al. Rare earth perovskite catalysts for purifying the exhaust of intercombustion engine [J]. Chinese Journal of Catalysis, 1980, 1(2): 154-156(in Chinese).

[7] 王其武, 戎晶芳, 林培琰, 等. 稀土汽车排气净化催化剂的研究 [J]. 石油炼制与化工, 1979, 8: 62-63. WANG Q W, RONG J F, LIN P Y, et al. Research on rare earth automobile exhaust purification catalyst [J]. Petroleum Processing and Petrochemicals, 1979, 8: 62-63(in Chinese).

[8] 王连驰, 于作龙, 吴越. 稀土催化新貌 [J]. 稀土, 1990, 5(11): 36-57. WANG L C, YU Z L, WU Y. The new look of rare earth catalysis [J]. Chinese Rare Earth, 1990, 5(11): 36-57(in Chinese).

[9] 李琬, 王道. 稀土钙钛矿型催化剂与Hopcalite [J]. 环境化学, 1985, 4(2): 1-6. LI W, WANG D. Rare earth perovskite catalyst and Hopcalite [J]. Environmental Chemistry, 1985, 4(2): 1-6(in Chinese).

[10] 邹向荣, 翁端. 汽车尾气净化催化剂研究进展: 催化剂材料与性能 [J]. 材料导报, 1997, 11(4): 22-24. ZOU X R, WENG D. Research progress of catalyst in the automotive exhaust gas control-the material and properties of catalyst [J]. Materials Reports,, 1997, 11(4): 22-24(in Chinese).

[11] 徐忠良, 周仁贤. J X-1000型汽车尾气催化净化器性能总结报告[R/OL].[2021-03-10]. 北京: 汽车催化净化技术产业化与发展战略研讨会专集, 1999. https://kns.cnki.net/kns8/defaultresult/index. XU Z L, ZHOU R X. Summary report on the performance of JX-1000 automobile exhaust catalytic converter[R/OL]. [2021-03-10].Beijing: Symposium on industrialization and development strategy of automotive catalytic purification technology, 1999. https://kns.cnki.net/kns8/defaultresult/index (inChinese).

[12] 沈美庆, 王军. 汽油车用蜂窝陶瓷载体催剂性能的研究 [J]. 汽车技术, 1999(7): 17-19. SHEN M Q, WANG J. Research on performance of honeycomb ceramic carrier catalyst for gasoline vehicles [J]. Automobile Technology, 1999(7): 17-19(in Chinese).

[13] 郝郑平, 翁端, 沈美庆, 等. 我国机动车排放污染控制与稀土催化剂的应用 [J]. 稀土, 2000, 21(3): 74-77. doi: 10.3969/j.issn.1004-0277.2000.03.020 HAO Z P, WENG D, SHEN M Q, et al. Vehicle emission pollution control and application of rare earth catalysts in China [J]. Chinese Rare Earths, 2000, 21(3): 74-77(in Chinese). doi: 10.3969/j.issn.1004-0277.2000.03.020

[14] 陈耀强, 袁书华, 林之恩, 等. 高性能汽车尾气净化三元催化剂的研制[C]//. 北京: 冶金工业出版社, 2000. CHEN Y Q, YUAN S H, LIN Z E, et al. Development of a three-way catalyst for high-performance automobile exhaust purification[C] //. Beijing: Metallurgical Industry Press, 2000(in Chinese).

[15] 李凤仪, 石秋杰, 罗来涛, 等. 三元汽车尾气净化催化剂的研制[C]//. 北京: 冶金工业出版社, 2000, LI F Y, SHI Q J, LUO L T, et al. Development of three-way automobile exhaust purification catalyst[C]//.Beijing: Metallurgical Industry Press, 2000 (in Chinese).

[16] 黄荣光, 贺小昆, 桓源峰, 等. 稀土基汽车尾气净化催化剂的研究成果和产业化前景[C]//.北京: 冶金工业出版社, 2000, HUANG R G, HE X K, HUAN Y F, et al. Research results and industrialization prospects of rare earth-based automobile exhaust purification catalysts[C]//. Beijing: Metallurgical Industry Press, 2000 (in Chinese).

[17] 肖益鸿, 蔡国辉, 詹瑛瑛, 等. 满足欧Ⅲ/Ⅳ排放限值的FD三效催化剂 [J]. 汽车工程, 2006, 28(4): 331-334, 365. doi: 10.3321/j.issn:1000-680X.2006.04.004 XIAO Y H, CAI G H, ZHAN Y Y, et al. Application of FD catalyst meeting the emission standards EURO-Ⅲ and EURO-Ⅳ [J]. Automotive Engineering, 2006, 28(4): 331-334, 365(in Chinese). doi: 10.3321/j.issn:1000-680X.2006.04.004

[18] 王亚军, 彭希, 冯长根. 汽车催化剂技术发展及研究概况 [J]. 工业催化, 2000, 8(2): 3-10. doi: 10.3969/j.issn.1008-1143.2000.02.001 WANG Y J, PENG X, FENG C G. Advances in technique for automotive catalyst and related research(Ⅰ) [J]. Industrial Catalysis, 2000, 8(2): 3-10(in Chinese). doi: 10.3969/j.issn.1008-1143.2000.02.001

[19] 张昭良, 机动车尾气净化技术和催化剂[C]//. 第四届全国环境化学学科中青年学者研讨会, 宜昌, 2008. ZHANG Z L, Motor vehicle exhaust purification technology and catalyst[C]//. The 4th National Symposium for Young and Middle-aged Scholars in Environmental Chemistry, Yichang, 2008[2021-03-10] (in Chinese).

[20] 胡逸民, 安翠, 龚云卿, 等. 纳米材料在三元催化剂中的应用研究[C]//. 贵阳: 环境催化和机动车尾气污染控制技术国际研讨会论文集, 2001.共119页[2021-03-10] HU Y M, AN C, GONG Y Q, et al. Research on the application of nanomaterials in three-way catalysts[C]//.Guiyang: Proceedings of the international symposium on environmental catalysis and vehicle exhaust pollution control technology, 2001 (in Chinese).

[21] 龚云卿, 戴华, 张昭良, 等. 柴油车氧化催化剂的研制 [J]. 中国稀土学报, 2003, 21(z2): 76-78. doi: 10.3321/j.issn:1000-4343.2003.z2.016 GONG Y Q, DAI H, ZHANG Z L, et al. Development of diesel oxidation catalysts [J]. Journal of the Chinese Rare Earth Society, 2003, 21(z2): 76-78(in Chinese). doi: 10.3321/j.issn:1000-4343.2003.z2.016

[22] 王宏, 贺小昆, 杨冬霞, 等. 稀土在国六汽车催化剂中的应用和挑战 [J]. 稀土信息, 2020(11): 10-14. WANG H, HE X K, YANG D X, et al. Application and challenge of rare earth in catalysts of national six automobile [J]. Rare Earth Information, 2020(11): 10-14(in Chinese).

[23] PAULETTO G, VACCARI A, GROPPI G, et al. FeCrAl as a catalyst support [J]. Chemical Reviews, 2020, 120(15): 7516-7550. doi: 10.1021/acs.chemrev.0c00149 -

下载:

下载: