-

二氧化碳(CO2)等温室气体的过量排放对生态环境造成严重危害,中国为此提出2060年前实现“碳中和”的目标[1],美国也有类似的计划,包括到2030年将温室气体污染从2005年的水平减少50%,以及2050年前实现零排放经济[2]. 尽管各地企业极力节能减排,但仍处于起步阶段,减少碳排放进展缓慢,高效处理烟气中的CO2为实现这一目标提供了一种新思路.

烟气中CO2的捕获与封存(carbon capture and storage,CCS)已经成为减少碳排放的主要手段[3],其中物理吸收法、化学吸收法、薄膜法等较为常用. 化学溶剂吸收法使用氨水、醇胺等来分离回收CO2,是目前工艺最成熟、应用最广泛的技术,但它也存在许多缺点,如腐蚀问题、溶剂易损失和成本较高等[4]. 近10年来,高性能固体吸附剂因其高效率、低能耗和适用于不同温度和压力范围等优点被广泛关注. 固体吸附剂包括多孔碳材料、沸石、金属-有机框架等,其中多孔碳材料(porous carbon materials,PCM)因其丰富可调的多孔结构、性质稳定、易于制备、可再生、价格低廉,在CO2吸附方面具有独特优势[5].

PCM的比表面积(SBET)、微孔容(Vmicro)、中孔容(Vmeso)等结构特性和C、H、O、N等元素组成是影响CO2吸附的重要因素。微孔被证明是PCM吸附CO2的主要影响因素[6],含氮官能团可以作为固定酸性CO2分子的Lewis碱性位点,增强CO2吸附能力. PCM的制备经过碳化和活化过程,不同碳化温度、活化剂(例如KOH,ZnCl2)、活化温度得到的PCM差异很大。为提高吸附性能,传统方法是改变活化温度、活化剂(类型和比例)制备PCM,根据吸附等温线判断其对CO2的吸附性能,选择最佳的制备条件. 这种方法周期长、工作量大[7],无法深入了解PCM的结构性质、元素组成对CO2吸附的影响[8].

为解决这个问题,越来越多的研究使用机器学习(machine learning,ML)进行高性能PCM的筛选,以计算为指导进行材料设计,减少了材料开发的时间和成本[9]. Yuan等利用3种基于决策树的ML模型,以结构特性、元素组成、吸附参数为输入特征,对常规多孔碳和杂原子掺杂多孔碳的CO2吸附量进行预测,其中梯度提升树(gradient boosting decision tree,GBDT)模型具有最佳的预测性能[10];Wang等利用卷积神经网络,直接将氮气(N2)吸附等温线作为输入来预测PCM的N2/CO2吸附选择性[11];Zhu等开发了一个随机森林模型来预测PCM对CO2的吸附能力,同时利用特征重要性量化了结构特性和吸附条件在吸附过程中的作用[12]. 机器学习作为一种数据挖掘技术,利用数据派生模型从给定数据集中提取复杂且隐蔽的相关性[13],通过机器学习算法建立CO2吸附量与材料性质和吸附条件(温度、压力)之间的模型,可以量化各变量与吸附性能之间的非线性关系,以及对具有不同结构特性PCM的CO2吸附量做出预测.

-

以CO2吸附、多孔碳材料为关键词,从文献库(例如Web of Science、ScienceDirect等)中搜索文献,进一步筛选,收集了在273 K、298 K两个温度下65个碳样品的CO2吸附数据,共计

1591 个数据点[14 − 27],除了文献中列出的数据,还通过Origin中图形数字化工具从CO2吸附等温线图中提取数据. 此外,本文所选取的碳材料都掺杂了氮元素,原材料成本较低且容易获得.考虑了10个对CO2吸附重要的预测变量,分为结构特性(TP):比表面积(SBET , m2·g−1)、微孔体积(Vmicro , cm3·g−1)、中孔体积(Vmeso , cm3·g−1)、总孔体积(Vtotal , cm3·g−1);元素组成(CC):C、H、O、N元素的质量百分比(wt%);吸附条件:温度(T , K)、压力(P , bar). 输出变量是CO2吸附量(Q , mmol·g−1).

-

为了解数据集的特点在进行建模训练前对CO2吸附数据进行单变量统计分布分析和任意两变量之间的相关关系分析[28]. 用小提琴图分析单变量的统计分布,结合了箱型图和密度图的特征,更直观反映数据的分布;皮尔逊相关性分析(pearson correlation coefficient,PCC)用于任意两变量之间相关关系的分析,对变量之间是否存在统计上的显著关系(

P 值小于0.05或0.01为显著,严格为0.01)进行检验,若呈现显著性说明两变量之间存在相关性,反之,则不存在相关性,再分析相关系数的正负向及相关性程度,两变量之间皮尔逊相关系数(r )以及进行显著性检验(t )的公式如下:式(1)中,

ˉx 、ˉy 为变量的均值,取值范围−1≤r≤1 ,其中|r| 越接近于1,两变量的线性相关程度越高.式(2)中,

r 为皮尔逊相关系数,n 为样本点数量,通过查t 分布表可得到P 值. -

为消除各变量之间不同量纲对模型训练的影响,将数据进行归一化处理,使其映射到[0,1]之间,计算公式如式(3)所示.

其中

xi 、x∗i 分别为归一化前后数据,xmax 、xmin 分别为变量的最大值和最小值. -

机器学习模型有很多,对于有监督的模型主要包括线性回归、支持向量机、k最近邻、决策树、神经网络以及集成学习等,其中集成学习是将多个单算法模型组合构成一个强模型,基于多颗决策树的随机森林是经典的集成学习模型. 没有万能的算法,需要根据不同特征及不同的数据集选取合适的算法模型[29]. 结合几种主要机器学习算法的优缺点及数据集的特点,选取线性回归(linear regression,LR)、反向传播神经网络(back propagation neural network,BPNN)、具有线性核函数(linear,L)和高斯核函数(radial basis function,RBF)的支持向量回归(support vector regression,SVR)、随机森林(random forest,RF)等5种机器学习模型对数据集进行训练和测试,回归模型进行超参数调整使其达到最佳性能,通过评价函数选择最佳模型进行特征分析[30].

-

线性回归是对一个或多个自变量和因变量之间关系进行建模的一种回归方法,回归预测速度快,对数据量的要求不高,虽然对于非线性数据的拟合效果欠佳,但对PCM吸附CO2的模型来说,总孔容、微孔容和比表面积相互关联,可使CO2的饱和吸附量与孔容之间呈一定线性相关[31],如式(4)所示.

其中,

ˆy 为因变量,x 为自变量,ω 和b 为参数,通过梯度下降法可得到最优的ω 和b . -

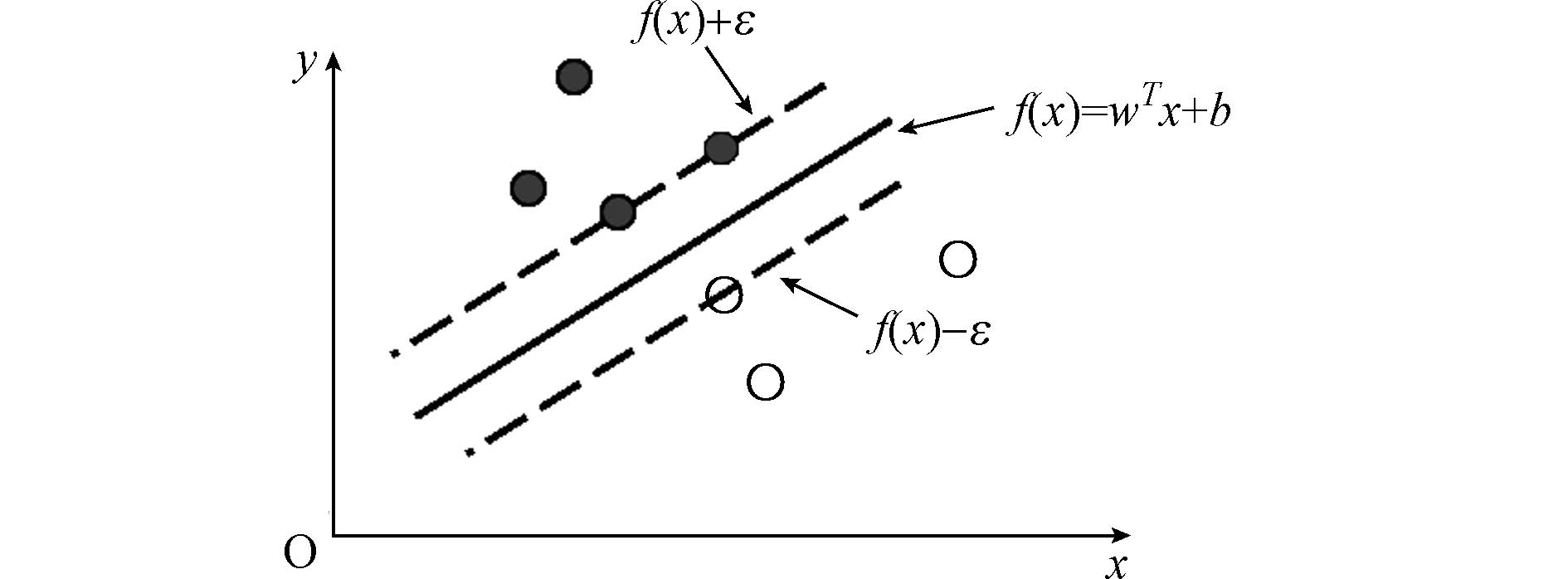

支持向量机利用核函数将原始数据向高维空间进行非线性映射,它的特点在于设置了一个宽度为

2ε 的间隔带,在间隔带内的样本点不计算损失(|z|≤ε ),决策函数只由少数支持向量确定,而不是样本空间的维数,对于考虑10个特征的吸附模型不会损失训练准确性[32],如图1所示. 图中,实线为最佳超平面,虚线为可接受误差的间隔带,空心球和实心球分别代表两类样本点,间隔带上的小球为支持向量.SVR问题的目标函数为式(5):

式中,

C 为正则化常数,lε 为ε 不敏感损失函数,z 为损失函数.为每个样本点引入松弛变量

ξi,^ξi (为松弛因子)可得式(6):引入拉格朗日乘子

α,α∗,μ,μ∗ ,并利用对偶条件(Karush-Kuhn-Tucker条件),得到式(7):引入核函数

κ(xi,x) ,将数据映射到高维空间,即可得到回归函数(8):式中,

κ(xi,x) 为核函数,可分为线性核函数、高斯核函数、Sigmoid核函数等. -

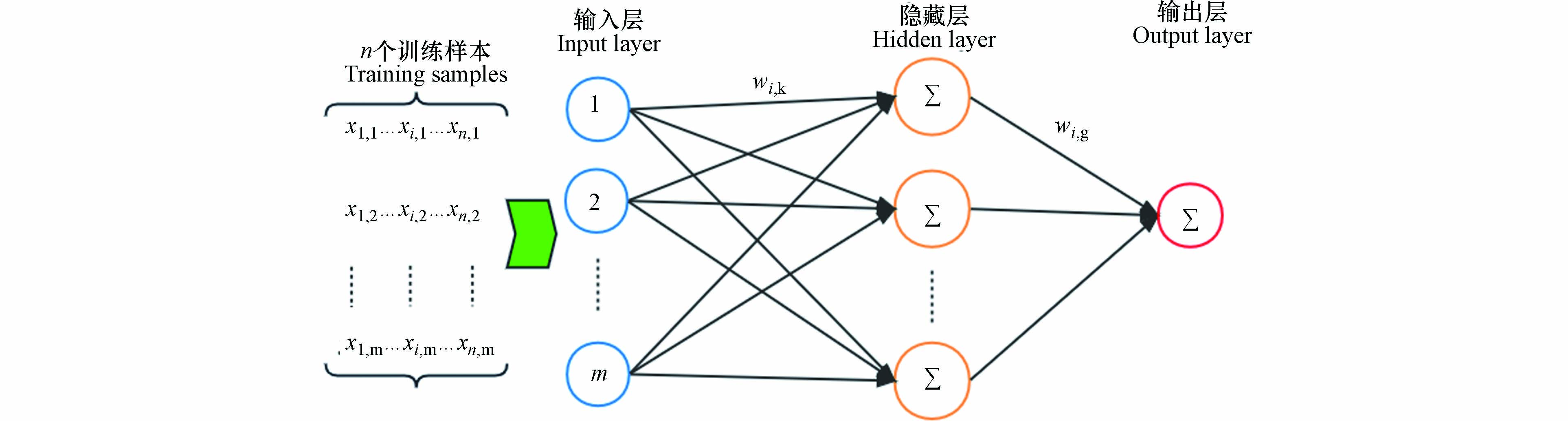

BP神经网络是一种按误差反向传播算法训练的多层前馈网络[33],通过不断反向传播调整网络的权值

ω 和阈值b ,使网络的误差最小,如图2所示. BP神经网络及具有多个隐藏层的深度神经网络具有适应性强、非线性计算的特点,利用网络内各神经元的权重和阈值分布存储信息,部分神经元受损对训练结果不会产生影响,这使得其能识别由65个不同碳样本所建立数据集的误差值,以不同结构特性的组合(Vmicro、Vmicro−Vmeso、Vmicro−Vmeso−SBET)作为输入,可解释各特性对CO2吸附的作用[34]. -

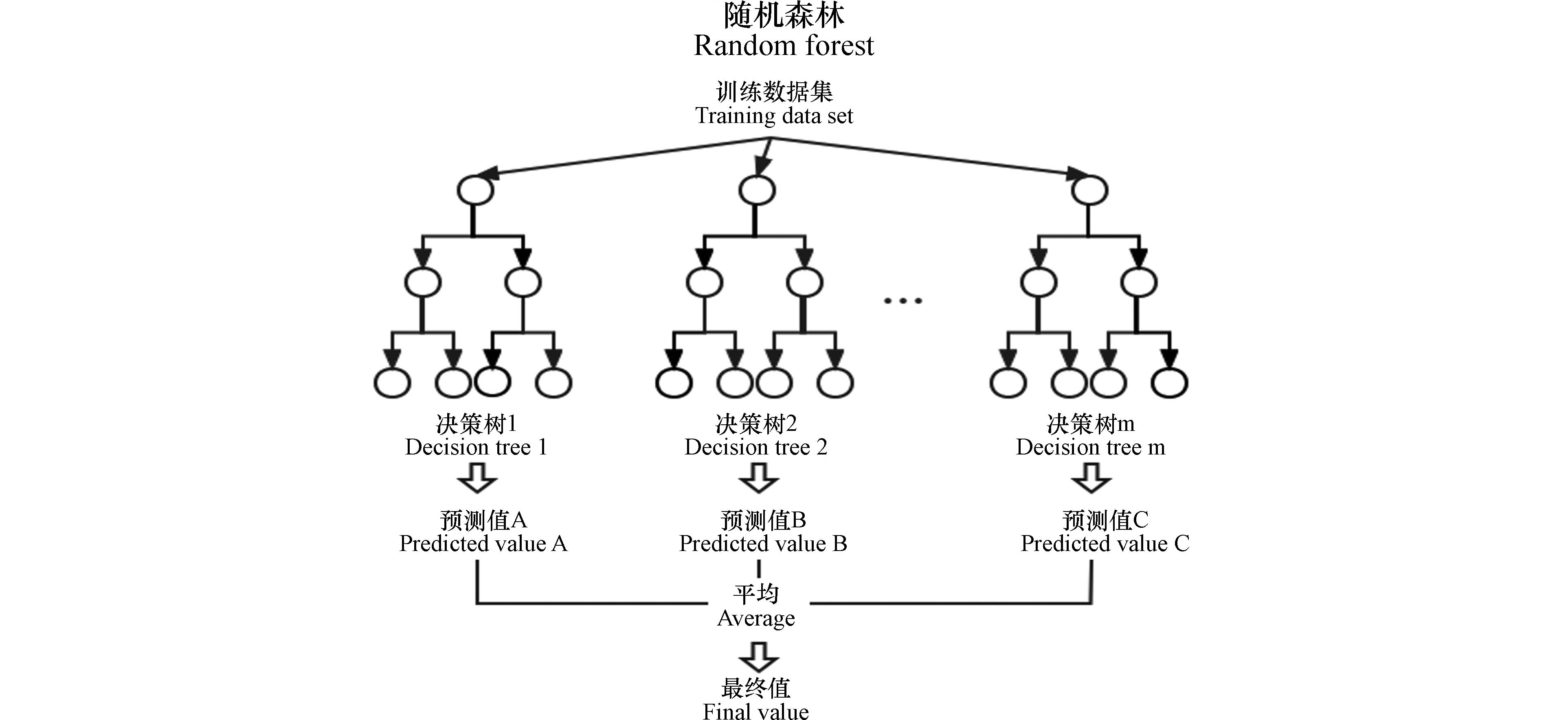

随机森林是一种基于决策树的集成学习算法,由多棵决策树结合在一起组成,如图3所示. 适合处理小样本数据集[10],且对不平衡数据集有很好的误差平衡,此外,在训练完成后可给出结构特性、元素组成、温度、压力等特征的重要性使寻找吸附CO2的关键因素变得简单.

-

各模型参数及参数空间如表1所示.

-

使用Jupyter Notebook程序并调用scikit-learn(用于机器学习的Python库)建立线性回归、BP神经网络、支持向量回归、随机森林等5种模型. 将数据集的70%作为训练集,通过调用scikit-learn中的网格搜索(grid search)和五折交叉验证(cross validation,CV)函数调整超参数,以提高模型的预测准确性,再重新训练;30%作为测试集,用于检验模型的预测性能. 模型性能根据决定系数(R2)和均方根误差(RMSE)进行评估,R2越接近于1、RMSE越小,模型的回归预测性能越好,公式如(9)、(10)所示.

其中y、

ˆy 和ˉy 分别为实际值、预测值和实际值的平均值,n为用于预测的样本数. -

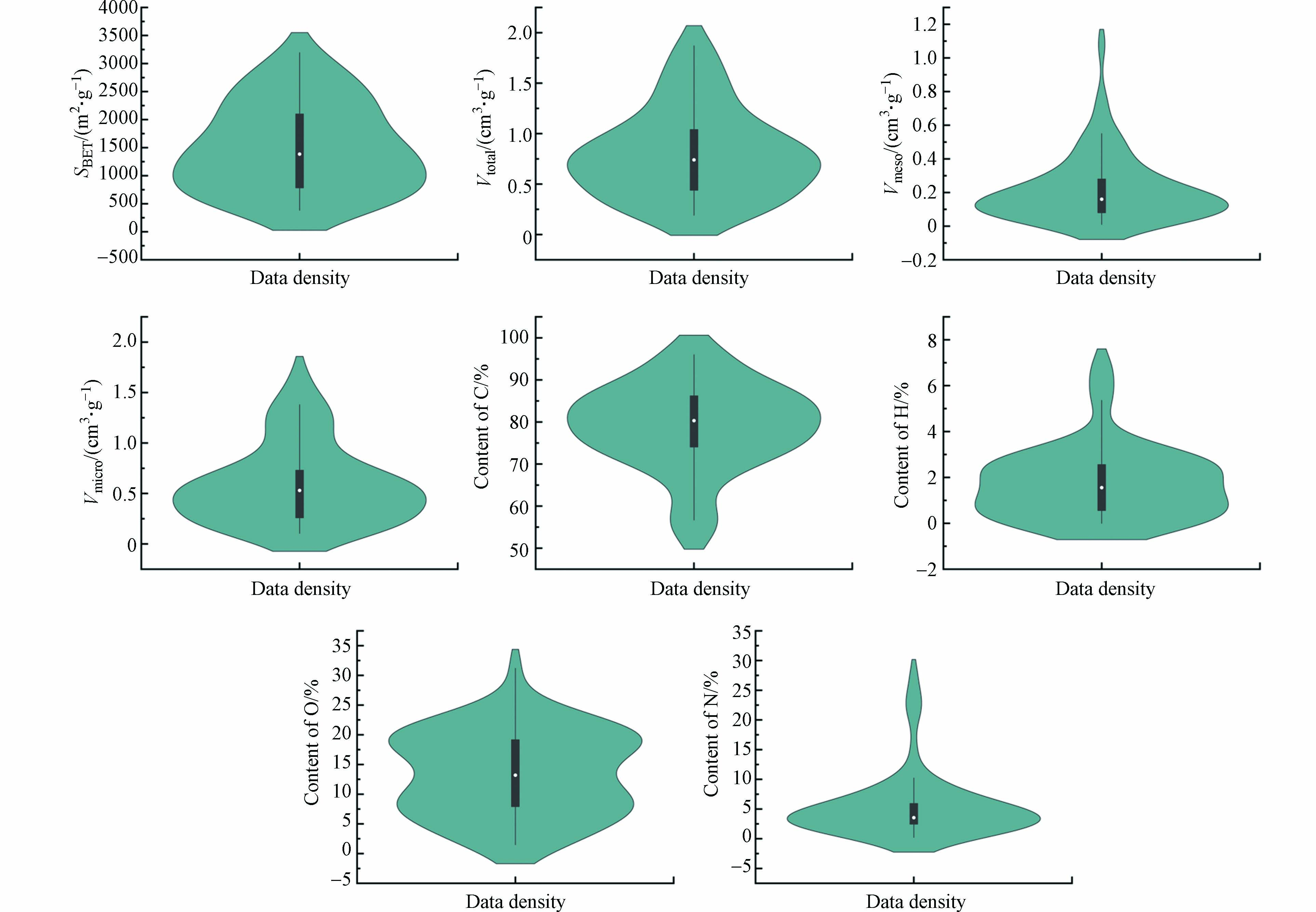

所选65种不同PCM的SBET、Vtotal、Vmeso、Vmicro、C、H、O、N分布如图4所示. PCM的比表面积主要分布在500—

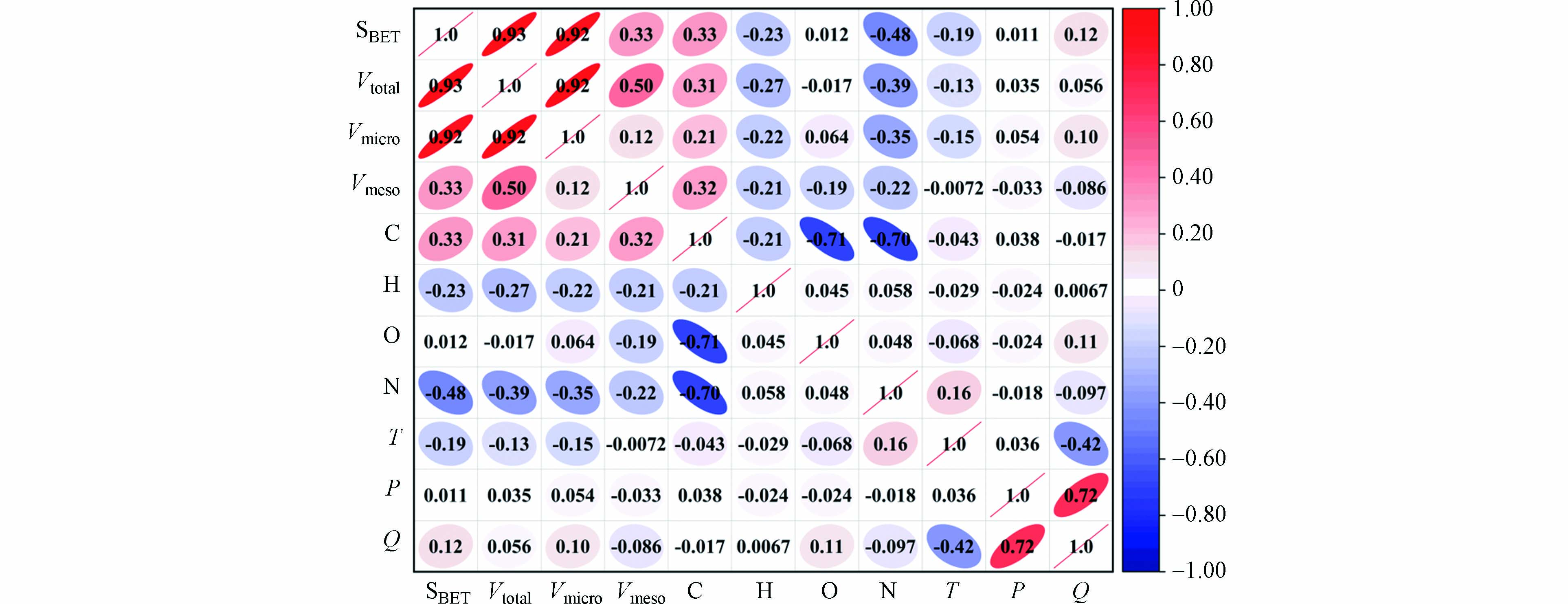

3000 m2·g−1之间,中值在1500 m2·g−1,具备潜在的良好吸附性能;总孔容和微孔容的分布大致相同,主要分布在0.2—1.5 cm3·g−1之间,中孔容主要分布0—0.6 cm3·g−1之间,多数碳材料的氮气吸附-脱附曲线表现出典型的Ⅰ型等温线,表明所选大部分碳材料为微孔型碳材料. 元素组成方面,由于碳化温度和活化方法的差异,碳、氢、氧元素含量分别在60%—90%、0%—4%、5%—25%之间,随着碳化温度的增加,氢、氧元素的含量降低;碳材料进行了氮掺杂处理后,氮元素的含量在0.2%—15%之间,中值在3%.任意两变量的皮尔逊相关性分析如图5所示. 吸附量与压力(r=0.72,P<0.01)呈强正相关,与温度(r=−0.42,P<0.01)呈中等负相关. 结构特性方面,吸附量与比表面积(r=0.12,P<0.01)、微孔容(r=0.10,P<0.01)、总孔容(r=0.056,P<0.01)仅呈现弱正相关性,和中孔容(r=−0.086,P<0.01)呈弱负相关,4种结构特性和吸附量之间整体呈弱相关性,这是比较意外的. 元素组成方面,碳、氢、氧、氮元素均呈现弱相关性,氮元素没表现出预想的效果,氧元素(r=0.11,P<0.01)有着不错的表现. 另外还发现比表面积与总孔容(r=0.93,P<0.01)、微孔容(r=0.92,P<0.01)之间存在强相关性,总孔容与微孔容(r=0.92,P<0.01)之间也存在强相关性,由于这种多个特征之间存在的多重共线性,使线性相关系数和实际相关性有一定偏差,无法仅从双变量相关性分析来衡量每个特征对吸附结果的影响,接下来将利用机器学习模型来解决这个问题.

-

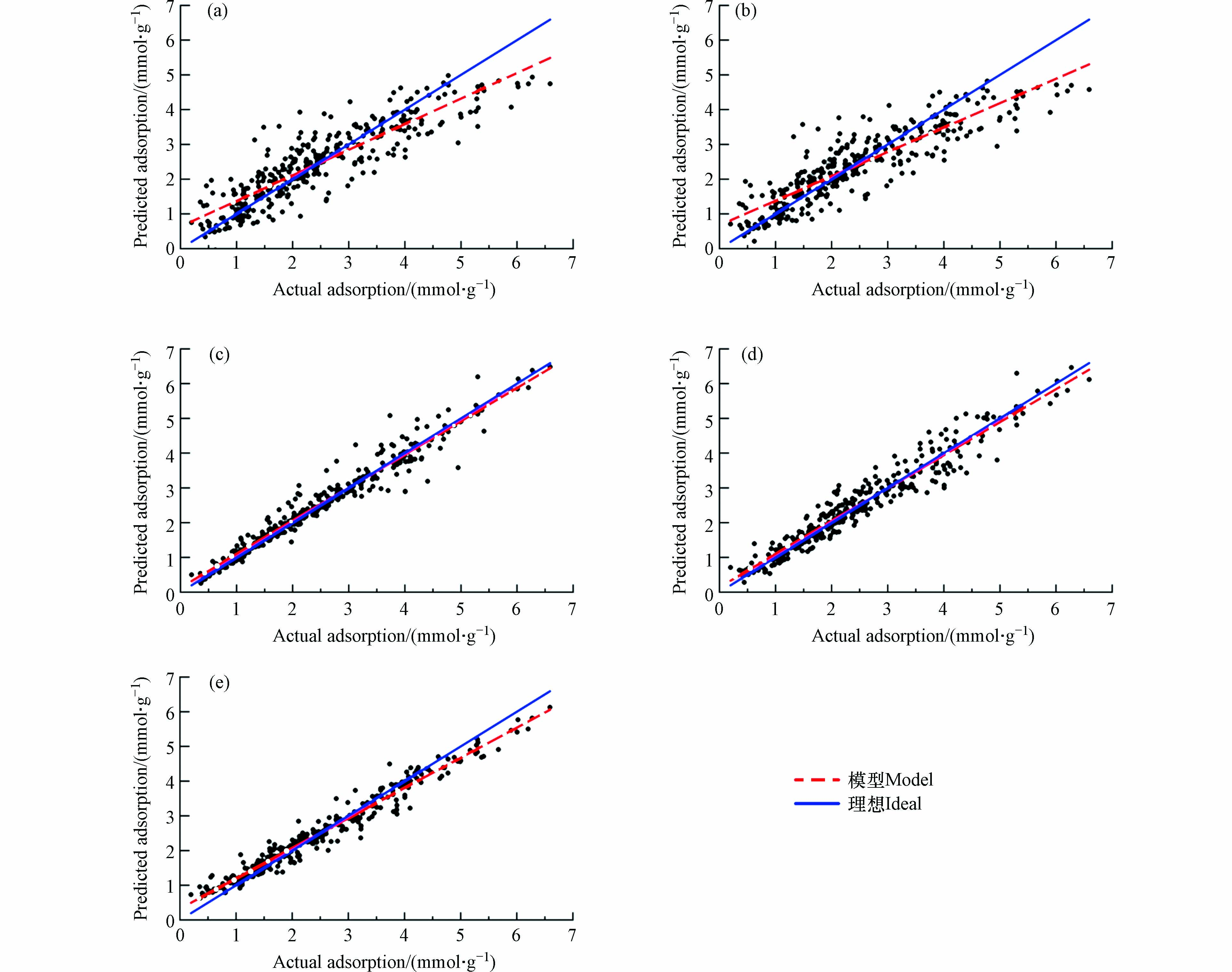

用5种不同模型对数据集进行训练测试,以实际值为x、预测值为y绘制拟合图,实线为y=x理想参照线,虚线为模型实际拟合线,各个模型的预测效果如图6所示.

不同模型在测试集上的评价函数值如表2所示. 可以看出,RF模型的RMSE和R2分别为0.286、0.954,在5个模型里表现最好,同时它还具有优良的抗过拟合能力和泛化能力[35]. 此外,RF模型可以返回特征的重要性值,当多个特征存在多重共线性时,他们的特征重要性会被相互抵消[36],从而准确理解和解释各个特征在吸附过程中的作用,因此选择RF模型进行下一步的特征分析.

-

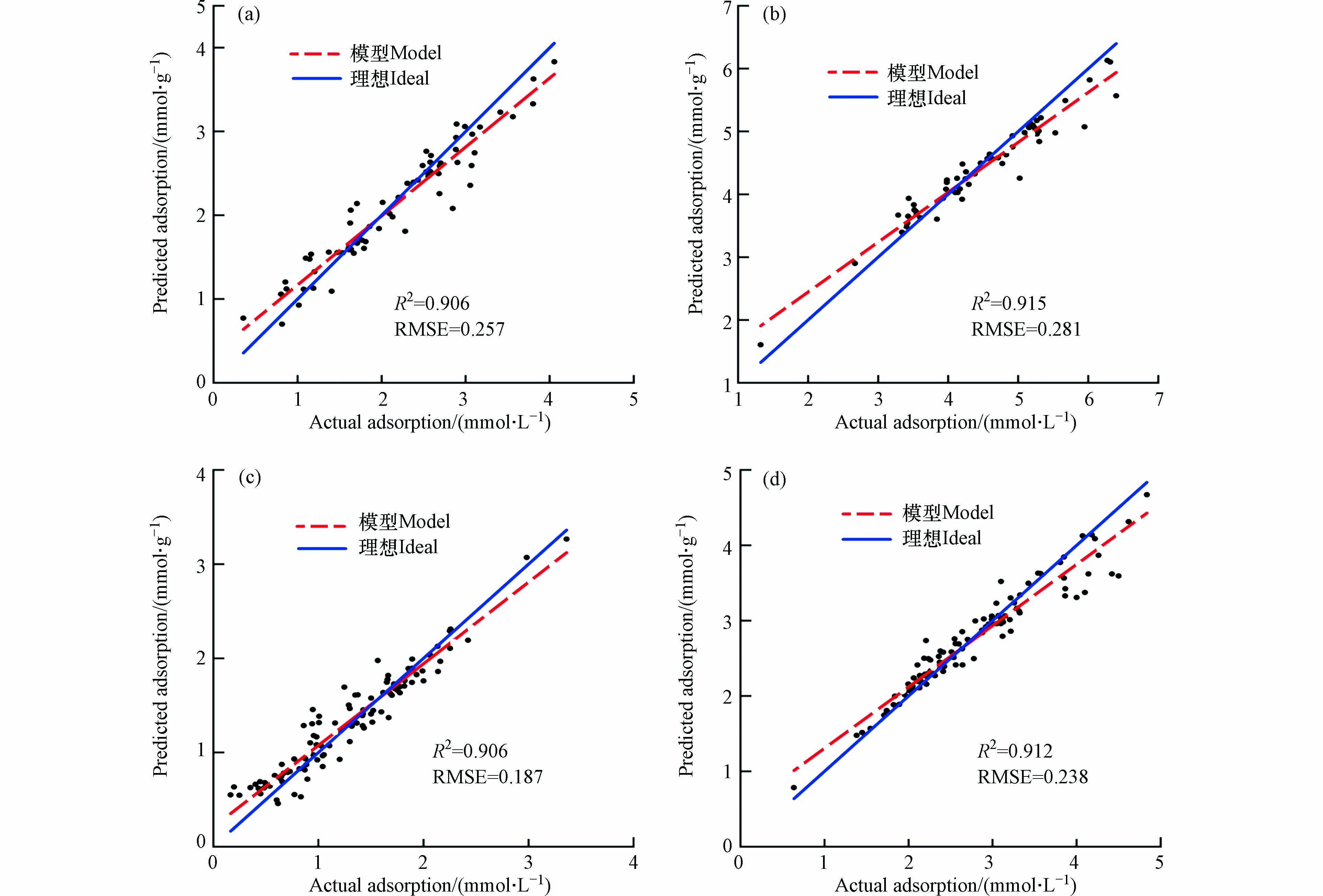

将数据集按不同温度(273 K,298 K)和压力(0—0.5 bar,0.5—1 bar)分为4组,用RF模型进行拟合预测,模型的预测结果如图7所示. 可以看出R2分别为0.906、0.915、0.906、0.912,均大于0.9,表明RF模型对4组数据集都有很好的拟合预测效果.

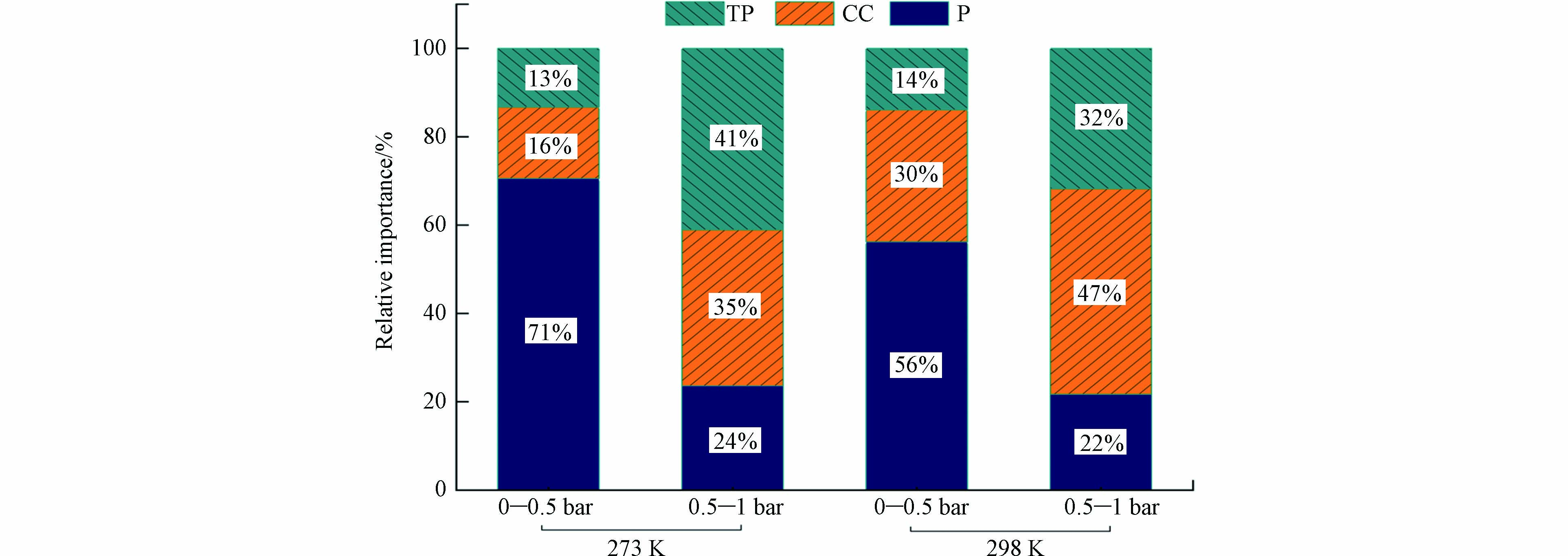

将RF模型得出的特征重要性绘制成百分比柱状图,以便直观表现不同温度压力下各特征重要性的变化[37],如图8所示. 压力是PCM吸附CO2最重要的影响因素,但随着压力和温度的提高,结构特性和元素组成逐渐成为主导因素. 压力升高,其本身的重要性在273 K和298 K下分别下降了66%和60%,可能的原因是这些PCM的孔隙结构中主要是微孔和超微孔,CO2的吸附机理是体积填充,相较于大孔和中孔上的层层吸附,当微孔填充达到饱和后增加压力对吸附量的影响降低. 此外,相较于298 K,273 K时的压力重要性更大(71%、24%),这可能是因为较高温度导致的CO2分子运动加剧[38],一定程度上削弱了压力带来的正向作用. 从此得到启发,对于烟气中CO2的处理,使用PCM作为吸附剂,可以结合变温、变压吸附来减少能耗.

结构特性和元素组成的特征重要性详细数据如表3所示. 结构特性方面,随着压力的提高比表面积、总孔容、微孔容、中孔容的重要性都有不同程度的提升,整体在273 K和298 K时分别提高3.1倍和2.3倍,值得注意的是比表面积的影响提升明显,是结构特性中影响CO2吸附能力最重要的因素,273 K时比表面积的特征重要性由2.95%提高到了18.27%,这可能是由于在更高的压力(0.5—1 bar)下,作为主要吸附空间的微孔吸附接近饱和后,增加压力对吸附的影响降低,这时较大的比表面积意味着更多的吸附位点[39 − 40];微孔容的特征重要性随着压力的变化也有很大提升,298 K时由2.18%提升到9.61%;中孔容的特征重要性随温度和压力的变化不大,在4%—8%之间,但特征重要性显示的是影响的绝对值,结合皮尔逊相关性分析的弱负相关性(r=−0.086,P<0.01),可以看出在常压(0—1 bar)下中孔对碳材料吸附CO2的性能影响较小. 元素组成方面,整体上特征重要性的排序为N>C>O>H,含氮基团可以作为Lewis碱性位点,通过酸碱相互作用有效地结合酸性二氧化碳分子,从而增强PCM的CO2吸附能力,氮元素的特征重要性在273 K、0.5—1 bar时可以达到15.27%.

有研究表明微孔不是控制吸附的唯一参数,强调中孔在CO2吸附方面的重要性[11],上述分析显示中孔在常压(0—1 bar)下对吸附的影响较小,对于更高压力下微孔和中孔的重要性,通过等高线图探究298 K、1/5 bar时,两种孔与吸附量之间的相关性,如图9所示. 结果表明,常压(0—1 bar)下PCM对CO2的吸附主要受微孔控制,高压(5 bar)下中孔对吸附也有重要作用.

-

通过比较5种不同的机器学习模型,选择了随机森林模型进行特征重要性分析,探究了不同吸附条件下结构特性、元素组成对PCM吸附CO2性能的影响. 结果表明,对收集的碳材料样本,随机森林模型表现出良好的拟合预测性能,测试集R2=0.954. 压力是PCM吸附CO2最重要的影响因素,但随着压力和温度的提高,结构特性和元素组成逐渐成为主导因素. 结构特性方面,比表面积和微孔是结构特性中影响CO2吸附能力的关键因素;常压下CO2吸附主要受微孔控制,高压(5 bar)下中孔对吸附也有重要作用. 元素组成方面,氮元素是最重要的因素,其特征重要性在273 K、0.5—1 bar时可以达到15.27%. 本研究通过机器学习模型量化了PCM的结构特性、元素组成和吸附条件在吸附CO2中的影响,明确了材料的优化方向,同时利用建立的随机森林模型以PCM的结构特性和元素组成作为输入来预测CO2吸附量,可以减少实验重复次数,未来有望在开发高效吸附CO2的活性炭方面得到应用.

基于机器学习的多孔碳材料吸附CO2的关键因素

Study on the key factors of CO2 adsorption by porous carbon materials based on machine learning

-

摘要: 多孔碳材料具有性质稳定、高孔隙率和高比表面积等优点,被广泛应用于气体分离和存储. 目前,针对多孔碳材料吸附CO2的优化主要通过“炒菜”的模式,但对于各种结构特性、元素组成对吸附的作用尚不明确. 机器学习算法通过构建特征与标签之间的模型从而量化其中的非线性关系,被逐渐运用于高性能多孔碳材料的筛选. 为了探究多孔碳材料吸附CO2的关键因素,建立了一个包含65个碳样本、

1591 个数据点的数据集,以7∶3的比例随机拆分为训练集和测试集,采用线性回归、反向传播神经网络、支持向量机、随机森林等5种不同机器学习模型训练和测试. 结果表明:随机森林模型在测试集上具有最佳的泛化能力(R2=0.954、RMSE=0.286). 压力是多孔碳材料吸附CO2最重要的影响因素,但随着压力和温度的提高,结构特性和元素组成逐渐成为主导因素. 结构特性方面,比表面积和微孔是结构特性中影响CO2吸附能力的关键因素;常压下CO2吸附主要受微孔控制,高压下中孔对吸附也有重要作用. 元素组成方面,氮元素是最重要的因素,其特征重要性在273 K、0.5—1 bar时可以达到15.27%.Abstract: Porous carbon materials are widely used for gas separation and storage because of their stable properties, high porosity and high specific surface area. Currently, the optimization of CO2 adsorption on porous carbon materials is mainly through the "frying" mode, but the role of various structural properties and elemental composition on adsorption is not clear. Machine learning algorithms, which quantify the nonlinear relationships by constructing models between features and labels, are gradually being applied to the screening of high-performance porous carbon materials. In order to find the key factors of CO2 adsorption by porous carbon materials, a dataset containing 65 carbon samples with1591 data points is established and randomly split into training and testing sets in the ratio of 7:3. Five different machine learning models, including linear regression, backward propagation neural network, support vector machine, and random forest, are used for training and testing. The results show that the random forest model has the best generalization ability on the test set (R2=0.954, RMSE=0.286). Pressure is the most important influencing factor for CO2 adsorption by porous carbon materials, but with increasing pressure and temperature, structural properties and elemental composition gradually become the dominant factors. As for the structural properties, specific surface area and micropores are the key factors affecting CO2 adsorption capacity in structural properties; CO2 adsorption at atmospheric pressure is mainly controlled by micropores, mesopores also play an important role in adsorption under high pressure. As for elemental composition, nitrogen is the most important factor, and its characteristic importance can reach 15.27% at 273 K and 0.5—1 bar.-

Key words:

- porous carbon materials /

- pore structure /

- carbon dioxide adsorption /

- machine learning.

-

二氧化碳(CO2)等温室气体的过量排放对生态环境造成严重危害,中国为此提出2060年前实现“碳中和”的目标[1],美国也有类似的计划,包括到2030年将温室气体污染从2005年的水平减少50%,以及2050年前实现零排放经济[2]. 尽管各地企业极力节能减排,但仍处于起步阶段,减少碳排放进展缓慢,高效处理烟气中的CO2为实现这一目标提供了一种新思路.

烟气中CO2的捕获与封存(carbon capture and storage,CCS)已经成为减少碳排放的主要手段[3],其中物理吸收法、化学吸收法、薄膜法等较为常用. 化学溶剂吸收法使用氨水、醇胺等来分离回收CO2,是目前工艺最成熟、应用最广泛的技术,但它也存在许多缺点,如腐蚀问题、溶剂易损失和成本较高等[4]. 近10年来,高性能固体吸附剂因其高效率、低能耗和适用于不同温度和压力范围等优点被广泛关注. 固体吸附剂包括多孔碳材料、沸石、金属-有机框架等,其中多孔碳材料(porous carbon materials,PCM)因其丰富可调的多孔结构、性质稳定、易于制备、可再生、价格低廉,在CO2吸附方面具有独特优势[5].

PCM的比表面积(SBET)、微孔容(Vmicro)、中孔容(Vmeso)等结构特性和C、H、O、N等元素组成是影响CO2吸附的重要因素。微孔被证明是PCM吸附CO2的主要影响因素[6],含氮官能团可以作为固定酸性CO2分子的Lewis碱性位点,增强CO2吸附能力. PCM的制备经过碳化和活化过程,不同碳化温度、活化剂(例如KOH,ZnCl2)、活化温度得到的PCM差异很大。为提高吸附性能,传统方法是改变活化温度、活化剂(类型和比例)制备PCM,根据吸附等温线判断其对CO2的吸附性能,选择最佳的制备条件. 这种方法周期长、工作量大[7],无法深入了解PCM的结构性质、元素组成对CO2吸附的影响[8].

为解决这个问题,越来越多的研究使用机器学习(machine learning,ML)进行高性能PCM的筛选,以计算为指导进行材料设计,减少了材料开发的时间和成本[9]. Yuan等利用3种基于决策树的ML模型,以结构特性、元素组成、吸附参数为输入特征,对常规多孔碳和杂原子掺杂多孔碳的CO2吸附量进行预测,其中梯度提升树(gradient boosting decision tree,GBDT)模型具有最佳的预测性能[10];Wang等利用卷积神经网络,直接将氮气(N2)吸附等温线作为输入来预测PCM的N2/CO2吸附选择性[11];Zhu等开发了一个随机森林模型来预测PCM对CO2的吸附能力,同时利用特征重要性量化了结构特性和吸附条件在吸附过程中的作用[12]. 机器学习作为一种数据挖掘技术,利用数据派生模型从给定数据集中提取复杂且隐蔽的相关性[13],通过机器学习算法建立CO2吸附量与材料性质和吸附条件(温度、压力)之间的模型,可以量化各变量与吸附性能之间的非线性关系,以及对具有不同结构特性PCM的CO2吸附量做出预测.

1. 材料与方法(Materials and methods)

1.1 数据集构建

以CO2吸附、多孔碳材料为关键词,从文献库(例如Web of Science、ScienceDirect等)中搜索文献,进一步筛选,收集了在273 K、298 K两个温度下65个碳样品的CO2吸附数据,共计

1591 个数据点[14 − 27],除了文献中列出的数据,还通过Origin中图形数字化工具从CO2吸附等温线图中提取数据. 此外,本文所选取的碳材料都掺杂了氮元素,原材料成本较低且容易获得.考虑了10个对CO2吸附重要的预测变量,分为结构特性(TP):比表面积(SBET , m2·g−1)、微孔体积(Vmicro , cm3·g−1)、中孔体积(Vmeso , cm3·g−1)、总孔体积(Vtotal , cm3·g−1);元素组成(CC):C、H、O、N元素的质量百分比(wt%);吸附条件:温度(T , K)、压力(P , bar). 输出变量是CO2吸附量(Q , mmol·g−1).

1.2 相关性分析

为了解数据集的特点在进行建模训练前对CO2吸附数据进行单变量统计分布分析和任意两变量之间的相关关系分析[28]. 用小提琴图分析单变量的统计分布,结合了箱型图和密度图的特征,更直观反映数据的分布;皮尔逊相关性分析(pearson correlation coefficient,PCC)用于任意两变量之间相关关系的分析,对变量之间是否存在统计上的显著关系(

P r t stringUtils.convertMath(!{formula.content}) (1) 式(1)中,

ˉx ˉy −1≤r≤1 |r| stringUtils.convertMath(!{formula.content}) (2) 式(2)中,

r n t P 1.3 数据归一化

为消除各变量之间不同量纲对模型训练的影响,将数据进行归一化处理,使其映射到[0,1]之间,计算公式如式(3)所示.

stringUtils.convertMath(!{formula.content}) (3) 其中

xi x∗i xmax xmin 1.4 模型选择

机器学习模型有很多,对于有监督的模型主要包括线性回归、支持向量机、k最近邻、决策树、神经网络以及集成学习等,其中集成学习是将多个单算法模型组合构成一个强模型,基于多颗决策树的随机森林是经典的集成学习模型. 没有万能的算法,需要根据不同特征及不同的数据集选取合适的算法模型[29]. 结合几种主要机器学习算法的优缺点及数据集的特点,选取线性回归(linear regression,LR)、反向传播神经网络(back propagation neural network,BPNN)、具有线性核函数(linear,L)和高斯核函数(radial basis function,RBF)的支持向量回归(support vector regression,SVR)、随机森林(random forest,RF)等5种机器学习模型对数据集进行训练和测试,回归模型进行超参数调整使其达到最佳性能,通过评价函数选择最佳模型进行特征分析[30].

1.4.1 线性回归(LR)

线性回归是对一个或多个自变量和因变量之间关系进行建模的一种回归方法,回归预测速度快,对数据量的要求不高,虽然对于非线性数据的拟合效果欠佳,但对PCM吸附CO2的模型来说,总孔容、微孔容和比表面积相互关联,可使CO2的饱和吸附量与孔容之间呈一定线性相关[31],如式(4)所示.

stringUtils.convertMath(!{formula.content}) (4) 其中,

ˆy x ω b ω b 1.4.2 支持向量回归(SVR)

支持向量机利用核函数将原始数据向高维空间进行非线性映射,它的特点在于设置了一个宽度为

2ε |z|≤ε SVR问题的目标函数为式(5):

stringUtils.convertMath(!{formula.content}) (5) 式中,

C lε ε z 为每个样本点引入松弛变量

ξi,^ξi stringUtils.convertMath(!{formula.content}) (6) 引入拉格朗日乘子

α,α∗,μ,μ∗ stringUtils.convertMath(!{formula.content}) (7) 引入核函数

κ(xi,x) stringUtils.convertMath(!{formula.content}) (8) 式中,

κ(xi,x) 1.4.3 BP神经网络

BP神经网络是一种按误差反向传播算法训练的多层前馈网络[33],通过不断反向传播调整网络的权值

ω b 1.4.4 随机森林(RF)

随机森林是一种基于决策树的集成学习算法,由多棵决策树结合在一起组成,如图3所示. 适合处理小样本数据集[10],且对不平衡数据集有很好的误差平衡,此外,在训练完成后可给出结构特性、元素组成、温度、压力等特征的重要性使寻找吸附CO2的关键因素变得简单.

1.5 超参数调整

各模型参数及参数空间如表1所示.

表 1 各模型的参数和参数空间Table 1. Parameters and parameter space of each model模型Models 参数Parameters 搜索空间Search space SVR(L) gamma [0.001, 0.005, 0.01, 0.02, 0.05, 0.1, 0.2, 0.3,0.4,0.5] C [0.1, 0.2, 0.25, 0.5, 1, 1.5, 2, 5, 10, 15, 16] SVR(RBF) gamma [0.001, 0.005, 0.01, 0.02, 0.05, 0.1, 0.2, 0.3,0.4,0.5] C [0.1, 0.2, 0.25, 0.5, 1, 1.5, 2, 5, 10, 15, 16] BP max_iter [10, 30, 50, 100, 200] learning rate ['constant', 'invscaling', 'adaptive'] solver ['lbfgs', 'sgd', 'adam'] RF n_estimators Range between 200 and 2000 with increments of 10 maximum tree depth [2, 3, 4, 5, 6, 7, 8, 9, 10] min_samples_leaf [1, 2, 4] 1.6 模型建立与评估

使用Jupyter Notebook程序并调用scikit-learn(用于机器学习的Python库)建立线性回归、BP神经网络、支持向量回归、随机森林等5种模型. 将数据集的70%作为训练集,通过调用scikit-learn中的网格搜索(grid search)和五折交叉验证(cross validation,CV)函数调整超参数,以提高模型的预测准确性,再重新训练;30%作为测试集,用于检验模型的预测性能. 模型性能根据决定系数(R2)和均方根误差(RMSE)进行评估,R2越接近于1、RMSE越小,模型的回归预测性能越好,公式如(9)、(10)所示.

stringUtils.convertMath(!{formula.content}) (9) stringUtils.convertMath(!{formula.content}) (10) 其中y、

ˆy ˉy 2. 结果与讨论(Results and discussion)

2.1 相关性分析

所选65种不同PCM的SBET、Vtotal、Vmeso、Vmicro、C、H、O、N分布如图4所示. PCM的比表面积主要分布在500—

3000 m2·g−1之间,中值在1500 m2·g−1,具备潜在的良好吸附性能;总孔容和微孔容的分布大致相同,主要分布在0.2—1.5 cm3·g−1之间,中孔容主要分布0—0.6 cm3·g−1之间,多数碳材料的氮气吸附-脱附曲线表现出典型的Ⅰ型等温线,表明所选大部分碳材料为微孔型碳材料. 元素组成方面,由于碳化温度和活化方法的差异,碳、氢、氧元素含量分别在60%—90%、0%—4%、5%—25%之间,随着碳化温度的增加,氢、氧元素的含量降低;碳材料进行了氮掺杂处理后,氮元素的含量在0.2%—15%之间,中值在3%.任意两变量的皮尔逊相关性分析如图5所示. 吸附量与压力(r=0.72,P<0.01)呈强正相关,与温度(r=−0.42,P<0.01)呈中等负相关. 结构特性方面,吸附量与比表面积(r=0.12,P<0.01)、微孔容(r=0.10,P<0.01)、总孔容(r=0.056,P<0.01)仅呈现弱正相关性,和中孔容(r=−0.086,P<0.01)呈弱负相关,4种结构特性和吸附量之间整体呈弱相关性,这是比较意外的. 元素组成方面,碳、氢、氧、氮元素均呈现弱相关性,氮元素没表现出预想的效果,氧元素(r=0.11,P<0.01)有着不错的表现. 另外还发现比表面积与总孔容(r=0.93,P<0.01)、微孔容(r=0.92,P<0.01)之间存在强相关性,总孔容与微孔容(r=0.92,P<0.01)之间也存在强相关性,由于这种多个特征之间存在的多重共线性,使线性相关系数和实际相关性有一定偏差,无法仅从双变量相关性分析来衡量每个特征对吸附结果的影响,接下来将利用机器学习模型来解决这个问题.

2.2 模型训练与评价

用5种不同模型对数据集进行训练测试,以实际值为x、预测值为y绘制拟合图,实线为y=x理想参照线,虚线为模型实际拟合线,各个模型的预测效果如图6所示.

不同模型在测试集上的评价函数值如表2所示. 可以看出,RF模型的RMSE和R2分别为0.286、0.954,在5个模型里表现最好,同时它还具有优良的抗过拟合能力和泛化能力[35]. 此外,RF模型可以返回特征的重要性值,当多个特征存在多重共线性时,他们的特征重要性会被相互抵消[36],从而准确理解和解释各个特征在吸附过程中的作用,因此选择RF模型进行下一步的特征分析.

表 2 5种不同模型的拟合性能Table 2. Fitting performance of the five different models模型Model 均方误差MSE 均方根误差RMSE 平均绝对误差MAE 决定系数R2 LR 0.402 0.634 0.471 0.775 SVR(L) 0.414 0.643 0.468 0.768 SVR(RBF) 0.089 0.299 0.192 0.95 BP 0.112 0.335 0.252 0.937 RF 0.082 0.286 0.215 0.954 2.3 特征重要性分析

将数据集按不同温度(273 K,298 K)和压力(0—0.5 bar,0.5—1 bar)分为4组,用RF模型进行拟合预测,模型的预测结果如图7所示. 可以看出R2分别为0.906、0.915、0.906、0.912,均大于0.9,表明RF模型对4组数据集都有很好的拟合预测效果.

将RF模型得出的特征重要性绘制成百分比柱状图,以便直观表现不同温度压力下各特征重要性的变化[37],如图8所示. 压力是PCM吸附CO2最重要的影响因素,但随着压力和温度的提高,结构特性和元素组成逐渐成为主导因素. 压力升高,其本身的重要性在273 K和298 K下分别下降了66%和60%,可能的原因是这些PCM的孔隙结构中主要是微孔和超微孔,CO2的吸附机理是体积填充,相较于大孔和中孔上的层层吸附,当微孔填充达到饱和后增加压力对吸附量的影响降低. 此外,相较于298 K,273 K时的压力重要性更大(71%、24%),这可能是因为较高温度导致的CO2分子运动加剧[38],一定程度上削弱了压力带来的正向作用. 从此得到启发,对于烟气中CO2的处理,使用PCM作为吸附剂,可以结合变温、变压吸附来减少能耗.

结构特性和元素组成的特征重要性详细数据如表3所示. 结构特性方面,随着压力的提高比表面积、总孔容、微孔容、中孔容的重要性都有不同程度的提升,整体在273 K和298 K时分别提高3.1倍和2.3倍,值得注意的是比表面积的影响提升明显,是结构特性中影响CO2吸附能力最重要的因素,273 K时比表面积的特征重要性由2.95%提高到了18.27%,这可能是由于在更高的压力(0.5—1 bar)下,作为主要吸附空间的微孔吸附接近饱和后,增加压力对吸附的影响降低,这时较大的比表面积意味着更多的吸附位点[39 − 40];微孔容的特征重要性随着压力的变化也有很大提升,298 K时由2.18%提升到9.61%;中孔容的特征重要性随温度和压力的变化不大,在4%—8%之间,但特征重要性显示的是影响的绝对值,结合皮尔逊相关性分析的弱负相关性(r=−0.086,P<0.01),可以看出在常压(0—1 bar)下中孔对碳材料吸附CO2的性能影响较小. 元素组成方面,整体上特征重要性的排序为N>C>O>H,含氮基团可以作为Lewis碱性位点,通过酸碱相互作用有效地结合酸性二氧化碳分子,从而增强PCM的CO2吸附能力,氮元素的特征重要性在273 K、0.5—1 bar时可以达到15.27%.

表 3 不同吸附条件下结构特性和元素组成的特征重要性Table 3. Characteristic importance of structural properties and elemental composition under different adsorption conditions273 K 298 K 0—0.5 bar 0.5—1 bar 0—0.5 bar 0.5—1 bar SBET 2.95% 18.27% 3.07% 10.69% Vtotal 1.95% 7.31% 3.27% 7.12% Vmicro 2.18% 9.61% 2.93% 6.04% Vmeso 6.22% 5.89% 4.64% 7.92% C 3.47% 6.31% 10.26% 10.1% H 3.2% 5.44% 5.55% 12.85% O 2.63% 8.28% 5.02% 12.22% N 6.87% 15.27% 9.07% 11.36% 有研究表明微孔不是控制吸附的唯一参数,强调中孔在CO2吸附方面的重要性[11],上述分析显示中孔在常压(0—1 bar)下对吸附的影响较小,对于更高压力下微孔和中孔的重要性,通过等高线图探究298 K、1/5 bar时,两种孔与吸附量之间的相关性,如图9所示. 结果表明,常压(0—1 bar)下PCM对CO2的吸附主要受微孔控制,高压(5 bar)下中孔对吸附也有重要作用.

3. 结论(Conclusion)

通过比较5种不同的机器学习模型,选择了随机森林模型进行特征重要性分析,探究了不同吸附条件下结构特性、元素组成对PCM吸附CO2性能的影响. 结果表明,对收集的碳材料样本,随机森林模型表现出良好的拟合预测性能,测试集R2=0.954. 压力是PCM吸附CO2最重要的影响因素,但随着压力和温度的提高,结构特性和元素组成逐渐成为主导因素. 结构特性方面,比表面积和微孔是结构特性中影响CO2吸附能力的关键因素;常压下CO2吸附主要受微孔控制,高压(5 bar)下中孔对吸附也有重要作用. 元素组成方面,氮元素是最重要的因素,其特征重要性在273 K、0.5—1 bar时可以达到15.27%. 本研究通过机器学习模型量化了PCM的结构特性、元素组成和吸附条件在吸附CO2中的影响,明确了材料的优化方向,同时利用建立的随机森林模型以PCM的结构特性和元素组成作为输入来预测CO2吸附量,可以减少实验重复次数,未来有望在开发高效吸附CO2的活性炭方面得到应用.

-

表 1 各模型的参数和参数空间

Table 1. Parameters and parameter space of each model

模型Models 参数Parameters 搜索空间Search space SVR(L) gamma [0.001, 0.005, 0.01, 0.02, 0.05, 0.1, 0.2, 0.3,0.4,0.5] C [0.1, 0.2, 0.25, 0.5, 1, 1.5, 2, 5, 10, 15, 16] SVR(RBF) gamma [0.001, 0.005, 0.01, 0.02, 0.05, 0.1, 0.2, 0.3,0.4,0.5] C [0.1, 0.2, 0.25, 0.5, 1, 1.5, 2, 5, 10, 15, 16] BP max_iter [10, 30, 50, 100, 200] learning rate ['constant', 'invscaling', 'adaptive'] solver ['lbfgs', 'sgd', 'adam'] RF n_estimators Range between 200 and 2000 with increments of 10 maximum tree depth [2, 3, 4, 5, 6, 7, 8, 9, 10] min_samples_leaf [1, 2, 4] 表 2 5种不同模型的拟合性能

Table 2. Fitting performance of the five different models

模型Model 均方误差MSE 均方根误差RMSE 平均绝对误差MAE 决定系数R2 LR 0.402 0.634 0.471 0.775 SVR(L) 0.414 0.643 0.468 0.768 SVR(RBF) 0.089 0.299 0.192 0.95 BP 0.112 0.335 0.252 0.937 RF 0.082 0.286 0.215 0.954 表 3 不同吸附条件下结构特性和元素组成的特征重要性

Table 3. Characteristic importance of structural properties and elemental composition under different adsorption conditions

273 K 298 K 0—0.5 bar 0.5—1 bar 0—0.5 bar 0.5—1 bar SBET 2.95% 18.27% 3.07% 10.69% Vtotal 1.95% 7.31% 3.27% 7.12% Vmicro 2.18% 9.61% 2.93% 6.04% Vmeso 6.22% 5.89% 4.64% 7.92% C 3.47% 6.31% 10.26% 10.1% H 3.2% 5.44% 5.55% 12.85% O 2.63% 8.28% 5.02% 12.22% N 6.87% 15.27% 9.07% 11.36% -

[1] CAO L, LEI S, GUAN Y X, et al. CCUS industry under target of carbon-peak and carbon-neutrality: Progress and challenges[J]. Frontiers in Energy Research, 2022, 10: 860665. doi: 10.3389/fenrg.2022.860665 [2] CHAPMAN A, ERTEKIN E, KUBOTA M, et al. Achieving a carbon neutral future through advanced functional materials and technologies[J]. Bulletin of the Chemical Society of Japan, 2022, 95(1): 73-103. doi: 10.1246/bcsj.20210323 [3] RAHMAN F A, AZIZ M M A, SAIDUR R, et al. Pollution to solution: Capture and sequestration of carbon dioxide (CO2) and its utilization as a renewable energy source for a sustainable future[J]. Renewable and Sustainable Energy Reviews, 2017, 71: 112-126. doi: 10.1016/j.rser.2017.01.011 [4] 王燕. 烟气中二氧化碳的化学处理技术及应用研究[J]. 科技信息, 2011(4): 114. WANG Y. Chemical treatment technology and application research of carbon dioxide in flue gas[J]. Science & Technology Information, 2011(4): 114 (in Chinese).

[5] CREAMER A E, GAO B. Carbon-based adsorbents for postcombustion CO2 capture: A critical review[J]. Environmental Science & Technology, 2016, 50(14): 7276-7289. [6] ZHANG Z H, SCHOTT J A, LIU M M, et al. Prediction of carbon dioxide adsorption via deep learning[J]. Angewandte Chemie International Edition, 2019, 58(1): 259-263. doi: 10.1002/anie.201812363 [7] 杨榛, 顾幸生, 梁晓怿, 等. 基于PCA-GA神经网络模式识别的炭纤维复合材料导电综合性能优化及预测的研究[J]. 计算机与应用化学, 2008, 25(12): 1543-1548. YANG Z, GU X S, LIANG X Y, et al. Optimization and prediction research on carbon fiber composite integrated conductive performance based on PCA-GANN pattern recognition[J]. Computers and Applied Chemistry, 2008, 25(12): 1543-1548(in Chinese).

[8] MAULANA KUSDHANY M I, LYTH S M. New insights into hydrogen uptake on porous carbon materials via explainable machine learning[J]. Carbon, 2021, 179: 190-201. doi: 10.1016/j.carbon.2021.04.036 [9] CAI J Z, CHU X, XU K, et al. Machine learning-driven new material discovery[J]. Nanoscale Advances, 2020, 2(8): 3115-3130. doi: 10.1039/D0NA00388C [10] YUAN X Z, SUVARNA M, LOW S, et al. Applied machine learning for prediction of CO2 adsorption on biomass waste-derived porous carbons[J]. Environmental Science & Technology, 2021, 55(17): 11925-11936. [11] WANG S, LI Y, DAI S, et al. Prediction by convolutional neural networks of CO2/N2 selectivity in porous carbons from N2 adsorption isotherm at 77 K[J]. Angewandte Chemie International Edition, 2020, 59(44): 19645-19648. doi: 10.1002/anie.202005931 [12] ZHU X Z, TSANG D C W, WANG L, et al. Machine learning exploration of the critical factors for CO2 adsorption capacity on porous carbon materials at different pressures[J]. Journal of Cleaner Production, 2020, 273: 122915. doi: 10.1016/j.jclepro.2020.122915 [13] HAGHIGHATLARI M, HACHMANN J. Advances of machine learning in molecular modeling and simulation[J]. Current Opinion in Chemical Engineering, 2019, 23: 51-57. doi: 10.1016/j.coche.2019.02.009 [14] 刘楠. 煤基多孔碳的制备、改性及其对CO2/CH4吸附分离研究[D]. 焦作: 河南理工大学, 2020. LIU N. Study on preparation and modification of coal-based porous carbon and its adsorption and separation for CO2/CH4[D]. Jiaozuo: Henan Polytechnic University, 2020(in Chinese).

[15] 张涛, 王彬彬, 李瑶. 基于玉米秸秆的氮掺杂多孔碳制备及其对CO2吸附和CO2/N2分离性能研究[J]. 河南理工大学学报(自然科学版), 2022, 41(6): 174-180. ZHANG T, WANG B B, LI Y. Preparation ofstalk-based nitrogen-doped porouscarbon and itsCO2 adsorption and CO2/N2 separation properties[J]. Journal of Henan Polytechnic University (Natural Science), 2022, 41(6): 174-180(in Chinese).

[16] 王娅鸽, 王彬彬, 杨德威, 等. 氮掺杂柔性块体多孔碳的制备及其对CO2/CH4吸附分离研究[J]. 材料导报, 2023, 37(22): 22050326. WANG Y G, WANG B B, YANG D W, et al. Preparation of nitrogen-doped flexible bulk porous carbon and its study on CO2/CH4 adsorption and separation[J]. Materials Reports, 2023, 37(22): 22050326(in Chinese).

[17] 熊龙. 氮掺杂多孔碳纤维的制备及其二氧化碳吸附性能研究[D]. 昆明: 昆明理工大学, 2020. XIONG L. Preparation of nitrogen doped porous carbon fiber and its carbon dioxide adsorption performance[D]. Kunming: Kunming University of Science and Technology, 2020 (in Chinese).

[18] 刘康恺, 韩云龙, 孟龙月, 等. Zeolites模板法制备氮掺杂多孔碳材料及其CO2吸附性能[J]. 实验室研究与探索, 2018, 37(9): 29-32. LIU K K, HAN Y L, MENG L Y, et al. Preparation and performance of CO2 adsorption of N-doped porous carbons by zeolites-template method[J]. Research and Exploration in Laboratory, 2018, 37(9): 29-32(in Chinese).

[19] SONG C C, LIU M H, YE W Y, et al. Nitrogen-containing porous carbon for highly selective and efficient CO2 capture[J]. Energy & Fuels, 2019, 33(12): 12601-12609. [20] QIN F F, GUO Z Y, WANG J S, et al. Nitrogen-doped asphaltene-based porous carbon nanosheet for carbon dioxide capture[J]. Applied Surface Science, 2019, 491: 607-615. doi: 10.1016/j.apsusc.2019.06.194 [21] KIM Y K, KIM G M, LEE J W. Highly porous N-doped carbons impregnated with sodium for efficient CO2 capture[J]. Journal of Materials Chemistry A, 2015, 3(20): 10919-10927. doi: 10.1039/C5TA01776A [22] WANG J C, SENKOVSKA I, OSCHATZ M, et al. Highly porous nitrogen-doped polyimine-based carbons with adjustable microstructures for CO2 capture[J]. Journal of Materials Chemistry A, 2013, 1(36): 10951-10961. doi: 10.1039/c3ta11995e [23] FU N, YANG B, WANG Y, et al. Micromeso hierarchical porous ultrathin nitrogen-doped carbon nanosheets with rough surfaces for efficient gas adsorption and separation[J]. Energy & Fuels, 2022, 36(22): 13705-13712. [24] SHARMA M, SNYDER M A. Facile synthesis of flower-like carbon microspheres for carbon dioxide capture[J]. Microporous and Mesoporous Materials, 2022, 335: 111801. doi: 10.1016/j.micromeso.2022.111801 [25] KOU J H, SUN L B. Fabrication of nitrogen-doped porous carbons for highly efficient CO2 capture: Rational choice of a polymer precursor[J]. Journal of Materials Chemistry A, 2016, 4(44): 17299-17307. doi: 10.1039/C6TA07305K [26] PARSHETTI G K, CHOWDHURY S, BALASUBRAMANIAN R. Biomass derived low-cost microporous adsorbents for efficient CO2 capture[J]. Fuel, 2015, 148: 246-254. doi: 10.1016/j.fuel.2015.01.032 [27] RAO L L, LIU S F, WANG L L, et al. N-doped porous carbons from low-temperature and single-step sodium amide activation of carbonized water chestnut shell with excellent CO2 capture performance[J]. Chemical Engineering Journal, 2019, 359: 428-435. doi: 10.1016/j.cej.2018.11.065 [28] THRUN M C, GEHLERT T, ULTSCH A. Analyzing the fine structure of distributions[J]. PLoS One, 2020, 15(10): e0238835. doi: 10.1371/journal.pone.0238835 [29] 戚兴怡, 胡耀峰, 王若愚, 等. 机器学习在新材料筛选方面的应用进展[J]. 化学学报, 2023, 81(2): 158-174. doi: 10.6023/A22110446 QI X Y, HU Y F, WANG R Y, et al. Recent advance of machine learning in selecting new materials[J]. Acta Chimica Sinica, 2023, 81(2): 158-174 (in Chinese). doi: 10.6023/A22110446

[30] FERNÁNDEZ-DELGADO M, SIRSAT M S, CERNADAS E, et al. An extensive experimental survey of regression methods[J]. Neural Networks, 2019, 111: 11-34. doi: 10.1016/j.neunet.2018.12.010 [31] 李炜, 梁添贵, 林元创, 等. 机器学习辅助高通量筛选金属有机骨架材料[J]. 化学进展, 2022, 34(12): 2619-2637. LI W, LIANG T G, LIN Y C, et al. Machine learning accelerated high-throughput computational screening of metal-organic frameworks[J]. Progress in Chemistry, 2022, 34(12): 2619-2637 (in Chinese).

[32] TANVEER M, RAJANI T, RASTOGI R, et al. Comprehensive review on twin support vector machines[J]. Annals of Operations Research, 2022: 1-46. [33] SITEK W, TRZASKA J. Practical aspects of the design and use of the artificial neural networks in materials engineering[J]. Metals, 2021, 11(11): 1832. doi: 10.3390/met11111832 [34] PALLE K, VUNGUTURI S, GAYATRI S N, et al. The prediction of CO2 adsorption on rice husk activated carbons via deep learning neural network[J]. MRS Communications, 2022, 12(4): 434-440. doi: 10.1557/s43579-022-00197-2 [35] AURET L, ALDRICH C. Interpretation of nonlinear relationships between process variables by use of random forests[J]. Minerals Engineering, 2012, 35: 27-42. doi: 10.1016/j.mineng.2012.05.008 [36] ARASHI M, LUKMAN A F, ALGAMAL Z Y. Liu regression after random forest for prediction and modeling in high dimension[J]. Journal of Chemometrics, 2022, 36(4): e3393. doi: 10.1002/cem.3393 [37] MIZUMOTO A. Calculating the relative importance of multiple regression predictor variables using dominance analysis and random forests[J]. Language Learning, 2023, 73(1): 161-196. doi: 10.1111/lang.12518 [38] ZHANG X, ZHANG S H, YANG H P, et al. Influence of NH3/CO2 modification on the characteristic of biochar and the CO2 capture[J]. BioEnergy Research, 2013, 6(4): 1147-1153. doi: 10.1007/s12155-013-9304-9 [39] OUYANG L K, XIAO J F, JIANG H S, et al. Nitrogen-doped porous carbon materials derived from graphene oxide/melamine resin composites for CO2 adsorption[J]. Molecules, 2021, 26(17): 5293. doi: 10.3390/molecules26175293 [40] QI S C, LIU Y, PENG A Z, et al. Fabrication of porous carbons from mesitylene for highly efficient CO2 capture: A rational choice improving the carbon loop[J]. Chemical Engineering Journal, 2019, 361: 945-952. doi: 10.1016/j.cej.2018.12.167 -

下载:

下载: