-

煤炭、建材、水泥、电力等行业产生的大量粉尘颗粒物,会威胁人群健康[1],可采用除尘装置收集环境中的粉尘颗粒物。滤筒除尘器具有除尘效率高、阻力适中、过滤面积大、价格低、占地面积小等优点,在除尘领域得到了广泛的应用[2]。滤筒清灰是除尘器运行的关键环节,清灰效果的好坏直接影响到除尘器的稳定运行[3-4]。目前,清灰技术应用最广泛的是脉冲气流反向喷吹[5]。但是,在脉冲清灰过程中,喷吹气流在滤筒侧壁分布不均匀,主要表现为滤筒上部清灰作用不足[6-7]。

国内外学者针对滤筒脉冲清灰性能的优化已开展了诸多研究。在脉冲喷嘴改进方面,刘东等[8]对不同锥度上部开口的散射器的侧壁压力峰值的分布规律进行了研究,考察了喷吹压力和喷吹距离对清灰效果的影响,发现上部开口散射器能有效解决上部清灰不足、下部清灰过度的问题。胥海伦等[9]采用数值模拟对开口散射器下的脉冲喷吹滤筒清灰气流流场进行了研究,发现安装上部开孔锥形散射器可提高滤筒脉冲清灰的均匀性,有利于解决滤筒下部滤料破损的问题。张情等[10]采用数值模拟的方法对诱导喷嘴下滤筒(外径×高度:325 mm×660 mm)的内部流场进行了研究,分析了滤筒内部流场变化规律和侧壁压力峰值的分布,发现诱导喷嘴使得滤筒内部喷吹压力更均匀,进而改善了清灰效果。巨敏等[11]采用普通喷嘴和诱导喷嘴对滤筒(外径×高度:325 mm×660 mm)脉冲清灰开展了研究,通过对比滤筒侧壁压力峰值和粉尘脱落的动态过程,发现采用诱导喷嘴可改善滤筒内部气流流场,从而提高清灰效率。

在滤筒结构优化方面,LI等[12]在滤筒内部安装了圆锥体,证明其有利于增加滤筒侧壁压力,并可改善清灰均匀性。杨燕霞等[2]研究了金锥滤筒(内置锥形过滤面的滤筒)的脉冲清灰性能,揭示了金锥滤筒对脉冲清灰性能的影响机制。张亚蕊等[13]利用Fluent数值模拟研究了内置锥形体滤筒的过滤与清灰性能,对比了普通滤筒和内置锥形体滤筒的速度云图、压力云图的规律后发现,内置锥形体滤筒的清灰效果有明显改善。

滤筒的清灰效果仍存在改进空间,而同时优化喷嘴和滤筒以提高脉喷清灰性能的研究尚未见报道。本研究中,通过构建CFD数值模型对比了普通喷嘴与扩散喷嘴、普通滤筒与金锥滤筒条件下滤筒内喷吹气流压力的时空演变,分析了各个测点压力的变化规律,并考察不同喷吹距离对滤筒脉冲喷吹强度和均匀性的影响,从而探究扩散喷嘴和金锥滤筒组合条件下的脉喷清灰性能,以期为滤筒除尘器脉喷清灰性能的优化提供参考。

全文HTML

-

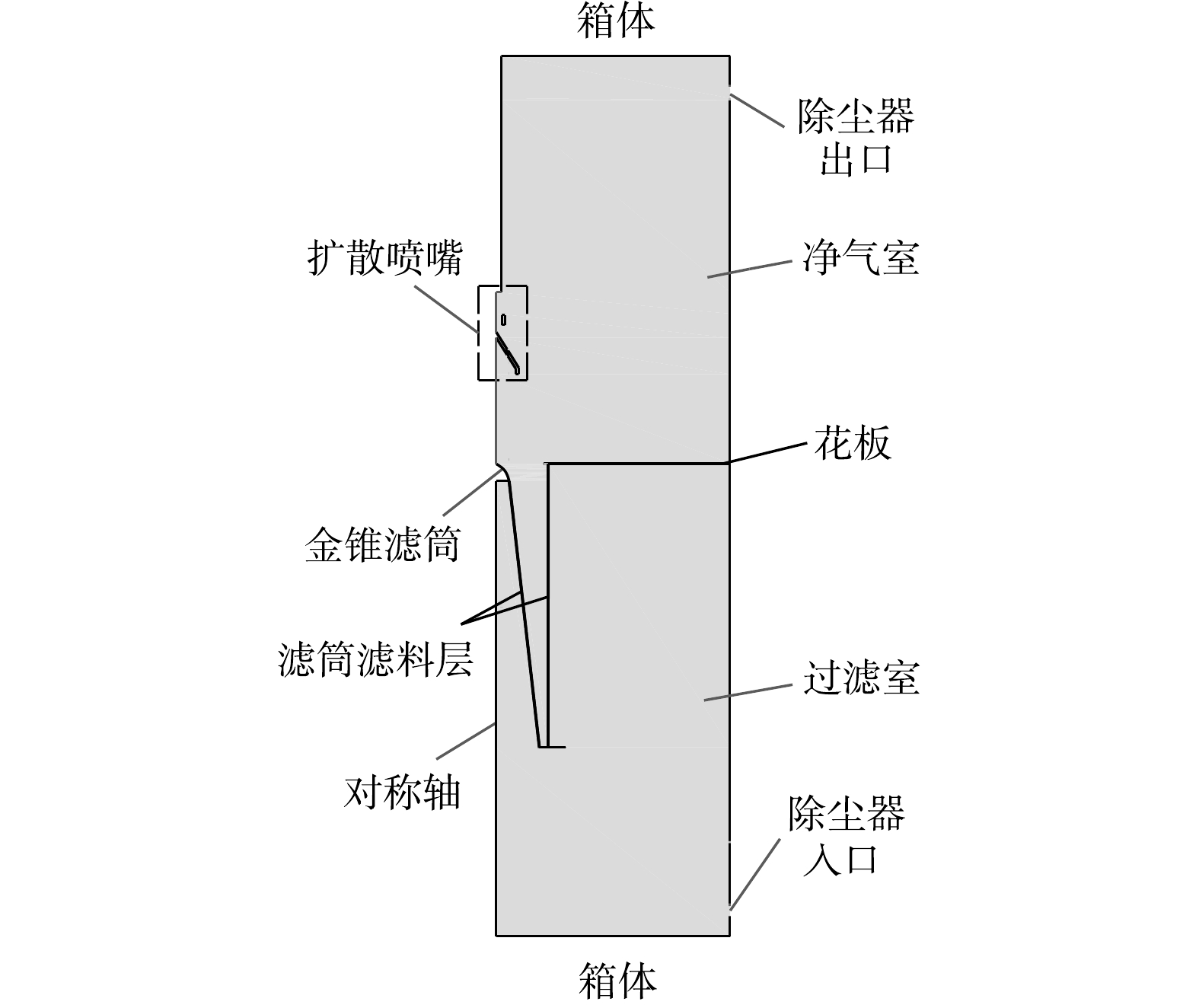

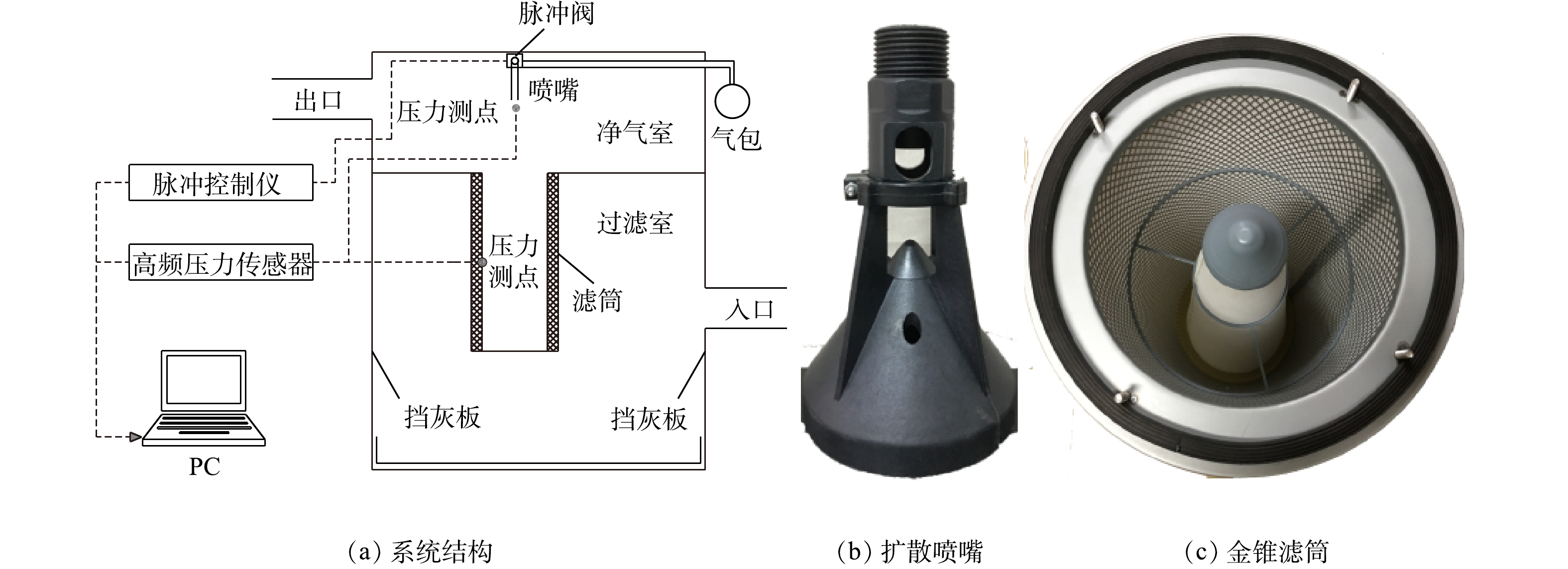

本数值模拟以脉冲喷吹除尘器实验系统为原型。系统结构如图1(a)所示。除尘器箱体长宽高尺寸为1 225 mm×750 mm×1 550 mm,内部竖直安装普通滤筒或金锥滤筒。图1(b)和(c)分别为扩散喷嘴和金锥滤筒的实物图。普通直管喷嘴或扩散喷嘴安装在滤筒的正上方,扩散喷嘴是在普通喷嘴的基础上增加了锥形扩散器,锥形扩散器的锥角71°、锥顶距普通喷嘴40 mm、锥底面直径102 mm。滤筒为无纺布长绒棉涤纶材质,滤筒的外形长度660 mm、直径240 mm,滤料厚度0.6 mm,普通喷嘴直径25 mm。金锥滤筒是在普通滤筒的基础上增加了内锥过滤面,内锥的底部开口且其直径为200 mm,内锥的顶部设有高度40 mm、底面直径65 mm的金属锥体。脉冲喷吹时长设为150 ms,初始气包压力0.5 MPa,气包容积20 L。喷嘴出口下方10 mm处和滤筒中部安装有压力传感器,该传感器为压电陶瓷高频动态压力传感器MYD-1530A型(ϕ7 mm×17 mm,灵敏度6~13 pC·(kPa)−1。

-

由于滤筒除尘器为中心轴对称结构,故为节省计算量,将其简化为二维模型。同时,将矩形箱体简化为体积相等的圆柱形箱体,计算得到简化柱形箱体的水平截面半径为541 mm。除尘器实际出入口直径为150 mm,按照面积相等的原则将其简化为高度5.2 mm的环形出入口以便于代入轴对称模型中,简化后的二维模型如图2所示。为研究更多的喷吹距离对喷吹压力的影响,模型中增加了除尘器上箱体的高度。

-

1)模拟边界条件的设置。喷嘴设为压力入口,除尘器入口和出口边界设置为压力出口;壁面设置为标准无滑移边界;滤筒中的滤料层设置为多孔介质区域。本研究中,把喷吹过程的流体视作可压缩、非稳态、等温、湍流的状态。喷吹过程不考虑粉尘的运移,忽略滤筒形变。选用Realizable k-ε湍流模型求解,采用压力-速度耦合算法。

2)脉冲喷吹清灰过程。喷吹气流从滤筒上方的喷嘴喷出,通过喷嘴下方的高频压力传感器测得喷嘴出口瞬间的压力变化(测试结束后移走);然后,对压力随时间的变化曲线进行分段拟合,获得喷嘴出口的压力(Pc)随时间(t)变化的函数,见式(1)。该压力入口应用于普通滤筒。同理,扩散喷嘴出口的压力(Pd)随时间(t)变化的函数,见式(2)。分别将式(1)和(2)以UDF的形式导入求解器进行计算,时间步长设置为0.000 5 s。

式中:Pc为喷嘴出口的压力,kPa;t为时间,s;Pd为扩散喷嘴出口的压力,kPa。因普通滤筒与金锥滤筒过滤面积的差异,二者的喷吹气流应匹配。根据文献[1],喷吹气量与过滤面积成正比,见式(3)。

式中:Q为最小喷气量,m·h−1;C1、C2为粉尘的特性参数;C3为过滤速度系数,

${C_3} = V_f^{0.6}$ ,m·s−1;C4为喷吹装置系数;F为总过滤面积,m2;Vf为过滤速度,m·s−1;k为诱导比。通过实验测试脉冲喷吹前后气包内的绝对压力,利用式(4)计算喷吹实际耗气量[14]。

式中:Qp为脉冲时间 t 内喷吹气量,m3·次−1;P0、P1为喷吹前、后气包内的绝对压力,MPa;Pa 为当地的标准大气压力,MPa(取 0.099 91 MPa);V 为气包容积,20×10−3 m3;K为绝热指数,空气取K = 1.4。

金锥滤筒的过滤面积是普通滤筒的1.62倍,实验初始气包压力为0.50 MPa时,喷吹剩余压力为0.32 MPa,普通喷嘴出口压力的峰值为95.31 kPa。可求得金锥滤筒条件下所需气包压力为Pt=0.72 MPa,其对应的喷嘴出口压力峰值为171.27 kPa,即金锥滤筒条件下的喷嘴出口压力应为普通滤筒条件下的1.80倍。

滤料层(多孔介质区)的计算是通过在标准的流体方程附加一个动量源

$ \Delta p $ 来实现,该动量源包括黏性损失和惯性损失项,计算公式见式(5)。式中:∆p为压力,Pa;

$ \mu $ 为层流黏度,Pa·s;α为渗透率,m2;C2为压强跃升系数,m−1;v为法向加速度,m·s−1;∆m为介质厚度,m;ρ为空气密度,kg·m−3。对于有限厚度的多孔介质的黏性损失项可用达西定律表示,而对于多孔介质内部速度较低的流动,其惯性损失项可忽略[15]。经实验测试与计算,所用滤料的厚度为0.6 mm,在过滤风速为0.5 m·min−1时压降为17.9 Pa,其黏性损失系数1/α为2.0×1011 m−2。

1.1. 实验系统

1.2. 几何模型的构建与简化

1.3. 模拟的边界条件

-

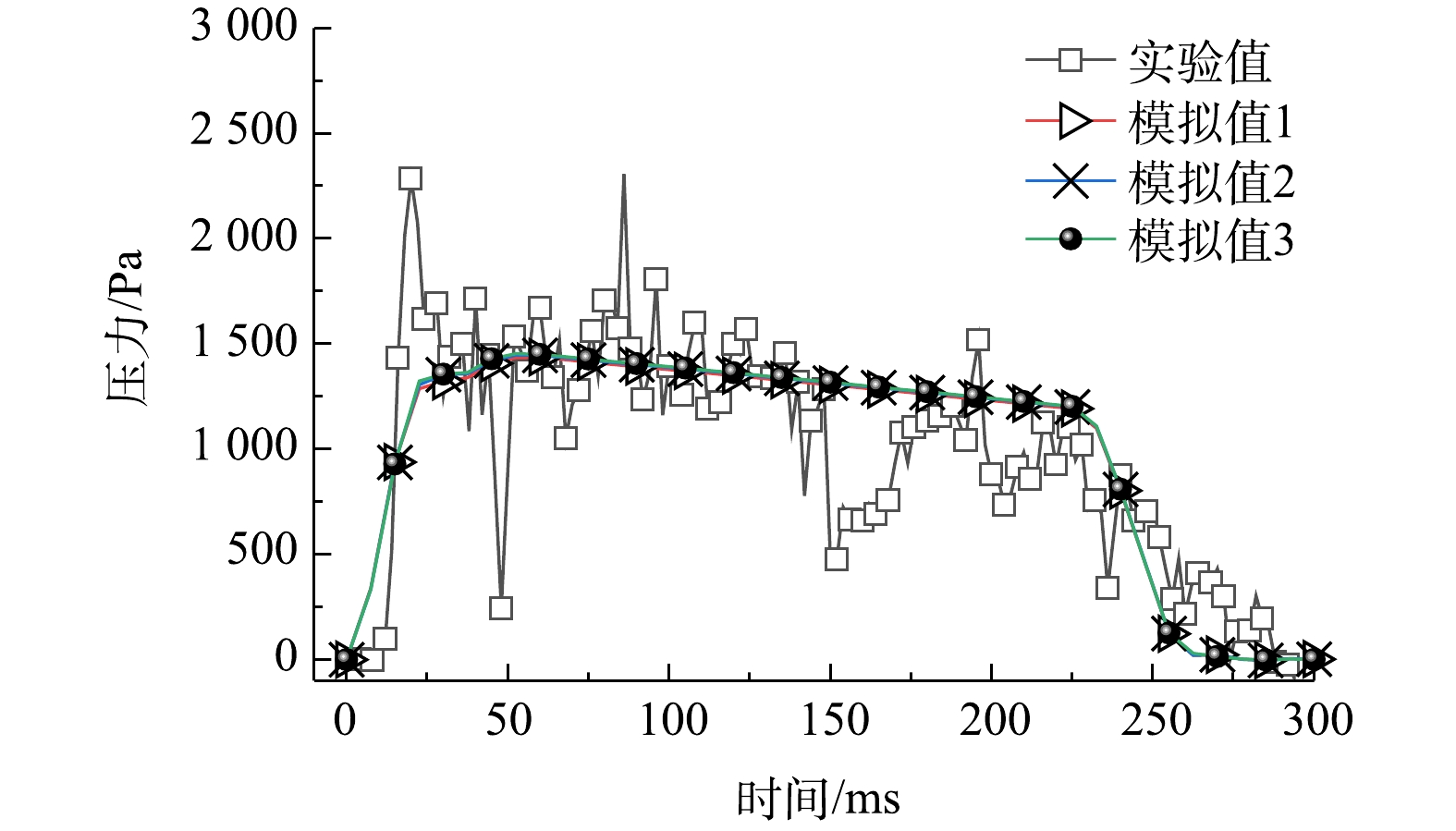

网格划分采用结构化网格,划分后网格节点总数为30 400个、元素为29 800个。为验证网格独立性将网格加密,加密后网格节点总数为41 100个、元素为40 400个。图3中对比了普通喷嘴和普通滤筒的组合条件下,初始气包压力0.5 MPa、脉冲宽度0.15 s、喷吹距离250 mm时,网格加密前(模拟值1)后(模拟值2)滤筒内壁中间观测点的压力变化,二者几乎吻合,可认为加密前网格已经达到网格独立性的要求,故本研究可以采用。另外,为满足更多喷吹距离实验,模型中增加了净化室高度。模拟结果表明,净化室高度增加前(模拟值3)后(模拟值1)的数据曲线基本吻合,由此可认为,增加的高度对气流影响可忽略。

对比图3中模拟与实验值后发现,实验测定的数值相比模拟计算结果波动较大。这可能是由于模拟未考虑滤筒侧壁区域的流固耦合,而实际脉冲喷吹过程中筒壁受脉冲喷吹的冲击波作用发生振动,并带起传感器运动引起测试数据的波动。总体来说,模拟结果反映了实验数值的整体变化趋势,并与实验测定数值的均值基本吻合,故可认为数值模拟所得结果满足分析要求。

-

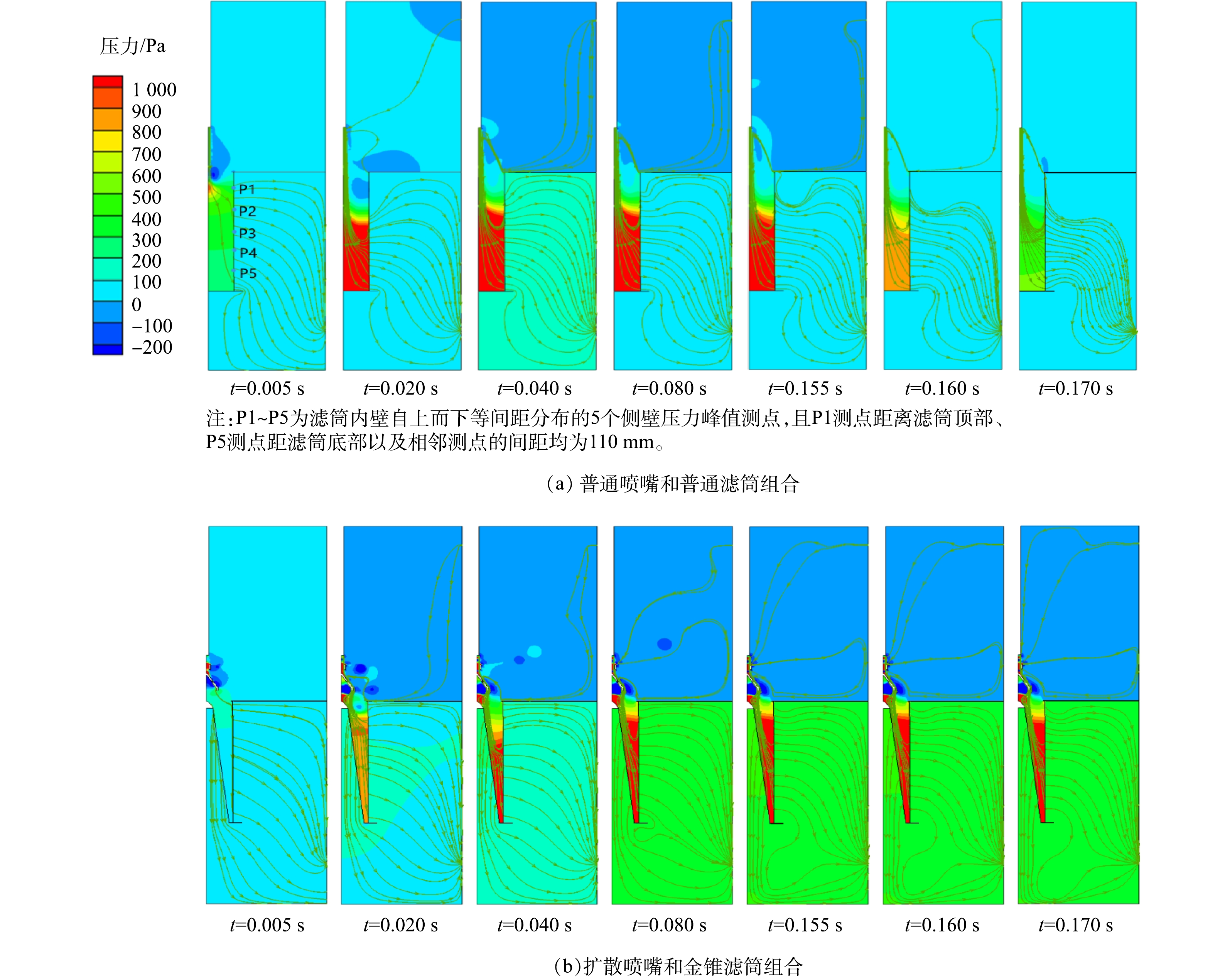

图4所示为初始气包压力0.5 MPa、脉冲宽度0.15 s、喷吹距离250 mm条件下,脉冲喷吹过程中除尘器内静压力云图与流线图。

在普通喷嘴和普通滤筒组合的条件下(见图4(a)),喷吹气流从喷嘴喷出,诱导周围的二次气流进入滤筒内部。根据滤筒内压力的空间分布,喷吹气流的静压自滤筒底部向上蓄积,底部的静压较高而顶部静压较低。这主要是由于当气流运动到普通滤筒底部时发生反弹蓄积而造成[16]。在滤筒顶部,受到的压力最小甚至出现了负压,使得滤筒顶部压力明显低于中下部区域,因而造成滤筒上部清灰不足。而喷吹压力在水平方向上(滤筒径向)的变化梯度不明显。从喷吹压力随时间的变化特征可知,滤筒内部压力先整体升高,到t=0.040 s时基本达到稳定,并持续到t=0.155 s时压力开始下降。

在扩散喷嘴和金锥滤筒组合的条件下(见图4(b)),滤筒内部压力先整体升高,到t=0.080 s时基本达到稳定,并持续到t=0.170 s时压力开始下降。与普通喷嘴和普通滤筒组合的条件(见图4(a))相比,从压力的空间分布看,扩散喷嘴和金锥滤筒组合的主要优势在于喷吹压力达到稳定的时刻以及大小。普通喷嘴和普通滤筒组合在t=0.040 s时基本达到稳定,而扩散喷嘴和金锥滤筒组合在t=0.080 s时基本达到稳定;前者气流直接进入滤筒底部,而后者气流在金锥的导流作用下进入滤筒,并且滤筒上部区域的喷吹压力更大。另外,当气流从金锥滤筒顶部向底部运动时,一部分气流直接穿过金锥过滤面流向滤筒下侧,这有利于粉尘颗粒沿着气流轨迹方向脱落。

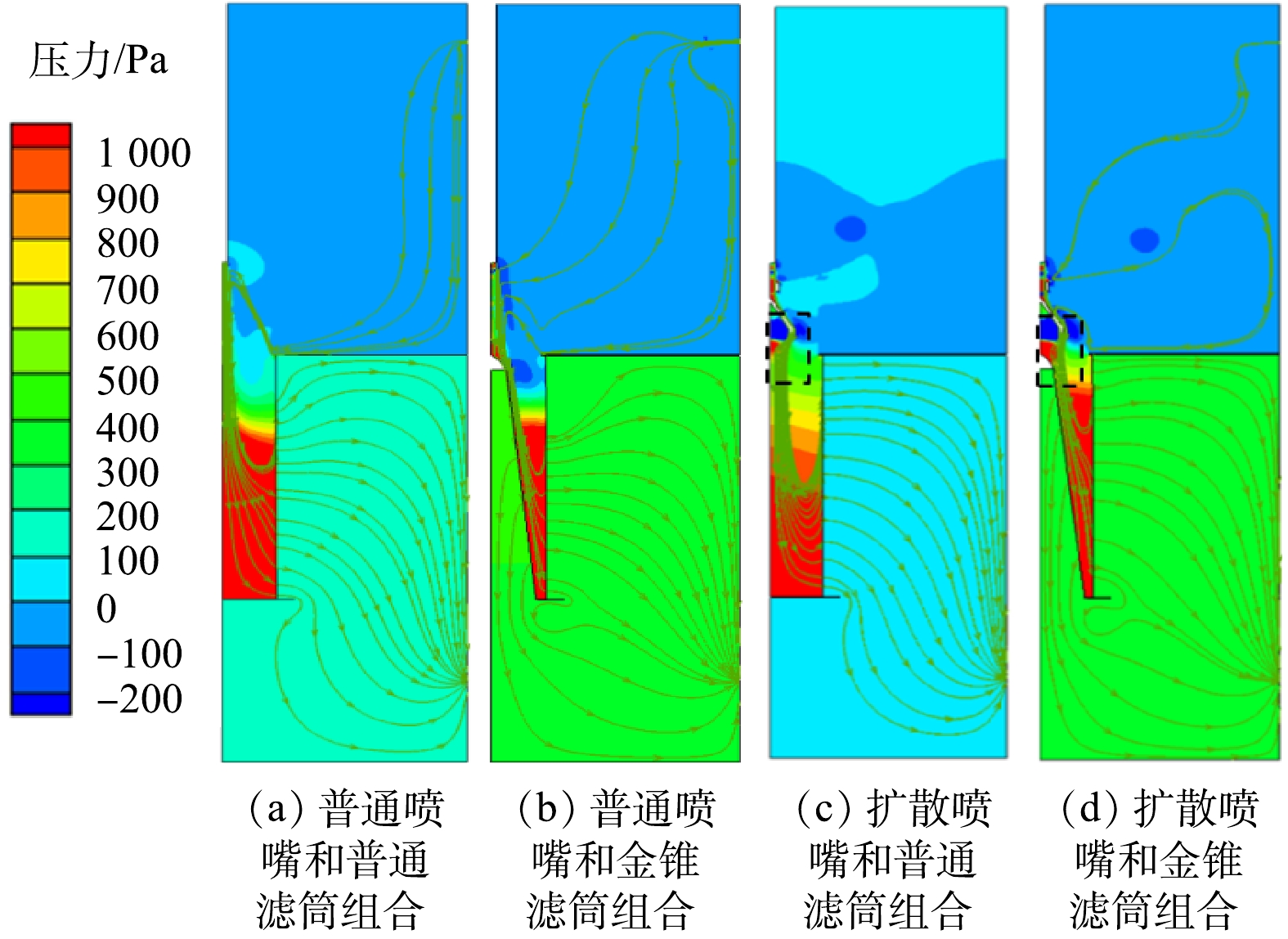

通过比较2种滤筒的使用情况(见图5各子图)可发现,金锥滤筒的压力自滤筒底部往上蓄积的效果更明显,滤筒内部压力更大。这是由于金锥滤筒比普通滤筒的内部空间更小,在2种滤筒单位过滤面积的喷吹气量相同的条件下,具有更大过滤面积的金锥滤筒在更小的内部空间中进入了更多的喷吹气量,从而实现了更强的气流压能蓄积。

通过比较2种喷嘴的使用情况(见图5各子图)后可发现,在普通滤筒条件下扩散喷嘴使得喷吹压力蓄积更小,而在金锥滤筒条件下扩散喷嘴使得喷吹压力更大。一方面,由于扩散喷嘴有利于将气流的动压能在进入滤筒之前转化为静压能,增大了滤筒内气流静压的蓄积(与喷吹气流在滤筒轴向上的动压相比,静压具有径向的分量,可对滤筒侧壁产生有效的清灰作用);另一方面,在普通滤筒条件下,扩散后的气流在喷嘴下方收缩(见图5(c)黑色虚线框,气流沿扩散喷嘴发生扩散后,在其下方迹线重新收束)并产生局部漩涡,故消耗较多气流能量;而在金锥滤筒条件下,由于金锥的导流作用,扩散后的喷吹气流直接进入滤筒内部而存在较少的局部漩涡(见图5(d)黑色虚线框,气流沿扩散喷嘴发生扩散后,其下方迹线收束程度相比图5(c)中更平缓),气流阻力相对更小。

进一步对比可发现,扩散喷嘴和金锥滤筒组合的条件下滤筒上部区域的喷吹压力在4种组合中最高,可见,两者的组合对于提高滤筒上部喷吹压力具有协同作用。一方面,金锥滤筒在更小的内部空间中进入了更多的喷吹气量;另一方面,扩散喷嘴和金锥的配合使得喷吹气流可在较小的阻力下实现动压转化为有利于喷吹的静压。

-

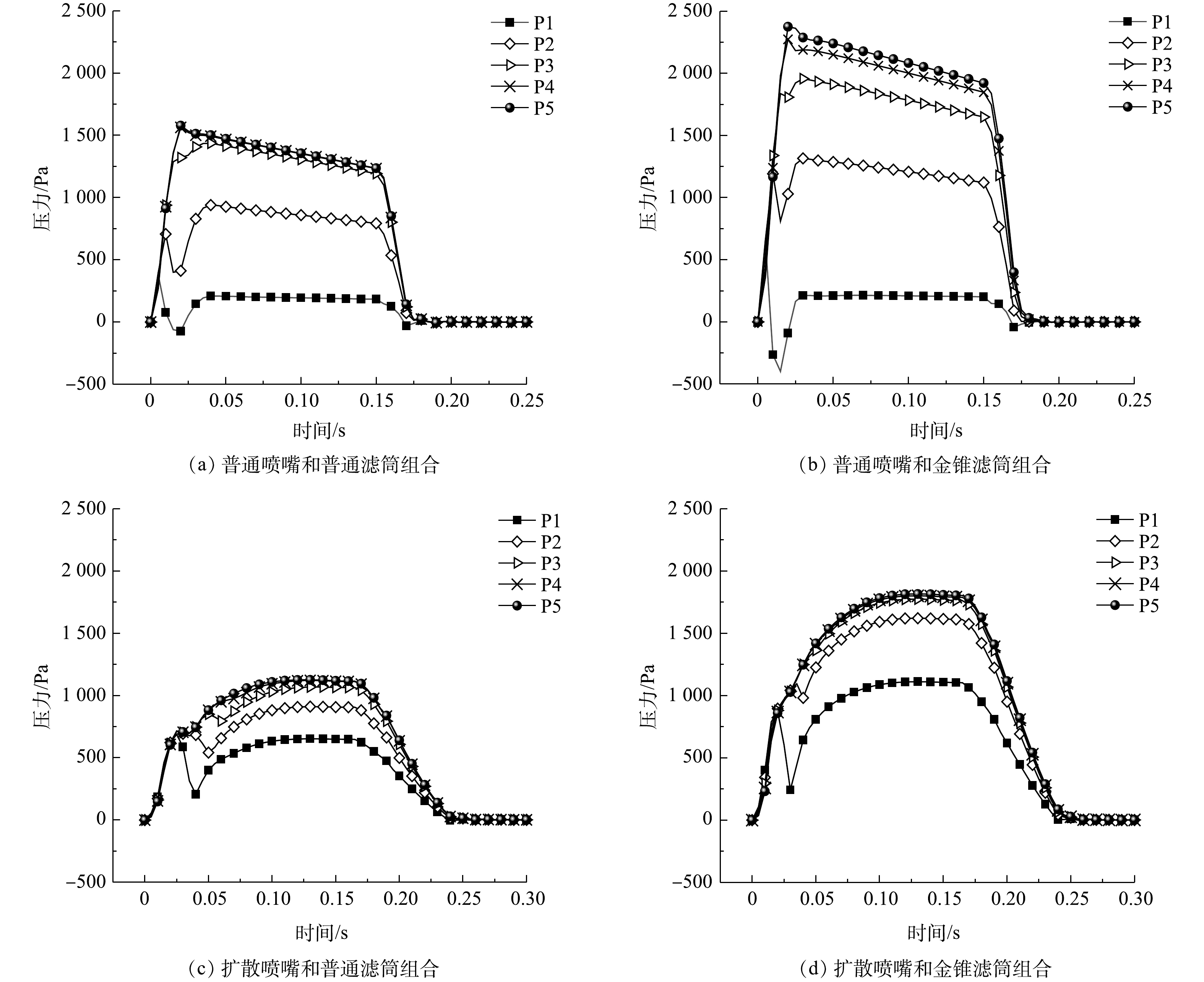

图6为各个观测点在脉冲喷吹过程中的压力随时间变化的数值模拟结果。为定量分析滤筒内压力变化,选取滤筒内壁自上而下等间距分布的5个观测点(P1测点距离滤筒顶部、P5测点距滤筒底部以及相邻测点的间距均为110 mm)(见图4)进行研究。图6(a)和(b)2种组合条件下的喷吹压力都在t=0.040 s时基本达到相对稳定,在t=0.155 s时开始快速减弱;图6(c)和(d)2种组合在t=0.080 s时基本达到稳定,在t=0.170 s时开始减弱(与2.2节对压力云图的分析一致)。另外,4种组合条件下,P3、P4、P5测点压力相近且最大,P2测点压力次之,P1测点压力最小。其中,普通喷嘴和普通滤筒组合条件下的喷吹压力空间分布与文献[17]的结果相一致。

由表1和2种滤筒对比(见图6(a)和(b))可知,在普通喷嘴条件下,金锥滤筒内的喷吹压力总体上比普通滤筒更大,其中对P3、P4、P5测点压力的影响较显著,对P2测点压力的影响次之,对P1测点压力的影响微弱。在扩散喷嘴条件下,对比2种滤筒的使用(见图6(c)和(d))可知,金锥滤筒内各测点喷吹压力均大于普通滤筒。因此,相对于普通滤筒,使用金锥滤筒对喷吹压力的提升效果更显著。

由表1并对比2种喷嘴的使用(图6(a)和(c))可知,在普通滤筒条件下,扩散喷嘴对P1测点喷吹压力的提升显著,P2~P5测点喷吹压力发生了不同程度的降低。在金锥滤筒条件下,对比2种喷嘴的使用(图6(b)和(d))可知,扩散喷嘴对P1、P2测点喷吹压力的提升显著(比普通滤筒条件下提升效果更显著),P3、P4、P5测点喷吹压力均发生了不同程度的降低。由此说明,在金锥滤筒的使用中,扩散喷嘴有利于增大滤筒上部喷吹压力,降低滤筒下部喷吹压力,可提升脉冲喷吹滤筒清灰的均匀性。因此,扩散喷嘴和金锥滤筒的组合对于提高滤筒上部喷吹压力具有协同作用。

-

喷吹距离对各个测点喷吹压力的影响如图7所示。在喷吹距离0~550 mm时,普通喷嘴和普通滤筒组合(见图7(a))与扩散喷嘴和普通滤筒组合(见图7(c))中,总体上各测点喷吹压力随喷吹距离的增加而增加,其中,P1、P2、P3测点喷吹压力的上升趋势相对明显,P4、P5测点喷吹压力的上升趋势相对缓和。这是由于滤筒下部始终处于喷吹射流前方的扩展区,而滤筒中上部区域(P1、P2、P3测点)在喷吹距离较小时处于喷吹射流的卷吸区,在喷吹距离增大时则逐渐远离射流卷吸区并进入气流扩展区,使得喷吹距离对滤筒中上部区域的影响更大。

研究还发现,各喷吹距离下,普通喷嘴和普通滤筒的组合比扩散喷嘴条件下各测点的喷吹压力更大。其原因可能是:一方面,扩散喷嘴通过扩散作用将收束的喷吹射流转化为扩张的气流,有利于提高进入滤筒内的喷吹气流静压;另一方面,扩散喷嘴增加了喷吹气流的阻力,降低了进入滤筒内气流的总体能量。在普通滤筒条件下,后者作用更明显。

在普通喷嘴和金锥滤筒组合中(见图7(b)),P1、P2、P3测点喷吹压力随着喷吹距离的增加而增加,这与2种喷嘴在普通滤筒条件下类似。而P4、P5测点喷吹压力随着喷吹距离的增加呈现出先减小后增大的趋势。在扩散喷嘴和金锥滤筒组合中(见图7(d)),各测点喷吹压力随着喷吹距离的增加总体上呈现出先减小后增大的趋势。其中,在喷吹距离为150 mm时,P1测点喷吹压力最大,达到2 137.3 Pa。这是由于扩散喷嘴和金锥滤筒的距离较近,扩散后的喷吹气流冲击至金锥位置,并在金锥的导流作用下直接对P1点附近区域产生了较大喷吹压力。

-

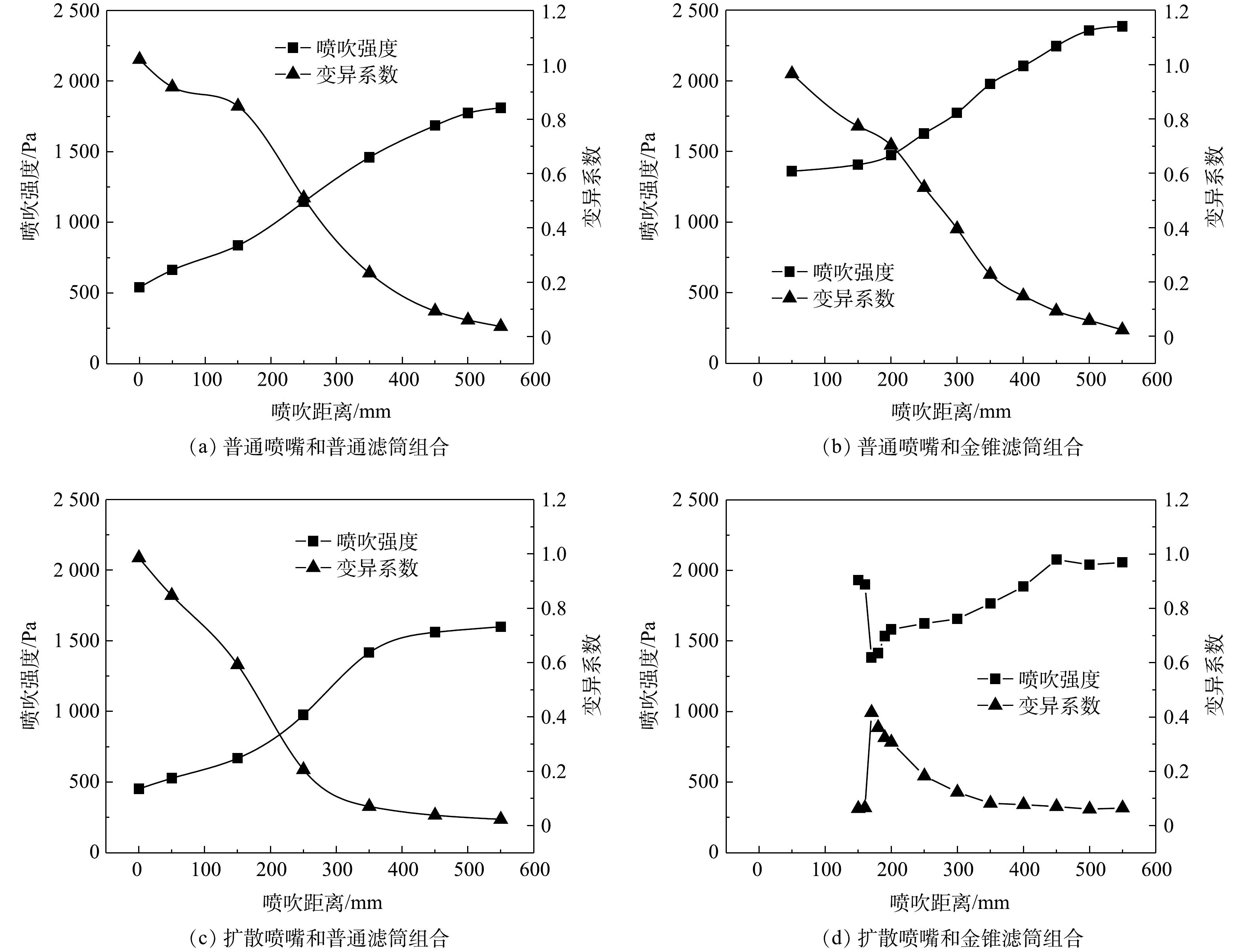

脉冲喷吹的性能一般可用喷吹强度和喷吹均匀性来表示,各测点正压力峰值的平均值常作为喷吹强度的指标,而峰值的变异系数常作为喷吹均匀性指标[15,18-19]。其中,平均值越大表明喷吹强度越大,而变异系数越小则表明均匀性越好。图8显示了4种组合在不同喷吹距离条件下脉冲喷吹强度和喷吹均匀性的对比。

在所考察的喷吹距离范围内,4种条件下的喷吹强度普遍随喷吹距离的增大而增大,峰值的变异系数随着喷吹距离的增大而减小。由此可知,随喷吹距离的增加,喷吹强度增大、喷吹均匀性改善,即脉喷清灰性能得到了提升。值得注意的是,扩散喷嘴和金锥滤筒组合中(见图8(d)),在喷吹距离为150~200 mm时,滤筒内部喷吹强度的提升效果较明显。

不管是普通喷嘴还是扩散喷嘴,使用金锥滤筒都可以增加脉冲喷吹强度。如喷吹距离为250 mm时,在普通喷嘴条件下,普通滤筒对应的喷吹强度为1 145.2 Pa,而金锥滤筒对应的喷吹强度则为1 626.8 Pa(为普通滤筒条件下的1.42倍);在扩散喷嘴条件下,普通滤筒对应的喷吹强度为975.7 Pa,金锥滤筒对应的喷吹强度为1 624.3 Pa(为普通滤筒条件下的1.66倍)。

扩散喷嘴和金锥滤筒组合条件下的喷吹强度均高于普通喷嘴与普通滤筒的组合,并明显高于扩散喷嘴与普通滤筒的组合。在喷吹距离大于250 mm时,扩散喷嘴和金锥滤筒组合条件下的喷吹强度相比普通喷嘴与金锥滤筒组合条件下提升不明显。当喷吹距离为150~250 mm时,对滤筒喷吹强度的提升效果明显。

值得注意的是,在喷吹距离为150~170 mm时(即扩散喷嘴与金锥距离接近时,此时金锥已伸入扩散喷嘴20~40 mm),若喷吹距离为150 mm,喷吹强度为1 931.3 Pa,变异系数为0.06,喷吹强度为普通喷嘴与普通滤筒的组合条件下的2.3倍,且均匀性显著提升(变异系数下降了13.5倍)。这是由于扩散后的喷吹气流可在金锥的导流作用下直接对滤筒上部区域产生喷吹作用。

综上所述,扩散喷嘴与金锥滤筒的组合在较小的喷吹距离下实现了较大的喷吹强度和较好的均匀性、获得了良好的脉喷清灰性能。而其他3种组合的条件下,都需要较大的喷吹距离才能实现良好的喷吹性能。因此,可认为扩散喷嘴与金锥滤筒在较小的喷吹距离下可实现良好喷吹性能,这有利于减小喷嘴装置的高度,进而减少净气室的空间、实现除尘装置的小型化。

2.1. 数值模拟验证

2.2. 喷吹压力的时空分布

2.3. 扩散喷嘴和金锥滤筒的组合对喷吹压力的影响

2.4. 喷吹距离对喷吹压力的影响

2.5. 喷吹距离对喷吹性能的影响

-

1)采用普通喷嘴或扩散喷嘴、普通滤筒或金锥滤筒,脉冲喷吹压力在滤筒内均为自下而上蓄积,上部压力小而下部压力大。其中,无论采用普通喷嘴还是扩散喷嘴,金锥滤筒内蓄积的喷吹压力均比普通滤筒条件下的更大;与普通喷嘴相比,扩散喷嘴有利于增大滤筒上部喷吹压力,降低滤筒下部喷吹压力。

2)扩散喷嘴和金锥滤筒的组合对于提高滤筒上部的喷吹压力具有协同作用,其原因是由于金锥滤筒在更小的内部空间中进入了更多的喷吹气量,同时扩散喷嘴和金锥的配合使用将喷吹气流的动压转化为有利于提高清灰性能的静压。

3)在所研究的喷吹距离550 mm下,普通喷嘴或扩散喷嘴、普通滤筒或金锥滤筒4种组合条件中,滤筒内部喷吹强度总体上均随喷吹距离的增加而增加、喷吹均匀性提高。其中,在扩散喷嘴和金锥滤筒组合的条件下,当扩散喷嘴与金锥距离接近时(金锥伸入扩散喷嘴20~40 mm),脉喷清灰性能改善显著,并有利于减少喷吹装置占据的空间。

下载:

下载: