-

随着我国全面推进生活垃圾分类,并将生活垃圾能源化回收、生物质沼气发电等列入国家能源发展规划,有机固体废弃物厌氧发酵的资源化技术成为研究热点。相较于采用传统湿式厌氧发酵工艺,有机生活垃圾因总固体含量高(TS>15%),更适合采用干式厌氧发酵进行生化处理[1]。近年来,干式厌氧发酵因其具有处理负荷高、沼液产生量少、容积产气率高以及发酵罐体积小等优点而广受关注[2]。目前,我国生活垃圾干式厌氧发酵的研究多处于实验室研究或中试阶段[3-5],工程应用少。相比而言,在欧洲,干式厌氧发酵技术起步早,其研究与应用发展较快[5-7];在过去10多年间,干式厌氧发酵系统的处理能力增加了50%[1]。由于生活饮食习惯不同,我国与欧洲生活垃圾的组成及特性差异大[7-9],且垃圾分类工作基础差,导致我国干式厌氧发酵工程面临原料垃圾量不稳定、有机物组分不高、预处理流程长且效率低、厌氧发酵产气效能低、过程控制难度大[10]等诸多技术问题,因此,需立足于我国国情,研发适于我国生活垃圾物料特性的干式厌氧发酵技术与工艺系统,为生活垃圾高效资源化提供科学技术支撑。

在厌氧发酵过程中,温度是影响厌氧微生物活性的关键参数[11]。通常,高温厌氧发酵的产气效能高于中温和常温厌氧发酵[12-13]。ROCAMORA等[1]综述了干式厌氧发酵的工程应用发现,有机垃圾中温厌氧发酵的单位挥发性固体(VS)去除率下的甲烷产率低于高温。SUN等[14]发现,高温(55 ℃)下啤酒渣和牛粪混合干式厌氧发酵的甲烷产量高于中温(35 ℃),但高温厌氧发酵需要考虑更多的能源输入以及高温下含氮有机物快速分解带来的氨氮抑制等问题[15-17]。因此,大多数厌氧发酵系统选择更稳定的中温条件。为节约运行成本和降低运行能耗,规模化干式厌氧发酵工程在实际运行中常采用非严格受控中温厌氧发酵方式。例如,在环境气温较低时(如冬季)进行加温操作使之维持在一定的运行温度;而在环境气温较高时(如夏季)则不进行干预,但厌氧发酵温度易受环境气温变化影响。目前,有关有机垃圾中温干式厌氧发酵工程的研究仍然较少[10],而中温干式厌氧发酵工程的运行温度受季节变化影响,其产气率、运行稳定性等关键特性的变化与恢复特征有待深入研究。

本研究以北京某生活垃圾干式厌氧发酵工程为对象,基于厌氧发酵温度和环境气温的温差,通过现场调研,考察不同季节下中温干式厌氧发酵的运行温度变化特征,分析温差对该干式厌氧发酵工程产气特征和运行效能的影响,以期为生活垃圾中温干式厌氧发酵工程的精准调控提供参考。

-

本研究对北京某生活垃圾干式厌氧发酵工程进行了为期1 a的研究。该工程采用法国Valorga仓筒型干式厌氧发酵技术,该技术的特点为:1)适用于高TS含量(可高达60%)和高容积有机负荷(OLR: organic loading rate)(最高可达15 kg·(m3·d)−1,以VS计)的厌氧发酵,可采用间歇或连续的进料方式;2)发酵温度通常采用中温(35 ℃)或高温(55~58 ℃);3)通过气动搅拌即沼气循环方式实现厌氧发酵物料的搅拌、混合[1]。

该生活垃圾干式厌氧发酵工程主要包含预处理、干式厌氧发酵、沼气处理与利用、发酵残渣处理4个工艺段。预处理段将组成复杂的生活垃圾进行分类、挤压破碎、过筛后,与厌氧发酵回流物料混合(回流量为进料量体积的3~5倍),泵入厌氧发酵罐。核心工艺采用干式厌氧发酵,预处理后的浆料泵入厌氧罐进行发酵,产生的沼气经加压注入发酵罐,对物料进行气动搅拌,一方面加快沼气的逸出和维持发酵罐内的温度均匀;另一方面推动物料往出料口方向缓慢流动。沼气处理与利用工艺段对生成的沼气进行过滤、冷凝脱水等处理,所得的沼气一部分回注厌氧罐用于搅拌,其余的经后续脱硫处理后,可进入热电联产系统。发酵残渣经过压榨脱水处理后可进行堆肥或外运处理。

所研究规模化干式厌氧发酵工程处理对象为生活垃圾,原料来自于北京市某垃圾转运站的生活垃圾。在本研究开展期间,北京尚未严格实施垃圾分类,运入厂区的生活垃圾有机组分偏低。经预处理后,进入厌氧罐发酵的物料中易生化有机组分平均含量约为62%,较难生化有机组分平均含量约为27%,而惰性物质包括塑料、砂砾玻璃、金属物质、木竹类和骨头贝类等平均含量约为11%。原料中大块惰性物质(如织物、陶瓷制品、树枝等)经过预处理后作为废料运出,但仍有部分直径较小的惰性物质(碎骨头、玻璃、砂砾等)进入厌氧发酵系统,沉积在厌氧罐内占据空间,并可能造成进、出料口及管道的堵塞,降低厌氧发酵效率。

-

工程采用中温干式厌氧发酵工艺,启动了2个并联干式厌氧罐。单个厌氧罐(直径16.5 m,高21.8 m)设计有效容积为3 735 m3,单罐运行有效容积约2 000 m3,2个厌氧罐共用1套预处理、进出料设备、搅拌系统和沼气处理系统,总产气量为2个厌氧罐的产气量之和。

正常工况下每天进料2次,进料时间依据进料量在1.5~2.5 h,进料的同时控制出料量,并通过控制进、出料的体积调节罐内液位高度。在厌氧发酵过程中,当pH≤7.5、挥发性脂肪酸(VFAs)≥8 000 mg·L−1等生物不平衡指征出现时减少进料量或停止进料,直至系统pH、平均产气量等指标恢复。工程运行时在环境低温期通过蒸汽加热进料提高厌氧发酵运行温度,其他季节不进行加热操作。

-

在剔除大块木料、玻璃、金属等物质后,有机生活垃圾及厌氧发酵物的TS、VS采用重量法测定;总挥发性脂肪酸(total volatile fatty acids, TVFAs)采用氢氧化钠滴定法测定,氨氮采用纳氏试剂分光光度法测定;碱度采用酸碱指示剂滴定法[18]。沼气产量采用E+H超声波流量计(GFM 200)测定。

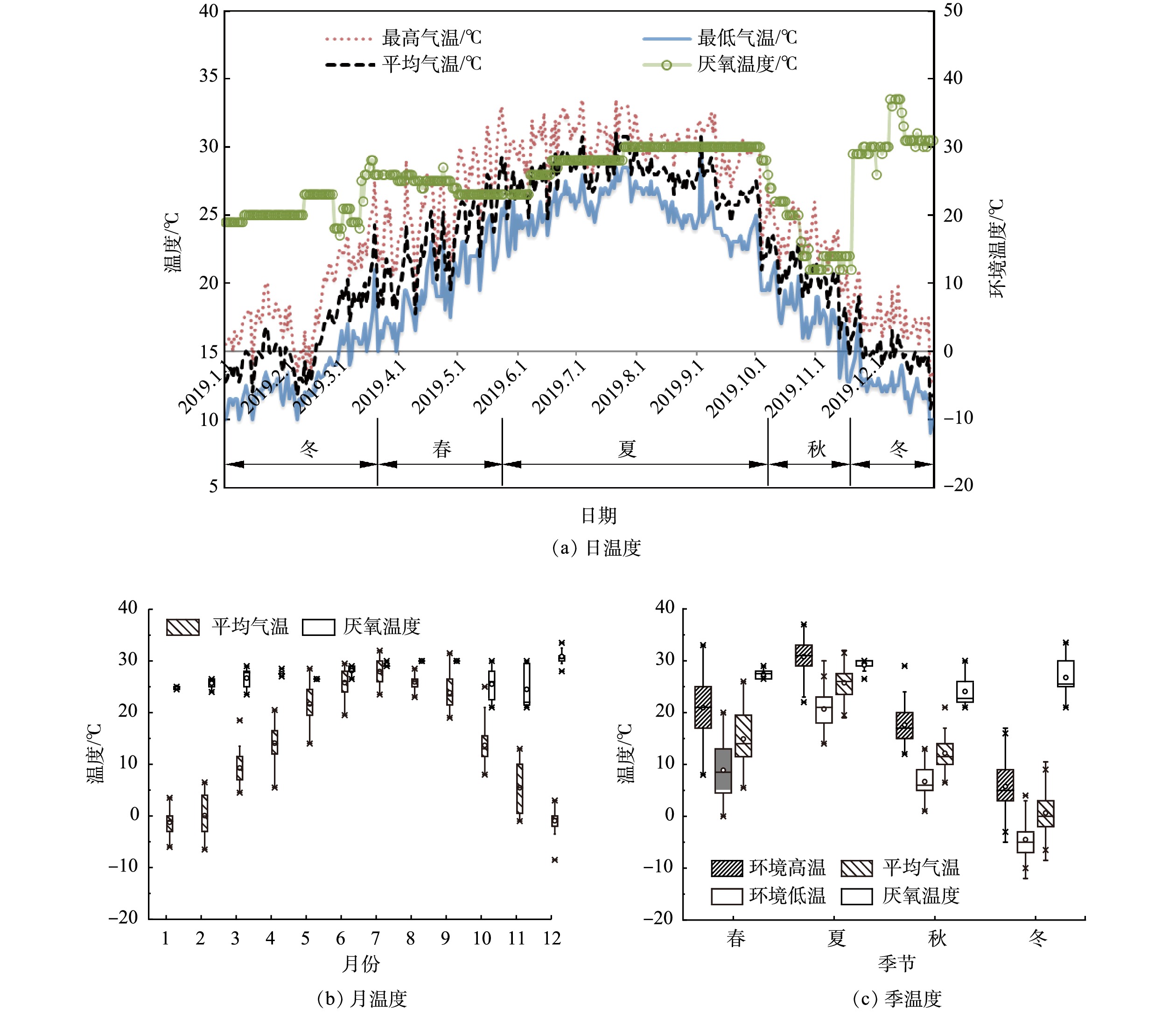

本研究采用候平均气温划分季节,当候平均气温小于10 ℃为冬季,10~22 ℃为春季或秋季(从10 ℃升到22 ℃是春季,从22 ℃降到10 ℃是秋季),大于22 ℃划为夏季[19]。因此,基于北京2019年全年气温数据,本研究中的四季划分为:春季3月14日至5月20日、夏季5月21日至10月2日、秋季10月3日至11月12日、冬季11月13日至3月13日。本研究所述的温差是不同季节下该生活垃圾干式厌氧发酵运行温度与气温的温差,并重点分析温差与厌氧发酵产气效能(VS产气率、容积产气率等)、操作参数(垃圾处理量、OLR、pH等)的相互关系。VS产气率、容积产气率、容积有机负荷的计算公式如式(1)~式(3)所示。

式中:

$ {{p}}_{\rm{m}} $ 为当日VS产气率,m3·(kg·d)−1;P是日产沼气量,m3·d−1;m为进料中VS质量,kg;$ {p}_{\rm{v}} $ 为容积产气率,m3·( m3·d)−1;V是厌氧有效容积,m3。 -

不同季节下该生活垃圾干式厌氧发酵工程的主要运行参数如表1所示。该工程在冬、夏2季的运行时间均较长,分别为121和135 d,且冬季的进料量、进料VS/TS比值最高,但冬季的进料TS含量最低。该工程全年厌氧发酵运行温度在24~30 ℃,四季环境气温与厌氧发酵温度的平均温差从高到低依次为冬季(26.63 ℃)>春季(12.45 ℃)>秋季(11.92 ℃)>夏季(3.43 ℃)。

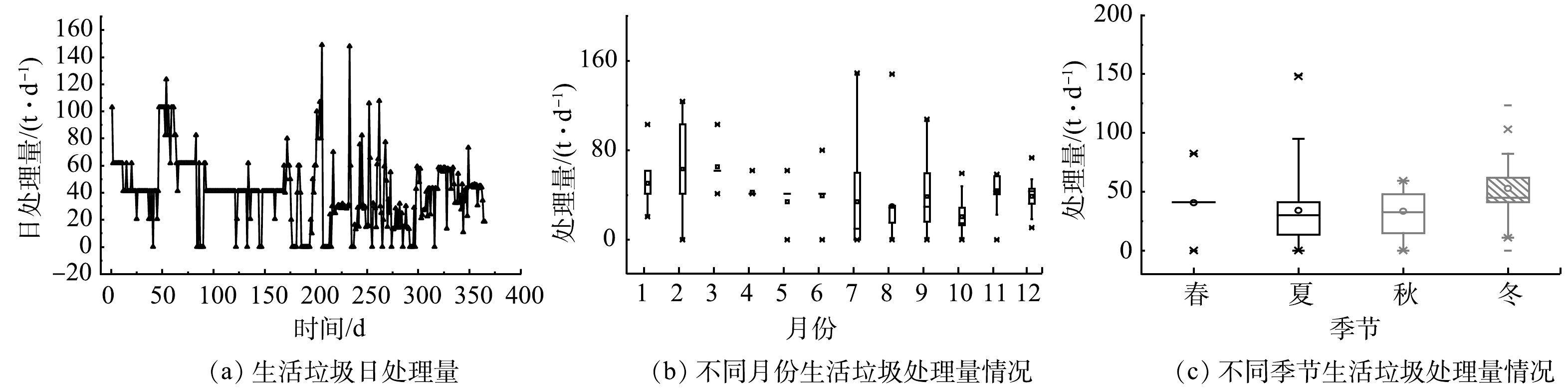

由图1(a)可知,不同于严格受控的实验室小试研究,该干式厌氧发酵工程采用连续运行方式,其进料量通常根据所需处理的垃圾量和运行参数调控的需求进行调整,其日均进料量为(40.38 ± 26) t·d−1,波动较大(变异系数0.65),进料TS在35%~55%,出料TS约为15%。月进料量(即处理量)波动较大,不同季节进料量差异较显著,冬季垃圾处理量最多,占全年处理量的40.88%(图1(b)、图1(c))。干式厌氧发酵工程实际运行期间,处理未进行垃圾分类的原料时,包含预处理废料和发酵残渣的垃圾残渣日外运量基本上高于每日进罐物料量,即日处理量。因此,为提高干式厌氧发酵工程的原料品质和产气效能,亟需做好生活垃圾源头分类。

-

干式厌氧发酵工程受进料量、物料特性、运行温度等参数综合影响,不同季节中日产气量波动幅度变化较大,如图2(a)所示,前90天即1-3月波动幅度为全年最小,而年日均产气量为(9 243±1 248) m3·d−1,日变异系数为0.14,最大日产气量14 498 m3·d−1出现在夏季,是最少日产气量(冬季,6 728 m3·d−1)的2.15倍。月均日产气量在7 989 m3·d−1 与10 623 m3·d−1之间波动(图2(b))。其中,4月的变异系数最大(0.16),最高月均日产气量出现在6月,最低月均日产气量是1月。按季节分析,如图2(c),产气量总体按春夏秋冬顺序呈先增加后减少再逐步上升的循环特征,产气量均值由高到低依次为:夏季>春季>冬季>秋季。其中,夏季和冬季的产气量波动较大可能受到进料量波动的直接影响,对应变异系数分别为0.14和0.13。该干式厌氧发酵工程全年累计产沼气量约340×104 m3,沼气中甲烷平均含量约为65%。经拟合分析,累积产气量与时间符合线性函数模型,数学模型见式(4)。

式中:y沼气为全年累积产沼气量,m3;t为时间,d。R2为0.999 7。

根据候平均气温划分,北京季节特征呈现为夏、冬季时间长,春、秋季短(表1)。调研年度内夏、冬季累积产气量占全年产气量的71.33%。其中,夏季贡献39.20%,冬季贡献32.13%。厌氧发酵温度是影响产气的关键参数,中温干式厌氧发酵温度易受到季节性环境气温变化的影响,尤其北京冬季低温条件不利于厌氧发酵反应。因此,针对北京的季节特征,为保障该干式厌氧发酵工程的稳定高效运行,需做好厌氧发酵温度的调控,以实现冬季低温期、春秋季环境气温升高和降低过程的平稳产气。

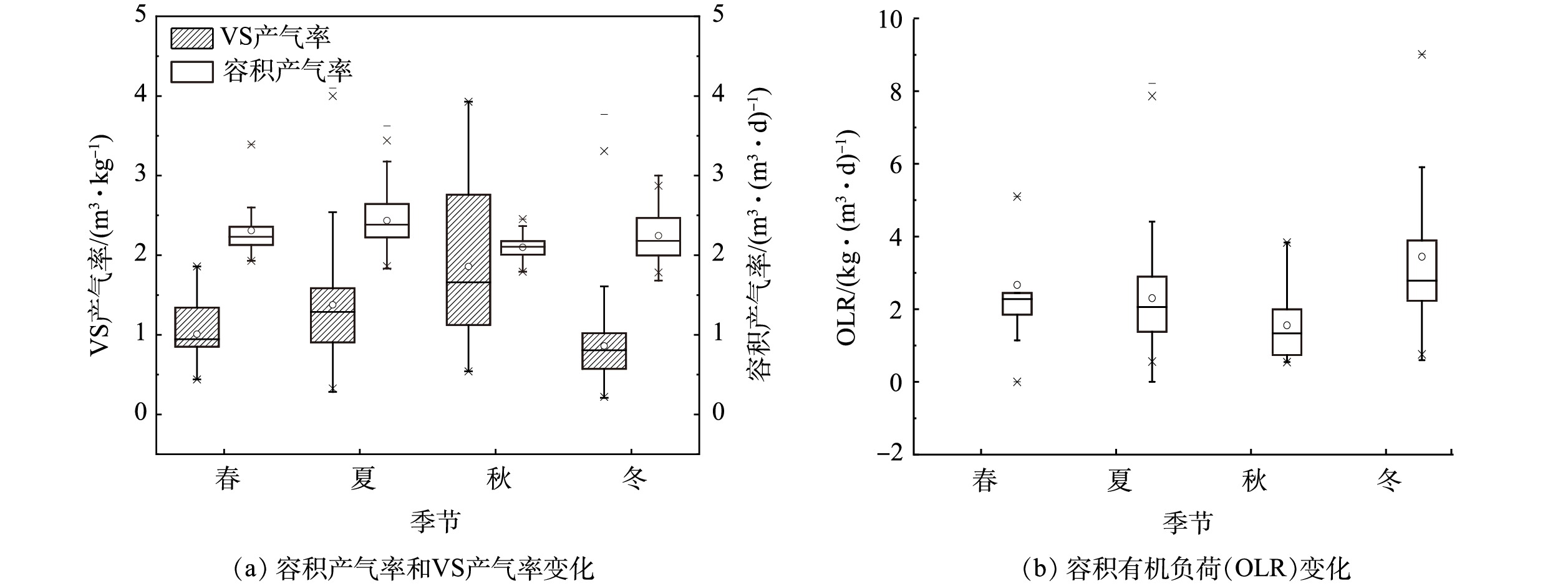

如图3(a)所示,平均容积产气率与VS产气率的季节性变化规律均为先升高后降低,但最高平均容积产气率出现在夏季((2.44±0.33) m3·(m3·d)−1),而最高VS产气率则出现在秋季,秋季的进料量最少,因此有可能在牺牲容积产气率的情况下进行了更充分的厌氧发酵产气过程。进料垃圾成分具有显著异质性是导致不同季节OLR均有较大波动(变异系数在0.58~0.89)的主要因素,如图3(b),冬季容积有机负荷(OLR)最高((3.42±1.98) kg·(m3·d)−1),而后依次是春季、夏季和秋季。不同批次的进料VS含量不同,这更凸显了垃圾分类的重要性。一方面,OLR的提高增加了新鲜物料对厌氧微生物的供给,在一定范围内可增加发酵产气;另一方面,随着OLR的提高,大量物料的分解、水解引起挥发性脂肪酸(VFAs)、氨氮等可能在系统中累积,进而抑制微生物的活性,打破厌氧发酵系统的微生物平衡,导致产气量下降。因此,冬季容积产气率较低的原因可能是OLR升高导致产气受到抑制。

如表2所示,该工程全年平均VS产气率为(1.28±0.66) m3·kg−1,其中秋季平均VS产气率最高,是冬季均值的2.16倍,高于ROCAMORAL[1]所报道的生活垃圾干式厌氧发酵工程。此外,提高OLR增加了产气量,但同时也降低了单位有机质产气率,表明VS产气率与OLR呈极显著负相关关系(p<0.001)。

-

1)运行温度。如图4(a)、图4(b)所示,自1月起,气温从冬季开始逐步升温,到夏季最高,再逐步降温,顺序经历春夏秋季,再到冬季,形成向下抛物线形的气温变化规律。不同于严格受控的中温和高温厌氧发酵需要持续外加热源,该中温干式厌氧发酵工程只在环境低温时(冬季和春季部分时间)进行外加热以维持厌氧微生物的活性,故其运行温度易受环境温度波动的影响。结合图4(a)和表1的温度参数可知,该工程全年运行温度变化范围为21~34 ℃。其中,夏季运行温度最高(图4(c)),在30 ℃运行维持了71 d,秋季运行温度最低,而冬季、春季初始阶段(图4(a)中1月至4月,11月中旬至12月底)通过蒸汽加热维持了一定的厌氧发酵运行温度,调控后运行温度维持在25~30 ℃,实际运行中温差大小依次是:冬季(26.63 ℃)>春季(12.45 ℃)>秋季(11.92 ℃)>夏季(3.43 ℃)。

工程上中温干式厌氧发酵具有规模效应,且易受环境温度的影响,季节性热量耗散率差异大,调节或维持厌氧运行温度难度大。因此,结合运行温度变化,该工程并不严格表现为随温度升高VS产气率提高。运行温度最低的秋季表现出最高的VS产气率,其原因可能是秋季的垃圾处理量较少,容积有机负荷低,处理单位垃圾的微生物菌群数量更多,使物料分解地更完全。此外,夏季较佳的厌氧发酵状态也持续影响到秋季,且生物产气有滞后效应,其结果表现为秋季VS产气率提高。秋季时间最短,又属于厌氧运行温度变化的过渡期,秋季的温度调控对干式厌氧发酵的平稳运行有重要影响。

在冬季采用外加蒸汽的操作,干式厌氧发酵运行温度均在25 ℃以上,甚至在11月和12月期间大多维持在30 ℃以上。然而,冬季的VS产气率和容积产气率均低于其他季节。其可能原因是,由垃圾原料的初始温度低引起的厌氧罐内外物料温差大,影响发酵效率。城市生活垃圾的收运通常在全天气温最低点的凌晨进行,这导致冬季进料时垃圾原料温度在0 ℃左右甚至更低,虽通过蒸汽加热将物料表面温度提升至39 ℃,但由于进料量大、有机负荷高、温差大等因素造成进料与罐内物料的传热与传质不均,加之微生物对温度变化敏感,故导致有机物未能及时被微生物分解利用,产气量低。考虑到进料量占整个厌氧罐物料的比例低,只加热进料的点源加热方式不能有效提升厌氧发酵产气效能,可考虑优化加热模式和气动搅拌频率、增加回流比、减缓进料速度、降低有机负荷等方式,提升进料与罐内物料的传热传质均匀性,从而提高冬季的VS产气率和容积产气率。

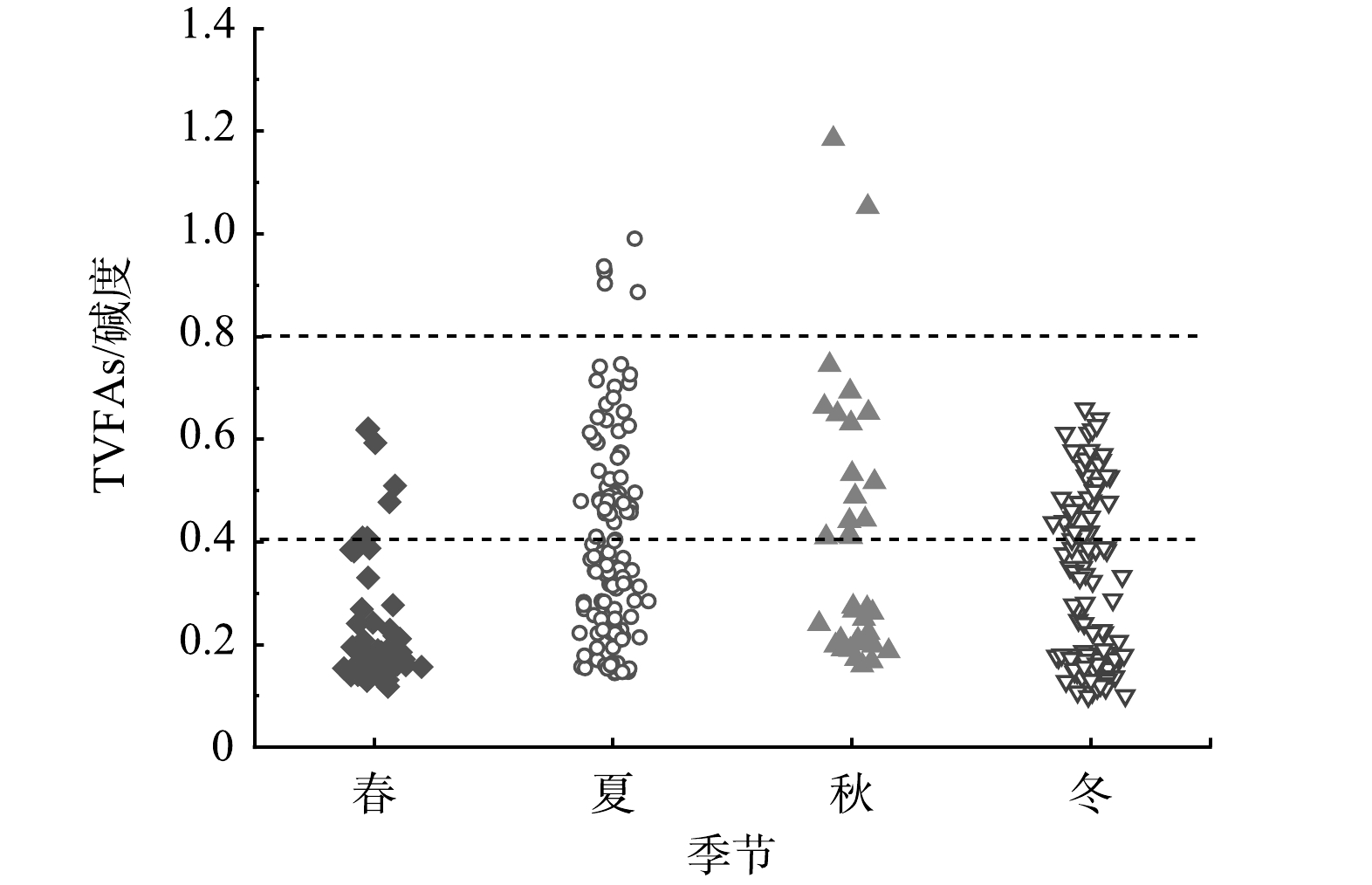

2)主要参数变化特征。VFAs、碱度和pH值是干式厌氧发酵主要参数,其中TVFAs和碱度的季节性变化如图5(a)所示。按季节分析,其变化总体表现为TVFAs增加,碱度降低。夏季TVFAs较高,相应的碱度((15 010±2 520) mg·L−1)均低于春、秋、冬季,而春季具有较低的TVFAs浓度和较高的碱度。全年干式厌氧发酵体系的TVFAs在2 500~10 900 mg·L−1变化,属于高 TVFAs浓度的厌氧体系。挥发性脂肪酸(VFAs)是厌氧发酵过程重要的中间产物,作为产甲烷菌的底物被利用生成甲烷。由于干式厌氧发酵的含固率高,物料搅拌难度大,因混合不均使代谢生成的VFAs不能很好地通过搅拌向周围扩散进而被产甲烷菌及时利用,造成VFAs在局部累积,局部酸浓度增高抑制产甲烷菌活性从而减少了产气。夏季环境温度和运行温度均高于其他3个季节,温度升高加速了有机质的分解和产酸速率,可能形成了局部抑制,是夏季VS产气率低于秋季的原因之一。VFAs代谢平衡对干式厌氧发酵体系稳定运行有重要作用。因此,在工程运行过程中应通过监测、预判、调控及时发现并缓解发酵体系酸化情况。此外,碱度也是评价厌氧发酵体系稳定运行的关键参数。

厌氧发酵体系的酸碱度受复杂微生物过程和化学过程控制,如有机酸、无机酸、钙等参与酸碱平衡反应,而pH是酸碱平衡综合呈现的指标[20]。由图5(b)可知,全年运行过程中pH值在7.5~8.0波动。其中,秋季的平均pH值(7.94±0.13)最高。这表明,各阶段都处于偏碱性环境,有利于避免酸化,维持发酵系统的稳定性。产甲烷菌对pH值的变化比产酸菌更为敏感,当pH值下降引起产甲烷菌活性降低,VFAs因代谢缓慢而累积,导致pH值进一步降低。因此,VFAs和pH值的变化是综合判断厌氧发酵系统是否稳定运行的重要指征。如系统出现pH值连续下降的趋势,TVFAs有所升高,同时,碱度降低,表明出现酸化的前兆,此时应及时调整进料量,降低有机负荷,以调控厌氧系统恢复到新的平衡。高含固或干式厌氧发酵系统中的氨氮浓度高,由于氨氮呈弱碱性,不少研究者日益认识到高浓度氨氮也贡献了碱度,在厌氧发酵pH调控中需考虑氨氮-碳酸盐-VFA的三元酸碱缓冲体系,讨论厌氧发酵系统的pH缓冲能力及相应的pH变化规律[21-23],这可为干式厌氧发酵的pH调控提供新思路。

3)pH缓冲能力及系统稳定性。厌氧发酵系统的pH缓冲能力一般是指系统对酸碱的抵抗能力,是厌氧发酵过程稳定性及生物不平衡自我调节能力的重要指征,可以指示或预警厌氧发酵系统的抑制状况。因此,厌氧发酵过程常用总挥发性脂肪酸(TVFAs)和碳酸氢盐碱度的比值作为厌氧系统pH缓冲能力大小的指标之一,其指示厌氧发酵系统的稳定性和平衡性,比值越小,系统缓冲能力越大。不同季节下TVFAs/碱度的比值变化如图6所示。该中温干式厌氧发酵在春季和冬季具有较大的体系缓冲能力,TVFAs/碱度的比值分别为(0.23±0.13)和(0.29±0.17),夏季和秋季时体系的缓冲能力相当,但最小缓冲能力出现在秋季为1.18,全年TVFAs/碱度大于1.0的天数仅2 d,均出现在秋季。这进一步表明,秋季运行调控对维持厌氧发酵工程整体产气稳定性至关重要。彭绪亚[3]等通过餐厨垃圾的小试研究指出,当TVFAs/碱度< 0.4,厌氧发酵系统具有足够的缓冲能力;而当TVFAs/碱度= 0.4~0.8,厌氧发酵系统具备有限的缓冲能力;当TVFAs/碱度> 0.8时,则认为缓冲能力极小,有酸累积的可能。GAO等[24]采用VFA/碱度评价厨余垃圾厌氧发酵性能及其稳定性。SONG等[25]在污泥单相厌氧中发现,中温厌氧比高温厌氧的缓冲能力大。按照缓冲能力理论参考值分析,综合pH值变化,当缓冲能力值为1.18时,系统已经出现酸累积。在该项目的实际操作过程中,根据指标提示减少了50%进料量,避免造成厌氧菌大量失活,系统又快速恢复了平衡,并且工程上厌氧反应罐具备规模化效应,局部酸累积可由搅拌混合缓解而不影响整个厌氧发酵系统的稳定,能包容更多局部生物不平衡态,可耐受更高的VFAs,一定程度上也更易恢复系统平衡。

-

由表3可知,该干式厌氧发酵的产气能力与运行温度显著相关,春、夏、冬3季的平均温差与VS产气率显著相关。春季厌氧运行温度与VS产气率显著负相关,但与平均温差、OLR、pH和碱度表现出显著正相关;夏季厌氧运行温度与日产气量、容积产气率以及TVFA显著负相关,而与反映系统稳定性的参数pH、碱度以及缓冲能力(-TVFAs/碱度)的大小显著正相关;秋季和冬季的厌氧运行温度与产气效能、运行稳定性各参数均显著相关,秋季的温差与缓冲能力显著正相关,冬季的温差与VS产气率、日处理量、OLR和TVFAs显著相关。温差与厌氧运行温度基本上呈正相关关系。

干式厌氧发酵的稳定高效运行主要从运行效能和稳定性这2方面综合平衡,体系稳定性是提高运行效能的基础,高运行效能可实现更高的环境与经济效益。该干式厌氧发酵工程通常采用垃圾日处理量、进料TS含量、加热进料这3个指标的单个或组合变化指导日常操作和调控,使物料在厌氧发酵体系下稳定高效产气。依据环境温度变化,候气温15 ℃以下对中温干式厌氧发酵产气的影响较大。这主要是因为,自秋季降温期至初春升温期阶段(10-12月和1-3月),此时干式厌氧发酵特征表现为秋季降温期,受厌氧温度逐步降低和夏季产气延后的影响,产气各参数指标间无显著相关性关系,且系统缓冲能力相对较小;冬季低温时,微生物活性降低,分解、产气速率均降低,增加处理量难以增加产气,反而使VS产气率等产气效能降低;春季升温期,微生物活性逐渐恢复,厌氧温度升,与体系的OLR呈正相关,体系发酵效能提高。而夏季厌氧运行温度较高时,有机质被微生物快速分解生成小分子酸、多糖等再进一步被利用产生沼气,容积产气率提高。进料TS因不同季节垃圾组成成份的显著差异而有较大波动,高TS时物料难以传质、传热均匀,导致在温差较大的冬季环境低温时,厌氧发酵局部低温而降低了产气能力,或者需要消耗更多能源使厌氧发酵正常运行。而在北方秋季的高TS中,木质素、纤维素等含量较高时,物料较难降解,为厌氧系统提供的可直接利用的有机物含量就少,故产气效能受到影响或延后产气。温度调控则体现为结合环境温度和厌氧发酵温度的全年变化规律,按季节性温差与厌氧值运行温度的关系,提出干式厌氧工程调控策略。

根据上文的分析以及各参数间的影响关系,在春季,中温干式厌氧发酵表现出较大的缓冲能力,可以适当增加处理量和提高厌氧发酵运行温度(增大温差),既提高微生物活性和日产气量,又确保厌氧发酵系统的稳定性。在夏季,厌氧发酵运行温度较高,可增加处理量以提高厌氧发酵效能。由表3可知,日处理量增加,可提高日产气量和容积产气率,而pH值升高,表明调控没有导致厌氧发酵酸化。在秋季,日处理量最少,VS产气率最高,但体系缓冲能力较小。因此,为提高厌氧发酵效能,一方面可通过增加垃圾处理量提高容积产气率和日产气量;另一方面可增大温差即提高厌氧发酵运行温度,达到减少TVFAs、增加VS产气率的目的。冬季环境温度最低,温差最大,厌氧发酵运行平均温度为(27.20±2.99) ℃,pH缓冲能力充足,产气率有进一步提高空间。因此,根据表3分析结果,厌氧发酵运行温度为影响冬季各项参数的重要因素,建议在冬季提高厌氧发酵运行温度(增大温差)或提高回流比例,可提高干式厌氧体系的产气效能以及体系稳定性。

综上所述,为实现该中温干式厌氧发酵工程的稳定高效运行,在冬季低温期通过蒸汽加热提高运行温度的基础上,建议依据气温升温期(春季初期)和降温期(秋季后期)进行调控,在现有运行条件下提高春季初期和秋季后期的厌氧发酵运行温度;冬季还可考虑通过回流提升运行温度;夏季可维持现有运行温度,并通过提高日处理量提升处理效能。

-

1)中温生活垃圾干式厌氧发酵工程的有机容积负荷波动大,呈现冬季最高、秋季最低的特征;产气效能表现为容积产气率变化趋势与平均厌氧发酵运行温度一致,不同季节平均容积产气率从高到低依次为夏季(2.44±0.33 m3·(m3·d)−1)>春季(2.31±0.28 m3·(m3·d)−1)>冬季(2.25±0.29 m3·(m3·d)−1)>秋季(2.10±0.14 m3·(m3·d)−1);VS产气率秋季最高,冬季最低。

2) 中温生活垃圾干式厌氧发酵过程呈现较高的TVFAs浓度和碱度浓度,大多数的TVFAs/碱度比值<0.8,pH在7.5~8.0波动,具备较大的pH缓冲能力。

3)干预条件下,中温生活垃圾干式厌氧发酵工程的全年运行温度在21~34 ℃,平均厌氧发酵运行温度表现为夏季高于春季和冬季,秋季最低。相关性分析结果表明,非严格受控中温干式厌氧发酵的产气能力与运行温度显著相关(p<0.05),春、夏、冬3季的温差与VS产气率显著相关(p<0.05)。

基于温差的规模化生活垃圾干式厌氧发酵工艺的产气特征

Performance of biogas production in a full-scale dry anaerobic digestion of municipal solid waste based on the temperature difference

-

摘要: 以北京某生活垃圾干式厌氧发酵工程为对象,通过对厌氧发酵运行温度与环境气温之间的温差调控,分析了不同季节下中温干式厌氧发酵工艺的产气特征。结果表明,干式厌氧发酵运行温度受环境气温影响较大,夏季平均运行温度最高,VS产气率以夏季和秋季较高,容积有机负荷波动大,不同季节平均容积产气率从高到低依次为:夏季>春季>冬季>秋季。统计分析结果表明,该干式厌氧发酵工程的产气能力与运行温度显著相关(p<0.01),春、夏、冬3季的温差与VS产气率显著相关(p<0.05),秋季温差与缓冲能力显著相关(p<0.05)。因此,在具备较大pH缓冲能力的条件下,加强春秋季变温期的温差调控,通过加温和增加回流比等方式提升春秋季变温期、冬季低温期的厌氧运行温度,并提高夏季容积有机负荷,有助于提高该干式厌氧发酵工程的产气效能和运行稳定性。本研究结果可为工程规模干式厌氧发酵工艺的稳定运行及高效产沼气提供参考。Abstract: A full scale dry anaerobic digestion (AD) plant of municipal solid waste in Beijing was selected in this study to investigate biogas production performance throughout one year on the basis of the difference between the AD operational temperature and the ambient temperature. Results showed that the operational temperature of this dry AD plant was significantly affected by the ambient temperature, and the average operational temperature of the dry AD in summer was higher than that in other seasons, while the biogas production rate per VS was higher in summer and autumn. The organic loading rate (OLR) of the dry AD plant fluctuated greatly, and the order of the average volume biogas production rate from high to low in different seasons was as follows: Summer ((2.44±0.33) m3·(m3·d)−1)> Spring ((2.31±0.28) m3·(m3·d)−1) > Winter ((2.25±0.29) m3·(m3·d)−1)> Autumn ((2.10±0.14) m3·(m3·d)−1). Results of correlation analysis showed that the gas production performance of the dry AD was significantly corelated with the operational temperature of the dry AD (p<0.01). The temperature differences in Spring, Summer and Winter were significantly related to the VS biogas production rate (p<0.05), and that in autumn was significantly related to buffer capacity (p<0.05). In a word, it was recommended to strengthen the control of temperature difference in the ambient temperature change period in Spring and Autumn. It was recommended that as far as the improvement of biogas production and operational stability of the full-scale dry AD plant was concerned, the operational temperature of the dry AD plant in the Spring, Autumn, and Winter should be increased by heating and increasing the return ratio, as well as increasing the OLR of the dry AD plant in summer with adequate pH buffer capacity. This study can provide a practical reference for the stable operation and efficient biogas production of engineering-scale dry digestion of municipal solid waste.

-

-

表 1 不同季节下生活垃圾干式厌氧发酵工程的主要运行参数变化特征

Table 1. Major operational parameters of the full-scale dry anaerobic digestion plant

季节 日期 历时/d 环境

气温/℃厌氧发酵

温度/℃温差/

℃进料量/

(t·d−1)进料

TS/%进料

VS∶TS/%日产气量/

(m3·d−1)VS产气率/

(m3·kg−1)春 3.14-5.20 68 14.90±4.99 27.35±0.68 12.45 40.59±18.14 45.06±4.23 50.72±11.26 9 236±1 111 1.01±0.40 夏 5.21-10.02 135 25.74±2.79 29.17±1.12 3.43 34.01±29.60 44.41±5.02 46.85±4.41 9 742±1325 1.38±0.74 秋 10.03-11.12 41 12.15±2.93 24.07±2.81 11.92 24.56±17.12 42.28±5.84 52.20±16.36 8 395±563 1.86±0.98 冬 11.13-3.13 121 0.57±3.84 27.20±2.99 26.63 52.74±22.75 37.89±4.00 63.63±8.80 8 983±1 176 0.86±0.53 表 2 生活垃圾干式厌氧发酵工程不同季节的产气率及容积有机负荷(OLR)

Table 2. Biogas production rates and OLRs of the full scale dry anaerobic digestion treating MSW

季节 VS产气率/

(m3·kg−1)容积产气率/

(m3·(m3·d)−1)OLR/

(kg·(m3·d)−1)春 1.01±0.40 2.31±0.28 2.36±1.46 夏 1.38±0.74 2.44±0.33 1.79±1.60 秋 1.86±0.98 2.10±0.14 1.29±1.04 冬 0.86±0.53 2.25±0.29 3.42±1.98 表 3 不同季节下中温干式厌氧发酵各参数的Pearson相关系数

Table 3. Pearson correlation coefficient of various parameters of dry anaerobic digestion in different seasons

指标 |△Tmax| |△Tmin| 平均|△T| 日处理量 日产气量 VS产气率 容积产气率 TVFA/碱度 厌氧VS/TS OLR pH TVFA 碱度 进料TS 厌氧温度 0.743*,

0.206*,

0.236,

0.709*0.542*,

−0.329*,

0.304,

0.651*0.707*,

0.338*,

0.328,

0.690*0.297*,

−0.102,

−0.469*,

−0.254*0.093,

−0.426*,

−0.479*,

0.526*−0.337*,

0.160,

0.713*,

0.465*0.093,

−0.426*,

−0.479*,

0.526*−0.063,

−0.335*,

−0.695*,

0.374*−0.011,

0.176,

−0.461,

0.3000.554*,

−0.042,

−0.611*,

−0.280*0.458*,

0.53*,

0.338*,

0.358*−0.015,

−0.310*,

−0.737*,

0.224*0.328*,

0.375*,

0.695*,

−0.555*−0.483,

−0.069,

0.722,

−0.351|△Tmax| 0.786*,

−0.325*,

0.468*,

0.919*0.958*,

0.828*,

0.783*,

0.974*0.172,

−0.065,

0.050,

−0.413*0.123,

0.029,

−0.093,

0.159−0.340*,

0.2429*,

0.192,

0.495*0.123,

0.029,

−0.093,

0.159−0.051,

0.161,

−0.248,

0.019−0.094,

0.070,

0.308,

0.530*0.5449*,

−0.219*,

−0.019,

-0.501*0.376*,

−0.179*,

0.139,

0.298*−0.024,

0.143,

−0.194,

-0.1790.294*,

−0.110,

0.249,

−0.214*−0.174,

−0.481,

0.362,

−0.461*|△Tmin| 0.8934*,

−0.350*,

0.912*,

0.984*−0.024,

0.208*,

−0.141,

−0.466*0.047,

0.298*,

−0.173,

0.154−0.170,

−0.205*,

0.331,

0.475*0.047,

0.298*,

−0.173,

0.154−0.072,

0.078,

−0.289,

−0.027−0.331,

0.020,

−0.163,

0.3900.327*,

0.224*,

−0.312,

−0.519*0.239,

−0.209*,

0.055,

0.382*−0.048,

0.095,

−0.251,

−0.213*0.188,

−0.103,

0.215,

−0.149−0.262,

0.118,

0.298,

−0.248平均|△T| 0.129,

−0.045,

−0.068,

−0.452*0.115,

−0.025,

−0.165,

0.159−0.293*,

0.252*,

0.315,

0.494*0.115,

−0.025,

−0.165,

0.159−0.025,

0.090,

−0.347*,

−0.007−0.198,

0.113,

0.036,

0.458*0.467*,

−0.146,

−0.217,

−0.52*0.323*,

−0.044,

0.132,

0.352*0.008,

0.099,

−0.289,

−0.202*0.248,

−0.045,

0.296,

−0.182−0.232,

−0.286,

0.320,

−0.351日处理量 0.110,

0.256*,

0.543*,

−0.049−0.783*,

−0.761*,

−0.888*,

−0.741*0.110,

0.256*,

0.543*,

−0.049−0.023,

0.005,

0.256,

−0.0440.532,

−0.137,

−0.249,

0.0220.906*,

0.996*,

0.962*,

0.929*0.217,

0.199*,

−0.209,

0.0050.006,

0.152,

0.292,

0.0730.132,

0.166,

−0.221,

0.182*−0.095,

0.702*,

0.668,

−0.196日产气量 0.549*,

−0.103,

−0.285,

0.2311*1.000,

1.000,

1.000,

1.0000.779*,

0.659*,

0.485*,

0.736*−0.068,

−0.185,

0.368,

0.225−0.162,

0.227*,

0.222,

−0.057−0.427*,

0.039,

−0.316,

−0.0700.779*,

0.619*,

0.5451*,

0.587*−0.669*,

−0.332*,

−0.478*,

−0.675*−0.377,

0.265,

0.395,

−0.138VS产气率 0.549*,

−0.103,

−0.285,

0.231*0.731*,

0.080,

−0.352*,

0.171−0.726,

0.446,

0.132,

0.245−0.851*,

−0.756*,

−0.856*,

−0.695*−0.607*,

0.004,

0.109,

0.0060.721*,

0.025,

−0.378*,

0.056−0.778*,

−0.125,

0.341,

−0.289*−0.344,

−0.571*,

−0.013,

−0.203容积产气率 0.779*,

0.659*,

0.485*,

0.736*−0.068,

−0.185,

0.368,

0.225−0.162,

0.227*,

0.222,

−0.057−0.427*,

0.039,

−0.316,

−0.0700.7799*,

0.619*,

0.545*,

0.587*−0.669*,

−0.332*,

−0.478*,

−0.675*−0.377,

0.265,

0.395,

−0.138TVFAs/碱度 −0.216,

−0.045,

0.507,

0.242−0.427*,

−0.014,

0.190,

−0.004−0.443*,

−0.701*,

−0.6421*,

−0.0920.986*,

0.977*,

0.9656*,

0.958*−0.882*,

−0.937*,

−0.9428*,

−0.8845*−0.605,

0.354,

−0.210,

0.054厌氧VS/TS 0.846*,

−0.169,

−0.124,

−0.076−0.278,

0.069,

−0.718,

0.019−0.237,

−0.058,

0.446,

0.204−0.051,

0.114,

−0.712,

−0.159−0.149,

−0.561,

−0.978,

−0.405OLR 0.604*,

−0.098,

−0.006,

0.003−0.411*,

0.053,

0.214,

0.1340.561*,

0.042,

−0.162,

0.192*0.031,

0.613*,

0.068,

0.089pH −0.411*,

0.389*,

−0.549*,

0.289*0.606*,

0.777*,

0.702*,

0.584*0.586,

−0.138,

−0.231,

−0.288TVFAs −0.829*,

−0.031,

−0.883*,

−0.395*−0.626,

0.419,

−0.121,

0.132碱度 0.465,

−0.392,

0.108,

0.096注:每组数据从左至右、再从上至下分别为春、夏、秋、冬不同季节各参数的Pearson相关系数;*代表在0.05水平上显著相关。 -

[1] ROCAMORA I, WAGLAND S T, VILLA R, et al. Dry anaerobic digestion of organic waste: A review of operational parameters and their impact on process performance[J]. Bioresource Technology, 2020, 299: 122681. doi: 10.1016/j.biortech.2019.122681 [2] 吕凡, 章骅, 邵立明, 等. 基于物质流分析餐厨垃圾厌氧消化工艺的问题与对策[J]. 环境卫生工程, 2017, 25(1): 1-9. doi: 10.3969/j.issn.1005-8206.2017.01.001 [3] 彭绪亚, 贾传兴, 潘坚, 等. 餐厨垃圾单相厌氧消化系统酸化预警指标[J]. 土木建筑与环境工程, 2011, 33(4): 146-150. [4] 王金辉. 餐厨垃圾固相物料干式厌氧消化处理研究[D]. 宁波: 宁波大学, 2017. [5] 刘建伟, 夏雪峰, 葛振. 城市有机固体废弃物干式厌氧发酵技术研究和应用进展[J]. 中国沼气, 2015, 33(4): 10-17. doi: 10.3969/j.issn.1000-1166.2015.04.002 [6] 党锋, 毕于运, 刘研萍, 等. 欧洲大中型沼气工程现状分析及对我国的启示[J]. 中国沼气, 2014, 32(1): 79-83+89. doi: 10.3969/j.issn.1000-1166.2014.01.017 [7] PANIGRAHI S, DUBEY B K. A critical review on operating parameters and strategies to improve the biogas yield from anaerobic digestion of organic fraction of municipal solid waste[J]. Renewable Energy, 2019, 143: 779-797. doi: 10.1016/j.renene.2019.05.040 [8] MA S, ZHOU C, CHI C, et al. Estimating Physical Composition of Municipal Solid Waste in China by Applying Artificial Neural Network Method[J]. Environmental Science Technology, 2020, 54(15): 9609-9617. doi: 10.1021/acs.est.0c01802 [9] NILSSON P S, HELLMAN E, MOESTEDT J. The effect of temperature, storage time and collection method on biomethane potential of source separated household food waste[J]. Waste Management, 2018, 71: 636-643. doi: 10.1016/j.wasman.2017.05.034 [10] KUMAR A, SAMADDER S R. Performance evaluation of anaerobic digestion technology for energy recovery from organic fraction of municipal solid waste: A review[J]. Energy, 2020, 197: 117253. doi: 10.1016/j.energy.2020.117253 [11] GRESES S, GABY J C, AGUADO D, et al. Microbial community characterization during anaerobic digestion of Scenedesmus spp. under mesophilic and thermophilic conditions[J]. Algal Research, 2017, 27: 121-130. doi: 10.1016/j.algal.2017.09.002 [12] LIU Y, FANG J, TONG X, et al. Change to biogas production in solid-state anaerobic digestion using rice straw as substrates at different temperatures[J]. Bioresource Technology, 2019, 293: 122066. doi: 10.1016/j.biortech.2019.122066 [13] FERNANDEZ-R J, PEREZ M, ROMERO L I. Comparison of mesophilic and thermophilic dry anaerobic digestion of OFMSW: Kinetic analysis[J]. Chemical Engineering Journal, 2013, 232: 59-64. doi: 10.1016/j.cej.2013.07.066 [14] SUN C, LIU F, SONG Z, et al. Feasibility of dry anaerobic digestion of beer lees for methane production and biochar enhanced performance at mesophilic and thermophilic temperature[J]. Bioresource Technology, 2019, 276: 65-73. doi: 10.1016/j.biortech.2018.12.105 [15] LI Q, QIAO W, WANG X, et al. Kinetic characterization of thermophilic and mesophilic anaerobic digestion for coffee grounds and waste activated sludge[J]. Waste Management, 2015, 36: 77-85. doi: 10.1016/j.wasman.2014.11.016 [16] KOMILIS D, BARRENA R, GRANDO R L, et al. A state of the art literature review on anaerobic digestion of food waste: influential operating parameters on methane yield[J]. Reviews in Environmental Science and Bio/Technology, 2017, 16(2): 347-360. doi: 10.1007/s11157-017-9428-z [17] MOMAYEZ F, KARIMI K, TAHERZADEH M J. Energy recovery from industrial crop wastes by dry anaerobic digestion: A review[J]. Industrial Crops and Products, 2019, 129: 673-687. doi: 10.1016/j.indcrop.2018.12.051 [18] 许国栋, 闫园园, 李彩斌, 等. 干式厌氧发酵反应器的中试研究[J]. 中国给水排水, 2020, 36(5): 33-38. doi: 10.19853/j.zgjsps.1000-4602.2020.05.006 [19] 孙树鹏, 张璐, 侯威, 等. 基于非线性相似度量方法研究中国季节划分[J]. 物理学报, 2011, 60(2): 809-815. doi: 10.7498/aps.60.029201 [20] 张旭, 王宝贞, 朱宏. 厌氧消化体系的酸碱性及其缓冲能力[J]. 中国环境科学, 1997(6): 13-17. doi: 10.3321/j.issn:1000-6923.1997.06.004 [21] 郁达伟, 孟晓山, 魏源送. 高负荷厌氧生物反应器的三元酸碱缓冲体系特征与调控[J]. 环境科学学报, 2019, 39(2): 279-289. doi: 10.13671/j.hjkxxb.2018.0224 [22] 刘吉宝, 牛雨彤, 郁达伟, 等. 零价铁对厌氧消化过程中氨氮抑制解除的影响[J]. 环境科学, 2020, 41(8): 1-13. doi: 10.13227/j.hjkx.201912270 [23] ZHAO J, HOU T, LEI Z, et al. Effect of biogas recirculation strategy on biogas upgrading and process stability of anaerobic digestion of sewage sludge under slightly alkaline condition[J]. Bioresource Technology, 2020, 308: 123293. doi: 10.1016/j.biortech.2020.123293 [24] GAO S, HUANG Y, YANG L, et al. Evaluation the anaerobic digestion performance of solid residual kitchen waste by NaHCO3 buffering[J]. Energy Conversion and Management, 2015, 93: 166-174. doi: 10.1016/j.enconman.2015.01.010 [25] SONG Y C, KWON S J, WOO J-H. Mesophilic and thermophilic temperature co-phase anaerobic digestion compared with single-stage mesophilic- and thermophilic digestion of sewage sludge[J]. Water Research, 2004, 38(7): 1653-1662. doi: 10.1016/j.watres.2003.12.019 -

下载:

下载: