-

石油炼制和基础化学原料制造过程会产生大量的废催化剂。近年来,石化产品的需求量逐年增加、原料油劣质化和油品质量升级促使炼油催化剂生命周期缩短,卸出量增大。早在2016年,环境保护部联合国家发展和改革委员会、公安部发布《国家危险废物名录(2016年版)》,增加了HW50废催化剂类废物。最新发布的《国家危险废物名录(2021年版)》中,废催化剂主要包括加氢精制、采用钝镍剂的催化裂化、加氢裂化、催化重整等工艺过程产生的废催化剂[1]。

浸出毒性通常指固体废物遇水浸沥,浸出的有害物质迁移转化,对人和生态环境造成的污染。挥发性有机化合物(VOCs)具有较低的沸点,极易挥发和迁移。VOCs具有亲脂性、高毒性和刺激性,在生物体内产生致癌、致畸、致突变以及生理毒性,危害人类健康,属于浸出毒性重点关注的有害物质[2-3]。VOCs是废催化剂危险废物鉴别中重点关注的指标之一。GB5085.3—2007《危险废物鉴别标准浸出毒性鉴别》中涉及多项固体废物浸出液中VOCs指标,超过浓度限值的固体废物是具有浸出毒性特征的危险废物。

由于固体废物浸出液中VOCs种类复杂,含量极低,因此有必要对浸出液进行样品前处理。VOCs的前处理方法主要有吹扫捕集、顶空、溶剂萃取、固相微萃取等。溶剂萃取法成本低,但操作繁琐,需使用大量有机溶剂,提取过程中会损失部分VOCs。顶空法可避免VOCs的损失,测定范围广,操作简便,但不能浓缩VOCs,灵敏度低,无法满足痕量分析的要求。固相微萃取法选择性不高,萃取头种类较少,易受污染而导致萃取效率降低。吹扫捕集是将惰性气体通过吹扫管连续吹扫样品,将样品中的VOCs不断吹入气相,在捕集管中被吸附剂或冷阱捕集,然后迅速加热捕集管,VOCs被解吸,最后进行测定。吹扫捕集灵敏度高、线性范围宽,广泛应用于固体废物VOCs的痕量分析。固体废物浸出液中VOCs的测定方法主要有GB5085.3—2007中推荐的附录O、附录P和附录Q,以及7项固体废物中VOCs的分析标准。前处理技术采用顶空法和吹扫捕集,检测方法有GC-FID[4-7]、GC-MS[4,8-11]、GC-PID[4]、GC-HECD[4]。

目前,国内针对废催化剂浸出液中VOCs的测定鲜有报道。本文选取了3种不同炼油工艺产生的废催化剂,建立了吹扫捕集/气相色谱-质谱法测定废催化剂浸出液中VOCs的分析方法。

-

仪器和设备:气相色谱-质谱仪Aglient 7890B-5977B;吹扫捕集样品浓缩仪OI Analytical Eclipse 4760,样品瓶体积为40 mL;振荡设备:转速为(30±2)r·min−1的翻转式振荡装置;零顶空提取器(Zero-Headspace Extraction Vessel,ZHE):500—600 mL。

试剂:VOCs混合标准溶液(2000 mg·L−1)(购自伊诺凯),甲醇(色谱纯),内标标准溶液(氟苯、氯苯-D5、1,4-二氯苯-D4的混合溶液,2500 mg·L−1),替代物标准溶液(二溴氟甲烷、甲苯-D8、4-溴氟苯的混合溶液,2000 mg·L−1)。实验用水为超纯水,电阻率≥18 MΩ·cm。废催化剂分别来自于催化裂化(FCC)、吸附脱硫(S Zorb)和渣油加氢工艺产生的废催化剂。

-

吹扫捕集条件:吹扫流量40 mL·min−1;吹扫温度40 ℃;吹扫时间11 min;脱附温度190 ℃;脱附时间2 min;烘烤温度200 ℃;烘烤时间8 min。

气相色谱条件:色谱柱:DB-624UI,60 m×0.25 mm×1.4 μm,6%腈丙苯基、94%二甲基聚硅氧烷固定液;柱流量(恒流模式):1 mL·min−1;阻尼柱1:1.8 m×150 μm,弹性石英柱管,流量1.53 mL·min−1;阻尼柱2:0.7 m×150 μm,弹性石英柱管;进样口温度:250 ℃;载气:氦气;分流比:20:1;柱流量(恒流模式):1 mL·min−1;升温程序:初始温度38 ℃,保持4 min,以5 ℃·min−1速率升温至240 ℃。保持20 min。

质谱条件:扫描方式:全扫描(SCAN)及选择离子扫描(SIM)模式;扫描范围35—270 amu;离子化能量70 eV;接口温度280 ℃。

-

配制质量浓度分别为5、20、50、100、200 μg·L−1的VOCs混合标准溶液和替代物标准溶液,分别加入内标溶液,使每点的内标质量浓度均为50.0 μg·L−1,立即密封待测。

-

执行HJ/T 299—2007的方法制备废催化剂浸出液试样,浸提剂为超纯水。称取40 g废催化剂样品,快速转入ZHE,缓慢加压以排除顶空。根据样品的含水率,按液固比为10∶1(L·kg−1)计算所需浸提剂的体积。将ZHE固定在翻转式振荡装置上,23 ℃下振荡18 h,收集浸出液。取5 ml浸出液试样,再加入内标溶液和替代物溶液,使内标和替代物质量浓度均为50.0 μg·L−1,快速注入吹扫管中,内标法定量。

-

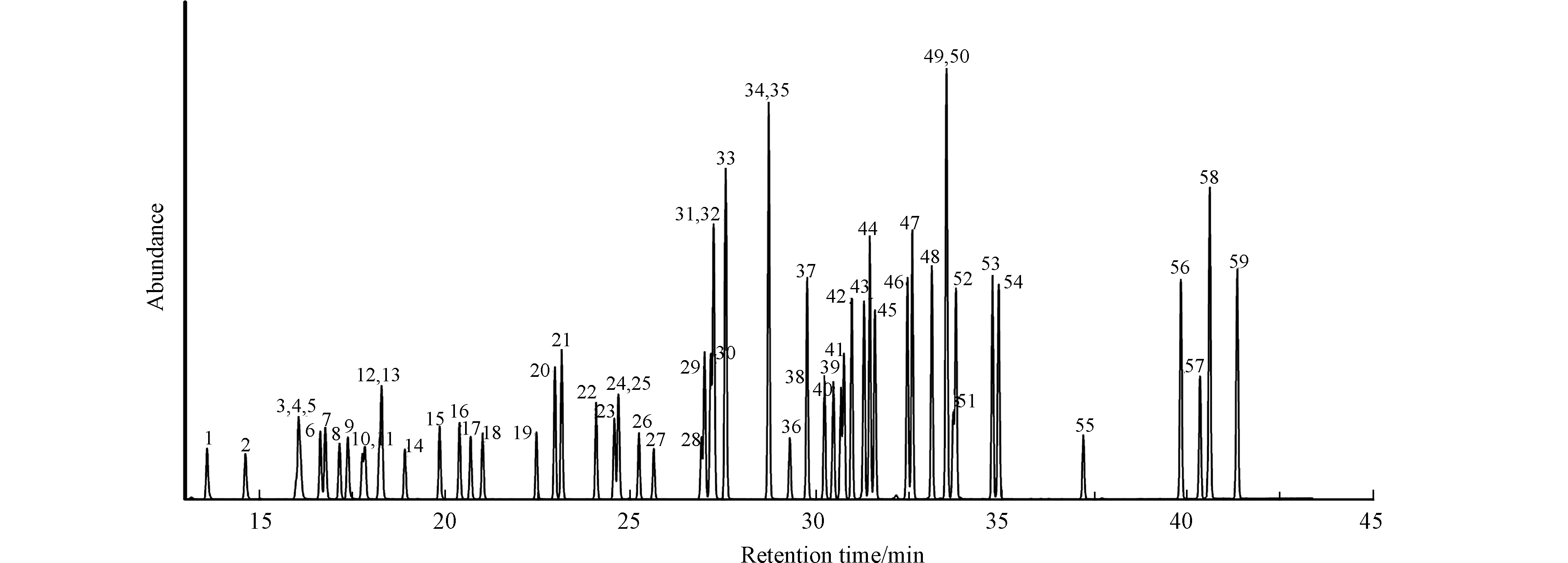

吹扫捕集/气相色谱-质谱法测定53种VOCs、3种内标和3种替代物的质谱的总离子流图如图1所示。吹扫捕集/气相色谱-质谱法的线性和检出限见表1,标准曲线的线性范围为5—200 μg·L−1,线性相关系数R2>0.99,方法检出限为0.1—2.0 μg·L−1,方法的线性程度和检出限均较为满意。

-

按照HJ/T 299—2007的方法制备废催化剂浸出液试样,浸提剂为超纯水。废催化剂分别来自于FCC、S Zorb和渣油加氢3种工艺产生的废催化剂。催化裂化是重质石油烃类在催化剂的作用下反应产生液化气、汽油和柴油等轻质油品的过程。FCC工艺所使用的催化剂属于Y型分子筛。S Zorb工艺是采用独特的吸附剂对汽油脱硫的过程。S Zorb催化剂的主要成分是含过渡金属的双金属氧化物。渣油加氢工艺是以渣油为原料加氢处理制得低硫燃料油,或加氢裂化制得轻质油的过程。渣油加氢催化剂主要是以大孔氧化铝、分子筛和复合金属氧化物为载体,以Mo、Mo-Ni、Mo-Co和Mo-W为活性组分与助剂一并合成的[12]。3种催化剂在使用过程中会负载有机物,严重时会造成积炭,失去活性成为废催化剂。负载上的一些有机物属于有毒物质,因此3种废催化剂属于《国家危险废物名录(2021年版)》中关注的固体废物。

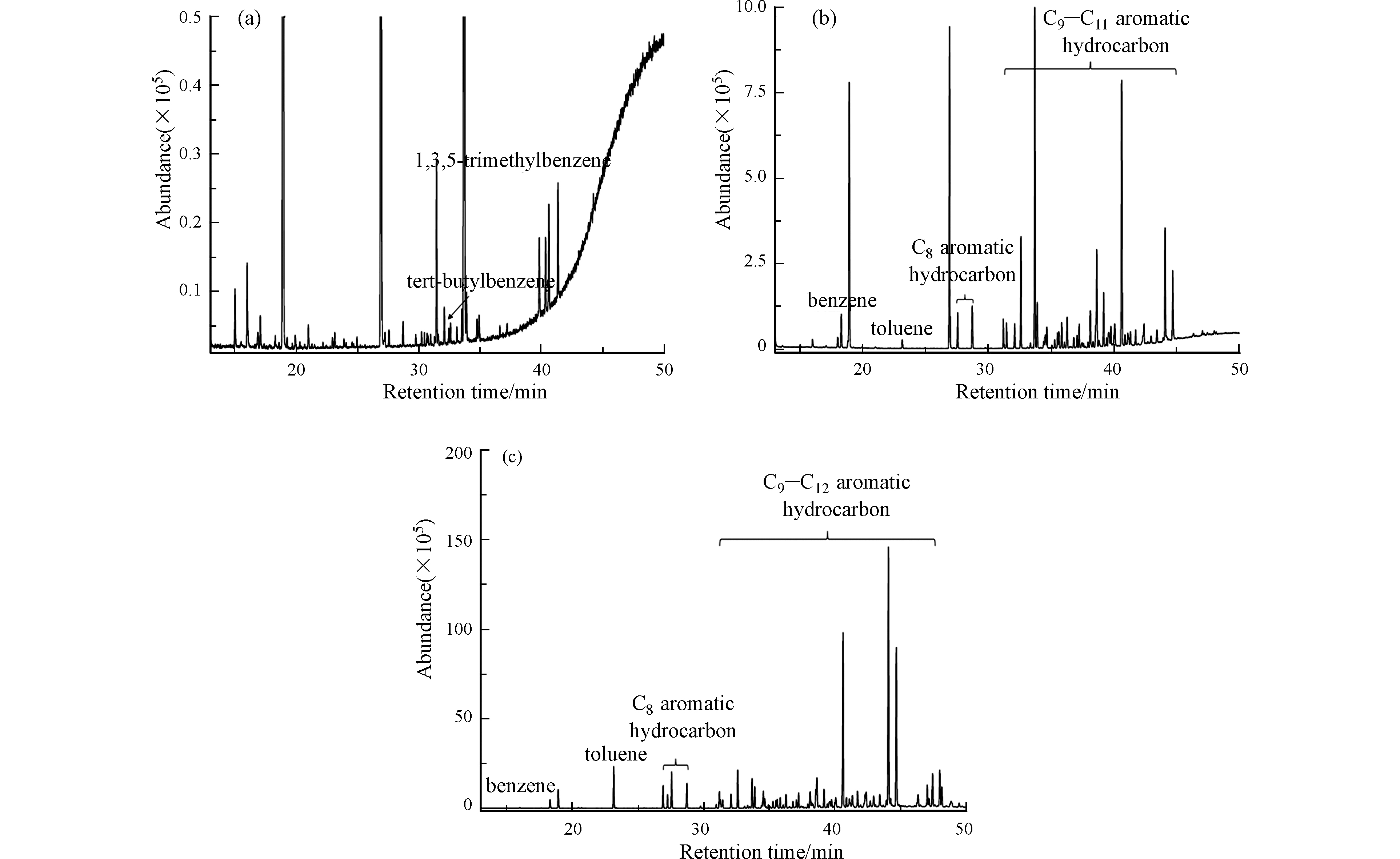

图2分别为3种废催化剂浸出液的总离子流色谱图。3种废催化剂浸出液的测定结果及精密度见表2,其中氯仿、四氯化碳、苯、三氯乙烯、甲苯、四氯乙烯、氯苯、乙苯、间,对二甲苯、邻二甲苯、1,2-二氯苯、1,4-二氯苯属于GB5085.3—2007《危险废物鉴别标准浸出毒性鉴别》中涉及的11项VOCs指标。3种废催化剂浸出液中的这11项VOCs含量均低于GB5085.3—2007中浸出毒性鉴别限值。FCC、S Zorb和渣油加氢三种废催化剂浸出液中VOCs的相对标准偏差(RSD,n=3)分别为0.2%—0.6%、0.7%—3.9%和0.9%—4.3%,精密度较为满意。

-

为了考察吹扫捕集/气相色谱-质谱法的回收率,向3种废催化剂浸出液加入标准溶液和替代物,使VOCs加标量为50.0 μg·L−1。3种废催化剂浸出液加标50.0 μg·L−1的回收率试验结果见表3,回收率分别为78.7%—161.0%、64.9%—145.6%和74.0%—167.6%,替代物二溴氟甲烷、甲苯-D8、4-溴氟苯回收率满足70%—130%之间,大部分目标VOCs的回收率在70%—130%。以上结果表明,所建立的吹扫捕集/气相色谱-质谱法可以用于废催化剂浸出液中VOCs的监测。

少数目标VOCs的回收率偏高,主要原因是内标响应值的波动造成的。个别组分如正丙苯、叔丁基苯、仲丁基苯、4-异丙基甲苯、正丁基苯、六氯丁二烯等,加标回收率不够理想,该结果与陈德阳等[13]的文献保持一致。这可能是由于高碳数组分沸点较高,吹扫捕集的前处理方法不容易将高碳数组分从浸出液中提取出来,导致这些组分的回收率不高。

-

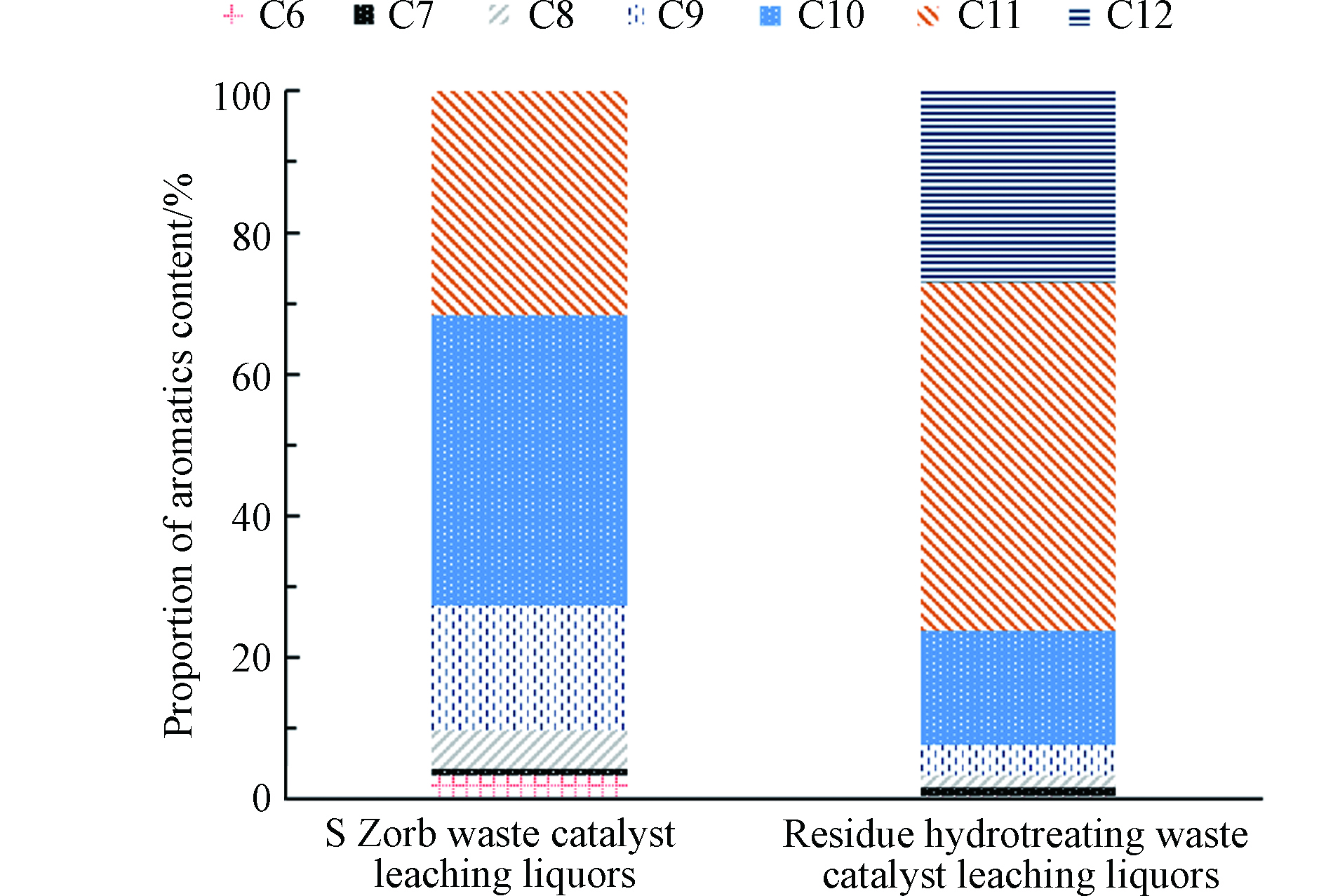

图2(a)可以看出,FCC废催化剂浸出液中大部分VOCs含量低于检出限。图2(b)和(c)表明,除了GB5085.3—2007所列的VOCs指标,S Zorb和渣油加氢废催化剂浸出液中含有大量以芳烃为主的VOCs,这些芳烃会对环境造成污染。如果芳烃的含量以正丙苯计算,S Zorb和渣油加氢废催化剂浸出液中芳烃总量分别为275 μg·L−1和6645 μg·L−1。S Zorb和渣油加氢废催化剂浸出液芳烃的组成和分布结果见图3。S Zorb废催化剂浸出液检出的化合物以C9—C11芳烃为主,其中C9芳烃、C10芳烃、C11芳烃的含量占比分别为17.7%、41.0%、31.7%。渣油加氢废催化剂检出的化合物以C10—C12芳烃为主,其中C10芳烃、C11芳烃、C12芳烃的含量占比分别为16.2%、49.1%、27.1%。结果表明,S Zorb和渣油加氢废催化剂浸出液中VOCs种类主要为C9+芳烃。

-

采用吹扫捕集/气相色谱-质谱法,建立了石油炼制工艺废催化剂浸出液中VOCs的检测方法。对线性范围、检出限、回收率及精密度进行了考察。结果表明该方法稳定性好、灵敏度高,可以满足废催化剂浸出液中VOCs的检测要求。不同石油炼制工艺产生的废催化剂,其负载VOCs的组成和分布可能差异较大,这对于废催化剂的认识、检测和治理提供了参考和支持。废催化剂浸出液的VOCs组成较为复杂,该方法针对的目标物数量有限,尚需开发新的方法进行分析测定。

吹扫捕集/气相色谱-质谱法测定石油炼制工艺废催化剂浸出液中挥发性有机物

Determination of volatile organic compounds in waste catalyst leaching liquor in petroleum refining process using P&T-GC-MS method

-

摘要: 采用吹扫捕集/气相色谱-质谱法,建立了石油炼制工艺废催化剂浸出液中挥发性有机物(VOCs)的检测方法。该方法标准曲线线性范围为5—200 μg L−1,线性相关系数R2>0.99,方法检出限为0.1—2.0 μg L−1。催化裂化(FCC)废催化剂浸出液、吸附脱硫(S Zorb)废催化剂浸出液和渣油加氢废催化剂浸出液的测定结果显示各组分的相对标准偏差(RSD)分别为0.2%—0.6%、0.7%—3.9%和0.9%—4.3%,基体加标回收率分别为78.7%—161.0%、64.9%—145.6%和74.0%—167.6%。所建立的方法可以满足废催化剂浸出液中VOCs的检测要求。FCC废催化剂浸出液中大部分VOCs的含量低于检出限。S Zorb废催化剂浸出液、渣油加氢废催化剂浸出液检出的化合物分别以C9—C11芳烃和C10—C12芳烃为主。所选取的3种废催化剂浸出液中目标VOCs含量均低于GB5085.3—2007中浸出毒性鉴别限值。Abstract: A method was established for the determination of volatile organic compounds (VOCs) in waste catalyst leaching liquor in petroleum refining process by gas chromatography-mass spectrometry (GC-MS) with purge and trap (P&T) pretreatment. The linear ranges were 5—200 μg L−1 and linear correlation coefficients were more than 0.99. The detection limits were 0.1—2.0 μg L−1. 3 kinds of waste catalysts from the semi synthetic fluid catalytic cracking (FCC), S Zorb and residue hydrotreating refinery process were investigated for leaching experiment. The recoveries of leaching liquors were 78.7%—161.0%, 64.9%—145.6% and 74.0%—167.6% with RSD of 0.2%—0.6%, 0.7%—3.9% and 0.9%—4.3% respectively. This method was suitable for the analysis of VOCs in waste catalyst leaching liquor.The concentration of most VOCs were below the detection limits in waste catalyst leaching liquor from FCC. C9—C11 aromatic hydrocarbons and C10—C12 aromatic hydrocarbons were the main compounds detected in waste catalyst leaching liquors from S Zorb and residue hydrotreating respectively. The contents of target VOCs in the leaching solution of the three waste catalysts selected were all lower than the limiting values for the identification of leaching toxicity in GB5085.3—2007.

-

Key words:

- waste catalyst /

- leaching liquor /

- volatile organic compounds /

- purge and trap

-

-

表 1 吹扫捕集/气相色谱-质谱法的校准曲线和检出限

Table 1. Calibration curves and detection limits of P&T-GC-MS

VOC种类 Type of VOCs 校准曲线 Calibration curves R2 检出限/(μg·L−1) Detection limits 反-1,2-二氯乙烯 y = 0.120x+0.003 0.9999 0.8 1,1-二氯乙烷 y = 0.246x+0.009 0.9998 0.6 顺-1,2-二氯乙烯 y = 0.196x+0.005 0.9999 0.7 2-丁酮 y = 0.035x+0.008 1.0000 2.0 2,2-二氯丙烷 y = 0.142x 0.9999 1.5 溴氯甲烷 y = 0.102x+0.003 0.9999 0.7 氯仿 y = 0.323x+0.011 0.9998 0.6 二溴氟甲烷 y = 0.176x 1.0000 0.4 1,1,1-三氯乙烷 y = 0.242x−0.002 0.9998 1.2 四氯化碳 y = 0.175x−0.002 0.9997 1.2 1,1-二氯丙烯 y = 0.126x−0.003 0.9999 0.3 苯 y = 0.545x+0.010 0.9999 0.3 1,2-二氯乙烷 y = 0.226x+0.007 0.9998 0.2 三氯乙烯 y = 0.136x+0.002 0.9999 0.3 1,2-二氯丙烷 y = 0.168x 1.0000 0.2 二溴甲烷 y = 0.122x+0.006 0.9991 0.4 一溴二氯甲烷 y = 0.238x−0.008 0.9998 0.2 4-甲基-2-戊酮 y = 0.045x−0.005 0.9987 0.4 甲苯-D8 y = 0.587x+0.010 0.9997 0.3 甲苯 y = 0.449x−0.001 1.0000 0.3 1,1,2-三氯乙烷 y = 0.180x+0.004 0.9997 0.3 四氯乙烯 y = 0.107x+0.003 0.9998 0.4 1,3-二氯丙烷 y = 0.357x+0.005 0.9997 0.2 2-己酮 y = 0.166x−0.012 0.9997 0.3 二溴氯甲烷 y = 0.226x−0.016 0.9995 0.2 1,2-二溴乙烷 y = 0.229x−0.005 1.0000 0.1 氯苯 y = 0.580x+0.010 0.9999 0.2 1,1,1,2-四氯乙烷 y = 0.277x−0.012 0.9997 0.5 乙苯 y = 0.289x−0.007 0.9999 0.3 1,1,2-三氯丙烷 y = 0.483x+0.001 0.9999 0.4 间,对二甲苯 y = 0.733x−0.022 0.9998 0.4 邻二甲苯 y = 0.448x−0.022 0.9996 0.5 苯乙烯 y = 0.660x−0.061 0.9991 0.6 溴仿 y = 0.171x−0.022 0.9972 0.4 异丙苯 y = 1.530x−0.025 0.9997 0.3 4-溴氟苯 y = 0.464x+0.009 0.9995 0.2 1,1,2,2-四氯乙烷 y = 0.567x−0.008 0.9999 1.0 溴苯 y = 0.426x+0.018 0.9990 0.2 1,2,3-三氯丙烷 y = 0.335x+0.007 0.9956 1.6 正丙苯 y = 1.270x+0.022 0.9962 0.6 2-氯甲苯 y = 1.251x+0.011 0.9997 0.3 1,3,5-三甲基苯 y = 1.526x−0.061 1.0000 0.5 4-氯甲苯 y = 1.225x+0.028 0.9995 0.3 叔丁基苯 y = 1.196x−0.082 0.9998 0.3 1,2,4-三甲基苯 y = 1.614x−0.046 1.0000 0.5 仲丁基苯 y = 1.729x−0.074 1.0000 0.5 1,3-二氯苯 y = 0.895x+0.026 0.9997 0.3 4-异丙基甲苯 y = 1.523x−0.061 1.0000 0.6 1,4-二氯苯 y = 0.936x+0.021 0.9999 0.2 正丁基苯 y = 1.356x−0.061 1.0000 0.6 1,2-二氯苯 y = 0.966x+0.022 0.9999 0.4 1,2-二溴-3-氯丙烷 y = 0.180x−0.017 0.9989 0.4 1,2,4-三氯苯 y = 0.720x−0.010 1.0000 0.7 六氯丁二烯 y = 0.234x 1.0000 2.0 萘 y = 2.596x−0.097 0.9984 0.8 1,2,3-三氯苯 y = 0.760x+0.023 0.9992 0.8 注:表中x为目标VOCs含量与相对应内标物含量的比值,y为目标VOCs峰面积与相对应内标物峰面积的比值.

Note: in the table, x is the ratio of target VOCs content to corresponding internal standard content, and y is the ratio of target VOCs peak area to corresponding internal standard peak area.表 2 废催化剂浸出液中VOCs测定结果及精密度

Table 2. Determination results and precisions of VOCs in waste catalyst leaching liquors

VOC种类

Type of VOCsFCC废催化剂浸出液

Waste catalyst leaching

liquor from FCCS Zorb废催化剂浸出液

Waste catalyst leaching

liquor from S Zorb渣油加氢废催化剂浸出液

Waste catalyst leaching liquor

from residue hydrotreatingS/(μg·L−1) 平均值/

(μg·L−1)RSD/% S/(μg·L−1) 平均值/

(μg·L−1)RSD/% S/(μg·L−1) 平均值/

(μg·L−1)RSD/% 氯仿 — — — — — — — — — 四氯化碳 — — — — — — — — — 苯 — — — 0.089 9.3 1.0 0.279 24.1 1.2 三氯乙烯 — — — — — — — — — 甲苯 — — — 0.028 2.40 1.2 1.217 87.3 1.4 四氯乙烯 — — — — — — — — — 氯苯 — — — — — — — — — 乙苯 — — — — — — 0.233 25.0 0.9 间,对二甲苯 — — — 0.064 5.10 1.2 0.405 36.5 1.1 邻二甲苯 — — — 0.163 9.72 1.7 0.470 44.1 1.1 苯乙烯 — — — — — — — — — 异丙苯 — — — — — — 0.083 4.86 1.7 正丙苯 — — — — — — 0.157 4.80 3.3 1,3,5-三甲基苯 0.024 3.89 0.6 0.070 6.47 1.1 0.617 16.9 3.7 叔丁基苯 0.005 3.44 0.2 0.139 3.55 3.9 — — — 1,2,4-三甲基苯 — — — 0.137 18.9 0.7 2.767 67.0 4.1 仲丁基苯 — — — — — — 0.283 7.79 3.6 4-异丙基甲苯 — — — — — — 0.246 6.96 3.5 1,4-二氯苯 — — — — — — — — — 正丁基苯 — — — — — — 0.362 8.45 4.3 1,2-二氯苯 — — — — — — — — — 萘 — — — 1.387 39.2 3.5 13.9 364 3.8 注:S为标准偏差(μg·L−1);表中未列出的VOCs表示其质量浓度低于方法检出限.

Note: S is the standard deviation(μg·L−1);VOCs not listed in the table indicated that their mass concentrations were lower than the detection limits of the method.表 3 废催化剂浸出液基体加标回收率测定结果

Table 3. Determination of recovery rates of waste catalyst leaching liquors by matrix standard addition

VOC

种类

Type of

VOCsFCC废催化剂浸出液

Waste catalyst leaching

liquor from FCCS Zorb废催化剂浸出液

Waste catalyst leaching

liquor from S Zorb渣油加氢废催化剂浸出液

Waste catalyst leaching liquor

from residue hydrotreating实际样品

含量/

(μg·L−)

Content in

practical sample加标后浓度/

(μg·L−1)

Content after

standard addition回收率/%

Recovery

rate实际样品

含量/

(μg·L−1)

Content in

practical sample加标后浓度/

(μg·L−1)

Content after

standard addition回收率/%

Recovery

rate实际样品

含量/

(μg·L−1)

Content in

practical sample加标后浓度/

(μg·L−1)

Content after

standard addition回收率/%

Recovery

rate反-1,2-二氯乙烯 — 80.5 161.0 — 72.8 145.6 — 67.8 135.6 1,1-二氯乙烷 — 68.5 137.0 — 61.1 122.2 — 83.8 167.6 顺-1,2-二氯乙烯 — 63.8 127.6 — 55.9 111.9 — 78.2 156.4 2-丁酮 — 60.7 121.4 — 55.0 109.9 — 82.8 165.6 2,2-二氯丙烷 — 71.4 142.9 — 52.2 104.4 — 77.7 155.5 溴氯甲烷 — 65.9 131.8 — 57.1 114.1 — 80.3 160.5 氯仿 — 54.8 109.7 — 48.1 96.2 — 65.8 131.7 二溴氟

甲烷— 52.3 104.6 — 45.0 90.0 — 62.8 125.5 1,1,1-三氯乙烷 — 54.8 109.7 — 45.1 90.2 — 53.4 106.9 四氯化碳 — 47.9 95.9 — 38.6 77.3 — 43.4 86.8 1,1-二氯丙烯 — 50.1 100.1 — 43.8 87.5 — 55.1 110.2 苯 — 61.2 122.5 9.3 58.3 97.9 24.1 92.0 135.7 1,2-二氯乙烷 — 60.2 120.5 — 52.9 105.9 — 71.3 142.6 三氯乙烯 — 50.5 101.1 — 44.0 88.0 — 57.3 114.7 1,2-二氯丙烷 — 58.3 116.7 — 50.7 101.4 — 66.5 133.1 二溴甲烷 — 59.6 119.3 — 51.7 103.4 — 69.9 139.8 一溴二氯甲烷 — 51.6 103.2 — 44.0 88.0 — 62.6 125.3 4-甲基-2-戊酮 — 62.1 124.2 — 52.6 105.2 — 75.3 150.6 甲苯-D8 — 48.4 96.9 — 42.6 85.3 — 54.9 109.7 甲苯 — 49.6 99.1 2.40 45.1 85.3 87.3 136.2 97.8 1,1,2-三氯乙烷 — 55.4 110.8 — 49.2 98.4 — 65.6 131.1 四氯乙烯 — 41.7 83.4 — 36.0 72.1 — 43.4 86.9 1,3-二氯丙烷 — 56.1 112.1 — 50.3 100.6 — 67.2 134.4 2-己酮 — 52.4 104.9 — 46.4 92.7 — 70.4 140.8 二溴氯

甲烷— 51.6 103.1 — 45.4 90.7 — 61.9 123.8 1,2-二溴乙烷 — 55.4 110.9 — 49.1 98.1 — 67.6 135.1 氯苯 — 52.0 104.1 — 45.2 90.3 — 58.3 116.6 1,1,1,2-四氯乙烷 — 51.8 103.6 — 43.4 86.8 — 56.9 113.8 乙苯 — 46.5 93.0 — 40.3 80.6 25.0 72.9 95.9 1,1,2-三氯丙烷 — 53.6 107.3 — 45.6 91.1 — 60.3 120.6 间,对二甲苯 — 47.0 93.9 5.10 42.5 74.7 36.5 84.6 96.2 邻二甲苯 — 50.9 101.7 9.72 47.7 75.9 44.1 95.9 103.6 苯乙烯 — 48.1 96.2 — 41.3 82.6 — 56.9 113.8 溴仿 — 50.4 100.7 — 43.1 86.3 — 60.8 121.6 异丙苯 — 47.5 95.0 — 41.1 82.2 4.86 52.1 94.5 4-溴氟苯 — 57.9 115.8 — 50.4 100.8 — 64.4 128.7 1,1,2,2-四氯乙烷 — 59.4 118.9 — 49.1 98.3 — 70.4 140.8 溴苯 — 54.9 109.8 — 48.1 96.1 — 58.8 117.6 1,2,3-三氯丙烷 — 45.0 90.1 — 42.6 85.2 — 53.6 107.3 正丙苯 — 42.1 84.3 — 37.5 75.0 4.80 50.7 91.9 2-氯甲苯 — 53.2 106.4 — 46.4 92.7 — 56.2 112.3 1,3,5-三甲基苯 3.89 51.5 95.3 6.47 45.4 77.8 16.9 67.5 101.3 4-氯甲苯 — 51.6 103.3 — 45.3 90.5 — 53.8 107.6 叔丁基苯 3.44 45.3 83.7 3.55 39.7 72.2 — 49.5 99.0 1,2,4-三甲基苯 — 53.0 106.0 18.9 56.5 75.2 67.0 128.1 122.2 仲丁基苯 — 42.5 85.0 — 36.5 72.9 7.79 47.2 78.9 1,3-二

氯苯— 53.9 107.7 — 46.5 92.9 — 54.4 108.8 4-异丙基甲苯 — 45.7 91.4 — 38.9 77.9 6.96 48.4 82.9 1,4-二

氯苯— 53.8 107.7 — 47.2 94.4 — 56.1 112.2 正丁基苯 — 42.3 84.7 — 37.1 74.2 8.45 47.7 78.6 1,2-二氯苯 — 58.5 116.9 — 49.8 99.5 — 59.6 119.2 1,2-二溴-3-氯丙烷 — 59.3 118.6 — 50.6 101.1 — 74.7 149.5 1,2,4-三氯苯 — 60.8 121.6 — 51.6 103.2 — 49.2 98.4 六氯丁

二烯— 39.3 78.7 — 32.5 64.9 — 37.0 74.0 萘 — 64.8 129.5 39.2 85.2 92.1 364 430.2 131.7 1,2,3-三氯苯 — 62.0 124.0 — 52.4 104.9 — 47.1 94.3 注:VOCs的加标量均为50.0 μg·L−1.

Note: adding standard amounts of VOCs were 50.0 μg·L−1. -

[1] 生态环境部, 国家发展和改革委员会, 公安部, 等. 国家危险废物名录(2021年版) [R/OL]. 2020: [000014672/2020-01495]. http://www.mee.gov.cn/xxgk2018/xxgk/xxgk02/202011/t20201127_810202.html. Ministry of Ecology and Environment, National Development and Reform Commission, Ministry of Public Security, et al. National hazardous waste list (2021 Edition) [R/OL]. 2020: [000014672/2020-01495]. http://www.mee.gov.cn/xxgk2018/xxgk/xxgk02/202011/t20201127_ 810202. html.

[2] 胡桐搏, 张长平, 刘浩, 等. VOCs废气危害及处理技术进展 [J]. 化工管理, 2018(10): 125-127. doi: 10.3969/j.issn.1008-4800.2018.10.088 HU T B, ZHANG C P, LIU H, et al. The damage and development of treatment technique of VOCs [J]. Chemical Enterprise Management, 2018(10): 125-127(in Chinese). doi: 10.3969/j.issn.1008-4800.2018.10.088

[3] 齐安安, 周小平, 雷春妮, 等. 兰州市功能区环境空气中挥发性有机物关键活性组分与来源解析 [J]. 环境化学, 2020, 39(11): 3083-3093. doi: 10.7524/j.issn.0254-6108.2019080402 QI A A, ZHOU X P, LEI C N, et al. Key active components and sources of volatile organic compounds in ambient air of Lanzhou City [J]. Environmental Chemistry, 2020, 39(11): 3083-3093(in Chinese). doi: 10.7524/j.issn.0254-6108.2019080402

[4] 国家环境保护总局, 国家质量监督检验检疫总局. 中华人民共和国国家标准: GB5085.3—2007 [S]. 北京: 中国环境科学出版社, 2007. State Environmental Protection Administration of China, General Administration of quality supervision, inspection and Quarantine of the people's Republic of China. National standards of China: GB5085.3—2007 [S]. Beijing: China Environmental Science Press, 2007.

[5] 中华人民共和国环境保护部. 中华人民共和国环保行业标准: 固体废物 挥发性有机物的测定 顶空-气相色谱法 HJ 760—2015[S]. 北京: 中国环境科学出版社, 2015. Ministry of Environmental Protection of the People's Republic of China. Environmental Protection Standard of the People's Republic of China: Solid waste—Determination of volatile organic compounds—Headspace-gas chromatography method. HJ 760—2015[S]. Beijing: China Environment Science Press, 2015(in Chinese).

[6] 环境保护部. 中华人民共和国国家环境保护标准: HJ 874—2017 [S]. 北京: 中国环境科学出版社, 2017. Ministry of Environmental Protection. National standards of China: HJ 874—2017 [S]. Beijing: China Environmental Science Press, 2017.

[7] 生态环境部. 中华人民共和国国家环境保护标准: HJ 975—2018 [S]. 北京: 中国环境科学出版社, 2018. Ministry of Ecology and Environment. National standards of China: HJ 975—2018 [S]. Beijing: China Environmental Science Press, 2018.

[8] 环境保护部. 中华人民共和国国家环境保护标准: HJ 643—2013 [S]. 北京: 中国环境科学出版社, 2013. Ministry of Environmental Protection. National standards of China: HJ 643—2013 [S]. Beijing: China Environmental Science Press, 2013.

[9] 环境保护部. 中华人民共和国国家环境保护标准: HJ 713—2014 [S]. 北京: 中国环境科学出版社, 2014. Ministry of Environmental Protection. National standards of China: HJ 713—2014 [S]. Beijing: China Environmental Science Press, 2014.

[10] 环境保护部. 中华人民共和国国家环境保护标准: HJ 714—2014 [S]. 北京: 中国环境科学出版社, 2014. Ministry of Environmental Protection. National standards of China: HJ 714—2014 [S]. Beijing: China Environmental Science Press, 2014.

[11] 生态环境部. 中华人民共和国国家环境保护标准: HJ 976—2018 [S]. 北京: 中国环境科学出版社, 2018. Ministry of Ecology and Environment. National standards of China: HJ 976—2018 [S]. Beijing: China Environmental Science Press, 2018.

[12] 王爽, 丁巍, 赵德智, 等. 渣油加氢催化剂酸性、孔结构及分散度对催化活性的影响 [J]. 化工进展, 2015, 34(9): 3317-3322. doi: 10.16085/j.issn.1000-6613.2015.09.017 WANG S, DING W, ZHAO D Z, et al. Influence on catalytic activity in residue hydrogenation by acidity, pore structure and dispersion [J]. Chemical Industry and Engineering Progress, 2015, 34(9): 3317-3322(in Chinese). doi: 10.16085/j.issn.1000-6613.2015.09.017

[13] 陈德阳, 江思雨. 吹扫捕集-气质联用法测定固体废物浸出液中64种挥发性有机物[J]. 环境科学导刊, 2018, 37(增刊1): 142-148. CHEN D Y, JIANG S Y. Determination of sixty-four kinds of volatile organic compounds in solid waste leaching liquor by purging and trapping-gas chromatography and mass spectrometry[J]. Environmental Science Survey, 2018, 37(Sup 1): 142-148(in Chinese).

-

下载:

下载: