-

随着国家经济发展以及人民生活水平的提高,城市生活垃圾的产量增长迅速。截至2019年,我国196个大、中型城市生活垃圾产量已达2.4×109 t,较2018年同期增长14.3%[1]。卫生填埋作为城市生活垃圾的主要处置方式之一,被国内外广泛采用[2-3]。然而生活垃圾在填埋过程中由于垃圾发酵、地表水及地下水的渗透作用,导致垃圾填埋场生成大量高污染性的有毒有害有机废水,即垃圾渗滤液[4]。垃圾渗滤液作为一类含高质量浓度氨氮(NH4+-N)的有机难处理废水,具有显著的低碳/氮比(C/N)水质特征[5]。特别是填埋场老龄垃圾渗滤液的C/N通常低于3.0[6],若采用传统硝化反硝化生物处理工艺往往需要大量的曝气能耗投入及有机碳源补充,不仅运行成本高昂且易造成大量温室气体排放[7]。此外,由于老龄垃圾渗滤液中除含有高质量浓度NH4+-N外,还赋存大量抗生素抗性基因、药物及个人护理品、全氟化合物等大量新污染物,从而使得老龄垃圾渗滤液生物毒性较高,严重影响垃圾渗滤液生物脱氮工艺的稳定性[8]。

近些年随着生物脱氮技术的快速发展,涌现出许多新型生物脱氮工艺,如短程硝化反硝化(partial nitrification and denitrification,PND)、厌氧氨氧化以及硫驱动自养反硝化(sulfur-driven autotrophic denitrification,SdAD)等工艺[9-10]。PND工艺可通过优化反应系统中游离氨(free ammonia,FA)及溶解氧(dissolved oxygen,DO)质量浓度,进而将硝化反应控制在短程硝化阶段,使老龄垃圾渗滤液中的NH4+-N仅氧化为亚硝态氮(NO2−-N)而不继续氧化为硝态氮(NO3−-N),随后通过短程反硝化反应将NO2−-N还原为氮气(N2)[11]。尽管较传统硝化反硝化工艺,PND工艺可节省约25%的曝气需氧量及40%的有机碳源消耗[12],但短程反硝化过程仍需补充有机碳源才能实现老龄垃圾渗滤液的高效深度脱氮。自养反硝化工艺则可无需有机碳源,仅通过无机电子供体即可实现垃圾渗滤液中硝态氮(NOx−-N,包括NO2−-N和NO3−-N)的高效脱除[10]。其中厌氧氨氧化自养反硝化工艺可利用NH4+-N为电子供体,NO2−-N为电子受体,在厌氧条件下实现NO2−-N与NH4+-N同步去除[13]。由于PND工艺能实现渗滤液中NH4+-N向NO2−-N的部分硝化,因此,当前许多研究尝试将PND工艺与厌氧氨氧化工艺相结合,以达到零碳源投加老龄垃圾渗滤液深度脱氮的效果[14-15]。LI等[16]采用短程硝化-厌氧氨氧化耦合工艺处理老龄垃圾渗滤液,结果表明在未补充任何有机碳源条件下,耦合工艺可实现约85.0%的总氮(total nitrogen,TN)去除。但受限于厌氧氨氧化自养脱氮工艺自身缺陷,其理论上会产生约进水总氮11%的NO3−-N[17],从而导致出水中含有较多的NO3−-N无法被彻底反硝化去除,使得短程硝化-厌氧氨氧化耦合工艺总氮去除效果不佳。

与厌氧氨氧化工艺利用NH4+-N作为电子供体不同,SdAD工艺在缺氧条件下可利用硫化物(S0、S2−、S2O32−等)作为电子供体进行自养反硝化,其中单质硫(S0)作为电子供体的脱氮反应公式如式(1)~(2)所示[18]。S0作为SdAD自养反硝化电子供体具有以下优势:1) S0作为石化行业副产物,价格低廉且易获取;2) S0可充当生物滤池填料,在脱氮的同时能有效过滤渗滤液中的大颗粒杂质;3)工艺脱氮稳定性高、耐负荷冲击等[19-20]。因此,SdAD工艺通常采用S0填充床反应器将低C/N废液中的NOx−-N还原为N2[21]。LI等[22]采用PND耦合以S0为电子供体的SdAD工艺处理低C/N废水,在高FA质量浓度调控下PND工艺出水NO2−-N积累率可达89.5%,随后SdAD工艺能实现约70%的NO2−-N去除效果。然而,目前PND-SdAD耦合工艺对处理具有高生物抑制性的老龄垃圾渗滤液的脱氮性能仍有待研究。

鉴于此,本研究以佛山市白石坳垃圾填埋场老龄垃圾渗滤液为研究对象,采用中试规模的新型PND-SdAD耦合工艺对其进行零碳源投加深度脱氮。考察了PND-SdAD耦合工艺在垃圾渗滤液实际处理工程中的脱氮处理效能,优化了各工艺单元控制条件,分析了各工艺单元微生物种群多样性,评估了各工艺单元出水生物毒性,并对耦合工艺综合运行费用进行初步核算,以期为老龄垃圾渗滤液等低C/N废水深度脱氮的实际工程应用提供相关实验基础和技术支持。

-

中试项目总占地面积约500 m3,所处理垃圾渗滤液取自佛山市白石坳垃圾填埋场1#调节池,垃圾渗滤液原液水质参数:COD为(12 985.1±1 702.9) mg·L−1,NH4+-N为(3 502.9±396.7) mg·L−1,NO3−-N为(37.2±4.9) mg·L−1,TN为(3 623.5±471.4) mg·L−1。中试项目所用装置为本研究团队设计开发的新型组合工艺,如图1所示,反应装置主体结构由不锈钢制成。其中PND工艺单元由缺氧(anoxia,A)池与间歇式反应器(sequencing batch reactor,SBR)结构的短程硝化池两部分构成,其中PND-A池长1 m,宽2 m,有效高度约3.5 m,有效容积约6.5 m3,PND-SBR池长为3 m,宽2 m,有效高度约3 m,有效容积约17.5 m3,PND工艺单元总有效容积约24 m3;SdAD反应器采用上流式填充床结构,本研究中共平行安装2套SdAD反应器,单套SdAD反应器长2 m,宽1.8 m,有效高度3.5 m,内部填料高度约2.5 m,填料空隙率45%,填料床有效容积约4 m3,本研究两套SdAD反应器总有效容积为8 m3。

-

垃圾渗滤液原液首先进入PND-A池,渗滤液原液中可降解有机污染物可与PND-SBR池硝化回流液中NOx−-N发生反硝化反应,脱除渗滤液部分NOx−-N;随后PND-A池渗滤液溢流至PND-SBR池,渗滤液中的NH4+-N在PND-SBR池进行短程硝化反应转化为NO2−-N,在批次反应结束后,静置沉淀1 h通过滗水器出水。中试PND工艺单元在本研究开展前期需完成微生物接种及启动工作,其接种启动运行方案如下:PND工艺单元接种取自佛山市白石坳垃圾填埋场渗滤液处理一厂生物脱氮工艺回流污泥8 m3,并加入16 m3垃圾渗滤液稀释液(渗滤液原液:自来水=1:3),混合均匀后PND工艺单元内污泥质量浓度约7 300 mg·L−1。启动期1~5 d,PND工艺单元进行闷曝(无进/排水操作);随后在启动期6~80 d内逐步提高反应器处理负荷,其中6~29 d,反应器渗滤液处理量调整至1 m3·d−1;30~80 d,反应器渗滤液处理量逐渐增加至3 m3·d−1。此外,整个PND工艺单元启动期内,对反应器曝气量进行动态调整,以控制DO质量浓度在0.5~1.0 mg·L−1。完成污泥接种及启动工作的PND工艺单元,其在I~IV运行阶段进行工艺控制参数优化。阶段I(81~206 d),批次反应运行时间24 h(第1阶段进水搅拌6 h,第2阶段曝气充氧17 h,第3阶段沉淀排水1 h),参数控制:回流速度~1.5 m3·h−1,曝气量30~34 m3·h−1,DO质量浓度1.2~1.6 mg·L−1;阶段II(207~257 d)优化工艺曝气强度,批次反应运行时间24 h(第1阶段进水搅拌6 h,第2阶段曝气充氧17 h,第3阶段沉淀排水1 h),参数控制:回流速度~1.5 m3·h−1,曝气量24~28 m3·h−1,DO质量浓度0.8~1.2 mg·L−1;阶段III(258~328 d)缩减工艺反应时间,批次反应运行时间减少至20 h(第1阶段进水搅拌4 h,第2阶段曝气充氧15 h,第3阶段沉淀排水1 h),参数控制:回流速度~1.5 m3·h−1,曝气量30~34 m3·h−1,DO质量浓度1.2~1.6 mg·L−1;阶段IV(329~406 d)进一步优化工艺反应时间,反应运行时间缩减至18 h(第1阶段进水搅拌4 h,第2阶段曝气充氧13 h,第3阶段沉淀排水1 h),参数控制:回流速度~1.5 m3·h−1,曝气量30~34 m3·h−1,DO质量浓度1.2~1.6 mg·L−1。此外,PND工艺单元的出水将作为SdAD工艺单元的进水。PND-SBR工艺单元通过滗水器将出水滗出至沉淀池后,沉淀池上部渗滤液以连续流方式进入SdAD工艺单元进行自养深度脱氮,进而使垃圾渗滤液中残余的NOx−-N还原为N2。SdAD工艺单元接种污泥取自于中试PND工艺单元,接种后SdAD工艺单元污泥质量浓度约3 000 mg·L−1,且污泥接种后逐步调整SdAD工艺单元处理量以实现PND-SdAD耦合工艺的稳定运行。

-

1)水样常规水质指标。各工艺单元出水定期采样,水样品经0.45 um尼龙滤膜过滤后,其相关常规水质指标均按照文献[23]操作。其中NH4+-N采用纳氏试剂分光光度法;NO2−-N采用N-(1-萘基)-乙二胺光度法;NO3−-N采用紫外分光光度法;TN采用碱性过硫酸钾消解紫外分光光度法;化学需氧量(chemical oxygen demand,COD)采用哈希DRB200快速消解仪测定;pH及DO均由便携式分析仪(SX836,三信)测定。

2)生物毒性检测。本研究通过水质急性毒性检测试剂盒(金达清创环境科技有限公司,北京)检测其生物毒性,并以费氏弧菌(V.fischeri)的发光抑制率作为渗滤液生物毒性指标。收集各工艺单元出水样本加入到培养好的V.fischeri菌液中震荡10 s后,置于空气中暴露15 min,测定V.fischeri菌的发光抑制率,发光抑制率计算方法见式(3)并根据文献[24]通过不同发光抑制率强度判别渗滤液急性毒性风险等级(0≤L<30为低毒;30≤L<50为中毒;50≤L<70为重毒;70≤L<100为高毒;L=100为剧毒)。

式中:L为发光抑制率;I0空白对照组暴露15 min后的发光强度;It为测试组暴露15 min后的发光强度。

3)微生物多样性分析。通过PowerSoil DNA试剂盒(12888-100,MOBIO,USA)提取生物样品中的总DNA,采用PCR技术对微生物16S rRNA的V3~V4高可变区域进行扩增,引物序列为338F (5'-ACTCCTACGGGAGGCAGCAG-3')和806R (5'- GGACTACHVGGGTWTCTAAT-3'),最后采用PacBio Sequel II平台完成测序,本研究已将微生物DNA序列上传至National Center for Biotechnology Information数据库,项目编号:PRJNA1086255。

式中:Q为水样中FA质量浓度,mg·L−1;

CNH+4 - N 为水样中游离NH4+-N质量浓度,mg·L−1;T为温度, ℃。4) FA质量浓度计算方法。老龄垃圾渗滤液中的NH4+-N因pH值的不同,存在离子态与分子态的两种形式。FA是渗滤液中NH4+-N分子态形式浓度,可通过公式(4)[25]计算得出。

5)硫酸盐产率计算方法。SdAD工艺单元中硫驱动自养反硝化反应的硫酸盐产率可通过SO42−-S的生成量与TN去除量间的比值体现,由R表示,其计算方法见式(5)。

式中:

C进水SO2−4−S 与C出水SO2−4−S 为SdAD工艺单元反应器进水与出水中的SO42−-S质量浓度,mg·L−1;C进水TN 与C出水TN 为SdAD工艺单元反应器进水与出水中的TN质量浓度,mg·L−1。 -

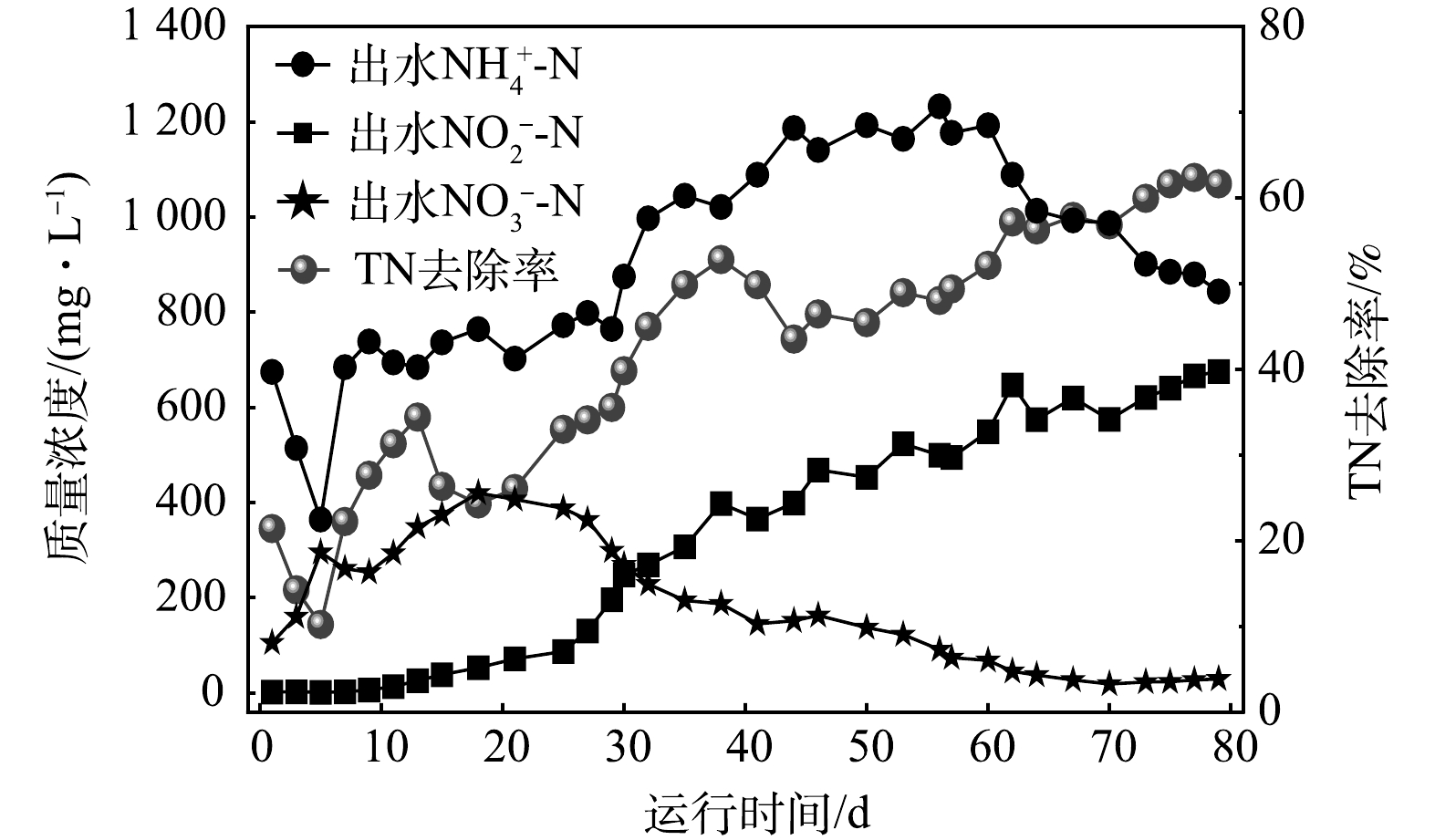

1) PND工艺单元启动阶段运行效能。PND工艺单元启动期运行效能如图2所示,启动期第1天时反应器渗滤液中NH4+-N、NO2−-N及NO3−-N质量浓度分别为674.9、1.4、102.8 mg·L−1。启动期前1~5 d内通过低DO质量浓度条件下的闷曝,PND工艺单元中NH4+-N质量浓度由674.9 mg·L−1迅速降至356.8 mg·L−1,同时NO3−-N质量浓度由102.8 mg·L−1增加至294.6 mg·L−1,而NO2−-N质量浓度无明显积累。这一结果可能是由于PND工艺单元接种污泥来源于填埋场渗滤液处理一厂,接种污泥中存在一定的亚硝酸盐氧化菌(nitrite oxidizing bacteria,NOB),闷曝硝化过程所产生的NO2−-N被快速转化为NO3−-N,因此未形成较好的NO2−-N累积。闷曝结束后6~29 d,PND工艺单元处理量提高至1 m3·d−1,出水NO3−-N质量浓度呈现先增加后下降的趋势,且出水NO2−-N质量浓度由1.9 mg·L−1提升至247.6 mg·L−1。随后30~80 d内,PND工艺单元处理量由1.5 m3·d−1逐步提升至3 m3·d−1,反应器出水NO3−-N质量浓度呈现降低趋势,且出水NO2−-N质量浓度逐渐升高至第80天时688.3 mg·L−1。此外,PND工艺单元启动阶段反应器TN去除率随运行时间逐渐提高,可由第1天时21.4%提高到80天时61.6%。上述结果表明,启动阶段通过低DO质量浓度(0.5~1.0 mg·L−1)及逐步提高处理负荷的条件下,PND工艺单元经80 d的启动运行可实现高质量浓度NO2−-N累积及具备良好的脱氮能力,实现了PND工艺单元反应器的启动。

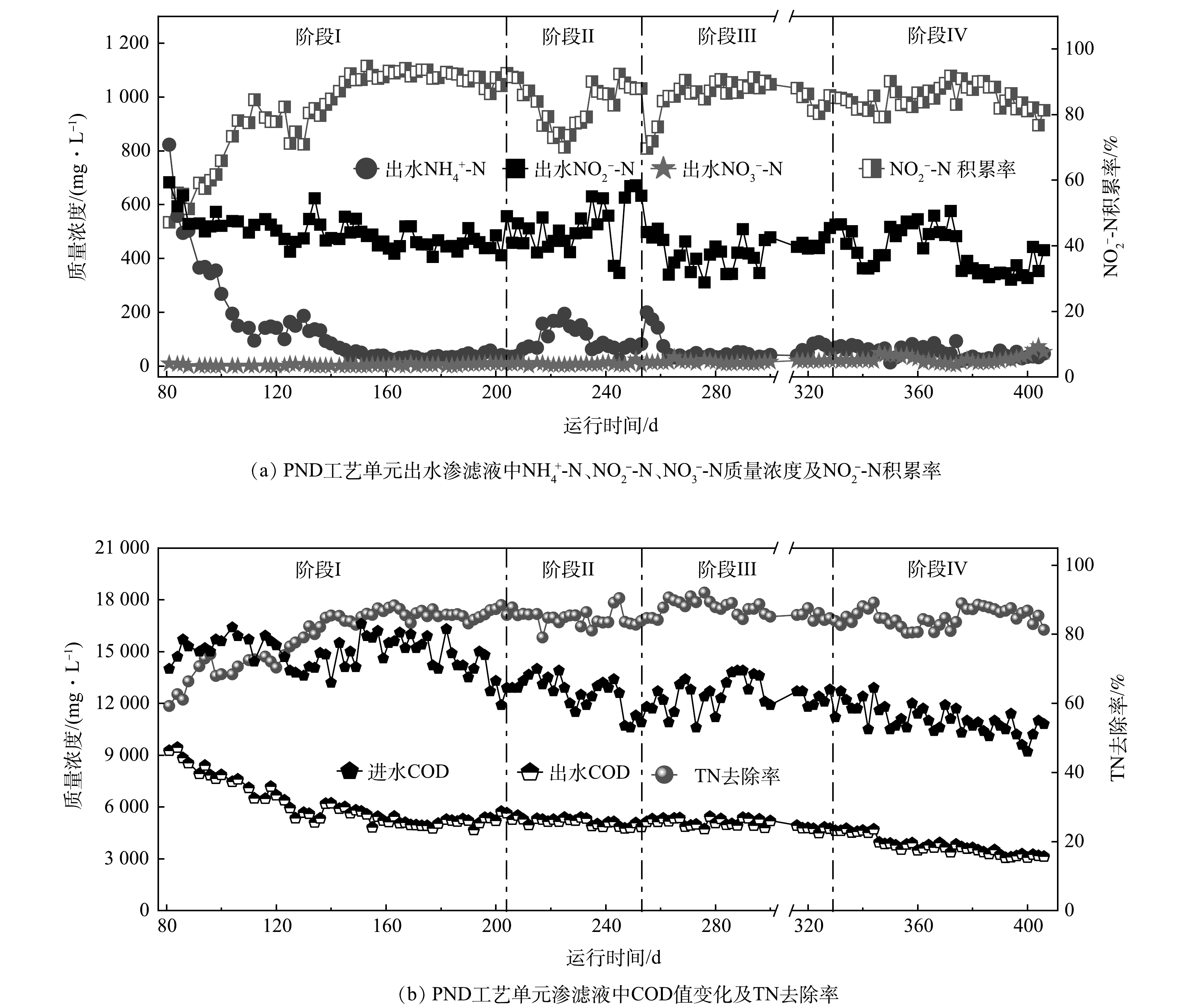

2) PND工艺单元运行效能。本研究完成PND工艺单元污泥接种启动后,通过4个运行阶段优化反应器的运行效能,结果如图3所示。其中阶段Ⅰ调整PND-SBR池曝气量,控制池中DO质量浓度在1.2~1.6 mg·L−1。反应器在81~147 d,出水NH4+-N质量浓度由852.6 mg·L−1(第81天)快速降至38.2 mg·L−1(第147天),且NO2−-N积累率由44.2%(第81天)上升至92.5%(第147天)。随后148~206 d期间内,反应器出水渗滤液中NH4+-N及NO2−-N质量浓度稳定,且无NO3−-N积累,TN去除率可达(83.9±1.5)%。阶段Ⅱ为进一步探究PND工艺单元DO质量浓度对反应器短程硝化反硝化运行效能的影响,降低PND-SBR池曝气强度,控制PND-SBR池内DO质量浓度在0.8~1.2 mg·L−1。发现PND工艺单元反应器在阶段Ⅱ(207~257 d)内未能实现稳定的短程硝化效果,出水NH4+-N质量浓度在23.5~194.6 mg·L−1区间内剧烈波动,且NO2−-N积累率和TN去除率分别降至(80.2±6.4)%与(80.6±2.3)%。该结果表明,相较于阶段Ⅰ的DO质量浓度(1.2~1.6 mg·L−1),阶段Ⅱ的PND-SBR池中DO质量浓度不足,池中渗滤液NH4+-N无法在24 h的序批次反应内实现高效短程硝化反硝化。因此,本研究PND-SBR池适宜的曝气量应调节至30~34 m3·h−1,DO质量浓度控制在1.2~1.6 mg·L−1。阶段Ⅲ与阶段Ⅳ控制DO质量浓度在1.2~1.6 mg·L−1条件下,进一步优化单个批次反应周期的运行时间。其中阶段Ⅲ在单个周期20 h内反应效果稳定,渗滤液中的NH4+-N可稳定进行短程硝化反应。因此,阶段Ⅳ进一步缩短批次运行时间至18 h,PND-SBR池中渗滤液NH4+-N仍可实现稳定短程硝化,出水NH4+-N质量浓度为(50.2±17.8) mg·L−1,NO2−-N积累率达到(84.9±3.6)%,TN去除率为(86.0±0.8)%。综上,本中试研究的PND工艺单元阶段Ⅳ为最佳运行阶段,序批次反应操作为第1阶段进水搅拌4 h,第2阶段曝气充氧13 h,第3阶段沉淀排水1 h,调节曝气量为30~34 m3·h−1,DO质量浓度为1.2~1.6 mg·L−1,该操作条件下可实现中试PND工艺单元高效稳定运行。此外,本研究PND工艺单元阶段Ⅳ出水COD值整体波动较小(图3(b)),平均值为(3 626.4±420.2) mg·L−1,较进水COD值(11 061.5±807.7) mg·L−1去除率约为67.2%。由此可见,在阶段Ⅳ老龄垃圾渗滤液中的可降解有机污染物也已被大量消耗,难以继续满足PND工艺单元后续进一步脱氮的碳源需求。

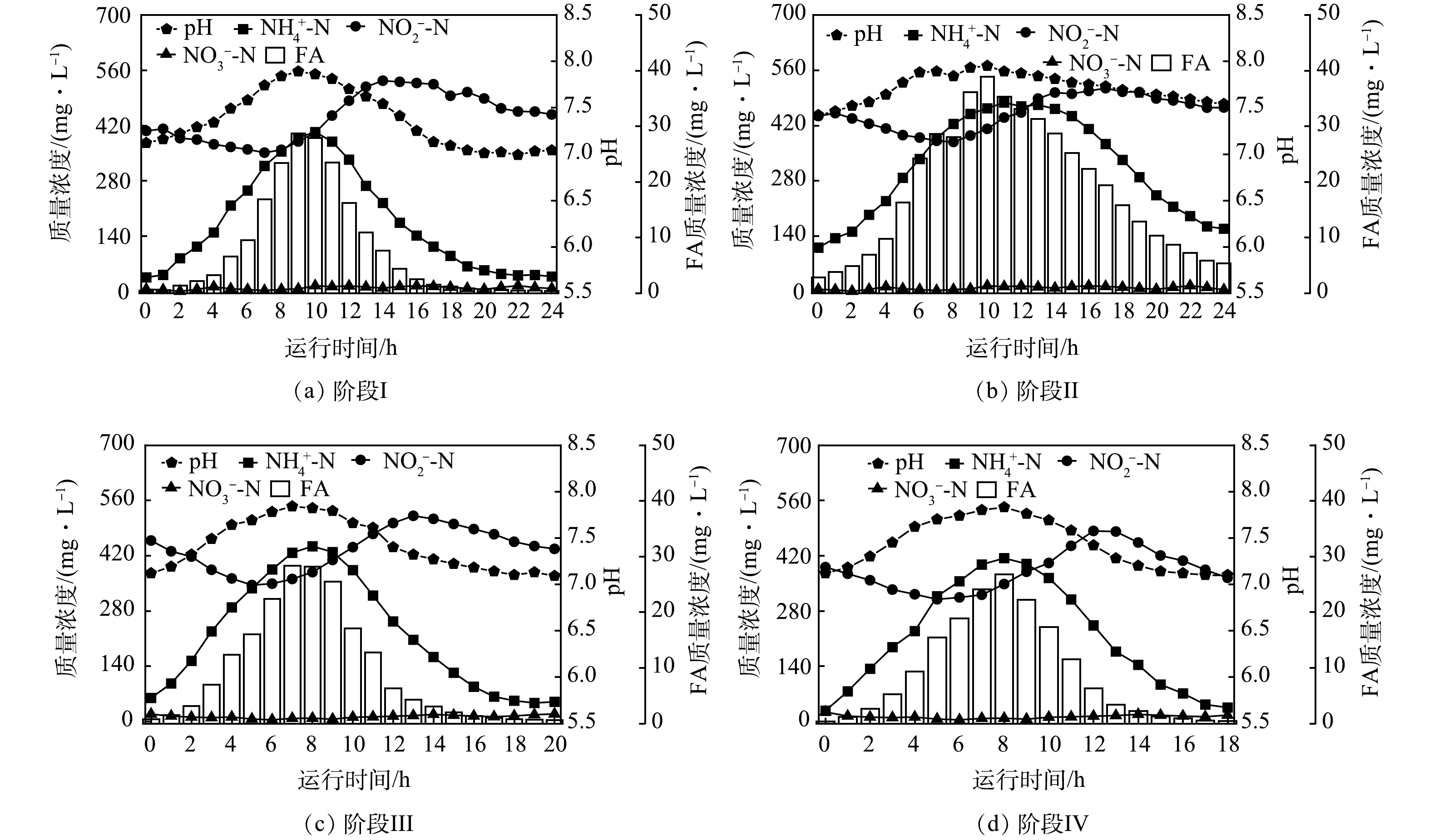

3) PND工艺单元序批次稳定运行关键参数分析。图4显示PND工艺单元在不同运行阶段单周期批次反应中(分析开展于反应器运行第180、220、320及380天时)PND-SBR池氮素及FA质量浓度变化规律。总的来看,图4中不同运行阶段PND-SBR池中垃圾渗滤液的NH4+-N质量浓度均由第1阶段进水搅拌开始随时间逐渐增加至峰值后下降,这是由于含高质量浓度NH4+-N((3 502.9±396.7) mg·L−1)的渗滤液原液由PND-A池逐渐溢流至PND-SBR池中,导致PN-SBR池中NH4+-N的质量浓度快速增加,在进水搅拌结束后,由于PND-SBR与PND-A池间存在回流,使得PND-SBR池的NH4+-N质量浓度在第1阶段进水搅拌结束后仍持续升高。随后第2阶段曝气充氧,PND-SBR池中NH4+-N经短程硝化作用逐步转化为NO2−-N,NH4+-N质量浓度快速下降。同时,渗滤液NO2−-N质量浓度在单周期批次实验过程中随运行时间呈现下降-升高-下降的变化趋势。这主要是由于进水搅拌阶段存在渗滤液稀释补充,且PND-SBR池内部分NO2−-N可与进水中补入的可降解有机污染物发生短程反硝化反应,从而导致NO2−-N质量浓度在反应开始时有所下降;随着曝气充氧阶段进行,NH4+-N被逐步转化为NO2−-N,从而使得池内渗滤液NO2−-N质量浓度随时间逐步升高;最后渗滤液中的NH4+-N已被大量转化,NO2−-N质量浓度得不到进一步提高,而短程反硝化反应的存在使得NO2−-N质量浓度在批次反应末期进一步降低。值得注意的是,PND-SBR池在不同反应阶段的单周期批次实验中,均无明显NO3−-N质量浓度积累,其原因是各阶段反应周期内生成的高质量浓度FA对NOB起到有效抑制[11],避免了渗滤液中NO2−-N向NO3−-N的转化。图4(a)~(d)中PND-SBR池阶段Ⅰ、阶段Ⅱ、阶段Ⅲ、阶段Ⅳ中FA质量浓度分别为0.4~28.7、2.9~39.4、0.8~28.3、0.4~26.8 mg·L−1,在上述FA质量浓度变化区间内,FA质量浓度始终存在由低到高再降低的变化趋势。有研究发现当FA质量浓度高于3.1 mg·L−1以上时即可实现稳定的短程硝化反应[26]。本研究PND-SBR池单周期批次反应内FA质量浓度大部分反应时间均高于3.1 mg·L−1以上,使得PND-SBR池内NOB受到严格抑制,且促使池内氨氧化菌(ammonia oxidizing bacteria,AOB)丰度升高,从而确保NO2−-N的高效积累。

-

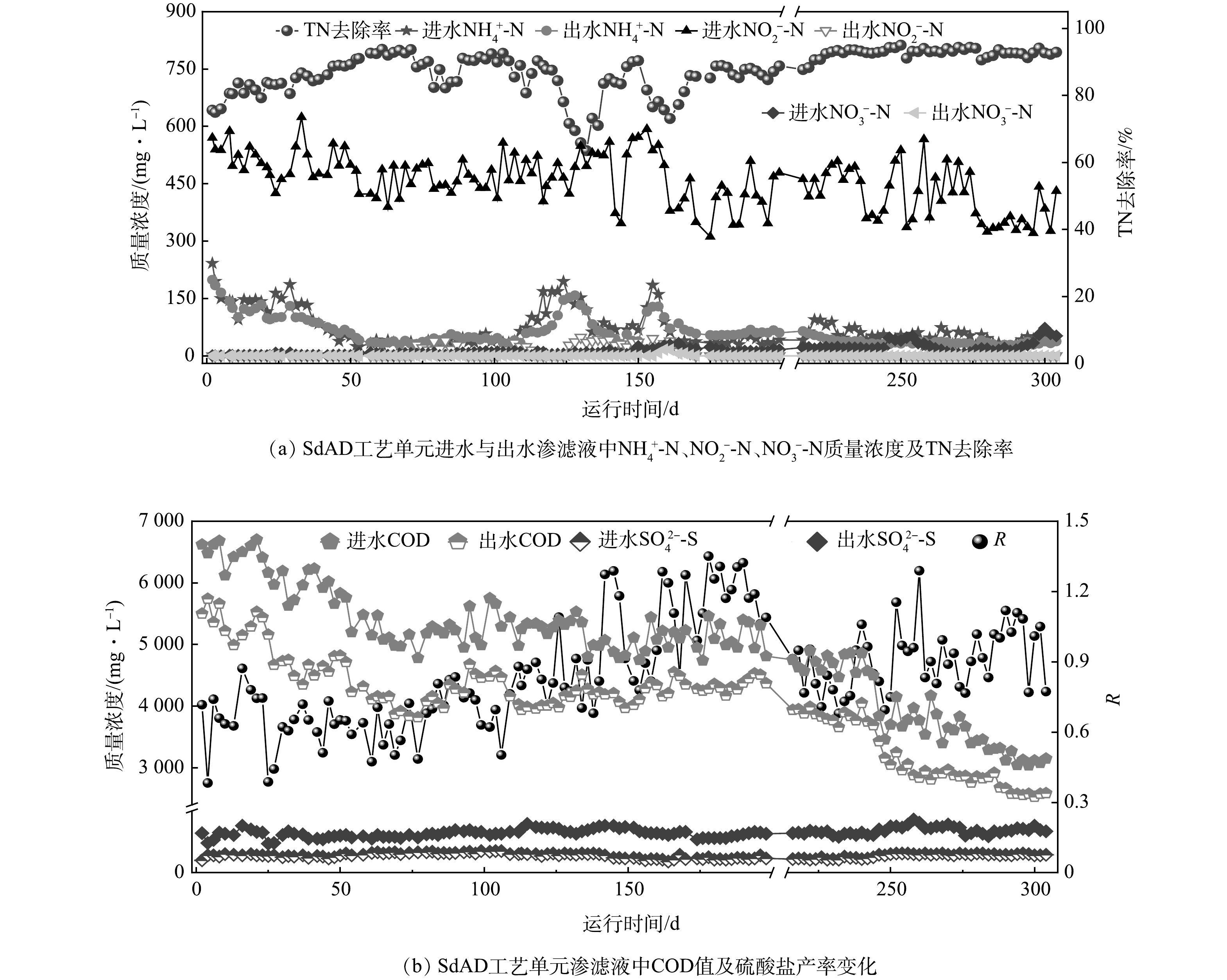

由于老龄垃圾渗滤液具有低C/N的特点,PND工艺单元出水渗滤液中的耗氧有机物(以COD计)难以满足对NOx−-N的进一步深度去除,因此,本研究采用以S0为电子供体的SdAD工艺单元对PND工艺单元出水垃圾渗滤液进行深度自养脱氮。图5(a)所示在整个305 d的运行期间内,SdAD工艺单元进水NO2−-N质量浓度为(455.9±68.5) mg·L−1,出水NO2−-N去除率可达98.5%左右。结果表明,PND工艺单元出水垃圾渗滤液中所含高质量浓度NO2−-N未对SdAD工艺单元中脱氮功能微生物产生抑制,这可能是由于硫氧化菌(sulfur oxidizing bacteria,SOB)对NO2−-N有较强的耐受性[27]。同时,SdAD工艺单元也对渗滤液中NO3−-N实现较为高效的去除,去除率达97.1%左右。由此可见,自养SdAD工艺单元无需外部有机碳源补入即可对PND工艺单元出水垃圾渗滤液中的NOx−-N实现高效稳定的去除,其在处理PND工艺单元阶段Ⅳ出水时的稳定运行阶段(228~305 d),TN去除效率可达(92.9±1.1)%。此外,SdAD工艺单元稳定运行阶段出水NH4+-N质量浓度为(33.4±3.9) mg·L−1较进水(50.2±17.8) mg·L−1略微下降。这可能是由于PND工艺单元出水渗滤液中残余的部分NH4+-N被SOB同化利用以维持自身生长;且SdAD工艺单元微生物利用渗滤液中的DO对NH4+-N进行硝化,从而导致SdAD工艺单元出水NH4+-N质量浓度略微下降的现象。由图5(b)可见,SdAD工艺单元进/出水中COD变化趋势相似,整体呈现随时间延长逐步降低的趋势,且整个运行阶段出水COD值为(4 002.6±745.3) mg·L−1,较进水COD((4 617.1±814.9 )mg·L−1)降低了约13.3%,表明SdAD反应单元中仍有部分有机污染物参与反硝化反应。此外,整个SdAD工艺单元由于硫自养反硝化反应所产生的硫酸盐,使出水中SO42−-S质量浓度为(661.2±68.9) mg·L−1较进水(275.8±39.5) mg·L−1升高了约239.7%。且SdAD工艺单元的硫酸盐产率R为0.95±0.18,低于硫自养反硝化R的理论值2.51[28]。综上所述,SdAD反应单元对PND工艺单元出水垃圾渗滤液高效深度脱氮是基于异养反硝化与自养反硝化的协同作用。

-

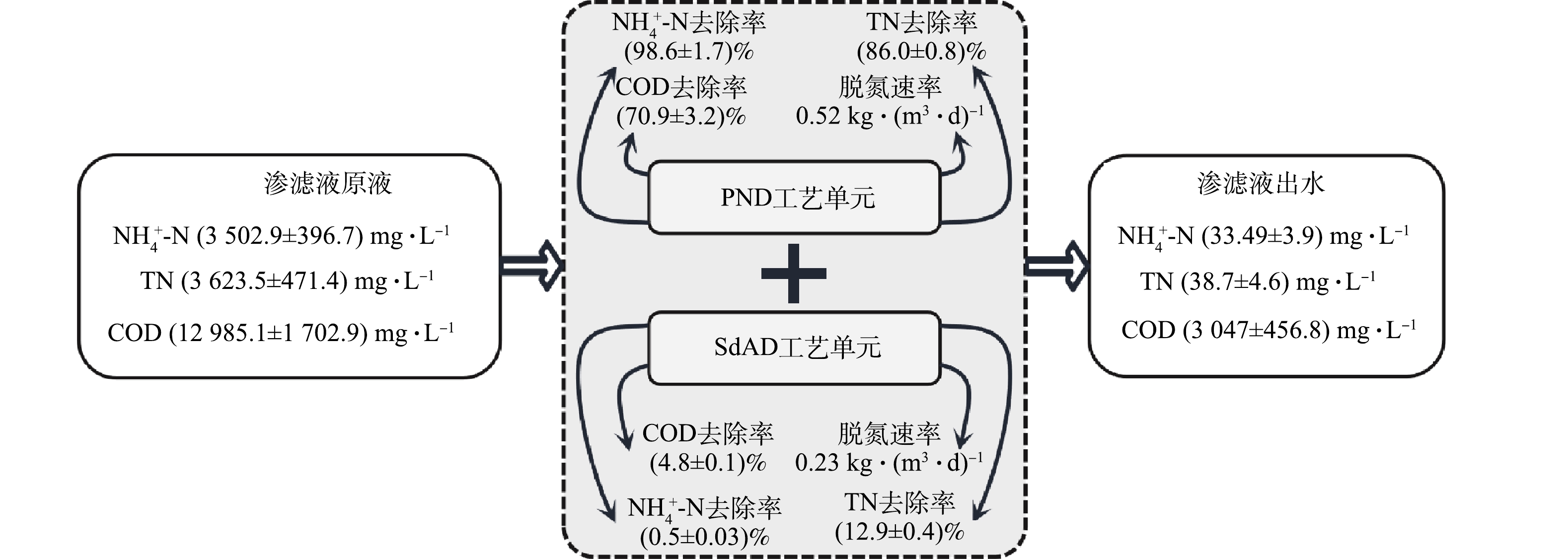

PND-SdAD耦合工艺作为低耗、零碳源投加的深度脱氮工艺,渗滤液中的NH4+-N、TN、COD等污染物去除效果分析见图6。其中PND工艺单元在第Ⅳ阶段,通过调节DO及FA质量浓度,不仅能达到(98.6±1.7)%的NH4+-N去除效果及(84.9±3.6)%的NO2−-N积累,还可以充分利用渗滤液中有机污染物实现(86.0±0.8)%的TN去除,且脱氮速率约为0.52 kg·(m3·d)−1。本研究采用的PND工艺处理老龄垃圾渗滤液较前人50%左右的TN去除效果[29]具有更好的脱氮效率,主要是由于本研究老龄垃圾渗滤液中不定期有新鲜垃圾渗滤液补入,新鲜渗滤液能较大程度赋存可降解的有机污染物作为短程反硝化的有机碳源。此外,本研究PND工艺单元的NO2−-N积累效果显著,渗滤液中的氮素可较大程度上通过NO2−-N的短程反硝化反应去除。随后,PND工艺单元出水经SdAD工艺单元进行深度脱氮,由于PND工艺单元出水渗滤液中可降解有机物已在PND工艺单元中被充分利用,SdAD工艺单元渗滤液中COD的去除率仅为(4.8±0.1)%。因此,SdAD工艺单元主要依靠无机S0为电子供体来实现NOx−-N的去除,SdAD工艺单元对渗滤液原液TN去除率的贡献为(12.9±0.4)%,且脱氮速率为0.23 kg·(m3·d)−1。综上,PND-SdAD耦合深度脱氮工艺,在低耗能、零碳源投加条件下,可实现垃圾渗滤液约98.9%的TN去除,出水TN质量浓度为(38.7±4.6) mg·L−1,满足国家《生活垃圾填埋场污染控制标准》(GB16889-2008)中TN低于40 mg·L−1的排放要求。

-

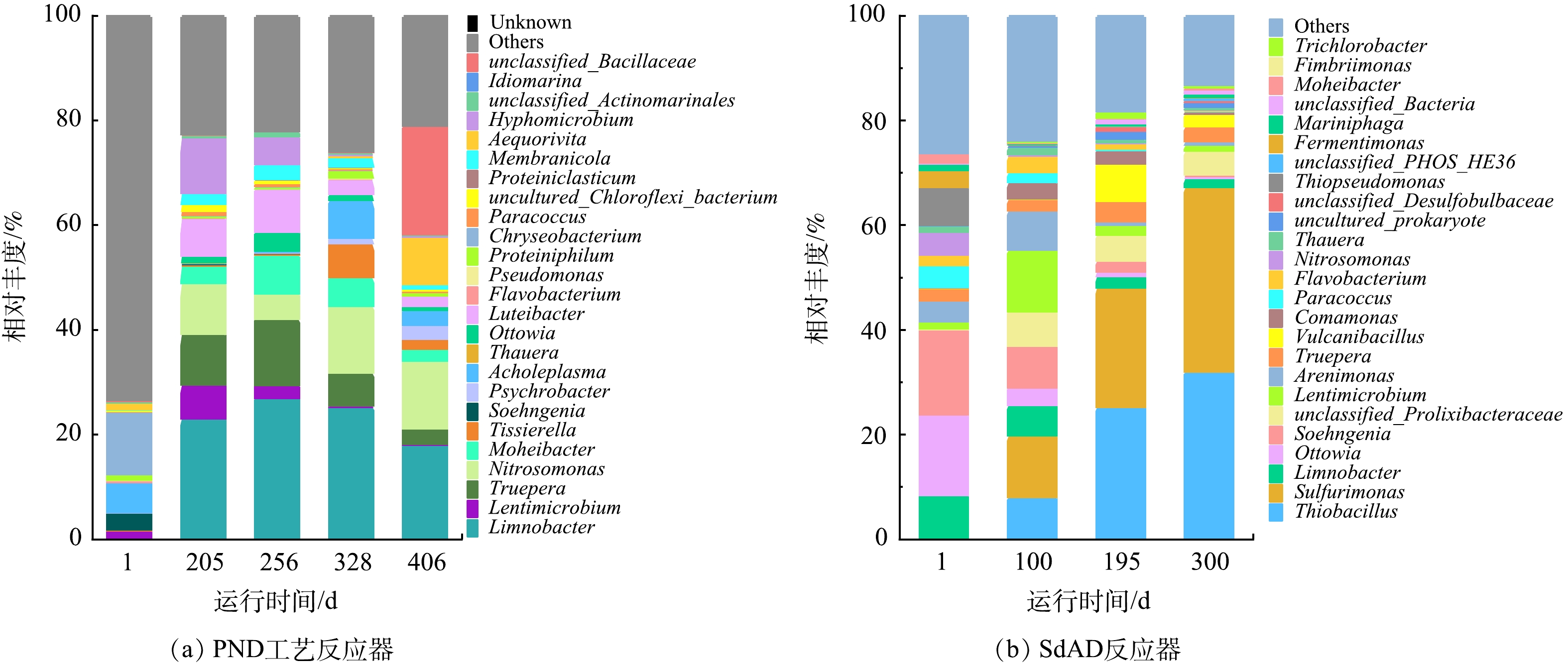

图7(a)所示为PND工艺单元反应器接种污泥和不同阶段下的污泥在属水平上微生物群落结构分布。各反应阶段污泥中所富集的Nitrosomonas菌属,是常见的好氧AOB菌属之一,可将NH4+-N转化为NO2−-N[30]。其在第1天(接种污泥)及不同运行阶段下的丰度分别为0%、9.7%(阶段Ⅰ,第205天)、4.8%(阶段Ⅱ,第256天)、12.8%(阶段Ⅲ,第328天)及12.9%(阶段Ⅳ,第406天),且阶段Ⅰ~Ⅳ污泥样品中未发现NOB菌属。上述结果表明,PND工艺单元在低DO及高FA质量浓度(>3.1 mg·L−1)条件下,有利于反应器中AOB菌属的高度富集,并抑制NOB菌属的生长,从而确保PND工艺单元出水实现NO2−-N的高效积累。此外,在PND工艺单元反应器中,truepera也发挥了重要作用,作为一种重要的异养反硝化脱氮菌属,可利用垃圾渗滤液中的有机污染物将NOx−-N还原为N2,从而实现PND工艺单元的高效脱氮[31]。图7(b)所示SdAD工艺单元在运行期间,Thiobacillus与Sulfurimonas菌属丰度分别由第1天(接种污泥)的0%提升至7.9%与11.8%(第100天),25.3%与22.8%(第195天)及第300天时的31.9%与34.8%。Thiobacillus与Sulfurimonas作为SdAD工艺单元反应器运行期间污泥中的优势菌属,是主要硫自养反硝化菌属,可利用S0作为电子供体将NOx−-N还原为N2[32]。同时,truepera、Comamonas及Thauera等其他反硝化菌菌属的协同作用,不仅有效保证SdAD工艺单元的深度脱氮性能,也可充分利用垃圾渗滤液中的有机污染物并降低S0的消耗。上述研究表明,在PND-SdAD耦合工艺反应器中,PND工艺单元中的AOB(Nitrosomonas)和SdAD工艺单元中的SOB(Thiobacillus与Sulfurimonas)关键功能菌占据重要地位,并在脱氮过程中发挥了关键作用。

-

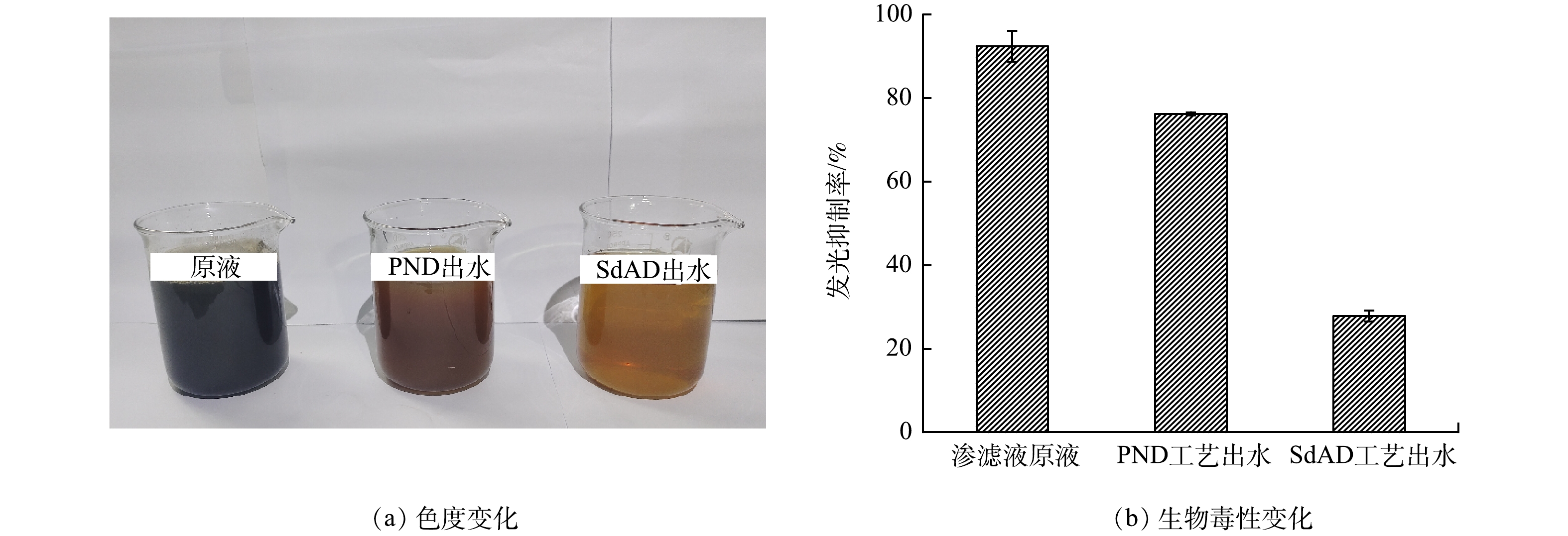

垃圾渗滤液原液经PND-SdAD耦合工艺处理后,渗滤液中大量有机污染物及NH4+-N被微生物降解转化,且渗滤液中固体杂质经SdAD工艺单元填料床截留,出水渗滤液色度得到显著改善,结果如图8(a)所示。此外,图8(b)为PND-SdAD工艺出水渗滤液生物毒性的变化,本研究所采用的老龄垃圾渗滤液原液的发光抑制率高达(92.4±3.7)%,属高毒水体,对于生物工艺的微生物种群有着较强的毒害作用。垃圾渗滤液原液经PND工艺处理后出水生物毒性有所降低,发光抑制率从垃圾渗滤液原液的(92.4±3.7)%降至PND工艺单元出水的(76.2±0.4)%,但其水质毒性等级仍为高毒,这可能是由于渗滤液原液中的NH4+-N转化为NO2−-N,而NO2−-N具有较高生物抑制性[33],从而导致PND工艺单元出水垃圾渗滤液依然保持较高的生物毒性。PND工艺单元出水经SdAD工艺单元进一步处理,出水渗滤液的发光细菌的抑制率从(76.2±0.4)%减少至(27.8±1.3)%,水质毒性等级从高毒降为低毒。这可归因于SdAD工艺单元出水渗滤液中有机污染物进一步降低、NO2−-N被高效脱除及渗滤液中大颗粒杂质被填料床有效截留等原因,从而使SdAD工艺单元对垃圾渗滤液的生物毒性具有明显改善作用。因此,采用PND-SdAD耦合工艺处理垃圾渗滤液,耦合工艺出水渗滤液对V.fischeri菌的发光抑制率可降低64.6%,水质毒性等级从高毒降至低毒级别,极大的降低了垃圾渗滤液排放风险。此外,本研究PND-SdAD耦合工艺处理具有较高生物毒性的老龄垃圾渗滤液时,其高毒老龄垃圾渗滤液未对耦合工艺脱氮性能造成显著影响,表明该工艺对处置垃圾渗滤液具有较好的适应性。

-

为评估PND-SdAD耦合工艺经济性,本研究对其进行综合运行成本估算,详见表1。中试PND-SdAD耦合工艺每日可稳定处理约4 m3老龄垃圾渗滤液,吨水综合运行费用为24.4元。其中电费占总运行费用的83.2%,主要因PND工艺单元需大量曝气,从而导致耦合工艺能耗成本占比较高。在SdAD过程中采用S0作为电子供体,其吨水深度脱氮成本仅为3.1元,较传统生物反硝化碳源电子供体成本显著降低。由于传统生物反硝化为保证脱氮效果,需过量投加可溶性有机碳源(如,甲醇、乙酸钠、葡萄糖等)以提高垃圾渗滤液的可生化性[34],且处理过程中未被微生物利用的溶解性有机碳源会随出水流失,造成不必要的有机碳源浪费。本研究所使用不溶性S0作为电子供体,可根据渗滤液中氮素浓度进行消耗,有效避免电子供体损失,从而降低垃圾渗滤液运行成本。

-

1) 中试PND工艺单元在第1阶段进水搅拌4 h、第2阶段曝气充氧13 h、第3阶段沉淀排水1 h的批次运行条件下,控制回流速度1.5 m3·h−1,曝气量30~34 m3·h−1,DO质量浓度1.2~1.6 mg·L−1,可实现约0.52 kg·(m3·d)−1的脱氮速率及(86.0±0.8)%的TN去除效果。随后通过SdAD工艺单元可对PND工艺单元出水渗滤液中的氮素进行深度去除,其脱氮速率约为0.23 kg·(m3·d)−1,并对老龄垃圾渗滤液原液的TN去除率贡献为(12.9±0.4)%。

2) 本研究在低DO及高FA质量浓度的环境下,PND工艺单元中的Nitrosomonas实现高度富集,从而保证PND工艺单元短程硝化反应的稳定。SdAD工艺单元中的SOB(Thiobacillus与Sulfurimonas)菌属占据重要地位,并在脱氮过程中发挥了关键作用。

3) PND-SdAD耦合工艺稳定运行可实现垃圾渗滤液约98.9%的TN去除效果,出水渗滤液TN质量浓度为(38.7±4.6) mg·L−1,满足《生活垃圾填埋场污染控制标准》(GB16889-2008)中对TN的排放要求。同时耦合工艺出水渗滤液对V.fischeri菌的发光抑制率整体可降低64.6%,水质毒性等级由高毒降至低毒,能有效降低老龄垃圾渗滤液的排放风险。

4) PND-SdAD耦合工艺作为绿色、高效的生物脱氮工艺,其渗滤液吨水处理的综合成本约为24.4元,具有较好的经济性,为我国全面推进美丽中国建设提供技术支持。

老龄垃圾渗滤液PND-SdAD耦合工艺深度脱氮

Advanced nitrogen removal from mature landfill leachate by coupled pilot PND-SdAD process

-

摘要: 针对老龄垃圾渗滤液具有低碳/氮比(C/N)水质特征和传统生物硝化反硝化工艺存在的高曝气能耗与碳源投加量大的问题,本研究通过构建中试规模短程硝化反硝化(partial nitrification and denitrification,PND)-硫驱动自养反硝化(sulfur-driven autotrophic denitrification,SdAD)耦合工艺,以期实现老龄垃圾渗滤液在低曝气能耗和零碳源投加条件下的深度脱氮。中试试验结果表明,PND工艺单元稳定运行阶段可对老龄垃圾渗滤液原液实现(86.0±0.8)%的总氮(total nitrogen,TN)去除效果,随后SdAD自养工艺单元可进一步去除老龄垃圾渗滤液原液(12.9±0.4)%的TN。耦合工艺出水渗滤液TN质量浓度为(38.7±4.6) mg·L−1,满足国家生活垃圾填埋场污染物控制标准(GB16889-2008)中TN的排放要求。同时,PND-SdAD耦合工艺出水渗滤液生物毒性降低约64.6%,毒性等级可由高毒降至低毒,有效降低了老龄垃圾渗滤液的排放风险。此外,综合运行成本分析表明,该耦合工艺垃圾渗滤液吨水综合处理成本仅为24.4元。Abstract: Aiming at the water quality characteristic of mature landfill leachate with a low carbon-to-nitrogen ratio (C/N), and the challenges faced by the conventional biological nitrification and denitrification processes such as high aeration energy consumption and large amount of carbon source dosage, a pilot-scale partial nitrification and denitrification coupled with sulfur-driven autotrophic denitrification (PND-SdAD) process was implemented to achieve advanced nitrogen removal from mature landfill leachate under the conditions of low aeration energy consumption and zero carbon source addition in this study. The results of the pilot experiment showed that the PND process could achieve a total nitrogen (TN) removal efficiency of (86.0±0.8)% from mature landfill leachate during the stabilized operation stage. Subsequently, the SdAD autotrophic process could further remove TN by (12.9%±0.4)% from the mature leachate. The TN mass concentration of leachate effluent from the coupled PND-SdAD process was only (38.7±4.6) mg·L−1, meeting the TN discharge standard of the pollution control standard for the domestic landfill (GB16889-2008). Meanwhile, the biological toxicity of leachate effluent from the coupled PND-SdAD process decreased by approximately 64.6%, and the toxicity level of leachate decreased from high to low, which effectively decreased the risk of leachate discharge. Moreover, based on the economic analysis, the comprehensive operating cost for advanced nitrogen removal from mature landfill leachate by this coupled process was only 24.4 RMB/m3.

-

随着国家经济发展以及人民生活水平的提高,城市生活垃圾的产量增长迅速。截至2019年,我国196个大、中型城市生活垃圾产量已达2.4×109 t,较2018年同期增长14.3%[1]。卫生填埋作为城市生活垃圾的主要处置方式之一,被国内外广泛采用[2-3]。然而生活垃圾在填埋过程中由于垃圾发酵、地表水及地下水的渗透作用,导致垃圾填埋场生成大量高污染性的有毒有害有机废水,即垃圾渗滤液[4]。垃圾渗滤液作为一类含高质量浓度氨氮(NH4+-N)的有机难处理废水,具有显著的低碳/氮比(C/N)水质特征[5]。特别是填埋场老龄垃圾渗滤液的C/N通常低于3.0[6],若采用传统硝化反硝化生物处理工艺往往需要大量的曝气能耗投入及有机碳源补充,不仅运行成本高昂且易造成大量温室气体排放[7]。此外,由于老龄垃圾渗滤液中除含有高质量浓度NH4+-N外,还赋存大量抗生素抗性基因、药物及个人护理品、全氟化合物等大量新污染物,从而使得老龄垃圾渗滤液生物毒性较高,严重影响垃圾渗滤液生物脱氮工艺的稳定性[8]。

近些年随着生物脱氮技术的快速发展,涌现出许多新型生物脱氮工艺,如短程硝化反硝化(partial nitrification and denitrification,PND)、厌氧氨氧化以及硫驱动自养反硝化(sulfur-driven autotrophic denitrification,SdAD)等工艺[9-10]。PND工艺可通过优化反应系统中游离氨(free ammonia,FA)及溶解氧(dissolved oxygen,DO)质量浓度,进而将硝化反应控制在短程硝化阶段,使老龄垃圾渗滤液中的NH4+-N仅氧化为亚硝态氮(NO2−-N)而不继续氧化为硝态氮(NO3−-N),随后通过短程反硝化反应将NO2−-N还原为氮气(N2)[11]。尽管较传统硝化反硝化工艺,PND工艺可节省约25%的曝气需氧量及40%的有机碳源消耗[12],但短程反硝化过程仍需补充有机碳源才能实现老龄垃圾渗滤液的高效深度脱氮。自养反硝化工艺则可无需有机碳源,仅通过无机电子供体即可实现垃圾渗滤液中硝态氮(NOx−-N,包括NO2−-N和NO3−-N)的高效脱除[10]。其中厌氧氨氧化自养反硝化工艺可利用NH4+-N为电子供体,NO2−-N为电子受体,在厌氧条件下实现NO2−-N与NH4+-N同步去除[13]。由于PND工艺能实现渗滤液中NH4+-N向NO2−-N的部分硝化,因此,当前许多研究尝试将PND工艺与厌氧氨氧化工艺相结合,以达到零碳源投加老龄垃圾渗滤液深度脱氮的效果[14-15]。LI等[16]采用短程硝化-厌氧氨氧化耦合工艺处理老龄垃圾渗滤液,结果表明在未补充任何有机碳源条件下,耦合工艺可实现约85.0%的总氮(total nitrogen,TN)去除。但受限于厌氧氨氧化自养脱氮工艺自身缺陷,其理论上会产生约进水总氮11%的NO3−-N[17],从而导致出水中含有较多的NO3−-N无法被彻底反硝化去除,使得短程硝化-厌氧氨氧化耦合工艺总氮去除效果不佳。

stringUtils.convertMath(!{formula.content}) (1) stringUtils.convertMath(!{formula.content}) (2) 与厌氧氨氧化工艺利用NH4+-N作为电子供体不同,SdAD工艺在缺氧条件下可利用硫化物(S0、S2−、S2O32−等)作为电子供体进行自养反硝化,其中单质硫(S0)作为电子供体的脱氮反应公式如式(1)~(2)所示[18]。S0作为SdAD自养反硝化电子供体具有以下优势:1) S0作为石化行业副产物,价格低廉且易获取;2) S0可充当生物滤池填料,在脱氮的同时能有效过滤渗滤液中的大颗粒杂质;3)工艺脱氮稳定性高、耐负荷冲击等[19-20]。因此,SdAD工艺通常采用S0填充床反应器将低C/N废液中的NOx−-N还原为N2[21]。LI等[22]采用PND耦合以S0为电子供体的SdAD工艺处理低C/N废水,在高FA质量浓度调控下PND工艺出水NO2−-N积累率可达89.5%,随后SdAD工艺能实现约70%的NO2−-N去除效果。然而,目前PND-SdAD耦合工艺对处理具有高生物抑制性的老龄垃圾渗滤液的脱氮性能仍有待研究。

鉴于此,本研究以佛山市白石坳垃圾填埋场老龄垃圾渗滤液为研究对象,采用中试规模的新型PND-SdAD耦合工艺对其进行零碳源投加深度脱氮。考察了PND-SdAD耦合工艺在垃圾渗滤液实际处理工程中的脱氮处理效能,优化了各工艺单元控制条件,分析了各工艺单元微生物种群多样性,评估了各工艺单元出水生物毒性,并对耦合工艺综合运行费用进行初步核算,以期为老龄垃圾渗滤液等低C/N废水深度脱氮的实际工程应用提供相关实验基础和技术支持。

1. 材料及方法

1.1 中试概况

中试项目总占地面积约500 m3,所处理垃圾渗滤液取自佛山市白石坳垃圾填埋场1#调节池,垃圾渗滤液原液水质参数:COD为(12 985.1±1 702.9) mg·L−1,NH4+-N为(3 502.9±396.7) mg·L−1,NO3−-N为(37.2±4.9) mg·L−1,TN为(3 623.5±471.4) mg·L−1。中试项目所用装置为本研究团队设计开发的新型组合工艺,如图1所示,反应装置主体结构由不锈钢制成。其中PND工艺单元由缺氧(anoxia,A)池与间歇式反应器(sequencing batch reactor,SBR)结构的短程硝化池两部分构成,其中PND-A池长1 m,宽2 m,有效高度约3.5 m,有效容积约6.5 m3,PND-SBR池长为3 m,宽2 m,有效高度约3 m,有效容积约17.5 m3,PND工艺单元总有效容积约24 m3;SdAD反应器采用上流式填充床结构,本研究中共平行安装2套SdAD反应器,单套SdAD反应器长2 m,宽1.8 m,有效高度3.5 m,内部填料高度约2.5 m,填料空隙率45%,填料床有效容积约4 m3,本研究两套SdAD反应器总有效容积为8 m3。

1.2 中试装置运行方案

垃圾渗滤液原液首先进入PND-A池,渗滤液原液中可降解有机污染物可与PND-SBR池硝化回流液中NOx−-N发生反硝化反应,脱除渗滤液部分NOx−-N;随后PND-A池渗滤液溢流至PND-SBR池,渗滤液中的NH4+-N在PND-SBR池进行短程硝化反应转化为NO2−-N,在批次反应结束后,静置沉淀1 h通过滗水器出水。中试PND工艺单元在本研究开展前期需完成微生物接种及启动工作,其接种启动运行方案如下:PND工艺单元接种取自佛山市白石坳垃圾填埋场渗滤液处理一厂生物脱氮工艺回流污泥8 m3,并加入16 m3垃圾渗滤液稀释液(渗滤液原液:自来水=1:3),混合均匀后PND工艺单元内污泥质量浓度约7 300 mg·L−1。启动期1~5 d,PND工艺单元进行闷曝(无进/排水操作);随后在启动期6~80 d内逐步提高反应器处理负荷,其中6~29 d,反应器渗滤液处理量调整至1 m3·d−1;30~80 d,反应器渗滤液处理量逐渐增加至3 m3·d−1。此外,整个PND工艺单元启动期内,对反应器曝气量进行动态调整,以控制DO质量浓度在0.5~1.0 mg·L−1。完成污泥接种及启动工作的PND工艺单元,其在I~IV运行阶段进行工艺控制参数优化。阶段I(81~206 d),批次反应运行时间24 h(第1阶段进水搅拌6 h,第2阶段曝气充氧17 h,第3阶段沉淀排水1 h),参数控制:回流速度~1.5 m3·h−1,曝气量30~34 m3·h−1,DO质量浓度1.2~1.6 mg·L−1;阶段II(207~257 d)优化工艺曝气强度,批次反应运行时间24 h(第1阶段进水搅拌6 h,第2阶段曝气充氧17 h,第3阶段沉淀排水1 h),参数控制:回流速度~1.5 m3·h−1,曝气量24~28 m3·h−1,DO质量浓度0.8~1.2 mg·L−1;阶段III(258~328 d)缩减工艺反应时间,批次反应运行时间减少至20 h(第1阶段进水搅拌4 h,第2阶段曝气充氧15 h,第3阶段沉淀排水1 h),参数控制:回流速度~1.5 m3·h−1,曝气量30~34 m3·h−1,DO质量浓度1.2~1.6 mg·L−1;阶段IV(329~406 d)进一步优化工艺反应时间,反应运行时间缩减至18 h(第1阶段进水搅拌4 h,第2阶段曝气充氧13 h,第3阶段沉淀排水1 h),参数控制:回流速度~1.5 m3·h−1,曝气量30~34 m3·h−1,DO质量浓度1.2~1.6 mg·L−1。此外,PND工艺单元的出水将作为SdAD工艺单元的进水。PND-SBR工艺单元通过滗水器将出水滗出至沉淀池后,沉淀池上部渗滤液以连续流方式进入SdAD工艺单元进行自养深度脱氮,进而使垃圾渗滤液中残余的NOx−-N还原为N2。SdAD工艺单元接种污泥取自于中试PND工艺单元,接种后SdAD工艺单元污泥质量浓度约3 000 mg·L−1,且污泥接种后逐步调整SdAD工艺单元处理量以实现PND-SdAD耦合工艺的稳定运行。

1.3 分析方法

1)水样常规水质指标。各工艺单元出水定期采样,水样品经0.45 um尼龙滤膜过滤后,其相关常规水质指标均按照文献[23]操作。其中NH4+-N采用纳氏试剂分光光度法;NO2−-N采用N-(1-萘基)-乙二胺光度法;NO3−-N采用紫外分光光度法;TN采用碱性过硫酸钾消解紫外分光光度法;化学需氧量(chemical oxygen demand,COD)采用哈希DRB200快速消解仪测定;pH及DO均由便携式分析仪(SX836,三信)测定。

2)生物毒性检测。本研究通过水质急性毒性检测试剂盒(金达清创环境科技有限公司,北京)检测其生物毒性,并以费氏弧菌(V.fischeri)的发光抑制率作为渗滤液生物毒性指标。收集各工艺单元出水样本加入到培养好的V.fischeri菌液中震荡10 s后,置于空气中暴露15 min,测定V.fischeri菌的发光抑制率,发光抑制率计算方法见式(3)并根据文献[24]通过不同发光抑制率强度判别渗滤液急性毒性风险等级(0≤L<30为低毒;30≤L<50为中毒;50≤L<70为重毒;70≤L<100为高毒;L=100为剧毒)。

stringUtils.convertMath(!{formula.content}) (3) 式中:L为发光抑制率;I0空白对照组暴露15 min后的发光强度;It为测试组暴露15 min后的发光强度。

3)微生物多样性分析。通过PowerSoil DNA试剂盒(12888-100,MOBIO,USA)提取生物样品中的总DNA,采用PCR技术对微生物16S rRNA的V3~V4高可变区域进行扩增,引物序列为338F (5'-ACTCCTACGGGAGGCAGCAG-3')和806R (5'- GGACTACHVGGGTWTCTAAT-3'),最后采用PacBio Sequel II平台完成测序,本研究已将微生物DNA序列上传至National Center for Biotechnology Information数据库,项目编号:PRJNA1086255。

stringUtils.convertMath(!{formula.content}) (4) 式中:Q为水样中FA质量浓度,mg·L−1;

CNH+4 - N 4) FA质量浓度计算方法。老龄垃圾渗滤液中的NH4+-N因pH值的不同,存在离子态与分子态的两种形式。FA是渗滤液中NH4+-N分子态形式浓度,可通过公式(4)[25]计算得出。

5)硫酸盐产率计算方法。SdAD工艺单元中硫驱动自养反硝化反应的硫酸盐产率可通过SO42−-S的生成量与TN去除量间的比值体现,由R表示,其计算方法见式(5)。

stringUtils.convertMath(!{formula.content}) (5) 式中:

C进水SO2−4−S C出水SO2−4−S C进水TN C出水TN 2. 结果与讨论

2.1 PND工艺单元运行效能及稳定性

1) PND工艺单元启动阶段运行效能。PND工艺单元启动期运行效能如图2所示,启动期第1天时反应器渗滤液中NH4+-N、NO2−-N及NO3−-N质量浓度分别为674.9、1.4、102.8 mg·L−1。启动期前1~5 d内通过低DO质量浓度条件下的闷曝,PND工艺单元中NH4+-N质量浓度由674.9 mg·L−1迅速降至356.8 mg·L−1,同时NO3−-N质量浓度由102.8 mg·L−1增加至294.6 mg·L−1,而NO2−-N质量浓度无明显积累。这一结果可能是由于PND工艺单元接种污泥来源于填埋场渗滤液处理一厂,接种污泥中存在一定的亚硝酸盐氧化菌(nitrite oxidizing bacteria,NOB),闷曝硝化过程所产生的NO2−-N被快速转化为NO3−-N,因此未形成较好的NO2−-N累积。闷曝结束后6~29 d,PND工艺单元处理量提高至1 m3·d−1,出水NO3−-N质量浓度呈现先增加后下降的趋势,且出水NO2−-N质量浓度由1.9 mg·L−1提升至247.6 mg·L−1。随后30~80 d内,PND工艺单元处理量由1.5 m3·d−1逐步提升至3 m3·d−1,反应器出水NO3−-N质量浓度呈现降低趋势,且出水NO2−-N质量浓度逐渐升高至第80天时688.3 mg·L−1。此外,PND工艺单元启动阶段反应器TN去除率随运行时间逐渐提高,可由第1天时21.4%提高到80天时61.6%。上述结果表明,启动阶段通过低DO质量浓度(0.5~1.0 mg·L−1)及逐步提高处理负荷的条件下,PND工艺单元经80 d的启动运行可实现高质量浓度NO2−-N累积及具备良好的脱氮能力,实现了PND工艺单元反应器的启动。

2) PND工艺单元运行效能。本研究完成PND工艺单元污泥接种启动后,通过4个运行阶段优化反应器的运行效能,结果如图3所示。其中阶段Ⅰ调整PND-SBR池曝气量,控制池中DO质量浓度在1.2~1.6 mg·L−1。反应器在81~147 d,出水NH4+-N质量浓度由852.6 mg·L−1(第81天)快速降至38.2 mg·L−1(第147天),且NO2−-N积累率由44.2%(第81天)上升至92.5%(第147天)。随后148~206 d期间内,反应器出水渗滤液中NH4+-N及NO2−-N质量浓度稳定,且无NO3−-N积累,TN去除率可达(83.9±1.5)%。阶段Ⅱ为进一步探究PND工艺单元DO质量浓度对反应器短程硝化反硝化运行效能的影响,降低PND-SBR池曝气强度,控制PND-SBR池内DO质量浓度在0.8~1.2 mg·L−1。发现PND工艺单元反应器在阶段Ⅱ(207~257 d)内未能实现稳定的短程硝化效果,出水NH4+-N质量浓度在23.5~194.6 mg·L−1区间内剧烈波动,且NO2−-N积累率和TN去除率分别降至(80.2±6.4)%与(80.6±2.3)%。该结果表明,相较于阶段Ⅰ的DO质量浓度(1.2~1.6 mg·L−1),阶段Ⅱ的PND-SBR池中DO质量浓度不足,池中渗滤液NH4+-N无法在24 h的序批次反应内实现高效短程硝化反硝化。因此,本研究PND-SBR池适宜的曝气量应调节至30~34 m3·h−1,DO质量浓度控制在1.2~1.6 mg·L−1。阶段Ⅲ与阶段Ⅳ控制DO质量浓度在1.2~1.6 mg·L−1条件下,进一步优化单个批次反应周期的运行时间。其中阶段Ⅲ在单个周期20 h内反应效果稳定,渗滤液中的NH4+-N可稳定进行短程硝化反应。因此,阶段Ⅳ进一步缩短批次运行时间至18 h,PND-SBR池中渗滤液NH4+-N仍可实现稳定短程硝化,出水NH4+-N质量浓度为(50.2±17.8) mg·L−1,NO2−-N积累率达到(84.9±3.6)%,TN去除率为(86.0±0.8)%。综上,本中试研究的PND工艺单元阶段Ⅳ为最佳运行阶段,序批次反应操作为第1阶段进水搅拌4 h,第2阶段曝气充氧13 h,第3阶段沉淀排水1 h,调节曝气量为30~34 m3·h−1,DO质量浓度为1.2~1.6 mg·L−1,该操作条件下可实现中试PND工艺单元高效稳定运行。此外,本研究PND工艺单元阶段Ⅳ出水COD值整体波动较小(图3(b)),平均值为(3 626.4±420.2) mg·L−1,较进水COD值(11 061.5±807.7) mg·L−1去除率约为67.2%。由此可见,在阶段Ⅳ老龄垃圾渗滤液中的可降解有机污染物也已被大量消耗,难以继续满足PND工艺单元后续进一步脱氮的碳源需求。

3) PND工艺单元序批次稳定运行关键参数分析。图4显示PND工艺单元在不同运行阶段单周期批次反应中(分析开展于反应器运行第180、220、320及380天时)PND-SBR池氮素及FA质量浓度变化规律。总的来看,图4中不同运行阶段PND-SBR池中垃圾渗滤液的NH4+-N质量浓度均由第1阶段进水搅拌开始随时间逐渐增加至峰值后下降,这是由于含高质量浓度NH4+-N((3 502.9±396.7) mg·L−1)的渗滤液原液由PND-A池逐渐溢流至PND-SBR池中,导致PN-SBR池中NH4+-N的质量浓度快速增加,在进水搅拌结束后,由于PND-SBR与PND-A池间存在回流,使得PND-SBR池的NH4+-N质量浓度在第1阶段进水搅拌结束后仍持续升高。随后第2阶段曝气充氧,PND-SBR池中NH4+-N经短程硝化作用逐步转化为NO2−-N,NH4+-N质量浓度快速下降。同时,渗滤液NO2−-N质量浓度在单周期批次实验过程中随运行时间呈现下降-升高-下降的变化趋势。这主要是由于进水搅拌阶段存在渗滤液稀释补充,且PND-SBR池内部分NO2−-N可与进水中补入的可降解有机污染物发生短程反硝化反应,从而导致NO2−-N质量浓度在反应开始时有所下降;随着曝气充氧阶段进行,NH4+-N被逐步转化为NO2−-N,从而使得池内渗滤液NO2−-N质量浓度随时间逐步升高;最后渗滤液中的NH4+-N已被大量转化,NO2−-N质量浓度得不到进一步提高,而短程反硝化反应的存在使得NO2−-N质量浓度在批次反应末期进一步降低。值得注意的是,PND-SBR池在不同反应阶段的单周期批次实验中,均无明显NO3−-N质量浓度积累,其原因是各阶段反应周期内生成的高质量浓度FA对NOB起到有效抑制[11],避免了渗滤液中NO2−-N向NO3−-N的转化。图4(a)~(d)中PND-SBR池阶段Ⅰ、阶段Ⅱ、阶段Ⅲ、阶段Ⅳ中FA质量浓度分别为0.4~28.7、2.9~39.4、0.8~28.3、0.4~26.8 mg·L−1,在上述FA质量浓度变化区间内,FA质量浓度始终存在由低到高再降低的变化趋势。有研究发现当FA质量浓度高于3.1 mg·L−1以上时即可实现稳定的短程硝化反应[26]。本研究PND-SBR池单周期批次反应内FA质量浓度大部分反应时间均高于3.1 mg·L−1以上,使得PND-SBR池内NOB受到严格抑制,且促使池内氨氧化菌(ammonia oxidizing bacteria,AOB)丰度升高,从而确保NO2−-N的高效积累。

2.2 SdAD工艺运行效能

由于老龄垃圾渗滤液具有低C/N的特点,PND工艺单元出水渗滤液中的耗氧有机物(以COD计)难以满足对NOx−-N的进一步深度去除,因此,本研究采用以S0为电子供体的SdAD工艺单元对PND工艺单元出水垃圾渗滤液进行深度自养脱氮。图5(a)所示在整个305 d的运行期间内,SdAD工艺单元进水NO2−-N质量浓度为(455.9±68.5) mg·L−1,出水NO2−-N去除率可达98.5%左右。结果表明,PND工艺单元出水垃圾渗滤液中所含高质量浓度NO2−-N未对SdAD工艺单元中脱氮功能微生物产生抑制,这可能是由于硫氧化菌(sulfur oxidizing bacteria,SOB)对NO2−-N有较强的耐受性[27]。同时,SdAD工艺单元也对渗滤液中NO3−-N实现较为高效的去除,去除率达97.1%左右。由此可见,自养SdAD工艺单元无需外部有机碳源补入即可对PND工艺单元出水垃圾渗滤液中的NOx−-N实现高效稳定的去除,其在处理PND工艺单元阶段Ⅳ出水时的稳定运行阶段(228~305 d),TN去除效率可达(92.9±1.1)%。此外,SdAD工艺单元稳定运行阶段出水NH4+-N质量浓度为(33.4±3.9) mg·L−1较进水(50.2±17.8) mg·L−1略微下降。这可能是由于PND工艺单元出水渗滤液中残余的部分NH4+-N被SOB同化利用以维持自身生长;且SdAD工艺单元微生物利用渗滤液中的DO对NH4+-N进行硝化,从而导致SdAD工艺单元出水NH4+-N质量浓度略微下降的现象。由图5(b)可见,SdAD工艺单元进/出水中COD变化趋势相似,整体呈现随时间延长逐步降低的趋势,且整个运行阶段出水COD值为(4 002.6±745.3) mg·L−1,较进水COD((4 617.1±814.9 )mg·L−1)降低了约13.3%,表明SdAD反应单元中仍有部分有机污染物参与反硝化反应。此外,整个SdAD工艺单元由于硫自养反硝化反应所产生的硫酸盐,使出水中SO42−-S质量浓度为(661.2±68.9) mg·L−1较进水(275.8±39.5) mg·L−1升高了约239.7%。且SdAD工艺单元的硫酸盐产率R为0.95±0.18,低于硫自养反硝化R的理论值2.51[28]。综上所述,SdAD反应单元对PND工艺单元出水垃圾渗滤液高效深度脱氮是基于异养反硝化与自养反硝化的协同作用。

2.3 PND-SdAD耦合工艺处理老龄垃圾渗滤液污染物去除贡献分析

PND-SdAD耦合工艺作为低耗、零碳源投加的深度脱氮工艺,渗滤液中的NH4+-N、TN、COD等污染物去除效果分析见图6。其中PND工艺单元在第Ⅳ阶段,通过调节DO及FA质量浓度,不仅能达到(98.6±1.7)%的NH4+-N去除效果及(84.9±3.6)%的NO2−-N积累,还可以充分利用渗滤液中有机污染物实现(86.0±0.8)%的TN去除,且脱氮速率约为0.52 kg·(m3·d)−1。本研究采用的PND工艺处理老龄垃圾渗滤液较前人50%左右的TN去除效果[29]具有更好的脱氮效率,主要是由于本研究老龄垃圾渗滤液中不定期有新鲜垃圾渗滤液补入,新鲜渗滤液能较大程度赋存可降解的有机污染物作为短程反硝化的有机碳源。此外,本研究PND工艺单元的NO2−-N积累效果显著,渗滤液中的氮素可较大程度上通过NO2−-N的短程反硝化反应去除。随后,PND工艺单元出水经SdAD工艺单元进行深度脱氮,由于PND工艺单元出水渗滤液中可降解有机物已在PND工艺单元中被充分利用,SdAD工艺单元渗滤液中COD的去除率仅为(4.8±0.1)%。因此,SdAD工艺单元主要依靠无机S0为电子供体来实现NOx−-N的去除,SdAD工艺单元对渗滤液原液TN去除率的贡献为(12.9±0.4)%,且脱氮速率为0.23 kg·(m3·d)−1。综上,PND-SdAD耦合深度脱氮工艺,在低耗能、零碳源投加条件下,可实现垃圾渗滤液约98.9%的TN去除,出水TN质量浓度为(38.7±4.6) mg·L−1,满足国家《生活垃圾填埋场污染控制标准》(GB16889-2008)中TN低于40 mg·L−1的排放要求。

2.4 微生物多样性分析

图7(a)所示为PND工艺单元反应器接种污泥和不同阶段下的污泥在属水平上微生物群落结构分布。各反应阶段污泥中所富集的Nitrosomonas菌属,是常见的好氧AOB菌属之一,可将NH4+-N转化为NO2−-N[30]。其在第1天(接种污泥)及不同运行阶段下的丰度分别为0%、9.7%(阶段Ⅰ,第205天)、4.8%(阶段Ⅱ,第256天)、12.8%(阶段Ⅲ,第328天)及12.9%(阶段Ⅳ,第406天),且阶段Ⅰ~Ⅳ污泥样品中未发现NOB菌属。上述结果表明,PND工艺单元在低DO及高FA质量浓度(>3.1 mg·L−1)条件下,有利于反应器中AOB菌属的高度富集,并抑制NOB菌属的生长,从而确保PND工艺单元出水实现NO2−-N的高效积累。此外,在PND工艺单元反应器中,truepera也发挥了重要作用,作为一种重要的异养反硝化脱氮菌属,可利用垃圾渗滤液中的有机污染物将NOx−-N还原为N2,从而实现PND工艺单元的高效脱氮[31]。图7(b)所示SdAD工艺单元在运行期间,Thiobacillus与Sulfurimonas菌属丰度分别由第1天(接种污泥)的0%提升至7.9%与11.8%(第100天),25.3%与22.8%(第195天)及第300天时的31.9%与34.8%。Thiobacillus与Sulfurimonas作为SdAD工艺单元反应器运行期间污泥中的优势菌属,是主要硫自养反硝化菌属,可利用S0作为电子供体将NOx−-N还原为N2[32]。同时,truepera、Comamonas及Thauera等其他反硝化菌菌属的协同作用,不仅有效保证SdAD工艺单元的深度脱氮性能,也可充分利用垃圾渗滤液中的有机污染物并降低S0的消耗。上述研究表明,在PND-SdAD耦合工艺反应器中,PND工艺单元中的AOB(Nitrosomonas)和SdAD工艺单元中的SOB(Thiobacillus与Sulfurimonas)关键功能菌占据重要地位,并在脱氮过程中发挥了关键作用。

2.5 各工艺单元出水渗滤液生物毒性变化

垃圾渗滤液原液经PND-SdAD耦合工艺处理后,渗滤液中大量有机污染物及NH4+-N被微生物降解转化,且渗滤液中固体杂质经SdAD工艺单元填料床截留,出水渗滤液色度得到显著改善,结果如图8(a)所示。此外,图8(b)为PND-SdAD工艺出水渗滤液生物毒性的变化,本研究所采用的老龄垃圾渗滤液原液的发光抑制率高达(92.4±3.7)%,属高毒水体,对于生物工艺的微生物种群有着较强的毒害作用。垃圾渗滤液原液经PND工艺处理后出水生物毒性有所降低,发光抑制率从垃圾渗滤液原液的(92.4±3.7)%降至PND工艺单元出水的(76.2±0.4)%,但其水质毒性等级仍为高毒,这可能是由于渗滤液原液中的NH4+-N转化为NO2−-N,而NO2−-N具有较高生物抑制性[33],从而导致PND工艺单元出水垃圾渗滤液依然保持较高的生物毒性。PND工艺单元出水经SdAD工艺单元进一步处理,出水渗滤液的发光细菌的抑制率从(76.2±0.4)%减少至(27.8±1.3)%,水质毒性等级从高毒降为低毒。这可归因于SdAD工艺单元出水渗滤液中有机污染物进一步降低、NO2−-N被高效脱除及渗滤液中大颗粒杂质被填料床有效截留等原因,从而使SdAD工艺单元对垃圾渗滤液的生物毒性具有明显改善作用。因此,采用PND-SdAD耦合工艺处理垃圾渗滤液,耦合工艺出水渗滤液对V.fischeri菌的发光抑制率可降低64.6%,水质毒性等级从高毒降至低毒级别,极大的降低了垃圾渗滤液排放风险。此外,本研究PND-SdAD耦合工艺处理具有较高生物毒性的老龄垃圾渗滤液时,其高毒老龄垃圾渗滤液未对耦合工艺脱氮性能造成显著影响,表明该工艺对处置垃圾渗滤液具有较好的适应性。

2.6 综合运行成本分析

为评估PND-SdAD耦合工艺经济性,本研究对其进行综合运行成本估算,详见表1。中试PND-SdAD耦合工艺每日可稳定处理约4 m3老龄垃圾渗滤液,吨水综合运行费用为24.4元。其中电费占总运行费用的83.2%,主要因PND工艺单元需大量曝气,从而导致耦合工艺能耗成本占比较高。在SdAD过程中采用S0作为电子供体,其吨水深度脱氮成本仅为3.1元,较传统生物反硝化碳源电子供体成本显著降低。由于传统生物反硝化为保证脱氮效果,需过量投加可溶性有机碳源(如,甲醇、乙酸钠、葡萄糖等)以提高垃圾渗滤液的可生化性[34],且处理过程中未被微生物利用的溶解性有机碳源会随出水流失,造成不必要的有机碳源浪费。本研究所使用不溶性S0作为电子供体,可根据渗滤液中氮素浓度进行消耗,有效避免电子供体损失,从而降低垃圾渗滤液运行成本。

表 1 垃圾渗滤液中试PND-SdAD耦合工艺深度脱氮综合运行成本Table 1. Comprehensive operating cost of pilot-scale PND-SdAD combined process for advanced nitrogen removal from landfill leachate项目 单价 消耗量 运行费用/(元·t−1) 电费 0.89 元·(kWh)−1 91.2 kWh·d−1 20.3 电子供体成本 2.4 元·kg−1 5.09 kg·d−1 3.1 药剂费 8 元·kg−1 0.5 kg·d−1 1 合计 — — 24.4 3. 结论

1) 中试PND工艺单元在第1阶段进水搅拌4 h、第2阶段曝气充氧13 h、第3阶段沉淀排水1 h的批次运行条件下,控制回流速度1.5 m3·h−1,曝气量30~34 m3·h−1,DO质量浓度1.2~1.6 mg·L−1,可实现约0.52 kg·(m3·d)−1的脱氮速率及(86.0±0.8)%的TN去除效果。随后通过SdAD工艺单元可对PND工艺单元出水渗滤液中的氮素进行深度去除,其脱氮速率约为0.23 kg·(m3·d)−1,并对老龄垃圾渗滤液原液的TN去除率贡献为(12.9±0.4)%。

2) 本研究在低DO及高FA质量浓度的环境下,PND工艺单元中的Nitrosomonas实现高度富集,从而保证PND工艺单元短程硝化反应的稳定。SdAD工艺单元中的SOB(Thiobacillus与Sulfurimonas)菌属占据重要地位,并在脱氮过程中发挥了关键作用。

3) PND-SdAD耦合工艺稳定运行可实现垃圾渗滤液约98.9%的TN去除效果,出水渗滤液TN质量浓度为(38.7±4.6) mg·L−1,满足《生活垃圾填埋场污染控制标准》(GB16889-2008)中对TN的排放要求。同时耦合工艺出水渗滤液对V.fischeri菌的发光抑制率整体可降低64.6%,水质毒性等级由高毒降至低毒,能有效降低老龄垃圾渗滤液的排放风险。

4) PND-SdAD耦合工艺作为绿色、高效的生物脱氮工艺,其渗滤液吨水处理的综合成本约为24.4元,具有较好的经济性,为我国全面推进美丽中国建设提供技术支持。

-

表 1 垃圾渗滤液中试PND-SdAD耦合工艺深度脱氮综合运行成本

Table 1. Comprehensive operating cost of pilot-scale PND-SdAD combined process for advanced nitrogen removal from landfill leachate

项目 单价 消耗量 运行费用/(元·t−1) 电费 0.89 元·(kWh)−1 91.2 kWh·d−1 20.3 电子供体成本 2.4 元·kg−1 5.09 kg·d−1 3.1 药剂费 8 元·kg−1 0.5 kg·d−1 1 合计 — — 24.4 -

[1] 中华人民共和国生态环境部. 2020年全国大、中城市固体废物污染环境防治年报[R]. 北京, 中华人民共和国生态环境部, 2020, 9-10. [2] MUKHERJEE C, DENNEY J, MBONIMPA E G, et al. A review on municipal solid waste-to-energy trends in the USA[J]. Renewable and Sustainable Energy Reviews, 2020, 119: 109512. doi: 10.1016/j.rser.2019.109512 [3] 黄林, 杨磊. 我国城市生活垃圾处理现状与展望[J]. 可持续发展, 2022, 12(5): 1347-1354. [4] NAVEEN B P, MAHAPATRA D M, SITHARAM T G, et al. Physico-chemical and biological characterization of urban municipal landfill leachate[J]. Environmental Pollution, 2017, 220(Pt A): 1-12. [5] TENG C, ZHOU K, PENG C, et al. Characterization and treatment of landfill leachate: A review[J]. Water Research, 2021, 203: 117525. doi: 10.1016/j.watres.2021.117525 [6] KULIKOWASKA D and KLIMIUK E. The effect of landfill age on municipal leachate composition[J]. Bioresource Technology, 2008, 99(13): 5981-5985. doi: 10.1016/j.biortech.2007.10.015 [7] ITOKAWA H, HANAKI K and MATSUO T. Nitrous oxide production in high-loading biological nitrogen removal process under low COD/N ratio condition[J]. Water Research, 2001, 35(3): 657-664. doi: 10.1016/S0043-1354(00)00309-2 [8] YI X, TIAN N H, YIN T, et al. Removal of selected PPCPs, EDCs, and antibiotic resistance genes in landfill leachate by a full-scale constructed wetlands system[J]. Water Research, 2017, 121: 46-60. doi: 10.1016/j.watres.2017.05.008 [9] ZHANG R C, XU X J, CHEN C, et al. Interactions of functional bacteria and their contributions to the performance in integrated autotrophic and heterotrophic denitrification[J]. Water Research, 2018, 143: 355-366. doi: 10.1016/j.watres.2018.06.053 [10] CAPUA F D, PIROZZI F, LENS P N L, et al. Electron donors for autotrophic denitrification[J]. Chemical Engineering Journal, 2019, 362: 922-937. doi: 10.1016/j.cej.2019.01.069 [11] DUAN H, YE L, LU X, et al. Overcoming nitrite oxidizing bacteria adaptation through alternating sludge treatment with free nitrous acid and free ammonia[J]. Environmental Science & Technology, 2019, 53(4): 1937-1946. [12] WANG J, LI L, LIU Y, et al. A review of partial nitrification in biological nitrogen removal processes: from development to application[J]. Biodegradation, 2021, 32(3): 229-249. doi: 10.1007/s10532-021-09938-x [13] TIAN T and YU H Q. Denitrification with non-organic electron donor for treating low C/N ratio wastewaters[J]. Bioresource Technology, 2020, 299: 122686. doi: 10.1016/j.biortech.2019.122686 [14] QIU J, LI X, PENG Y, et al. Advanced nitrogen removal from landfill leachate via a two-stage combined process of partial nitrification-anammox (PN-A) and partial denitrification-anammox (PD-A)[J]. Science of Total Environment, 2022, 810: 151186. doi: 10.1016/j.scitotenv.2021.151186 [15] ZHANG F, PENG Y, MIAO L, et al. A novel simultaneous partial nitrification anammox and denitrification (SNAD) with intermittent aeration for cost-effective nitrogen removal from mature landfill leachate[J]. Chemical Engineering Journal, 2017, 313: 619-628. doi: 10.1016/j.cej.2016.12.105 [16] LI H, ZHOU S, MA W, et al. Long-term performance and microbial ecology of a two-stage PN-ANAMMOX process treating mature landfill leachate[J]. Bioresource Technology, 2014, 159: 404-411. doi: 10.1016/j.biortech.2014.02.054 [17] DU R, CAO S, ZHANG H, et al. Flexible nitrite supply alternative for mainstream anammox: Advances in enhancing process stability[J]. Environmental Science & Technology, 2020, 54(10): 6353-6364. [18] WANG T, LI X, WANG H, et al. Sulfur autotrophic denitrification as an efficient nitrogen removals method for wastewater treatment towards lower organic requirement: A review[J]. Water Research, 2023, 245: 120569. doi: 10.1016/j.watres.2023.120569 [19] ZENG C, SU Q, PENG L, et al. Elemental sulfur-driven autotrophic denitrification for advanced nitrogen removal from mature landfill leachate after PN/A pretreatment[J]. Chemical Engineering Journal, 2021, 410: 128256. doi: 10.1016/j.cej.2020.128256 [20] SAHINKAYA E, KILIC A and DUYGULU, B. Pilot and full scale applications of sulfur-based autotrophic denitrification process for nitrate removal from activated sludge process effluent[J]. Water Research, 2014, 60: 210-217. doi: 10.1016/j.watres.2014.04.052 [21] HUANG S, ZHENG Z, WEI Q, et al. Performance of sulfur-based autotrophic denitrification and denitrifiers for wastewater treatment under acidic conditions[J]. Bioresource Technology, 2019, 294: 122176. doi: 10.1016/j.biortech.2019.122176 [22] LI Y, CHEN B, ZHANG X, et al. Elemental sulfur autotrophic partial denitrification (S0-PDN) with high pH and free ammonia control strategy for low-carbon wastewater: From performance to microbial mechanism[J]. Chemical Engineering Journal, 2023, 474: 145419. doi: 10.1016/j.cej.2023.145419 [23] 国家环境保护总局. 水和废水监测分析方法 (第四版)[M]. 北京, 中国环境科学出版社, 2002, 88-284. [24] 那广水, 张月梅, 陈彤, 等. 发光细菌法评价排污口污水中总有机污染物毒性[J]. 中国环境监测, 2010, 26(5): 61-64. doi: 10.3969/j.issn.1002-6002.2010.05.017 [25] XU H, DENG Y, ZOU J, et al. Nitrification performance and bacterial community dynamics in a membrane bioreactor with elevated ammonia concentration: The combined inhibition effect of salinity, free ammonia and free nitrous acid on nitrification at high ammonia loading rates[J]. Science of Total Environment, 2022, 831: 154972. doi: 10.1016/j.scitotenv.2022.154972 [26] 刘牡, 彭永臻, 吴莉娜, 等. FA与FNA对两级UASB-A/O处理垃圾渗滤液短程硝化的影响[J]. 化工学报, 2010, 61(1): 172-179. [27] KOSTRYTSIA A, PAPIRIO S, FRUNZO L, et al. Elemental sulfur-based autotrophic denitrification and denitritation: Microbially catalyzed sulfur hydrolysis and nitrogen conversions[J]. Journal of Environmental Management, 2018, 211: 313-322. [28] SAHINKAYA E, DURSUM N, KILIC A, et al. Simultaneous heterotrophic and sulfur-oxidizing autotrophic denitrification process for drinking water treatment: control of sulfate production[J]. Water Research, 2011, 45(20): 6661-6667. doi: 10.1016/j.watres.2011.09.056 [29] 赵晴, 周浩, 吕慧, 等. AO-SBR短程硝化反硝化垃圾渗滤液预处理中试应用[J]. 环境工程学报, 2021, 15(2): 545-552. doi: 10.12030/j.cjee.202004110 [30] 韩梦欣, 周明达, 汪涵, 等. 污水短程硝化体系氨氧化菌与亚硝酸盐氧化菌的生态学研究进展[J]. 微生物学通报, 2023, 50(4): 1621-1638. [31] SHI S, HE L, ZHOU Y, et al. Response of nitrogen removal performance and microbial community to a wide range of pH in thermophilic denitrification system[J]. Bioresource Technology, 2022, 352: 127061. doi: 10.1016/j.biortech.2022.127061 [32] SHAO M F, ZHANG T and FANG H H. Sulfur-driven autotrophic denitrification: diversity, biochemistry, and engineering applications[J]. Applied Microbiology And Biotechnology, 2010, 88(5): 1027-1042. doi: 10.1007/s00253-010-2847-1 [33] MARC S J, GIJS K and MIKE S M. Key physiology of anaerobic ammonium oxidation[J]. APPLIED AND ENVIRONMENTAL MICROBIOLOGY, 1999, 65(7): 3248-3250. doi: 10.1128/AEM.65.7.3248-3250.1999 [34] 徐晨璐, 尹志轩, 李春雨, 等. 垃圾渗滤液补充反硝化碳源强化脱氮效果[J]. 环境工程学报, 2019, 13(5): 1106-1112. doi: 10.12030/j.cjee.2019512 -

下载:

下载: