-

室内空气污染对人类居住生活环境的影响日趋严重,据世界卫生组织估计,2016年全球有420万人因室内空气污染而过早死亡,相比之下,户外空气污染导致的过早死亡只有380万人[1]。糟糕的室内空气质量已成为全球第九大疾病风险负担[2]。室内空气的污染除室外污染空气的影响外,还与室内装修、人类活动以及室内家居用品等密切相关。随着人们健康意识的提高,空气净化器作为改善室内空气品质的一种有效途径,已逐渐成为室内空气净化的主要手段[3]。

目前市场上销售的空气净化器大都采用HEPA滤网过滤空气中的颗粒物,研究表明,HEPA滤网可以将颗粒物质量和颗粒物数浓度降低50%以上[4-7],技术相对成熟稳定。近年来,HEPA技术也一直占据着空气净化器市场的最主要份额[8-9]。相较于颗粒物的净化方式,对气态污染物的净化方式较多,但一直没有取得质的突破。较为主流的净化方式是应用改性活性炭制作成填充滤网或者夹炭复合布材料,整个过程中涉及到很多化学反应,如果选用的化学试剂不当,会将新的污染物引入到环境空气中,造成二次污染。近年来空气净化器在使用过程中出现酸臭异味的问题成为了消费者主要的投诉项目,这个酸臭异味也主要来源于活性炭滤网[10]。但由于各个厂商活性炭滤网的制作工艺及其中活性炭的改性配方各不相同[11-16],造成活性炭类滤网的性状差异较大,酸臭异味的成因来源一直没有明确的结论。

为了解决这一室内空气净化领域难题,本文通过感官评价与仪器分析相结合的方法对典型受试样本进行剖析[17-19],采用气相色谱-质谱、离子色谱及平板计数法测定了活性炭滤网中的挥发性有机物、有机酸、无机离子及菌落总数和霉菌等,并通过感官等级评价与不同成分的相关性分析,全面客观的对活性炭滤芯酸臭异味的成因及来源进行了探讨,为改善活性炭滤芯生产工艺与防治异味提供科学参考依据,以期促进空气净化器市场的持续健康发展。

-

试验选取的滤网分别采用不同的活性炭种类包括椰壳活性炭和煤质活性炭,改性与未经改性的活性炭,用胶粘炭和撒炭的形式,以及正常人居环境下使用过和未使用过的样品。本实验所用活性炭滤网样品由北京三五二环保科技有限公司提供。具体情况如表1所示。

-

选取10位不吸烟,嗅觉器官灵敏且训练有素的普通人群作为感官评价人员(6名女性+4名男性),参照张晓等的研究方法[10]在室温下对活性炭滤网异味的强度进行了评估,强度分为0—5的6个等级,根据0表示无酸臭味,1表示似有似无,不敢确定,2表示微弱的酸臭味,3表示感觉到明显的酸臭味,4表示感觉到比较强烈的酸臭味,5表示感觉到非常强的酸臭味来打分。每位嗅闻员对同一样品嗅闻3次,3次数据中有2次重复时才被记录用来分析。

-

采用7890A/5975C气相色谱-质谱仪(美国Agilent公司)对滤网中的挥发性有机物进行了测定,为了让实验结果更贴近于实际应用情况,实验在容积14 m3大型环境舱(中国林业科学院木材工业研究所)中进行。将待测滤网放置于同一空气净化器中,以相同风量开启净化器一段时间后,在净化器出气口处架设恒流空气采样泵(美国Gilian IAQ—Pro—II),应用Tenax—TA吸附管(美国CAMSCO)采集出口处气体,采样流速200 mL·min−1,采样时间20 min。采集完毕后,应用ATD—35二级热脱附装置(美国Perkin Elmer公司)对吸附管进行加热脱附,然后进入气相色谱质谱仪分析。

热脱附条件:样品管除湿时间2 min;阀温225 ℃;传输线温度230 ℃;一级脱附温度80 ℃;一级脱附时间5 min;冷阱温度-30 ℃至290 ℃(升温速率40 ℃·s−1);二级脱附时间2 min;分流比10∶1。

气相色谱条件:色谱柱:HP—VOC(60 m×0.32 mm×1.8 μm);程序升温初始温度45 ℃,保留2 min,5 ℃·min−1升至250 ℃,保留5 min;载气为高纯He气,柱流量1 mL·min−1。

质谱条件:EI离子源,电子能量70 eV,离子源温度230 ℃,四极杆温度150 ℃,传输线温度280 ℃,扫描质量范围:45—450 amu。

-

采用ICS2000离子色谱仪(美国Dionex公司)对24个样品中的主要水溶性阴离子和有机酸进行了测定。准确称取柱状炭及颗粒状炭样品5 g,置于小烧杯中,加入50 mL去离子水后震荡萃取12 h,提取液经0.45 μm的水系滤膜过滤,待测。夹碳布样品,首先经炭粒与滤布分离后,称取2 g炭粒样品,加入20 mL去离子水,后续步骤同上。

阴离子测试条件:色谱柱型号:AS14A 4 mm×250 mm;淋洗液:30 mmol·L−1 KOH;流速:1.0 mL·min−1;抑制器电流:59 mA;进样体积:25 μL。

有机酸测试条件:色谱柱型号:AS11-HC 4 mm×250 mm;淋洗液:5 mmol·L−1 KOH;流速:1.2 mL·min−1;抑制器电流:223 mA;进样体积:25 μL。

分别配制5个不同浓度的阴离子(Cl−、NO2−、NO3−、SO42-和PO43-,国家有色金属及电子材料分析测试中心)和有机酸(甲酸、乙酸、丙酸、丁酸和乳酸,北京百灵威科技有限公司)混合标准品溶液系列,用标准溶液系列中各组分的峰面积与浓度数据作标准曲线,计算回归方程和相关系数,将低浓度的混合标准溶液不断稀释并进样分析,并以S/N=3计算出各阴离子和有机酸的检出限。无机阴离子相关系数均≥0.9995,有机酸均≥0.9993。5种阴离子的检出限为0.03—0.08 µg·mL−1,5种有机酸的检出限为0.02—0.07 µg·mL−1。

-

取5 g样品用50 mL去离子水浸泡,震荡12 h后经0.45 μm的水系滤膜过滤。滤液的pH值由上海雷磁PHS-3C pH计测定。

-

灭菌棉拭子于10 mL灭菌生理盐水内浸润(吸取约1 mL溶液),在净化器滤网的前后中央部位5 cm×5 cm面积上,用力均匀涂抹5次,再用灭菌剪刀剪去棉签手接触部分。棉拭子放入剩余9 mL生理盐水内,尽快测定。按照GB/T 18204.4—2013《公共场所微生物检验方法第4 部分:公共用品用具微生物》检测菌落总数和霉菌数量[20]。

-

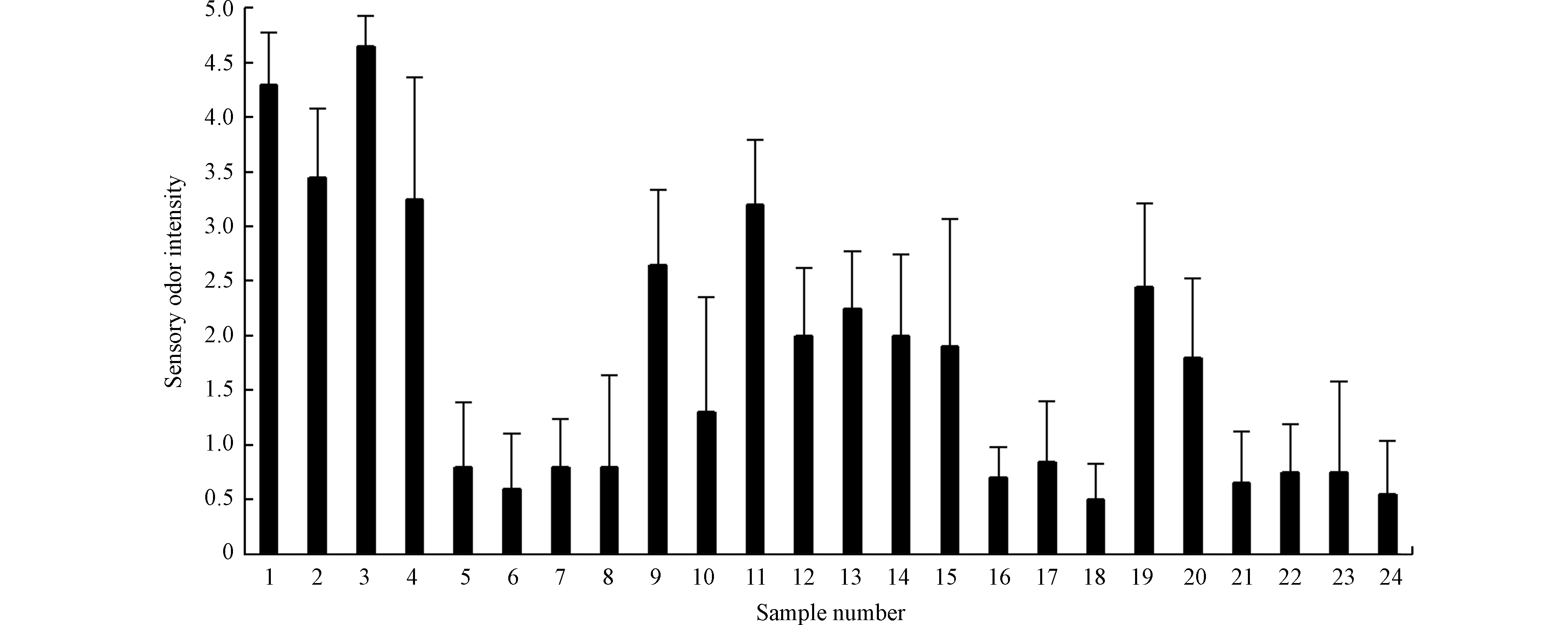

本试验首先对24种不同类型的活性炭滤网样品进行了感官评价,评分大于2的判定为存在异味,24个样品的感官气味评级如图1所示。由图1可以看出,所测样品中有8个明确存在异味。

同时,为了考察感官气味与滤网样品特征是否存在联系,对不同类型的活性炭样品进行赋值处理,运用SPSS软件对感官评分和滤网类型、是否添加催化剂、是否改性、是否用胶以及是否使用过总共8项因子进行了Spearman相关性分析,结果如表2所示。通过表2可以看出,酸臭味大小与活性炭滤网是否经过改性、活性炭种类、活性炭滤网的制备形式、是否在制作过程中使用有机胶粘剂无相关性,而与是否添加催化剂及是否使用过两项属性具有较高的相关性。由此可以初步判断,添加催化剂及长期使用的活性炭滤网更容易产生酸臭味。

-

考虑到这种难闻的酸臭味可能是由滤网释放的挥发性成分造成的,对感官评级结果中产生酸臭异味较明显的8块滤网使用吸附管采集-热脱附-气相色谱质谱进行测定。将检测的总离子流图中各峰一级质谱经计算机NIST08标准谱库检索鉴定,检测出挥发性成分匹配度大于80 的化合物。甲苯通常用于总挥发性有机化合物(TVOC)的测量,以及在参考化合物无法获得的情况下可用于单一VOC的定量[21],因此本实验采用甲苯对各VOCs的含量进行相对定量分析。在1.2.2节确定的实验条件下,甲苯的方法检出限为0.60 µg·m−3,实验结果如表3所示。

由表3可以看出,样品中检出的挥发性有机物质含量均较低,且以烷烃类为主,这类物质的嗅阈值通常较高,故对整体酸臭味的贡献可能不大,由此可见,滤网吸附空气中的可检出高浓度挥发性有机污染物并不是滤网产生异味的主要来源。并由此可推断产生酸臭异味物质的嗅阈值较低,其挥发到空气中的含量较少,通过空气捕捉采样的方法很难被检测到。此外,值得指出的是,受限于检测方法,本实验中未检出挥发性脂肪酸,是否存在挥发性脂肪酸以及其可能的异味贡献,值得进一步研究确认。

-

考虑到一些小分子有机酸可能是导致酸臭味产生的一个重要因素,因此对24个实验样品中的甲酸、乙酸、丙酸、丁酸和乳酸5种有机酸含量进行了测定。实验结果如图2所示。

由图2可以看出,小分子有机酸在测试样品中普遍存在,其中乙酸在感官评分大于2的样品中含量最为丰富。研究表明[22],小分子有机酸嗅阈值很低,且都有强烈的不愉快的味道,例如,乙酸具有刺激性的醋酸味,丁酸具有腐臭味,初步判断这些酸类可能是滤网酸臭味的主要贡献者,因此进一步采用SPSS软件对感官气味与5种有机酸及总酸(5种有机酸之和)之间进行相关性分析(表4)。

由表4可以看出,滤网酸臭异味的产生和总酸、乙酸、丙酸之间具有良好的相关性,和乳酸的含量相关性较小。而总酸与乙酸、丙酸、丁酸的3种小分子酸显著相关,说明总酸主要是由上述3种物质构成。结合图2可以看出,以乙酸为主的小分子有机酸可能是活性炭滤网产生酸臭味的主要原因。但是人居环境的空气中含有小分子有机酸的量极少,因此由净化器吸收空气中有机酸而导致酸臭异味产生的可能性较小。众所周知,活性炭对有机化合物具有很大的吸附能力,这与它们发达的内部孔结构、比表面积和表面官能团的存在有关,因此,可以采用热处理或化学处理,以提高活性炭的特殊功能和表面极性[23]。大量研究表明,活性炭表面含氧官能团的多少对有机物吸附性能起着重要的作用,改变活性炭表面酸性含氧官能团的数量和极性已被证明是增强极性有机化合物吸附的一种有效手段[24-26]。以往研究发现,含氧官能团在改性活性炭中十分常见,而且很容易被硝酸、过氧化氢、高锰酸钾、过硫酸铵、臭氧等氧化而引入。研究普遍采用了Boehm滴定法对活性炭表面的含氧官能团进行定量,均发现氧化改性后的活性炭表面含有大量的羧基和羰基[27-29]。综合以上分析,可以初步判定小分子有机酸是由活性炭表面的羧基脱落产生,尽而导致滤网酸臭异味发生。值得指出的是,净化器滤网捕捉到的有机物经过长时间的氧化作用(臭氧或氧气),也可能形成羧酸类,Hyttinen等在对接触臭氧的通风过滤器的实验室测试中发现了包括有机酸在内的氧化产物[30-31],这也是使用一段时间的活性炭滤网产生酸臭异味的几率较大的原因。

另外,经调研,目前市内空气净化活性炭多会添加锰系催化剂对甲醛进行催化,从而加大甲醛清除效果。一方面,锰系催化剂在生成过程中,某些工艺会用到有机酸-锰化合物作为原料[32-33],这些原料在最终催化剂中的降解残留也可能是小分子有机酸的来源之一。另外在催化氧化有机污染物的过程中,有时也会有一些有毒的醛类、酮类以及有机酸等有机副产物的产生[34-35]。

-

为了考察无机酸根离子和酸碱性与滤网酸臭味的产生是否存在联系,利用离子色谱、酸度计对24个样品的阴离子及PH值进行了测定,并与感官等级评价进行相关性分析,结果如图3、表5和表6所示。

由图3可以看出,感官气味强度并没有随无机离子含量的不同而出现规律性变化。相关性分析结果显示(表5和表6),感官气味与无机酸根离子及pH值无显著相关性,表明了酸臭异味不是由无机酸根离子产生,也不会随着活性炭自身pH值偏酸而加重。相比之下,总离子与PO43-离子及pH值之间呈现出了较高的相关性,说明活性炭上的无机阴离子以PO43-离子为主,这与图3离子色谱的测定结果相一致,另一方面也反映出活性炭pH值和活性炭水浸提液中的PO43-离子含量存在一定程度的联系。

-

人们通常认为空气净化器滤网产生酸臭异味可能是由于长期放置导致“发霉变质”产生的。为此本实验截取了不同种类的活性炭滤网材料,通过对滤网材料进行微生物培养,利用平板计数法进行统计分析,并与感官气味进行相关性分析,结果如表7所示。由表7可以看出,感官气味与菌落总数及霉菌数相关程度均较低,可以推断活性炭滤网的酸臭异味由细菌滋生的贡献较小。但滤网本身确有可能生长霉菌,建议使用者定期更换滤膜并进行清洁保养。

-

本文首先通过感官评价与滤网样品特征进行了Spearman相关性分析,发现使用过的滤网,以及添加催化剂的滤网比较容易产生酸臭异味。进一步通过气相色谱质谱、离子色谱等多种仪器从酸臭异味的角度对滤网样本进行剖析,通过与感官评分的相关性分析,判断出以乙酸为主的小分子有机酸可能是活性炭滤网酸臭异味的主要贡献者,并且很可能源于活性炭表面羧基基团脱落、常用催化剂的降解残留以及使用过程中的催化氧化。无机酸根离子、活性炭自身酸碱性及细菌滋生对滤网酸臭异味的贡献较小。值得指出的是,受限于检测方法,酸臭明显的气味与气相色谱鉴定出的主峰并不相关,这表明嗅阈值低的微量化合物可能是重要的气味贡献者之一。为了精确测定这些异味活性物质,需要更复杂和耗时的方法。目前这项研究的目标是对净化器滤网中不愉快的酸臭气味进行相关特性分析,以便了解潜在的异味来源和形成途径,以期为改善活性炭滤芯生产工艺与防治异味提供科学参考依据。

Characteristics and sources apportionment of sour odor in activated carbon filter of indoor air purifier

- Received Date: 08/05/2021

- Accepted Date: 26/05/2021

- Available Online: 27/09/2022

-

Key words:

- air purifier /

- filter /

- sour odor /

- characteristics /

- source apportionment

Abstract: Air purifier will produce a strong sour odor after a period of use, which will seriously affect the use experience of consumers. In order to investigate the cause and source of the sour odor, this study first adopted sensory grade evaluation to obtain the characteristics of the filter samples with sour odor. Then, a variety of instruments such as gas chromatography-mass spectrometry and ion chromatography were further used to analyze the filter samples from the perspective of sour odor, and the correlation analysis was carried out by combining sensory grade scores. Results showed that small molecular organic acids, mainly acetic acid, may be the main contributors to the odor of activated carbon filter. According to the literature investigation, it can be inferred that the source is probably from the removal of the surface carboxyl group of activated carbon, the degradation of commonly used catalysts and the catalytic oxidation in the process of use. In addition, trace compounds with a low olfactory threshold may also be one of the important odor contributors. On the basis of the experimental study, the potential odor sources and formation pathways of activated carbon filter were identified, in order to provide scientific reference for improving the production process of activated carbon filter and preventing and controlling odor.

DownLoad:

DownLoad: