-

厌氧生物处理技术开发至今已有100多年的应用历史,在早期,由于对厌氧作用及其处理效率的误解,因此,在相当长的一段时间内,其发展落后于废水好氧生物处理技术的发展。至20世纪60年代,随着水环境污染加剧以及能源短缺问题日益突出,厌氧生物处理技术被重新重视,并逐渐得到广泛的应用。

从近几十年厌氧技术的发展来看,在微观上,进一步明确了厌氧生物处理的反应机理;在宏观上,厌氧反应器的发展从最初的普通污泥消化池到如今的第3代厌氧反应器,新型的高效厌氧反应器被不断开发,它们共同的特点是:更高的处理负荷;更强的生物截留能力;更佳的传质条件;更稳定的处理效率。

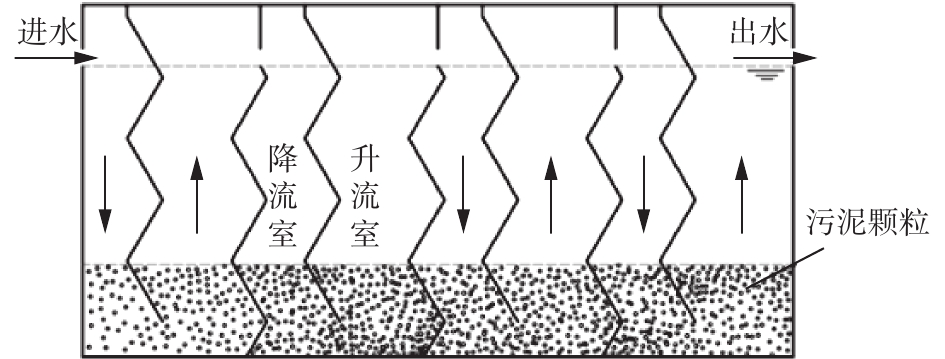

厌氧折流板反应器(ABR)作为第3代厌氧反应器的杰出代表工艺之一,首先是由斯坦福大学的MCCARTY[1]提出的一种高效厌氧反应器。从概念上说,ABR可以表示为一系列垂直安装的折流板分割串联而成的上流式厌氧污泥床(UASB)反应器,这些挡板使得废水在反应器中呈现上下流动状态[2-3]。ABR具有结构简单、生物截留能力强、处理效果好、运行管理方便等优点。目前,在高浓度有机废水的发酵产沼气以及中、低浓度难降解工业废水的水解酸化处理上均有一定的应用,具有很高的推广价值。

改良型ABR厌氧反应器(mABR)是将传统ABR的折流板结构设计成波纹折流形式,在保留原有反应器优点的基础上,进一步延长水流在反应器内部的流径,形成更强烈的涡流和湍流扩散作用,从而使整个反应系统的传质效率显著提高,为提高有机物的去除创造更有利的条件[4-5]。LI等[6]通过水力实验得出异波形式ABR比传统ABR水力死区小。

目前,国内外对ABR的研究主要集中在污水处理效果方面,在ABR设计方面大多数依据经验参数,对反应器内部流场无法精确预测[7-11]。计算流体力学(computational fluid dynamics,CFD)是一种解决流体流动和传热以及其他相关物理和生化过程的数值方法,它已被广泛和成功地用于废水处理系统的研究[12-15]。CFD能够提供详细的流场空间分布的有力方法[16],近年来的快速发展进一步促进了人们对废水处理构筑物流场的认识[17]。CFD允许在许多不同的设计约束下使用计算模型,是水处理装置设计和优化的有效工具[18]。刘伟京等[19]通过对苏北某化工园区ABR进行数值模拟改造后,反应器的水力特性、处理效果和抗冲击负荷能力均得到较大的提升。因此,本研究从数值仿真角度,基于CFD-fluent软件平台,对mABR进行两相流(难降解废水水解酸化)和三相流(高浓度有机废水发酵产沼)数值模拟,针对反应器内水流速度及固含率分布特征,探索不同升流速度对反应器内流场及水力特性的影响,为mABR的进一步推广应用提供参考。

-

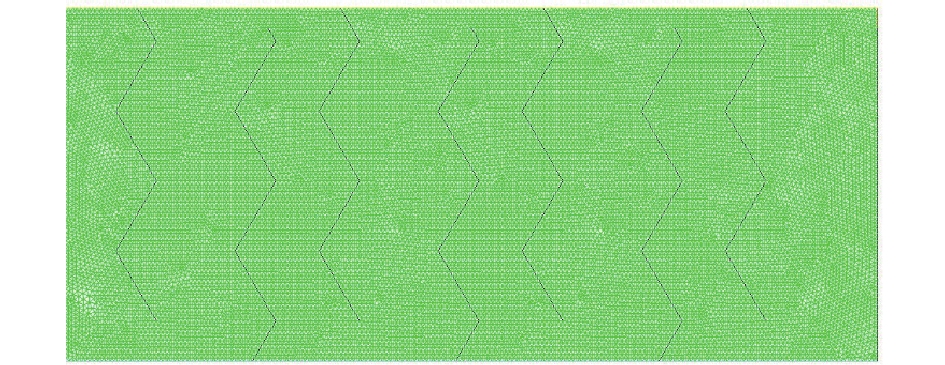

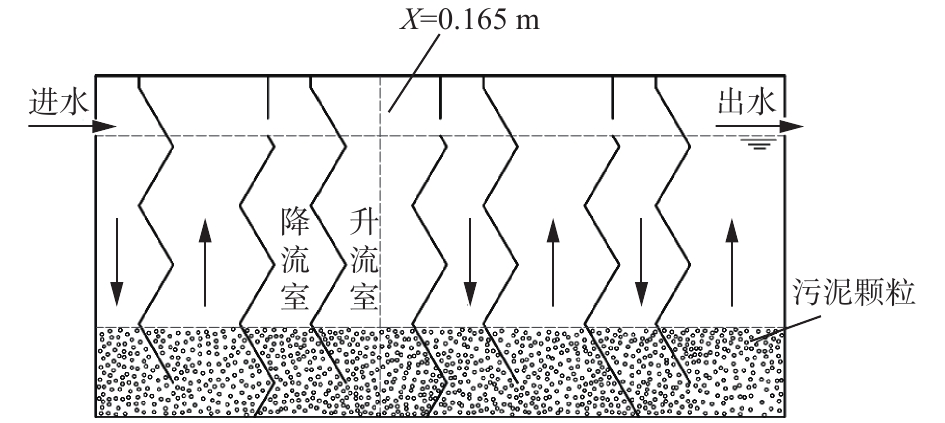

几何模型源于耿亚鸽[20]的研究并将其平面折流板改为异波折流板,在ICEM CFD 16.0中建立mABR的二维模型。模型长400 mm,宽100 mm,高200 mm,有效水深175 mm,总容积8 L,有效容积7 L,故将有效水深175 mm位置设置为自由液面。其中,反应器由4个隔室组成,隔室由上下流室组成,进出口管的管径为10 mm,mABR中的异波夹角为120°,波高为20 mm,波峰平行,模型的装置如图1所示。

-

当两相流模拟时,设定水为主相,颗粒污泥为第2相。当3相流产甲烷时,设定水为主相,颗粒污泥为第2相,甲烷为第3相,均为不可压缩的流体,不考虑每个相之间的质量和能量传递作用。外界的大气压强为101 325 Pa,重力加速度为−9.81 m·s−2,温度为20 ℃,反应器的液相(水)-固相(颗粒污泥)-气相(甲烷)的常用物理参数如表1所示。

-

网格划分的精度在CFD模拟过程中是一个重要的指标,基于mABR结构的特点,本次模拟将反应器简化为二维三角形非结构化网格划分,共44 308个,网格划分如图2所示。

-

由于mABR内的水流形态复杂,标准k-ε湍流模型[21]是最简单和完整的湍流模型,在学术界和工业界都得到广泛的认可和使用,计算工作量方面经济实惠,对于各种湍流问题中具有精确的准确性,故实验采用欧拉多相流数学模型[22-23]和标准k-ε湍流模型。将反应器内液相(水)作为连续相,气相(甲烷)和固相(污泥颗粒)为离散相,并将离散相视作与连续相相互渗透的拟流体。控制方程采用有限体积法对其进行离散化,均采用一阶迎风格式,采用SIMPLE算法。

-

1)进口边界条件。进水管及三相流底部进气均采用速度进口条件,设置两相流升流速度为0.5、1.0、1.5、2.0和2.5 m·h−1,则相应的进水流速度为0.010 4、0.020 8、0.031 2、0.041 6和0.051 9 m·s−1。三相流给定的升流速度为0.5、1.0、1.25、1.5和2.0 m·h−1,故相应的进水流速度是0.010 4、0.020 8、0.026 0、0.031 2和0.041 6 m·s−1,由于三相流时单独产甲烷,所以气相的体积设置为1,相间无滑移,假设产气量为6.0 L·h−1,故产气的速度是4.17×10−5 m·s−1。

2)出口边界条件。出水管口采用自由出流的边界条件。

3)壁面边界条件。反应器边壁和折流板设置为壁面边界,均采用无滑移边界条件。

-

在初始时刻,整个反应器内流场视为静水,除进水端外,其余全部流场速度均为0 m·s−1。设置y=175 mm截面为自由液面的高度,y=0~52.5 mm区域内的固相(污泥颗粒)体积分数为0.3(污泥浓度3 g·L−1);液相(水)体积分数为0.7;气相(甲烷)为0;在y=52.5~175 mm区域液相体积为1;固、气的体积分数均为0。

-

采用瞬态模型进行求解计算,时间步长设置为0.001 s,时间步数设置为20 000步,表示有较好的收敛性和稳定性,最大迭代次数/时间轴设置为20次,表示每一个时间步最多进行20次迭代计算。

-

升流室的升流速度是ABR设计的关键参数。本研究在固定其他操作参数不变的情况下,改变升流速度为0.5、1.0、1.25、1.5、2.0和2.5 m·h−1,模拟两相流和三相流工况,分析不同升流速度在两相流和三相流时对mABR水力特性的影响,在分析反应器内部流场分布、固体含率分布的同时,确定在不同应用条件下最优的升流速度参数。

-

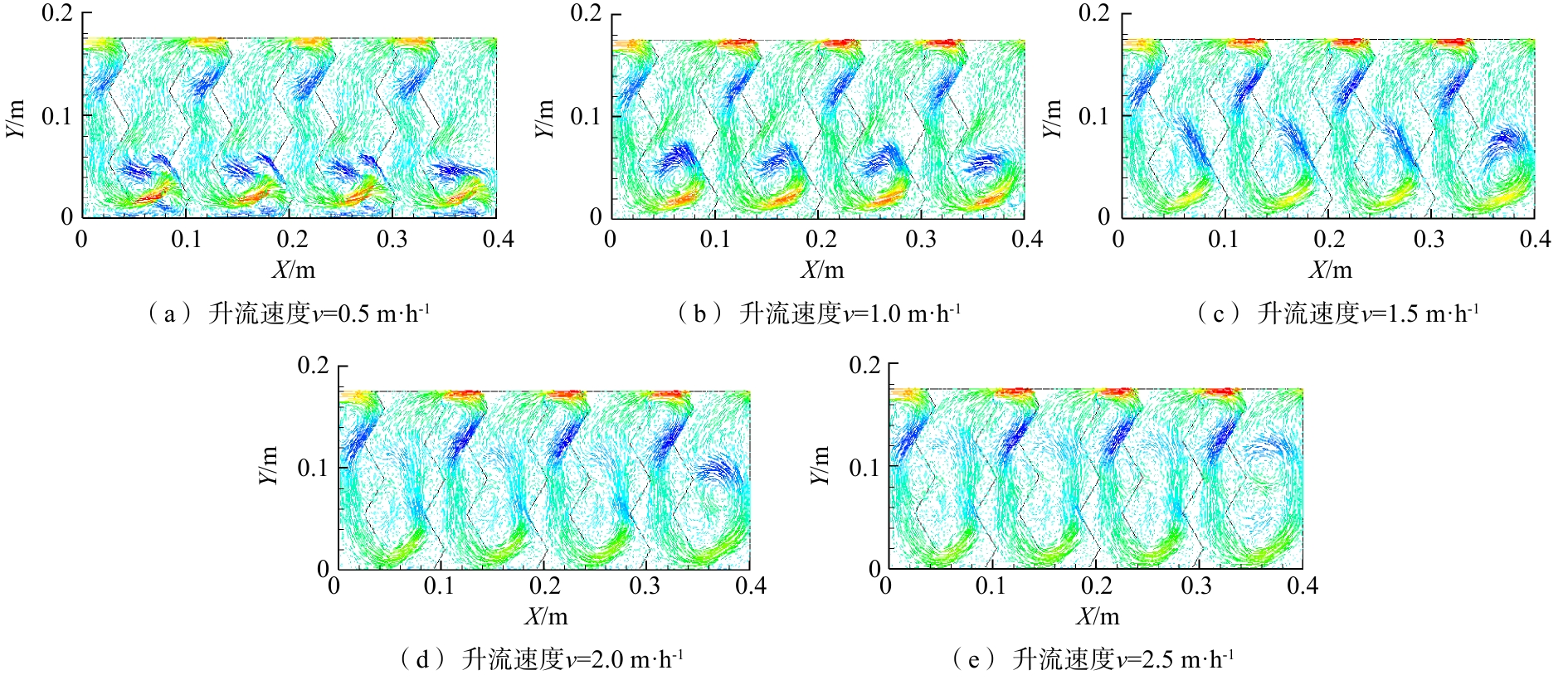

1)两相流反应器内部流速矢量分布。图3表示两相流条件下不同升流速度水流流场分布。由图3可知,由于波纹折流挡板的阻挡作用,表观水流产生波形运动,使反应器升流室内产生大大小小的涡流,随着升流速度的增加,在升流室,涡流数逐渐增加。在低升流速度时,反应器内的涡流少,并且分布在反应器升流室底部折板挡板附近;在高升流速度时,涡流多且分布在反应器的上、中、下部。

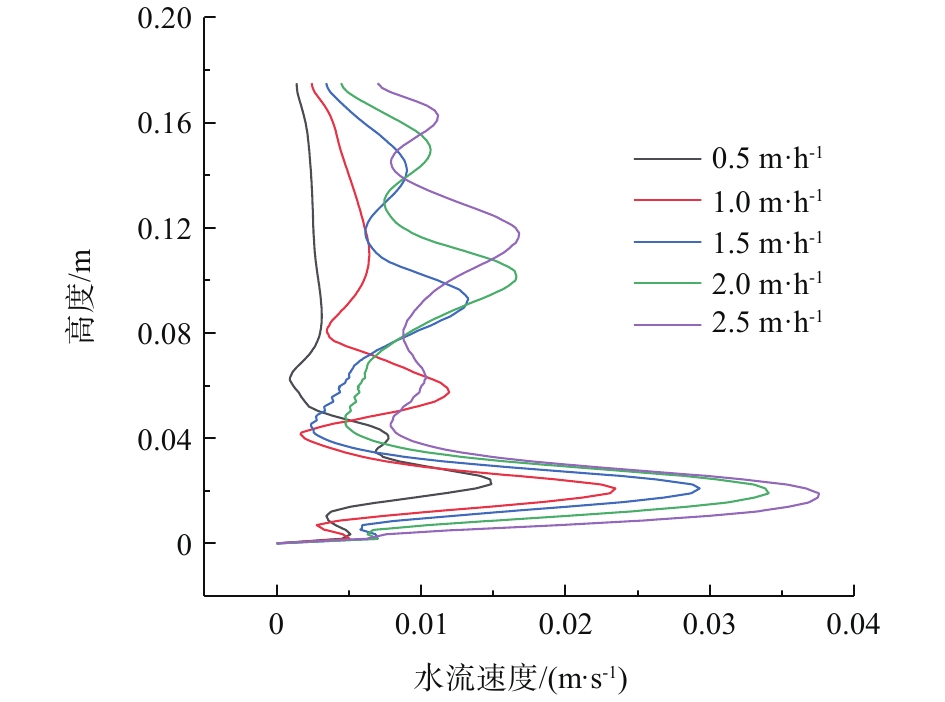

mABR为多隔室折流反应器,除进水和出水隔室外,其余隔室基本相同。本研究针对第2反应室X=0.165 m位置水流速度进行研究分析,结果如图4所示。

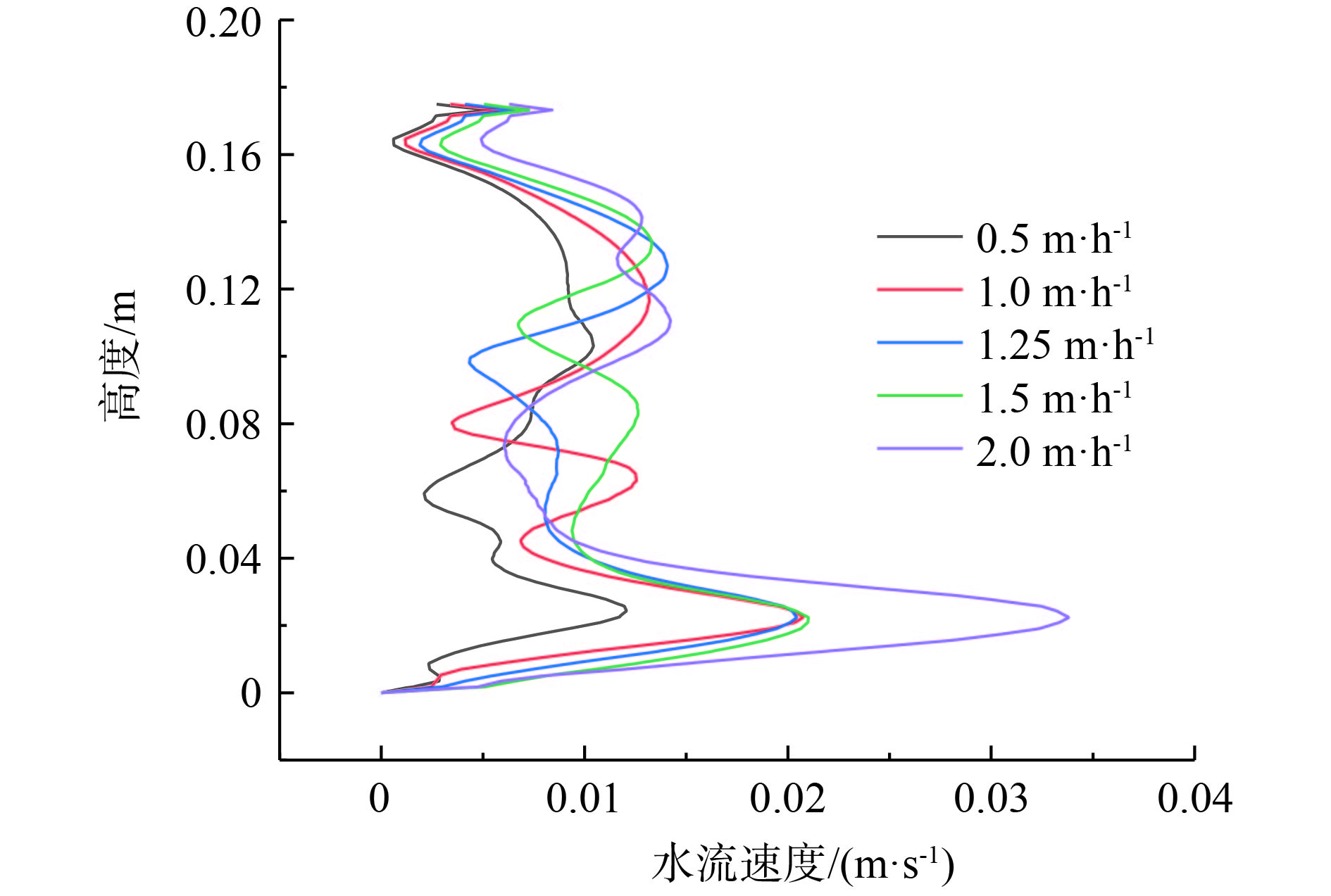

图5为不同升流速度下第2升流隔室X=0.165 m处垂直水流速度分布曲线。可以看出,无论升流速度如何变化,水流速度在反应器底部向下流转为向上流时为最大,这有利于防止固相污泥颗粒在反应器的底部过分沉积。随后由于异波折流板的消能以及水流速度方向的改变作用,水流速度迅速减小,当升流速度为0.5 m·h−1和1.0 m·h−1时,水流的扰动存在反应器的下部,而在反应器的中、上部,水流呈现平稳推流形态。当升流速度为1.5、2.0和2.5 m·h−1时,扰动幅度和次数与0.5 m·h−1和1.0 m·h−1相比都明显增大、增多,这有利于泥水混合和接触停留,加大了传质和生物降解效果。

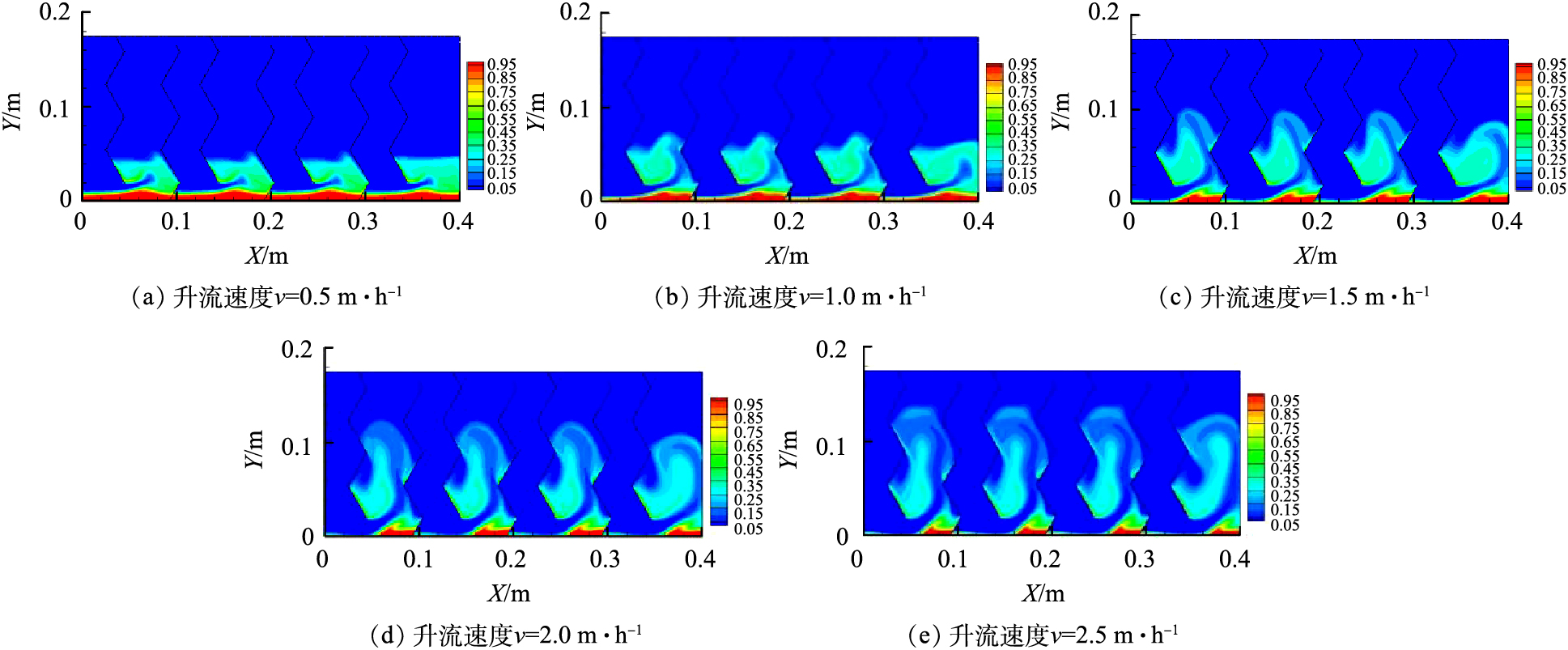

2)两相流反应器固含率的分布。图6表示两相流条件下不同升流速度固含率(污泥颗粒体积百分数)的分布。从图6(a)和图6(b)中可以看出,在升流速度为0.5 m·h−1和1.0 m·h−1时,由于升流速度过小,大量的污泥颗粒没有被水流冲刷起来,堆积在反应器的底部,形成死区,不利于泥水混合,并且反应器内涡流少,反应器的中、上部都为推流流态,使得反应器总体处理效率低。如图6(c)和图6(d)所示,当升流速度为1.5 m·h−1和2.0 m·h−1时,反应器底部污泥颗粒堆积量减少,污泥颗粒被冲刷至反应器中、下部和中部附近。由于内部涡流的存在,大量的污泥颗粒与水得到了均匀充分地混合,使得反应器的处理效率得到了很大的提高。

如图6(e)所示,当升流速度为2.5 m·h−1时,反应器内存在的涡流数进一步增多,污泥颗粒被冲刷分布在反应器大部分区域,底部污泥颗粒堆积量少,但是反应室存在少量污泥颗粒流失现象(如图7所示),污泥颗粒被冲刷至下一个反应室。因此,虽然较大的升流速度有利于泥水混合,但当升流速度过大时,升流室的污泥循环流速加快,污泥颗粒被水冲刷至反应器中、上半部,造成颗粒污泥流失,从而降低了污泥颗粒在反应器内的含量。

因此,过高的升流速度或过低的升流速度都不能够提高反应器去除率,在两相流条件下,当升流速度为2.0 m·h−1和2.5 m·h−1时,反应器中泥水混合效果较好,反应器的处理效果相对比较高,不存在大量污泥层堆积等现象。

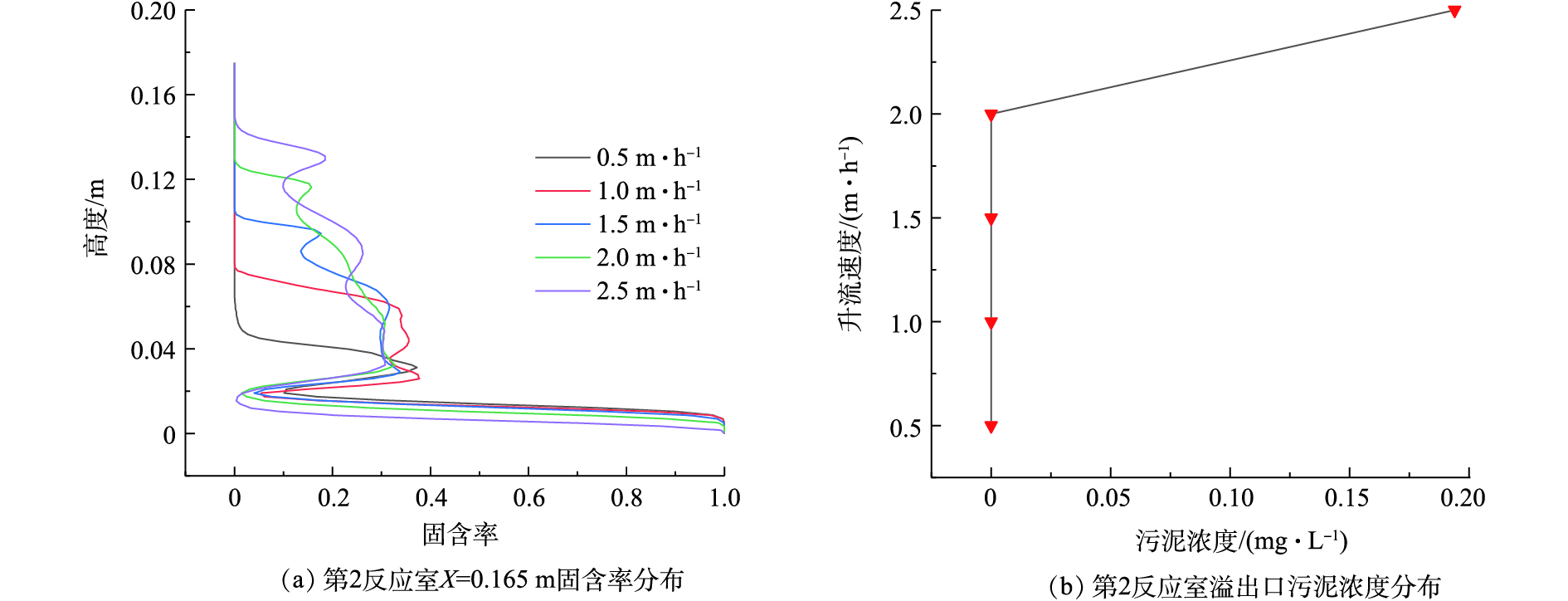

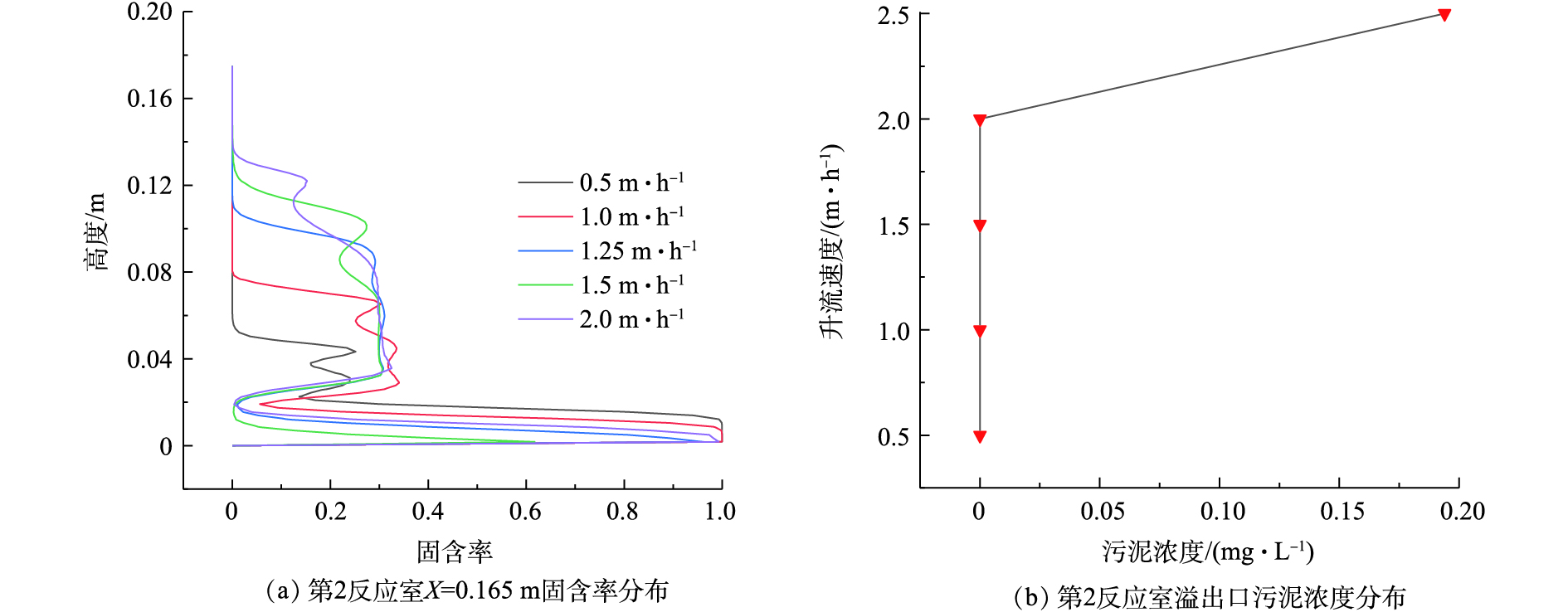

图7表示两相流条件下不同升流速度升流室X=0.165 m以及第2反应室出口固含率分布。由图7(a)中可以看出,由于折流板是异波形状,水流进入反应器之后,不断地被异波作用改变原有水流方向,形成大大小小的涡流,所以固含率的分布同样随水流不断地发生扰动变化,但升流速度越小,变化的幅度和高度越小,反之越大。

当升流速度为0.5 m·h−1时,升流室内水流上升流速过小,污泥颗粒的沉降效果明显,大部分污泥颗粒未被冲刷起来,所以污泥颗粒主要沉积在反应器底部。当升流速度为1.0 m·h−1时,虽然升流室内水流速度有所增加,污泥颗粒被冲刷至一定高度,但污泥颗粒基本仍然分布在反应器的中、下部。当升流速度升至1.5 m·h−1和2.0 m·h−1时,污泥层被水流冲刷至反应器的中、上部,泥水混合效果好,没有污泥颗粒流失。升流速度为2.5 m·h−1时,污泥颗粒同样分布在反应器中、上部,但是在第2反应室出口位置,存在少量污泥颗粒流失现象(如图7(b)所示)。

-

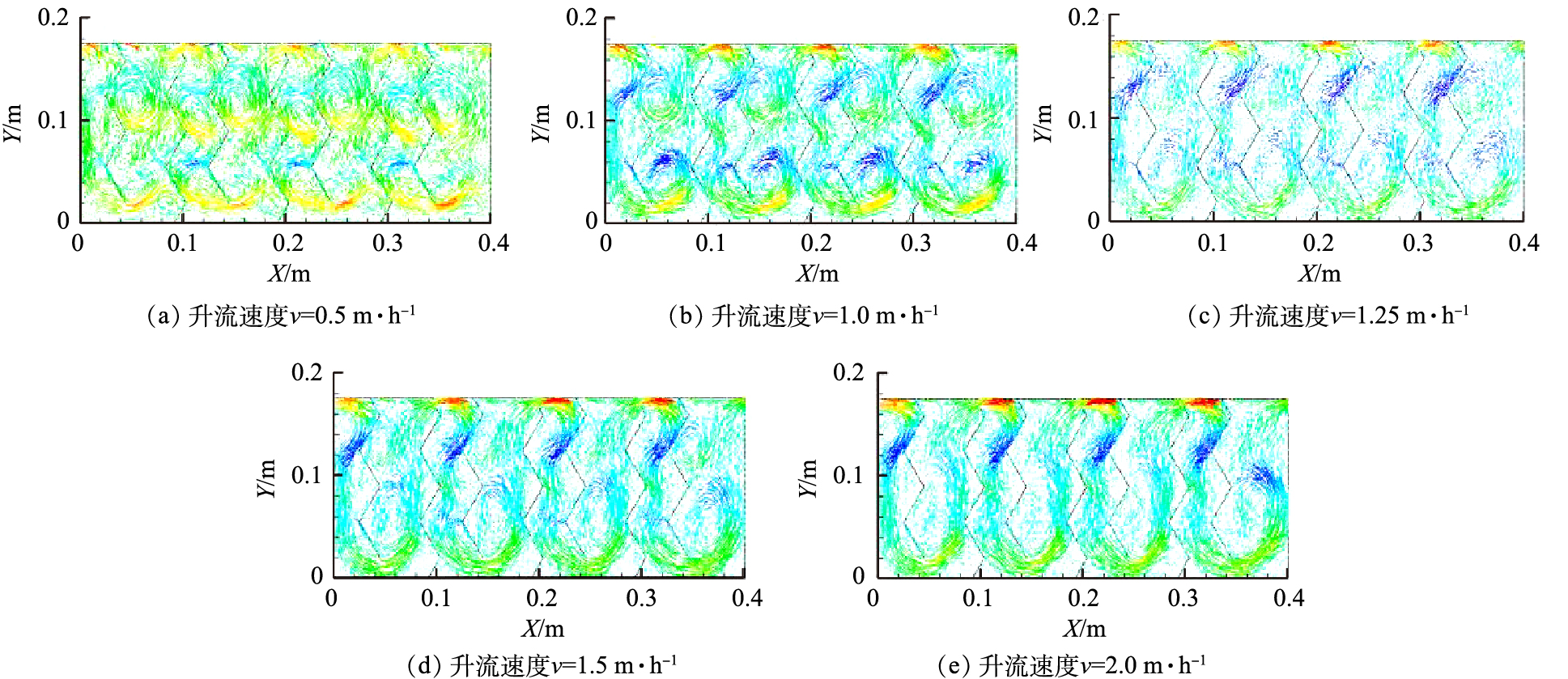

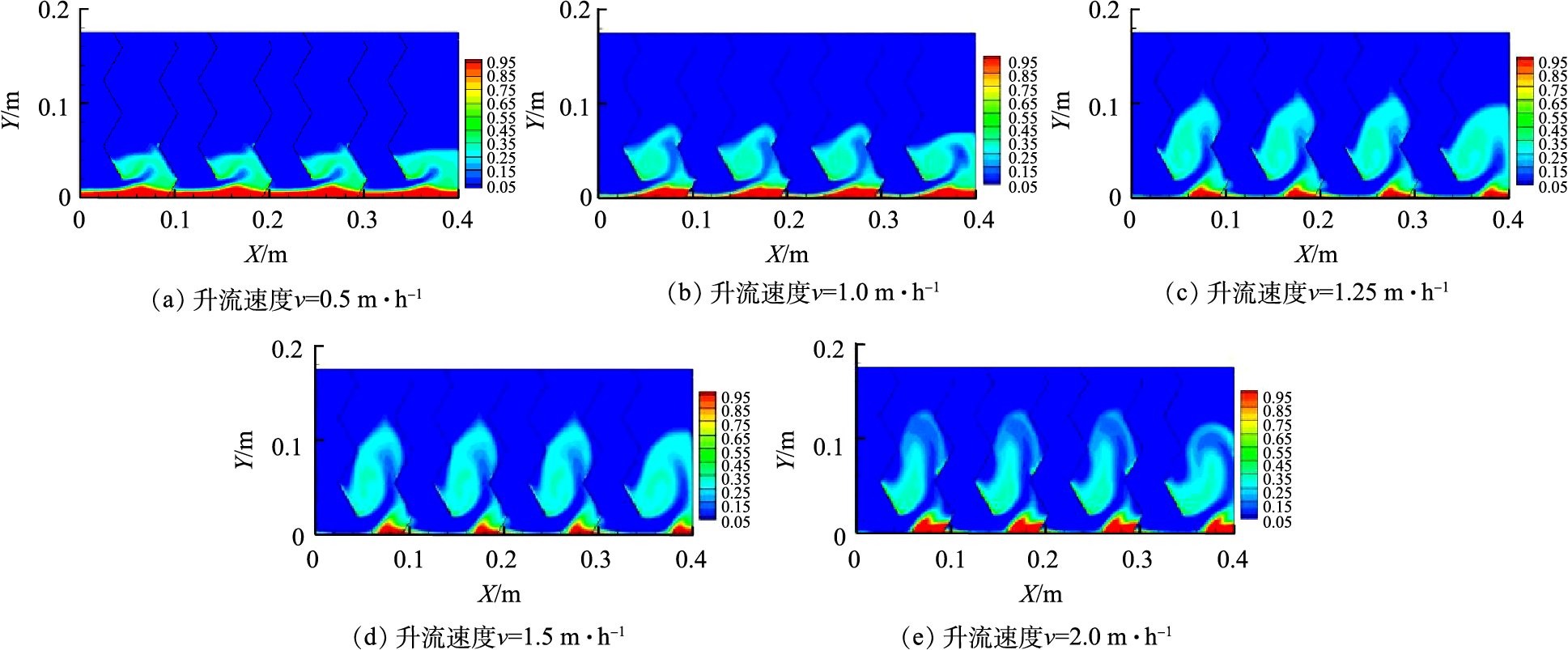

1)三相流反应器流速矢量分布。图8表示三相流条件下不同升流速度水流流场分布云图。由图8可知,反应器内部产甲烷的搅动作用,在低升流速度时,较二相流有更多涡流存在并集中在反应器的中部和中上部。但随着升流速度加大,由于气泡的快速上升,升流室中、上部涡流反而逐渐减小。

图9表示三相流条件下不同升流速度反应器垂直水流速度分布曲线。可以看出,因为产甲烷作用,所以在升流室内上、中、下部都存在涡流,整体水流呈现扰动絮流变化较两相流更为剧烈的情况。随着升流速度的增加,水流变化幅度逐步变大。

2)三相流反应器内固含率分布。图10表示三相流条件下不同升流速度固含率分布。由图10(a)和图10(b)可知,升流速度为0.5 m·h−1和1.0 m·h−1时,在反应器的底部依然存在大量的污泥颗粒。由图10(c)可知,当升流速度增大至1.25 m·h−1时,大量的污泥颗粒被冲刷到反应器中部范围。由图10(d)可知,当升流速度为1.5 m·h−1时,污泥颗粒被冲刷到反应器的中、上部区域。由图10(e)可知,当升流速度为2.0 m·h−1时,相比于升流速度为1.5 m·h−1,分布的区域范围更广。

图11表示三相流条件下不同升流速度X=0.165 m以及第2反应室出口固含率分布。由图11(a)可知,在0.03 m水深以下,不同升流速度固含率分布趋势大体相同,反应器底部有一定的污泥沉积。升流速度为0.5 m·h−1和1.0 m·h−1时,因为水流运动方向向上且速度较小,污泥颗粒上升运动不明显,所以固含率主要分布升流室中、下部。当升流速度升至1.25 m·h−1和1.5 m·h−1时,水流上升流速增加,污泥层被进一步抬升,升流室固含率分布在中、上部区域以下。当升流速度为2.0 m·h−1时,污泥层有更高的抬升,固含率分布的区域更广,到达自由液面附近,但是污泥颗粒由于产气和上升水流速度过大,造成第2反应室出口出现污泥颗粒少量流失的情况(如图11(b)所示)。

-

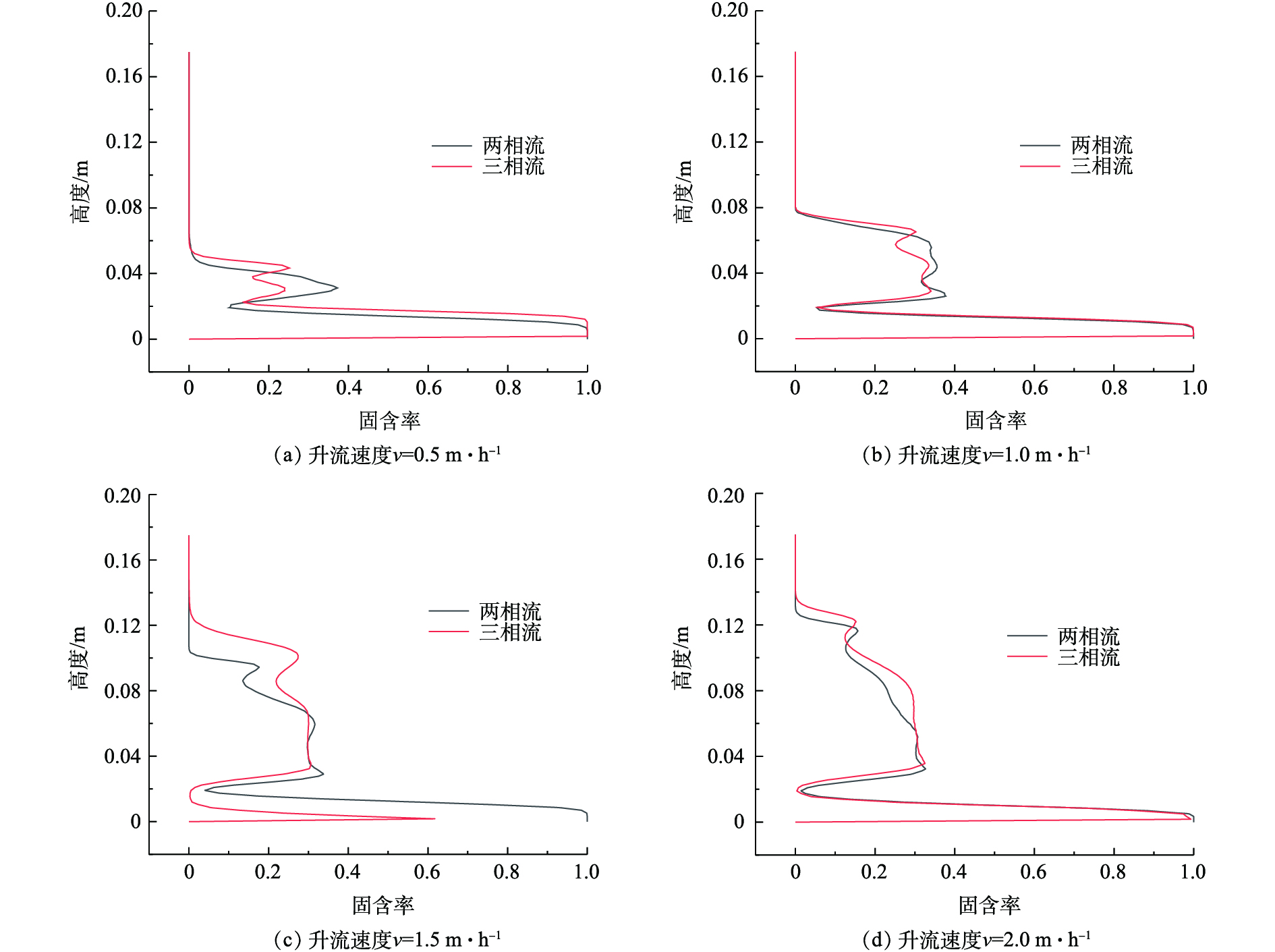

图12表示两相流与三相流固含率的分布曲线。可以看出,由于水流及内部产甲烷的共同作用,使得三相流较二相流升流室内污泥颗粒更容易被带至更高的区域,获得更好的泥水混合条件。当升流速度小于1.0 m·h−1时,由于速度过小,无论是两相流还是三相流,污泥颗粒都容易聚集于反应器底部,由于水力搅拌不明显,造成反应器泥水混合不足,生化反应效率下降。过高的升流速度(三相流升流速度大于2.0 m·h−1,两相流升流速度大于2.5 m·h−1),虽然减少了死区,但是由于流速过快造成污泥颗粒流失,从而使反应器生物截留量下降,污泥颗粒含量减小,降低了污泥与污染物之间的接触效果。因此,过高的升流速度和过低的升流速度都不利于反应器的整体去除效率,合理的升流速度有益于水力搅拌,使得污泥颗粒更好地与废水混合,从而提高了COD去除。

-

1)由于波纹状的折流挡板的阻挡作用,mABR在一定的升流速度下,反应器升流室内可产生较多的涡流,有利于反应器内部泥水混合,加速传质,增加反应接触时间,有利于提高反应器的生物处理效率。

2)反应器内各升流室垂直速度随升流速度增大,扰动变化幅度变大,涡流数量增多,升流室污泥高度也随着升流速度的增加而抬高。在相同升流速度时,三相流由于产气以及气泡的上升扰动,能够获得较二相流更好的泥水混合条件。但过高的升流速度(三相流升流速度大于2.0 m·h−1,两相流升流速度大于2.5 m·h−1)容易造成污泥颗粒流失,使反应器生物截留量下降,污泥颗粒含量减小,从而降低了反应器厌氧生物处理效率。

3)基于模拟研究结果,在厌氧折流板反应器(ABR)的设计应用过程中,针对高浓度有机废水的厌氧产沼气处理,建议升流室的升流速度宜控制为1.5~2.0 m·h−1;而针对难生物降解工业废水的水解酸化ABR设计,升流室的升流速度可适当提升至2.0~2.5 m·h−1。

基于CFD模拟改良型厌氧折流板反应器(mABR)水力特性

Hydraulic characteristics of modified anaerobic baffled reactor (mABR) based on CFD simulation

-

摘要: 改良型厌氧折流板反应器(modified anaerobic baffled reactor,mABR)的处理效率受水力特性的影响很大,而反应器升流室的升流速度又是影响反应器内水力特性的重要参数。使用CFD-fluent软件平台进行二维多相流数值模拟,在难降解废水水解酸化(固-液两相流)与高浓度有机废水发酵产气(气-液-固三相流)条件下,针对水流速度与固含率的变化,探究不同升流速度对反应器内流场特性的影响。结果表明:升流速度的增加及反应器厌氧产气有利于抬升泥水界面,促进泥水混合,提高传质效率;但过高的升流速度将导致污泥流失,使生物量的保持能力下降。通过分析可知,当两相流和三相流升流速度分别为2.0~2.5 m·h−1和1.5~2.0 m·h−1时,水力搅动及固含率分布较为显著,有利于泥水混合,使得反应器去除污染物效率最佳。

-

关键词:

- 改良型厌氧折流板反应器(mABR) /

- 多相流 /

- 升流速度 /

- 固含率

Abstract: The treatment efficiency of the modified anaerobic baffled reactor (mABR) is greatly affected by the hydraulic characteristics, which is specifically influenced by upflow velocity of the riser chamber. In this study, two-dimensional multiphase-flow with CFD-fluent software was used to perform the numerically simulation for two-dimensional multi-phase flow. Under conditions of hydrolytic acidification (solid-liquid two-phase flow) of refractory wastewater and fermentation-gas yield (gas-liquid-solid three-phase flow) of high-concentration organic wastewater, when the variations of flow velocity and solid content occurred, the effects of upflow velocity on the flow field characteristics in mABR were investigated.. The results showed that the increase of upflow velocity and anaerobic biogas production was beneficial to the sludge-water interface lifting, sludge-water mixing enhancement and mass-transfer efficiency improvement. However, exorbitant upflow velocity could result in sludge loss and reduce the hold capacity of biomass. As a result analysis, the hydraulic agitation and solid content are preferable for sludge-water mixing at an upflow velocity of 2.0~2.5 m·h−1 for two-phase flow or an upflow velocity of 1.5~2.0 m·h−1 for three-phase flow, achieving the best pollutants removal performance. -

-

表 1 各相物理参数

Table 1. Physical parameters of each phase

物质 密度/(kg·m−3) 动力黏度/(Pa·s) 粒径/mm 液相(水) 999.8 1.003×10−3 — 固相(污泥颗粒) 1 006 2.001×10−3 1 气相(甲烷) 0.667 9 1.087×10−5 1 -

[1] MCCARTY P L. One hundred years of anaerobic treatment digestion[M]//HUGHES E. Anaerobic Digestion: Vol.1. Amsterdam: Elsevier Biomedical Press, 1981: 3-21. [2] MARIN J, KENNEDY K J, ESKICIOGLU C. Characterization of an anaerobic baffled reactor treating dilute aircraft deicing fluid and long term effects of operation on granular biomass[J]. Bioresource Technology, 2010, 101(7): 2217-2223. doi: 10.1016/j.biortech.2009.11.055 [3] WILLIAM P R, DAVID C Y. The use of the anaerobic baffled reactor (ABR) for wastewater treatment: A review[J]. Water Research, 1999, 33(7): 1559-1578. doi: 10.1016/S0043-1354(98)00371-6 [4] 李胜男. 基于水力学特性的改良型厌氧折流板反器(mABR)运行效能及数值模拟研究[D]. 哈尔滨: 哈尔滨工业大学, 2016. [5] 宋铁红. 不等距异波复合厌氧反应器高效机理及水力特性研究[D]. 长春: 吉林大学, 2008. [6] LI S N, NAN J, YU H, et al. Comparative analyses of hydraulic characteristics between the different structures of two anaerobic baffled reactors (ABRs)[J]. Ecological Engineering, 2015, 82: 138-144. doi: 10.1016/j.ecoleng.2015.04.095 [7] PICHET N, KUPRIANOV V I. Experimental investigation and empirical modeling of flow regimes and hydrodynamic characteristics of a cone-shaped bed using sand-biomass binary mixtures[J]. Chemical Engineering and Processing: Process Intensification, 2018, 131: 1-11. doi: 10.1016/j.cep.2018.06.025 [8] LI J, SHI E, ANTWI P, et al. Modeling the performance of an anaerobic baffled reactor with the variation of hydraulic retention time[J]. Bioresource Technology, 2016, 214: 477-486. doi: 10.1016/j.biortech.2016.04.128 [9] HASSANVAND J M, ALIGHARDASHI A. Application of froude dynamic similitude in anaerobic baffled reactors to prediction of hydrodynamic characteristics of a prototype reactor using a model reactor[J]. Water Science and Engineering, 2017, 10(1): 53-58. doi: 10.1016/j.wse.2017.03.002 [10] LIU X L, REN N Q, WAN C L. Hydrodynamic characteristics of a four-compartment periodic anaerobic baffled reactor[J]. Journal of Environmental Sciences, 2007, 19(10): 1159-1165. doi: 10.1016/S1001-0742(07)60189-2 [11] LI S N, NAN J, GAO F. Hydraulic characteristics and performance modeling of a modified anaerobic baffled reactor (MABR)[J]. Chemical Engineering Journal, 2016, 284: 85-92. doi: 10.1016/j.cej.2015.08.129 [12] MICHALOPOU L I, KAMPERIDIS T, SEINTIS G, et al. Experimental and numerical assessment of the hydraulic behavior of a pilot-scale periodic anaerobic baffled reactor (PABR)[J]. Computers & Chemical Engineering, 2018, 111: 278-287. [13] HU Y F, DAN J F, PU W H, et al. CFD optimization of the baffle angle of an expanded granular sludge bed reactor[J]. Journal of Environmental Chemical Engineering, 2017, 5(5): 4531-4538. doi: 10.1016/j.jece.2017.07.050 [14] QI W K, HO JO T, LI Y Y. Hydraulic characteristics simulation of an innovative self-agitation anaerobic baffled reactor (SA-ABR)[J]. Bioresource Technology, 2013, 136: 94-101. doi: 10.1016/j.biortech.2013.02.033 [15] KAR PINS KA A M, BRIDGEMAN J. CFD-aided modelling of activated sludge systems: A critical review[J]. Water Research, 2015, 88: 861-879. [16] SÁNCHEZ F, REY H, VIED M A, et al. CFD simulation of fluid dynamic and biokinetic processes within activated sludge reactors under intermittent aeration regime[J]. Water Research, 2018, 139: 47-57. doi: 10.1016/j.watres.2018.03.067 [17] LIU M Y. Age distribution and the degree of mixing in continuous flow stirred tank reactors[J]. Chemical Engineering Science, 2011, 69(1): 382-393. [18] ZHANG J, CHANG X G, LIU J S, et al. Structural characteristics of a spiral symmetry stream anaerobic bioreactor based on CFD[J]. Biochemical Engineering Journal, 2018, 137: 50-61. doi: 10.1016/j.bej.2018.05.016 [19] 刘伟京, 李根锋, 徐军, 等. 厌氧折流板反应器的水力流态模拟及优化[J]. 中国给水排水, 2012, 28(11): 6-9. doi: 10.3969/j.issn.1000-4602.2012.11.002 [20] 耿亚鸽. 厌氧折流板反应器的水力特性实验与流场模拟研究[D]. 郑州: 郑州大学, 2008. [21] LAUNDER B E, SPALDING D B. The numerical computation of turbulent flows[J]. Computer Methods in Applied Mechanics and Engineering, 1974, 3(2): 269-289. doi: 10.1016/0045-7825(74)90029-2 [22] 刘大有. 二相流体动力学[M]. 北京: 高等教育出版社, 2007. [23] 车德福, 李会雄. 多相流及其应用[D]. 西安: 西安交通大学出版社, 2007. -

下载:

下载: