-

脱氮除磷是污水处理厂的重要任务。生物法脱氮除磷比物化法更具经济性和环保效益[1],但其运行条件更为严苛[1-3]。污水处理过程控制条件的不合理会降低有机物去除效率,以及脱氮和除磷效率,严重时会导致出水水质不达标。因此,为有效提高生物脱氮除磷工艺的处理效率,研究者对生物脱氮除磷工艺进行了不断改进,采取了诸如多点进水[4]、好氧池末端设置消氧区[5]、优化回流比设置[6]、精确曝气[7]、调整运行模式[8]、借助数学模型[9]等措施。污水处理属于非线性、强耦合复杂过程,而生物脱氮除磷的效率影响因素尤其多[10]。其中,由于碳源是微生物生长必须的营养元素,故其也是传统生物脱氮除磷工艺的控制因素。在污水处理过程中,碳源主要用于厌氧释磷、缺氧反硝化和异养菌代谢。然而,关于污水处理厂微生物生态系统中,碳源消耗量与生物脱氮除磷效率之间的关系研究较少,因此,对基于碳源储存的生物脱氮除磷效率调控方法研究对污水处理厂的运行优化有参考意义。

针对我国城市污水处理厂进水COD 低、碳氮比低的问题 [11],采用投加外碳源以促进生物脱氮除磷往往成为有效措施[12-13]。近年来,研究者在碳源种类对污泥产量影响[14-15]、低成本碳源开发[16]、外碳源投加方式[9]等方面进行了相关研究。然而,外加碳源在提供电子供体提高污水处理效率的同时,会增加碳足迹[17]。另外,在污水处理过程中投加外碳源,不仅增加直接运行成本,还会增加诸如投加泵能耗、污泥产量、污泥处理等延伸成本,这一点尚未引起重视。因此,从污水处理全流程角度出发,研究外加碳源的延伸成本有助于全面了解污水处理厂运行成本的内部构成。本研究以我国北方某改良型A2/O工艺为例,探讨碳源消耗量与TN、TP、耗电量之间的关系,并对外碳源投加引起的延伸成本进行分析,以期为城市污水A2/O工艺及其他常规工艺的调控优化提供参考。

-

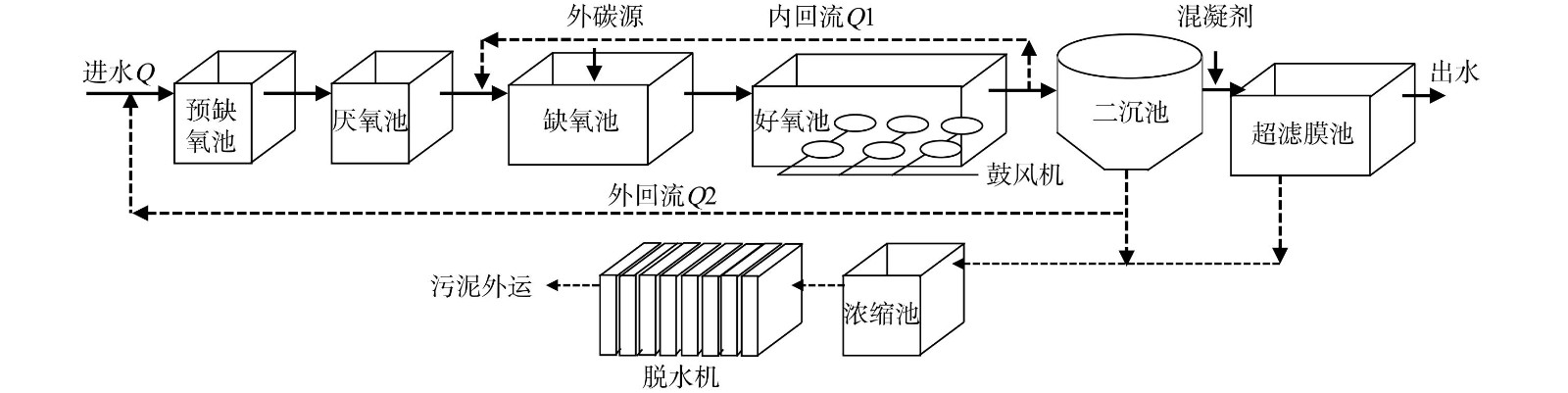

我国北方某市政污水处理厂(简称“A厂”)设计流量Q为6×104 m3·d−1,采用改良A2/O工艺+膜超滤系统,工艺流程如图1所示。该污水处理厂的进水主要为生活污水,出水可达到该市地方标准《水污染物综合排放标准》 (DB11/307-2013) B标准。

生化池总水力停留时间(hydraulic retention time,HRT)为16.5 h。其中,预缺氧段0.5 h,厌氧段HRT为1 h,缺氧段HRT为5 h,好氧段为10 h。进水至选择区与缺氧区的分配比例为5%~10%和90%~95%。混合液回流至缺氧池,内回流比为300%;外回流污泥回流至预缺氧区,外回流比100%。外碳源投加点在缺氧段前端,二沉池后投加混凝剂后进超滤膜池。进水TN较高时,投加质量分数为25%的乙酸钠溶液作为外碳源促进脱氮。污泥龄控制在15~20 d。

-

对2018年全年的A厂运行数据进行统计,包括进水出水标准及进水水质情况 (表1) 。该厂地处暖温带,为半湿润半干旱季风气候,四季分明。夏季炎热多雨,水温高达27 ℃;冬季寒冷,水温低至9 ℃;春秋季节气候温和。

-

污水处理厂的耗氧有机物 (以COD计) 的变化情况分析采用式(1)~(8)。

式中:∆TCOD为污水处理厂总的COD变化量,mg·L−1;CODinf为污水处理厂的进水COD,mg·L−1;CODeff为污水处理厂的出水COD,mg·L−1;CODext为投加外碳源的COD,mg·L−1。

式中:R∆COD/∆TN为去除每千克TN所消耗的耗氧有机物质量 (kg,以COD换算) ,kg·kg−1;Q为污水处理厂每日处理水量,m3·d−1;TNinf为污水处理厂的进水TN,mg·L−1;TNeff为污水处理厂的出水TN,mg·L−1。

式中:R∆COD/∆TP为去除每千克TP所消耗的耗氧有机物质量 (kg,以COD换算) ,kg·kg−1;Q为污水处理厂每日处理水量,m3·d−1;TPinf为污水处理厂的进水TP,mg·L−1;TPeff为污水处理厂的出水TP,mg·L−1;TPchem为污水处理厂投加化学药剂后的TP去除量,mg·L−1。

式中:M为每日投加的混凝剂质量,kg;m为去除每千克TP所消耗的混凝剂质量(kg) ,kg·kg−1;KP(无量纲)是化学除磷的摩尔系数。本研究中KP取3。

式中:R∆BP/∆TP为生物除磷量占总除磷量的百分比。

式中:∆CODTN, TP 为污水处理厂用于生物脱氮除磷的耗氧有机物 (以COD计) 的变化量,mg·L−1;K1为去除1个单位质量的硝态氮转化为氮气的电子接收能力所需耗氧有机物 (以COD计) 提供电子供体的系数,本研究按传统脱氮方式考虑,取K1=2.86,即1 mg硝态氮反硝化为氮气的电子接受能力与2.86 mg 耗氧有机物 (以COD计) 的电子接受能力相当;K2为生物聚磷菌释放1个单位质量的磷所需耗氧有机物 (以COD计) 的重量系数,本研究中K2取值为2。

式中:RCOD为污水处理厂用于生物脱氮除磷的耗氧有机物 (以COD计) 占总COD去除量的百分比。

式中:ECOD为去除单位耗氧有机物 (以COD计) 所需电耗, (kW·h) ·kg−1;N为耗电量, (kw·h)·d−1。

-

COD、BOD5、NH+4-N、TN、MLSS、MLVSS等指标均按《水和废水检测分析方法》 (第4版) 标准方法测定。

-

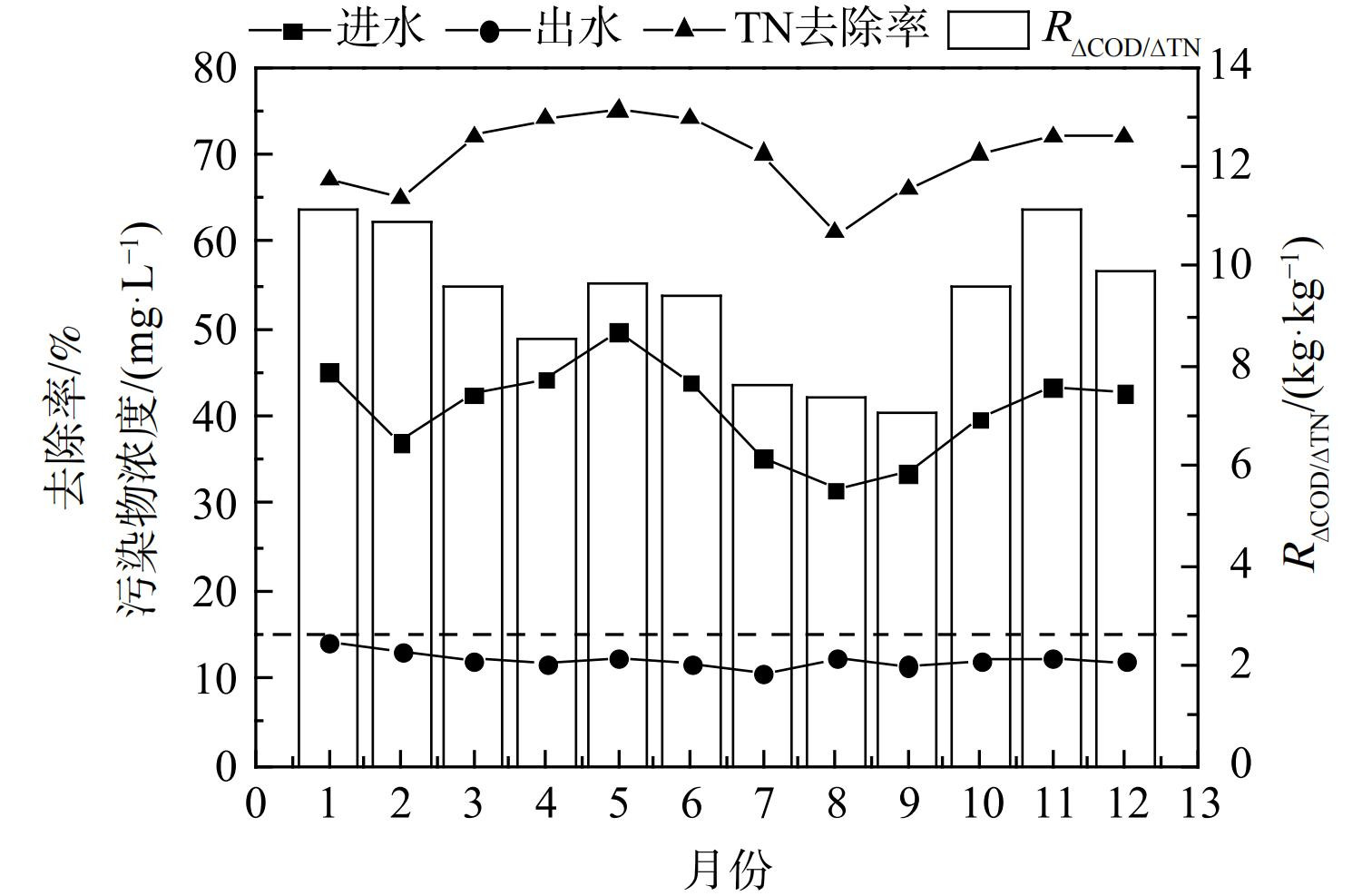

图2为A厂全年各月份进出水TN的变化、∆COD/∆TN的变化情况。A厂进水TN波动较大,为31.6~49.7 mg·L−1,出水则稳定维持在15 mg·L−1以下。TN平均月去除率为61.1%~75.1%,全年平均去除率达69.7%。R∆COD/∆TN平均月值为7.1~11.2 kg·kg−1,全年平均值为9.3 kg·kg−1。R∆COD/∆TN在7月、8月、9月较低,这说明去除单位TN所消耗的耗氧有机物 (以COD计) 较少。特别是在9月份,每去除1 kg TN仅需7.1 kg 耗氧有机物 (以COD换算) ,出水平均TN为11.5 mg·L−1。在春季 (1—3月) 水温较低,微生物活性较低,代谢能力较弱。随着水温上升,微生物活性逐渐唤醒,TN去除率逐渐上升。到了夏季,由于雨水冲击引起温度波动,给硝化菌和反硝化菌带来较大影响。秋季 (7—9月) 的水温为20~26 ℃,水温相对变化不大,非常有利于硝化菌和反硝化菌的生长,该季节脱氮效率较高。生物酶对环境条件的变化比较敏感,温度的改变使活性随之发生改变[18]。在冬季,水温降低,进水TN升高,微生物活性降低,进水中慢速降解的有机物利用不充分,往往需要投加易降解的碳源来促进反硝化脱氮。其重要表现为R∆COD/∆TN较高,在11月份达到11.2 kg·kg−1。

-

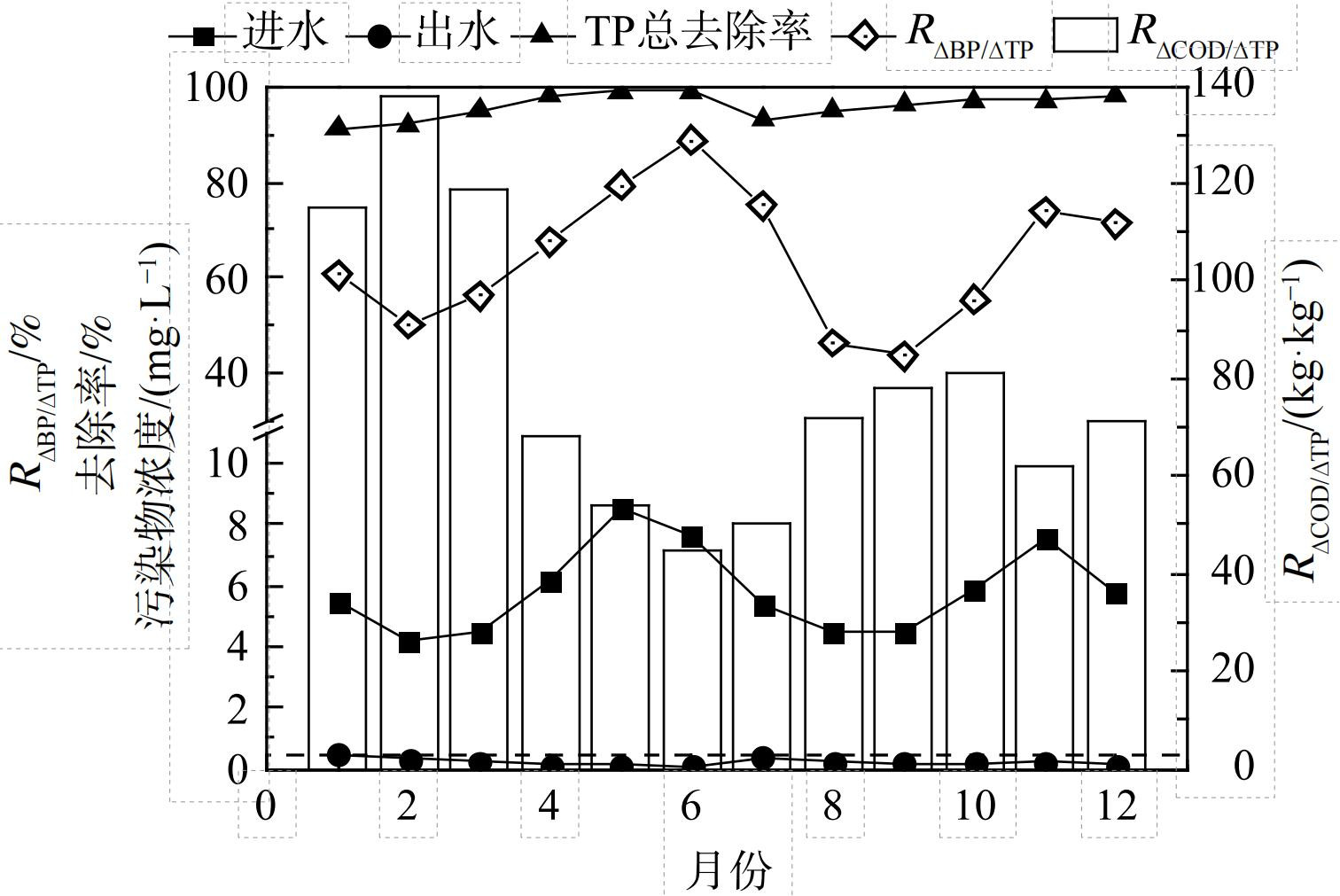

图3为A厂全年各月份进出水TP变化情况,以及∆COD/∆TN的变化情况。A厂进水TP波动较大,为4.15~8.51 mg·L−1,出水稳定维持在0.5 mg·L−1以下。平均月TP去除率为91.4%~98.8%,全年平均去除率高达96.9%。月度R∆BP/∆TP为43.8%~88.8%,全年平均值为64.1%。这表明该厂的生化除磷效果较好。月度R∆COD/∆TP平均值为45.5~138.5 kg·kg−1,全年平均值为79.5 kg·kg−1。R∆COD/∆TP从2月开始逐渐降低,到6月达到最低,为45.5 kg·kg−1;7月与6月持平,随后R∆COD/∆TP逐渐升高。这说明生物法去除单位TP所消耗的耗氧有机物 (以COD换算) 逐渐增多。总体来说,R∆BP/∆TP与进水TP变化趋势几乎一致,而R∆COD/∆TP与进水TP变化趋势则相反。R∆BP/∆TP与R∆COD/∆TP这2个指标均表明生化除磷效率随着进水浓度升高而升高。这与陈清[19]的研究结果一致,TP去除率会随着进水TP增加而增加。这可能主要原因是部分微生物的功能冗余[18],尽管进水TP较高,这些污染物也会激发某些聚磷菌的活性,促进其对P元素生化去除。

-

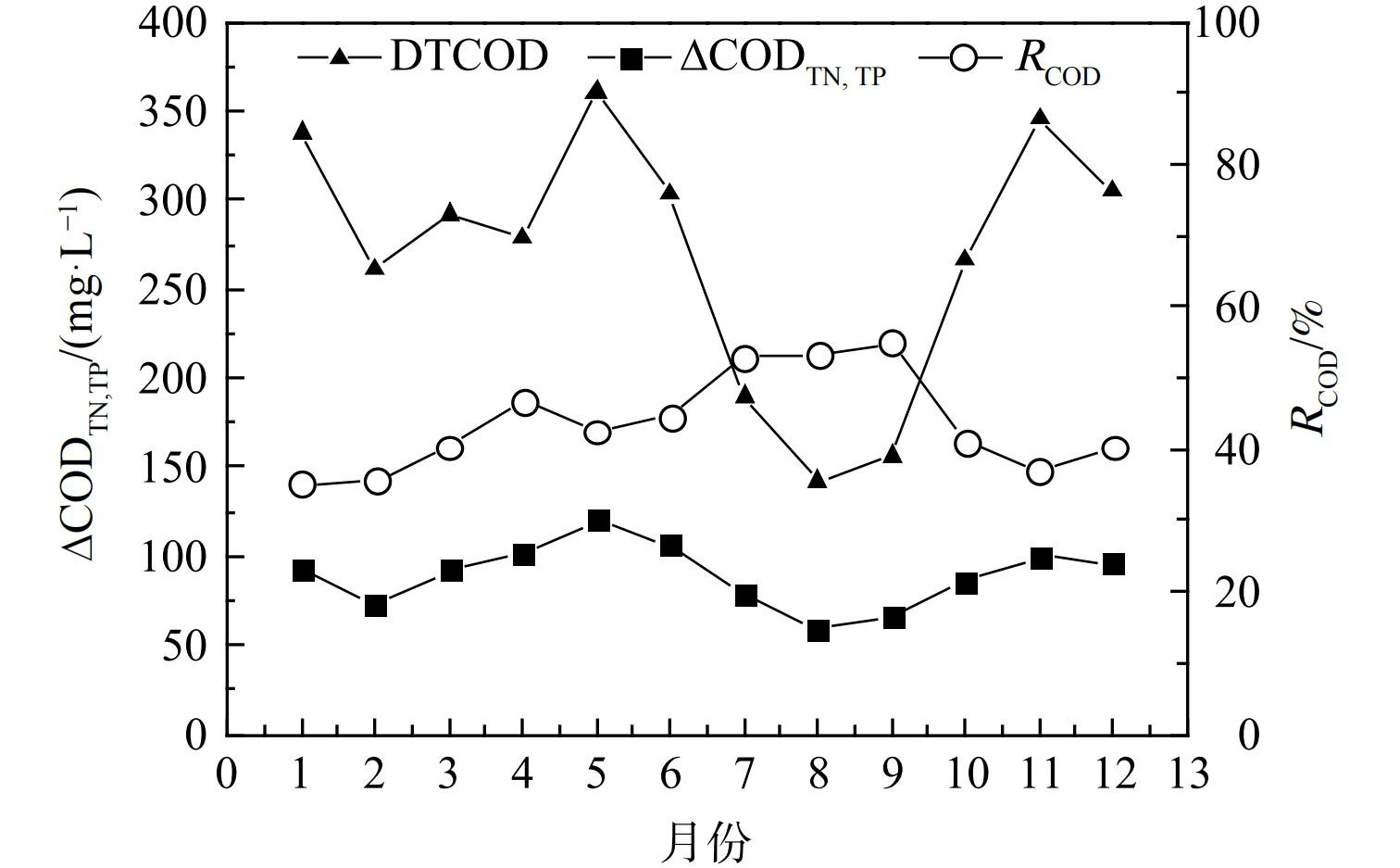

污水处理厂的生物脱氮除磷过程均需碳源参与。从工艺运行管理的角度出发,应提高碳源利用效率,减少外碳源和除磷剂的使用,从而降低生产成本。∆TCOD、∆CODTN, TP及碳源综合利用效率随月份变化情况见图4。A厂的∆TCOD波动较大,为142~361 mg·L−1,∆COD TN, TP则变化较小,为60~120 mg·L−1。总体上,∆CODTN, TP与∆TCOD变化趋势几乎一致。碳源综合利用效率在1—9月总体逐渐升高,随后逐渐下降。特别是在7—9月,碳源综合利用效率较高,达到53%~55%。这表明超过一半的∆TCOD用于生物脱氮除磷。尽管在10月∆TCOD较9月增加了110 mg·L−1,然而碳源综合利用效率却大幅下降,由55%降至41%。对比图2,10月的R∆COD/∆TN较9月有大幅提高。这表明反硝化菌的代谢能力随月份变化较大。对比图3,10月的R∆COD/∆TP较9月小幅提高。这表明反硝化菌较聚磷菌对环境的变化更敏感。

-

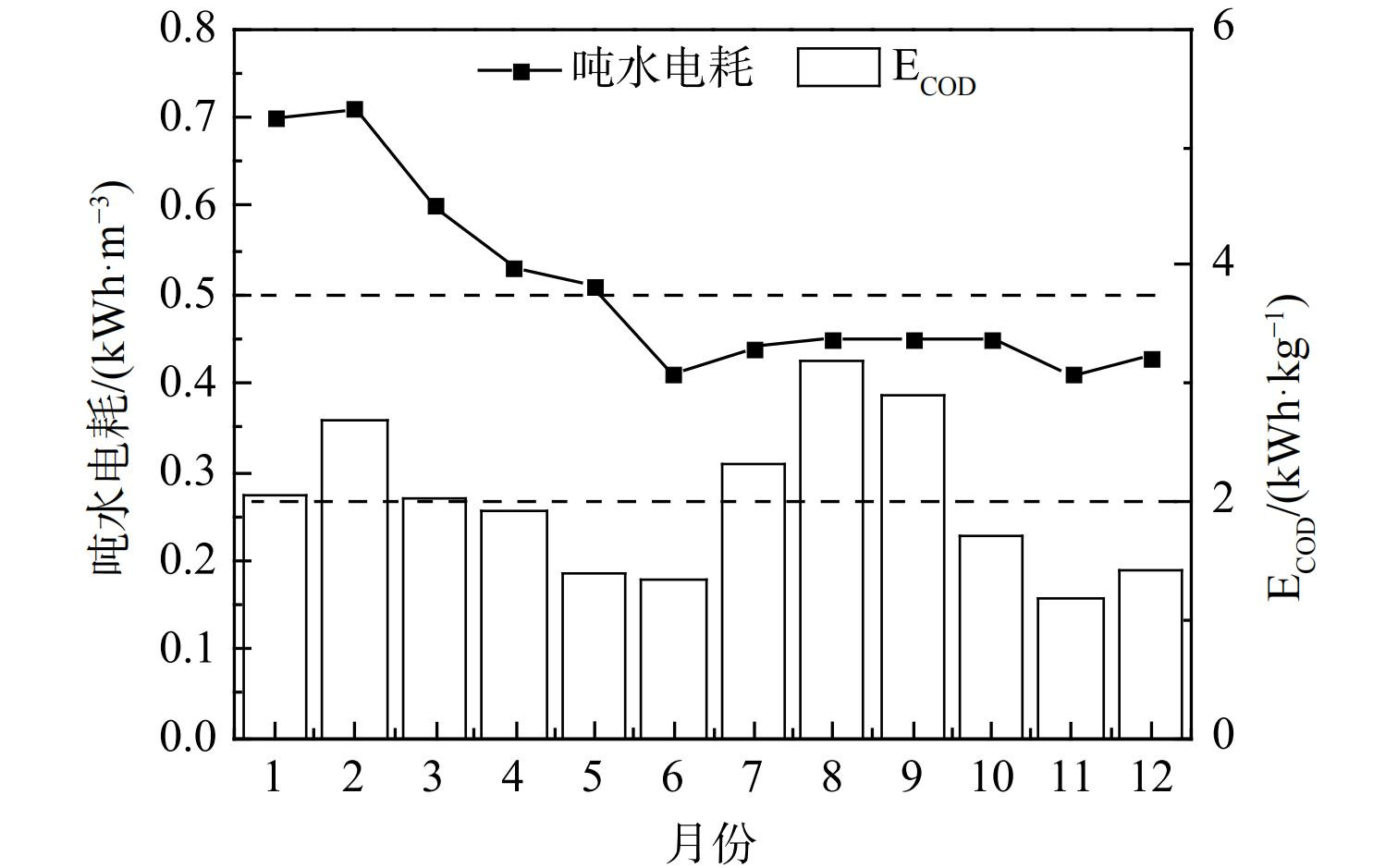

吨水电耗及单位COD变化量 (降低) 所需电耗随着时间的变化见图5。1月、2月年平均吨水电耗最高,达到0.70~0.71 (kW·h)·m−3,随后快速下降,6月平均吨水电耗最低,为0.41 (kW·h)·m−3,下降幅度达42%。7—12月平均吨水电耗变化幅度不大,为0.41~0.45 (kW·h)·m−3。单位COD变化量 (降低) 所需耗电量在8月份达到最高,为3.18 (kW·h)·kg−1。1—3月、7月、9月超过全年平均值2.0 (kW·h)·kg−1 ,而单位COD变化量 (降低) 所需耗电量在11月降至最低,为1.17 (kW·h)·kg−1。对比可知,7—9月这3个月份的吨水电耗变化不大,并处于较低水平,而单位COD变化量 (降低) 所需耗电量较高。随后,单位COD变化量 (降低) 所需耗电量逐渐降低。7—12月吨水电耗变化不大,而单位COD变化量 (降低) 的耗电量差别很大。8月平均日处理水量6.24万吨,ECOD高达3.18 (kW·h)·kg−1;11月平均日处理水量6.16万吨,ECOD最低至1.17 (kW·h)·kg−1,仅为8月份的37%。11月平均TN去除率、RBP/CP明显较高,分别为72%和74%。这表明低ECOD有助于生物脱氮除磷效果。污水处理厂能耗分布中,曝气能耗占比最大,同时鼓风机的鼓风量可调范围则非常大,ECOD的降低主要是曝气量减少的结果。王启镔等[20]发现,在改良AAO系统中,对好氧区曝气系统进行优化调整,将好氧区后端5根曝气管上阀门关闭,曝气量由平均8 800 m3·h−1降至7 000 m3·h−1,出水 TN、TP明显降低。低溶解氧环境能降低微生物菌体内内源聚合物氧化速率,可提高进水碳源用于生物脱氮除磷的利用率。

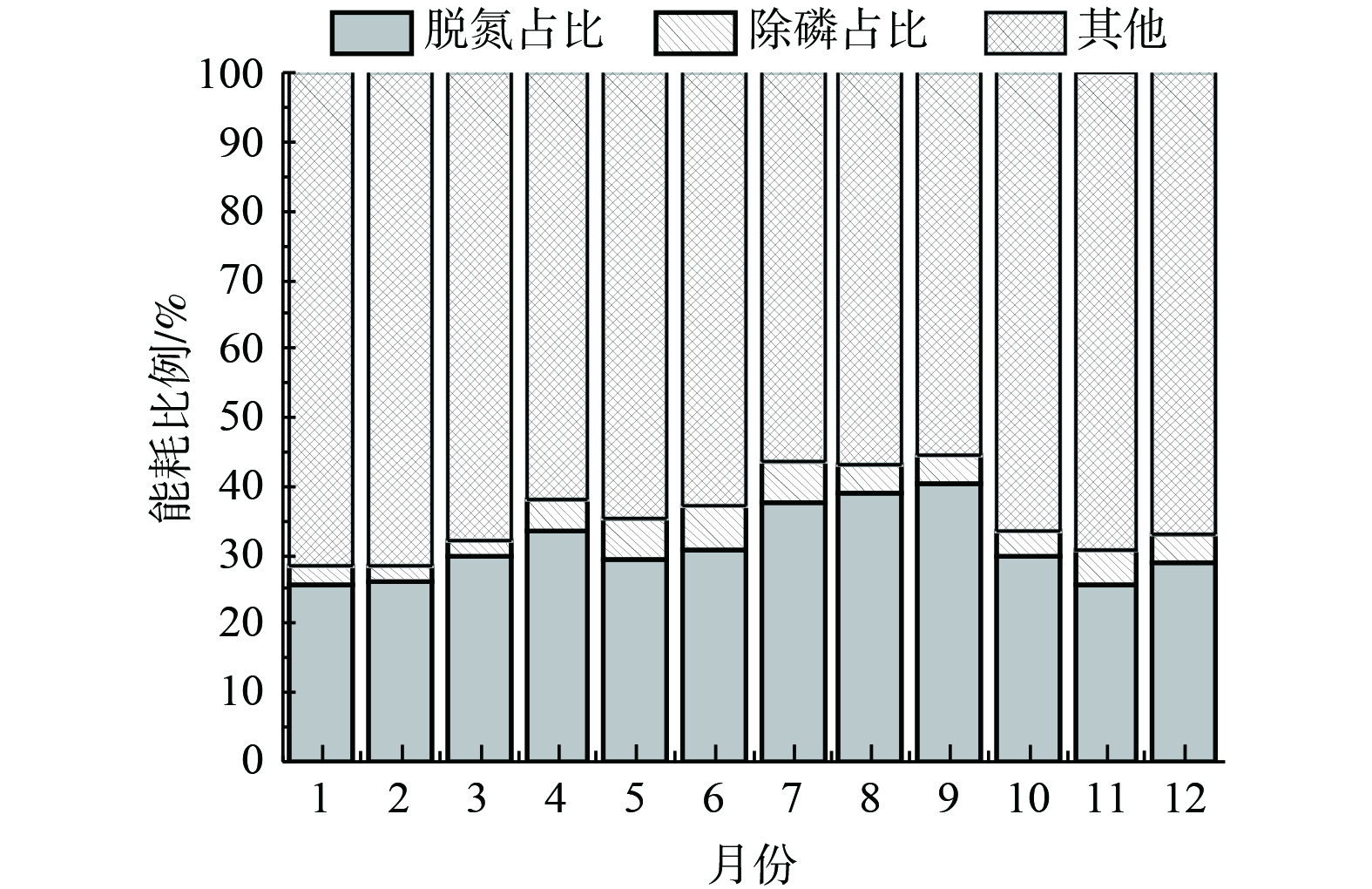

在生物脱氮除磷系统中,去除1 kg氮和磷分别消耗耗氧有机物 (以COD计) 的理论值量为2.86 kg[9]、3kg[21],单位COD变化量 (降低) 的脱氮及除磷能耗占比如图6所示。脱氮消耗耗氧有机物 (以COD计) 在ECOD占比为25.6%~40.5%。在秋季,特别是在9月份,脱氮消耗耗氧有机物 (以COD计) 的能耗占比最高。除磷消耗耗氧有机物 (以COD计) 在ECOD占比为2.2%~6.7%,在6月份,除磷消耗耗氧有机物 (以COD计) 的能耗占比最高。综合分析可知,7—9月的生物脱氮除磷消耗耗氧有机物 (以COD计) 在ECOD 占比中较高,表明耗氧有机物 (以COD计) 的利用效率较高,与前面碳源综合利用效率分析的结果一致。另一方面,即使在7—9月,生物脱氮除磷消耗耗氧有机物 (以COD计) 在ECOD占比中不足50%。这表明非生物脱氮除磷占用的耗氧有机物 (以COD计) 消耗了更多能耗。因此,从可持续发展的角度,应该考虑回收利用进水中的碳[22-23],以此角度来开发低碳污水处理技术。

-

为强化生物脱氮除磷效果,投加碳源会增加直接生产成本,且与曝气能耗、污水处理费、污水处置费等环节相关,增加了更多生产成本。以每投加1 kg耗氧有机物 (以COD换算) (乙酸钠液体,质量分数为25%) 为例来核算碳源延伸成本,结果见表2。间接成本为1.47元·kg−1,占直接碳源成本的20.5%。由于投加外碳源还会增加二氧化碳、甲烷等温室气体,不利于污水处理厂推进减污降碳协同增效。该厂每年投加外碳源 (乙酸钠液体,质量分数25%) 约800 t,外碳源直接成本为112万元,间接成本则高达23万元,两者共增加生产成本135万元。因此,有必要深入研究污水处理过程的污染物变化规律,挖掘工艺潜力,从提高原水碳源的储存效率入手,提高反硝化除磷、同步硝化反硝化、厌氧氨氧化等低碳技术在污染物去除中的占比,从而减少能耗物耗。

-

1) 在7—9月,R∆COD/∆TN的变化表明去除单位TN所消耗耗氧有机物 (以COD计) 较少。特别是在9月份,去除每千克TN仅需7.1 kg耗氧有机物 (以COD计) ;R∆BP/∆TP与进水TP的变化趋势几乎一致,而R∆COD/∆TP则反之。R∆BP/∆TP与R∆COD/∆TP这2个指标均表明生化除磷效率会随着进水浓度的升高而升高。

2) ∆COD TN, TP与∆TCOD变化趋势几乎一致。在7—9月,碳源的综合利用效率较高,达到53%~55%。这表明超过一半的∆TCOD用于生物脱氮除磷。反硝化菌较聚磷菌对环境的变化更敏感。从可持续发展的角度,还应该考虑回收利用进水中的碳,开发相应的低碳污水处理技术。

3) 投加外碳源不仅增加直接生产成本,而且与曝气能耗、污水处理费、污水处置费等环节相关联,间接成本占直接碳源成本的20.5%。因此,可考虑从提高原水碳源的储存效率入手,提高反硝化除磷、同步硝化反硝化、厌氧氨氧化等低碳技术在污染物去除中的占比,从而减少能耗物耗的输入。本研究的计算方法充分考虑了进出水水质及环境条件变化对碳源有效利用的影响,可为污水处理厂的碳源管理提供参考。

基于碳源储存的污水生物脱氮除磷效率及污水处理系统延伸成本分析

Biological nitrogen and phosphorus removal efficiency of wastewater based on carbon source storage and cost analysis of sewage treatment system extension

-

摘要: 以我国北方某改良型A2/O工艺 (设计规模6×104 m3·d−1) 为例,基于一年的运行数据,考察碳源储存与生物脱氮除磷能力之间的关系,分析碳源利用效率和能耗情况。结果表明:在7—9月,系统碳源的综合利用效率为53%~55%,这说明消耗的碳源中超过50%比例用于生物脱氮除磷;反硝化菌较聚磷菌对环境的变化更敏感;外加碳源的延伸成本占直接成本的20.5%。因此,污水处理厂应充分考虑进出水水质及环境条件变化对碳源有效利用的影响。本研究结果可为减污降碳协同增效背景下城市污水处理厂A2/O工艺及其他常规工艺的优化调控提供参考。Abstract: Taking an improved A2/O process in northern China (with a design scale of 6×104 m3·d−1) as an example, the relationship between carbon source storage and biological nitrogen and phosphorus removal was investigated based on the operation data of a whole year, and the utilization efficiency of carbon source and energy consumption was analyzed. The results showed that from July to September, the comprehensive utilization efficiency of carbon source reached 53%~55%, which proved that more than 50% consumed carbon source was used for biological nitrogen and phosphorus removal. Denitrifying bacteria were more sensitive to environmental changes than phosphorus accumulating bacteria. The extension cost of additional carbon source accounted for 20.5% of the direct cost. It was pointed out that the sewage treatment plant should fully consider the influence of the change of inlet and outlet water quality and environmental conditions on the effective utilization of carbon sources, so as to provide technical guidance and reference for the regulation and operation of municipal wastewater treatment plant with A2/O process and other conventional processes.

-

-

表 1 A厂进水及出水的设计标准及实际进水水质情况

Table 1. Design criteria for designed influent and effluent and actual influent quality in A plant

运行数据类型 COD/ (mg·L−1) BOD5/ (mg·L−1) SS/(mg·L−1) NH4+-N/ (mg·L−1) TN/(mg·L−1) TP/(mg·L−1) COD/TN COD/TP 进水设计值 460 250 250 50 55 7 - - 出水设计值 ≤30 ≤6 ≤10 ≤1.5(2.5) ≤15 ≤0.3 - - 进水浓度范围 83~898 37~484 88~1 480 8~48 22~69 2.5~22.1 4.1~16.9 19~193 进水浓度平均值 298 152 307 31 41 5.9 6.6 52 注:12月1日至3月31日执行括号内排放限值。 表 2 外碳源延伸成本分析

Table 2. Analysis of extension cost of external carbon source

项目 直接成本 间接成本 碳源成本/

(元·kg−1)曝气能耗/

(元·kg−1)污泥处理费/

(元·kg−1)污泥处置费/

(元·kg−1)投加泵电耗/

(元·kg−1)人工费、水泵等

装置按年折算、

维护费等的比例小计/

(元·kg−1)数值 7.18 0.7 0.07 0.5 0.01 15% 1.47 说明 以乙酸钠含量25%液体 (市场价约每吨1 400元) 计,折合耗氧有机物 (以COD计) 为195 kg·t−1。 取本研究中全年

平均值

2 (kw·h)·kg−1

计,电费0.7元·(kW·h)−1。污泥产量的参数取自文献[24]。污泥从含水率98.8%降至80%计算。 按污泥处置费 (80%含水率) 200元·t−1计。 按常规隔膜泵考虑,功率

0.55 kW计。主要考虑加药泵、管路、配件等年折算、维修维护费用。 注:所有成本核算中涉及耗氧有机物的量均以COD换算。 -

[1] ZOU L Z, ZHOU M, LUO Z W, et al. Selection and synthesization of multi-carbon source composites to enhance simultaneous nitrification-denitrification in treating low C/N wastewater[J]. Chemosphere, 2022, 288: 132567. doi: 10.1016/j.chemosphere.2021.132567 [2] 柴蓓蓓, 曹锋锋, 鞠恺, 等. 不同碳源条件生物滤池深度脱氮效能及其经济性[J]. 水处理技术, 2021, 47(5): 83-88. [3] 司文曦, 李辰, 马庆. 污水处理厂强化生物脱氮措施探析[J]. 中国给水排水, 2015, 31(16): 21-25. [4] AGNE K B; NEVIN Y. Evaluation of sludge reduction in an oxic-settling-anoxic system operated with step feeding regime for nutrient removal and fed with real domestic wastewater[J]. Journal of Environmental Management, 2019, 243: 385-392. [5] 冯云刚, 张飞, 冯凯, 等. 消氧强化反硝化脱氮 AAO 生物池在合肥某污水厂的应用[J]. 中国给水排水, 2021, 37(14): 80-84. [6] WANG Q B, CHEN Q W. Simultaneous denitrification and denitrifying phosphorus removal in a full-scale anoxic-oxic process without internal recycle treating low strength wastewater[J]. Journal of Environmental Sciences, 2016, 39: 175-183. doi: 10.1016/j.jes.2015.10.012 [7] 谢小明. 精确曝气控制在污水处理厂中的应用和探索[J]. 中国给水排水, 2016, 32(6): 24-27. [8] 王启镔, 宫徽, 朱越, 等. SBR运行模式对市政污水脱氮除磷性能的影响分析[J]. 环境科学学报, 2020, 40(4): 1167-1173. [9] WANG Q B, CHEN Q W, CHEN J. Optimizing external carbon source addition in domestics wastewater treatment based on online sensoring data and a numerical model[J]. Water Science and Technology, 2017, 75(11): 2716-2725. doi: 10.2166/wst.2017.128 [10] 李子锋. 污水处理生物脱氮除磷影响因素及对策的研究[J]. 皮革制作与环保科技, 2021, 2(5): 101-102. [11] 王启镔, 苑泉, 宫徽, 等. SBR系统在低浓度污水条件下培养好氧颗粒污泥的特性及微生物分析[J]. 环境工程学报, 2018, 12(11): 3043-3052. [12] FENG X C, BAO X, CHE L, et al. Enhance biological nitrogen and phosphorus removal in wastewater treatment process by adding food waste fermentation liquid as external carbon source[J]. Biochemical Engineering Journal, 2021, 165: 107811. doi: 10.1016/j.bej.2020.107811 [13] MANNINA G, CAPODICI M, COSENZA A, et al. Carbon and nutrient biological removal in a University of Cape Town membrane bioreactor: Analysis of a pilot plant operated under two different C/N ratios[J]. Chemical Engineering Journal, 2016, 296: 289-299. doi: 10.1016/j.cej.2016.03.114 [14] 陈浬, 周健, 窦艳艳. 碳源种类对原位生物解偶联污泥减量系统效能影响[J]. 环境工程学报, 2015, 9(3): 1131-1135. [15] 张怡芳, 吉芳英, 姜蕾. 固液碳源对反硝化脱氮及污泥产量影响研究[J]. 水处理技术, 2020, 46(4): 121-124,132. [16] 赵国强, 李亚, 武双, 等. 基于低成本碳源微生物合成聚羟基脂肪酸酯的研究进展[J]. 高分子通报, 2020(11): 22-30. [17] CANIANI D, CAIVANO M, PASCALE R, et al. CO2 and N2O from water resource recovery facilities: Evaluation of emissions from biological treatment, settling, disinfection, and receiving water body[J]. Science of the Total Environment, 2019, 648: 1130-1140. doi: 10.1016/j.scitotenv.2018.08.150 [18] 王启镔, 龚春辰, 魏彬, 等. 季节性气候变化下污水处理厂性能及污泥特性分析[J]. 给水排水, 2021, 47(3): 49-54. [19] 陈清. 污水处理厂进水水质变化对污染物去除效率的影响分析[J]. 水资源开发与管理, 2015(2): 80-84 [20] 王启镔, 李浩, 董旭, 等. 改良型 A2/O 污水处理厂的工艺优化调控方案及其对同步脱氮除磷效率的提升[J]. 环境工程学报, 2022, 16(2): 659-665. [21] JANSSEN P M J, MEINEMA K, VAN DER ROEST H F, 著. 祝贵兵, 彭永臻, 译. 生物除磷设计与运行手册[ M]. 北京: 中国建筑工业出版社, 2005. [22] GONG H, JIN Z Y, WANG Q B, et al. Effects of adsorbent cake layer on membrane fouling during hybrid coagulation/adsorption microfiltration for sewage organic recovery[J]. Chemical Engineering Journal, 2017, 317: 751-757. doi: 10.1016/j.cej.2017.02.122 [23] JING Z Y, GONG H, WANG K J. Application of hybrid coagulation microfiltration with air backflushing to direct sewage concentration for organic matter recovery[J]. Journal of Hazardous Materials, 2015, 283: 824-831. doi: 10.1016/j.jhazmat.2014.10.038 [24] HENZE M, VAN L M C M, EKAMA A G B D. Biological wastewater treatment: Principles, modelling and design[M]. London: IWA publishing, 2008. -

下载:

下载: