-

传统预处理系统通常由格栅、沉砂池及初沉池组成[1]。其中,格栅的最小去除尺寸一般为500 μm,沉砂池则被设计用于去除200 μm以上重质砂粒,无法有效去除轻质的渣及200 μm以下细砂[2]。初沉池对于悬浮物的去除效果较好,但出于节省碳源和占地的考虑,我国90%以上的污水处理厂未设置[3]。由于现有预处理系统设计标准较低,大量未被格栅、沉砂池拦截的砂渣穿透进入生化系统已成常态,造成了一系列问题,包括砂粒加剧设备磨损、砂渣挤占有效池容、活性污泥高浓度低活性、堵塞膜组件及生物膜填料等[4]。

强化改造预处理系统,将砂渣等难降解、不可降解杂质在预处理单元彻底分离,是解决上述问题并提升生化系统整体效能的有效措施,已成为我国预处理发展的重要方向之一[3]。目前,众多学者在强化除砂方面开展了大量研究工作,包括优化传统沉砂池、研发新型除砂工艺等[5-7],然而针对砂渣强化去除方面的相关研究却仍显不足。旋转式带式过滤器是一类在国外应用较为广泛的预处理设备,通过过滤原理可同步去除污水中砂渣杂质和悬浮固体,其配套的过滤筛网通过往复旋转实现自动清洁与动态过滤,筛网孔径通常在50~500 μm不等[8-9]。该设备从过滤孔径和机械结构上可被划分为微筛类预处理装备[1],在我国预处理砂渣强化去除方面有一定的应用潜力,但在国内并未得到广泛研究和应用[10]。

已有研究[4,11]表明,以贵阳、重庆等为代表的污水处理厂存在较为突出的砂渣问题。为此,本文以旋转式带式过滤器为研究对象,选取位于贵阳市的代表性污水处理厂,搭建了处理规模为4 000 m3·d−1的生产性实验装置,研究了其处理效果及相关的影响因素,核算了其提升生化系统效能的效果,考察了该设备支撑预处理系统强化改造的可行性。

-

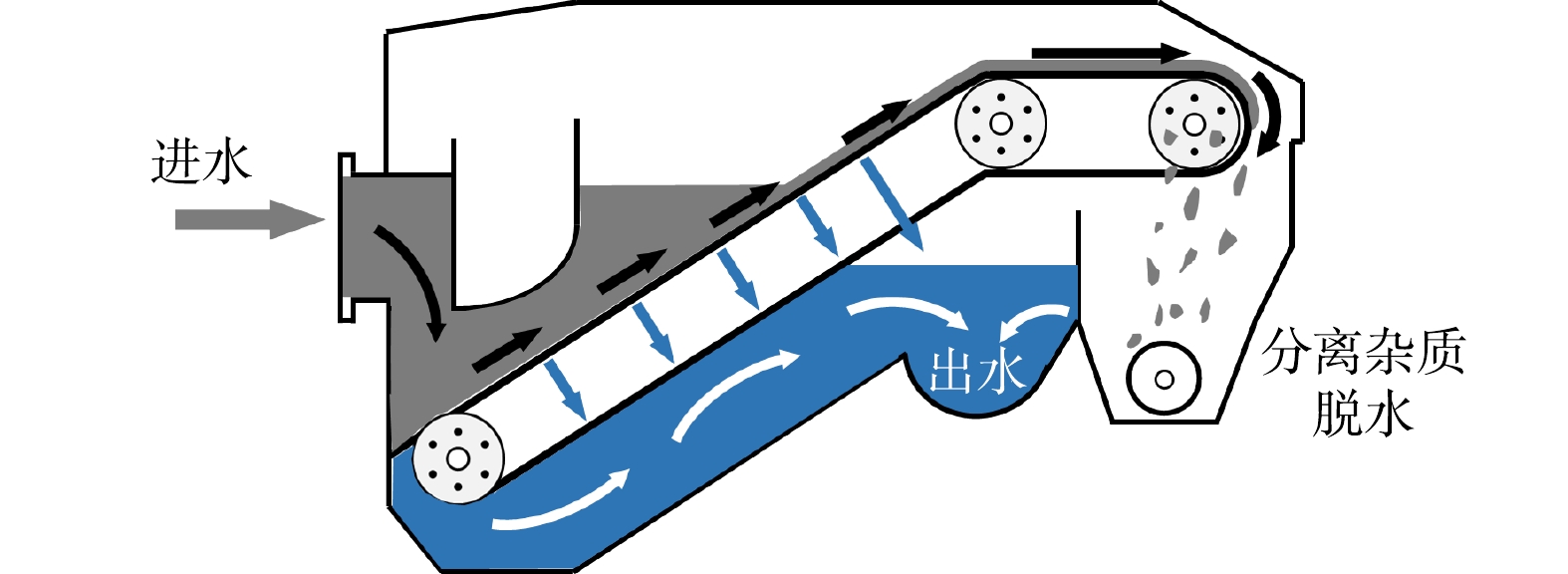

如图1所示,旋转式带式过滤器主要由过滤单元、脱水单元、电气控制系统等组成。其中过滤单元包含由电机驱动的旋转滤网、气水冲洗系统、喷淋系统等;脱水单元主要由螺旋压榨机完成分离杂质的收集和脱水;设备的自动运行通过电气控制系统实现。该设备的长、宽、高分别为2.45、1.48、1.49 m,设计处理规模为4 000 m3·d−1,滤网孔径为350 μm,滤网最大转速为14.2 m·min−1,进水端最大液位为500 mm。

实际运行时,污水通过进水管进入实验装置的进水端腔体,经滤网过滤后进入出水端腔体并通过出水管流出。污水中杂质被滤网截留并随着滤网的转动进入脱水区域,滤网上的杂质被高压气水冲洗系统及刮板分离至螺旋压榨机内,经挤压脱水后由出渣口排出。

-

本实验分2个阶段开展:第1阶段评估实验装置的性能,进水端液位设定为330 mm,依靠电气控制系统控制滤网转速以实现进水端液位相对稳定,进水流量稳定在160 m3·h−1;第2阶段考察影响实验装置去除效果的因素,包括过滤时间和水力负荷,同步考察滤网转速、进水流量、进水端液位等参数间的相互关系。实验期间,设备进水取自实验污水厂旋流沉砂池进水端。

-

实验期间的主要测试指标包括SS、COD、BOD5、ISS、VSS、不同粒径颗粒物浓度、含水率、粒径分布。其中:SS、COD、BOD5、含水率采用标准方法测试;ISS及VSS分别为无机悬浮物浓度和有机悬浮物浓度,其参照文献[12]报道的550 ℃灼烧减重法测试。水样经0.45 μm微滤膜过滤后,不可滤残渣经马弗炉550 ℃灼烧,根据烧失量及残渣量分别计算有机悬浮物浓度与无机悬浮物浓度;不同粒径颗粒物浓度参照文献[13]报道的湿式筛分法进行测试。取50~100 L水样,依次过滤350、200、100 μm不锈钢标准筛,烘干、称量筛上物并计算得到不同粒径颗粒物浓度(以SS计);颗粒物粒径分布采用BT-9300 HT型激光粒度分析仪进行测定,测定3次取平均值。

-

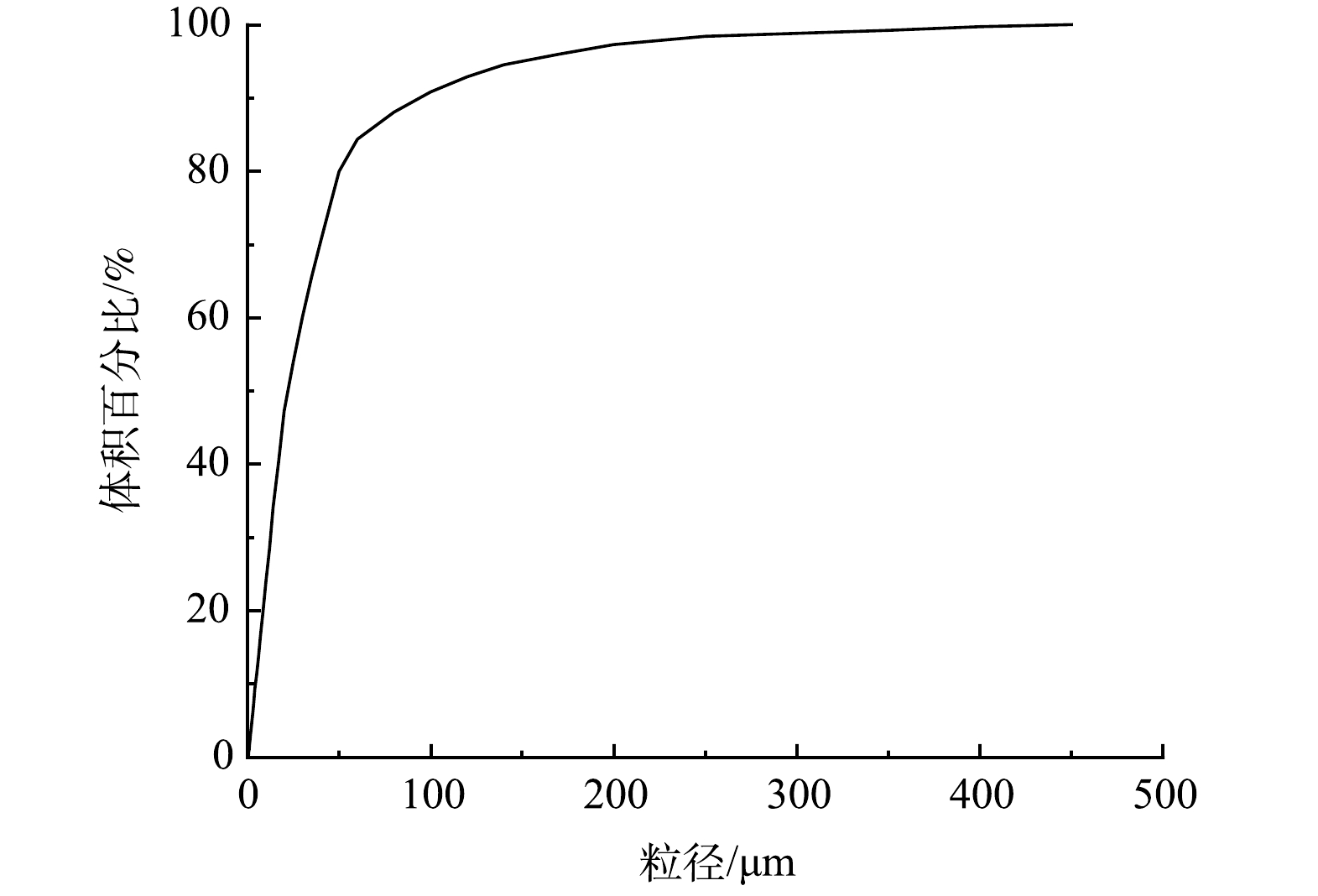

1)污染物去除效果。在设计进水流量为4 000 m3·d−1的条件下,旋转式带式过滤器对SS、COD及ISS的去除效果见表1。实验装置对于SS及COD的去除率较低,SS平均去除率仅为5.9%,COD平均去除率仅为4.2%;对于ISS的平均去除率为11.8%,与传统沉砂池基本相当[4,11,14]。采用激光粒度分析仪测试进水颗粒物的粒径分布,结果见图2。可以发现,进水中粒径大于350 μm的颗粒体积占比极低,均值仅为1.26%,体积加权平均粒径D(3,4)为45.74 μm,远小于滤网过滤孔径。由于旋转式带式过滤器对于SS及COD的去除主要依靠滤网本身的机械过滤作用,因此,进水中颗粒物粒径偏小是导致SS及COD去除率较低的主要原因。

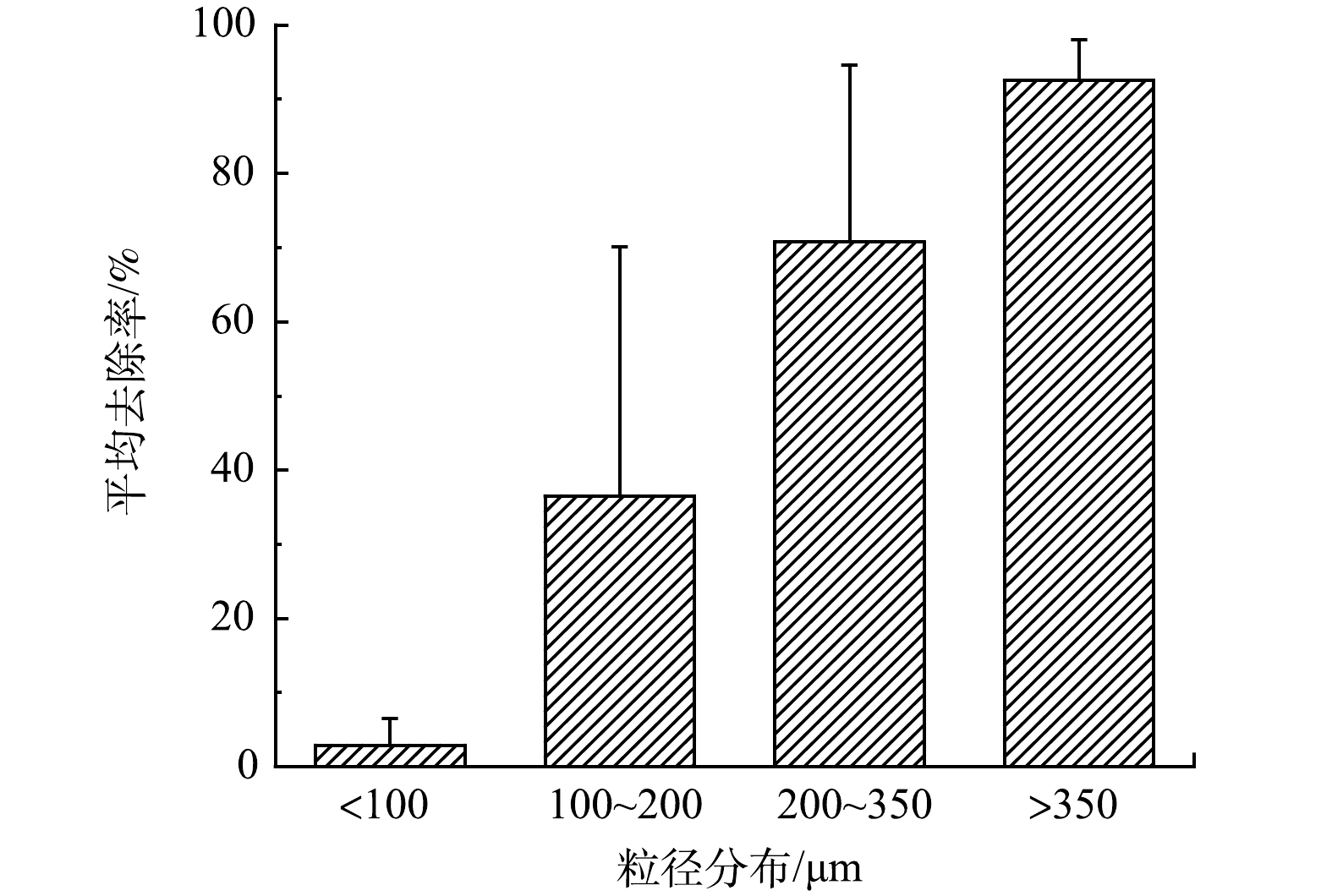

鉴于进水颗粒物粒径显著偏小,采用湿式筛分法进一步考察了旋转式带式过滤器对不同粒径颗粒物的去除效果,结果如图3所示。结果表明,实验装置对各级粒径颗粒物均可去除,大于200 μm颗粒物的平均去除率为81.6%,由于滤网具备的机械过滤特性,其对大于350 μm颗粒物的去除率最高,达92.5%。旋转式带式过滤器对尺寸小于滤网孔径的颗粒物也有一定的去除,200~350 μm颗粒物的去除率为70.7%,100~200 μm颗粒物的去除率为38.0%。这是由于滤网的网状结构对于拦截长径比较大的纤维毛发类悬浮物起到了促进作用。此外,已被截留的颗粒物会在滤网表面形成一层较薄的泥饼层结构,同样有助于提升对粒径小于滤网孔径的颗粒物的截留效果。

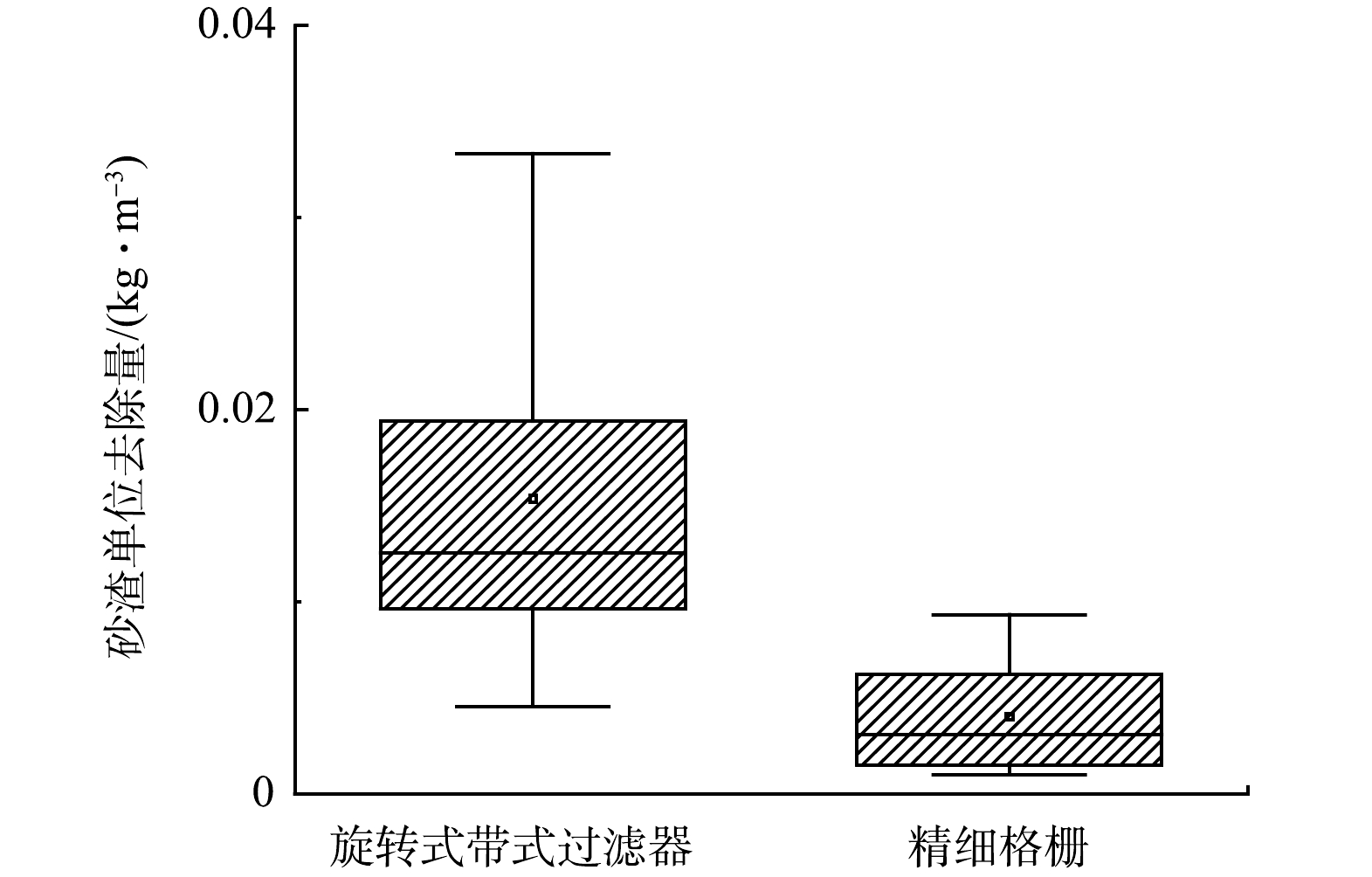

2)砂渣分离效果。图4为旋转式带式过滤器与实验污水厂精细格栅(栅孔为500 μm)砂渣去除效果的对比。旋转式带式过滤器的砂渣单位去除量均值为0.015 4 kg·m−3,含水率为50.2%,VSS含量为84.1%;而精细格栅的砂渣单位去除量均值仅为0.004 kg·m−3,含水率则高达67.2%,VSS含量为50.2%。旋转式带式过滤器对固体杂质的去除能力远高于传统的精细格栅,去除量是实验污水厂精细格栅的3.8倍,产生的砂渣含水率低、有机物含量高。

由于旋转式带式过滤器分离出的砂渣杂质有机物含量较高,为进一步考察实验装置对进水中颗粒态碳源的保留程度,采用间接计算法(式(1))[15]计算分离出的砂渣杂质所含的有机物组分构成。其中,砂渣杂质所含的慢速可降解颗粒性有机物Xs的含量根据式(2)计算。

式中:CTCOD为砂渣杂质的有机物含量,g·kg−1;Xl为砂渣杂质的惰性颗粒性有机物含量,g·kg−1;Xs为砂渣杂质的慢速可降解颗粒性有机物含量,g·kg−1;S为砂渣杂质的溶解性有机物含量,g·kg−1,其来源于砂渣杂质所含水分,由进水溶解性有机物、砂渣产量、含水率推算得出。

式中:fBOD为纠正系数,取0.15[16];XBOD为砂渣杂质的五日生化需氧量含量,g·kg−1;a为五日生化需氧量占极限生化需氧量的百分比,以70%计。

如表2所示,实验装置分离出的砂渣杂质所含有机物以惰性颗粒性有机物Xl为主,占比高达77.63%,而由砂渣所含水分贡献的溶解性有机物则可忽略不计。可以发现,得益于旋转式带式过滤器较低的COD去除率及较好的滤网截留能力,其可较好地保留污水中可降解的颗粒性及溶解性有机碳源,不会对后续生物脱氮除磷产生不良影响。

-

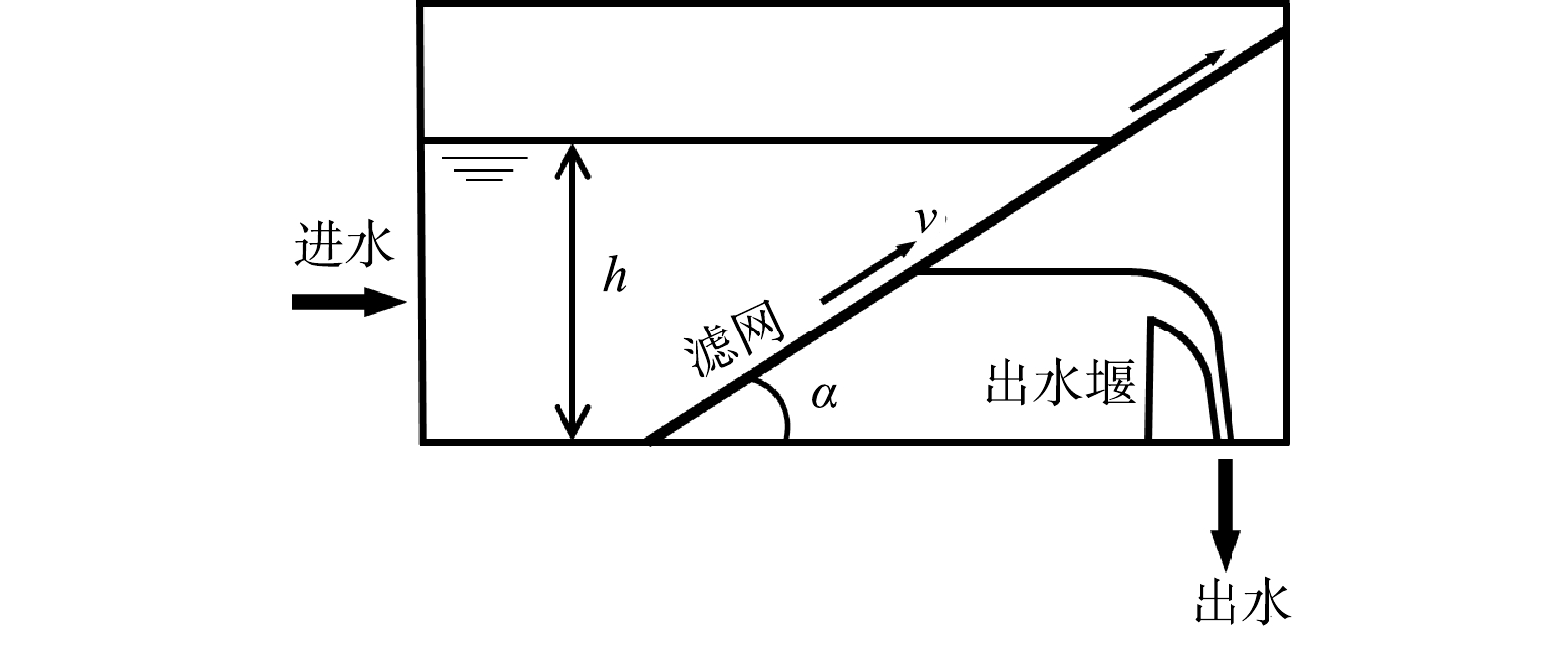

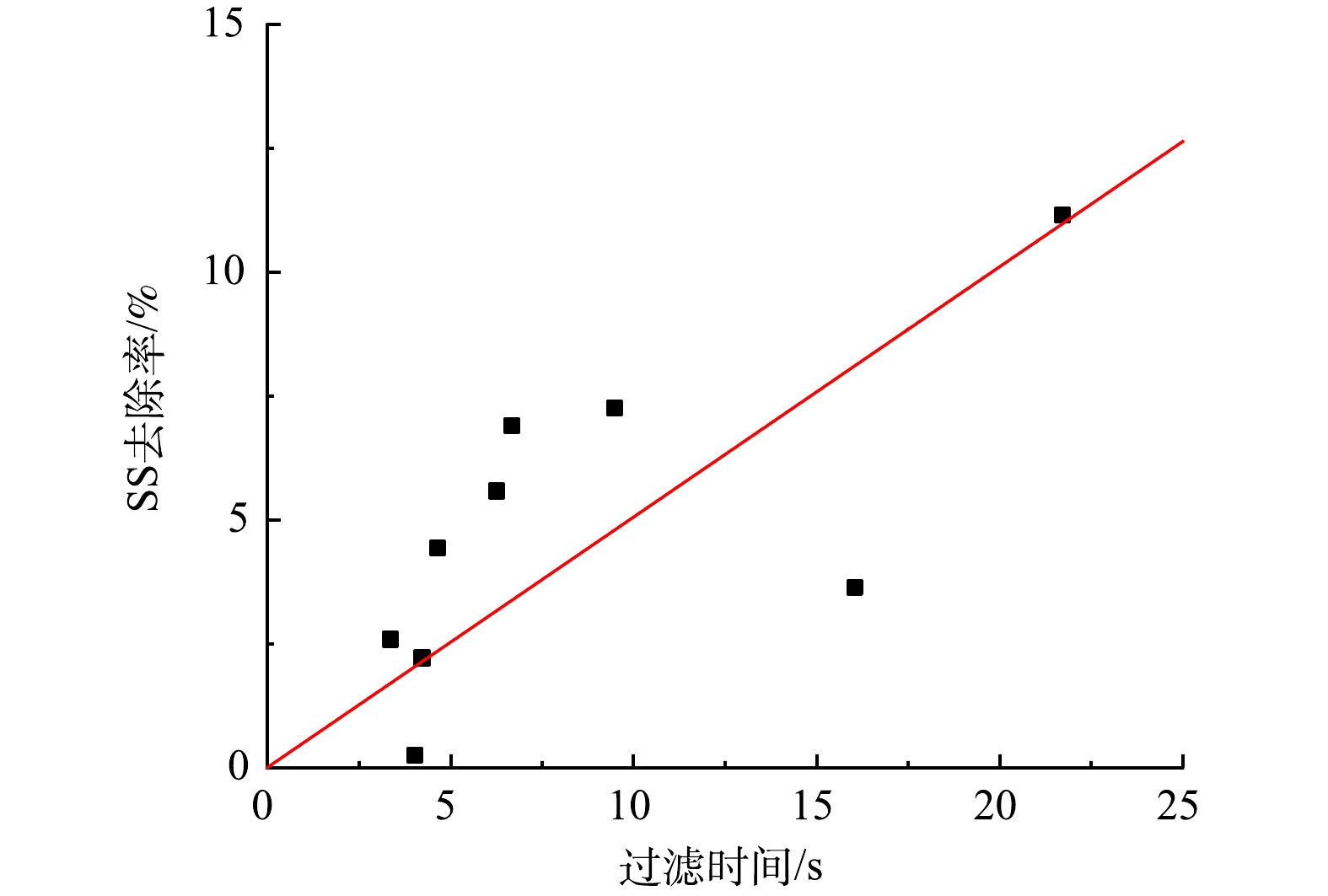

1)过滤时间。过滤时间是指滤网从液位底端移动至水面所需要的时间,等价于泥饼层形成时间(图5)。过滤时间采用式(3)进行计算,影响过滤时间的主要因素为进水端液位高度与滤网转速。为考察不同过滤时间对污染物去除效果的影响,在设计进水流量为4 000 m3·d−1条件下,设置不同的进水端液位高度并通过自控程序控制液位恒定,以实验期间的滤网转速均值计算过滤时间,以SS去除率衡量污染物的去除效果,结果见图6。

式中:t为过滤时间,s;h为滤网前水深,即液位高度,m;v为滤网转速,m·s−1;α为滤网倾角,35°。

实验期间,随着过滤时间的增加,SS去除率有一定程度的提升,过滤时间与SS去除率有较高的相关性,两者的ρ为0.91。可以发现,当过滤时间超过5 s时,旋转式带式过滤器普遍能够取得较好的SS去除效果,SS去除率在5.6%~11.2%。虽然该设备污染物的去除以机械过滤去除为主,但过滤时间的增加同样有利于泥饼层的形成,也可增加颗粒物与滤网表面的接触机会,增加不规则颗粒物被滤网截留的概率,因此,延长过滤时间可一定程度上提高SS去除率。

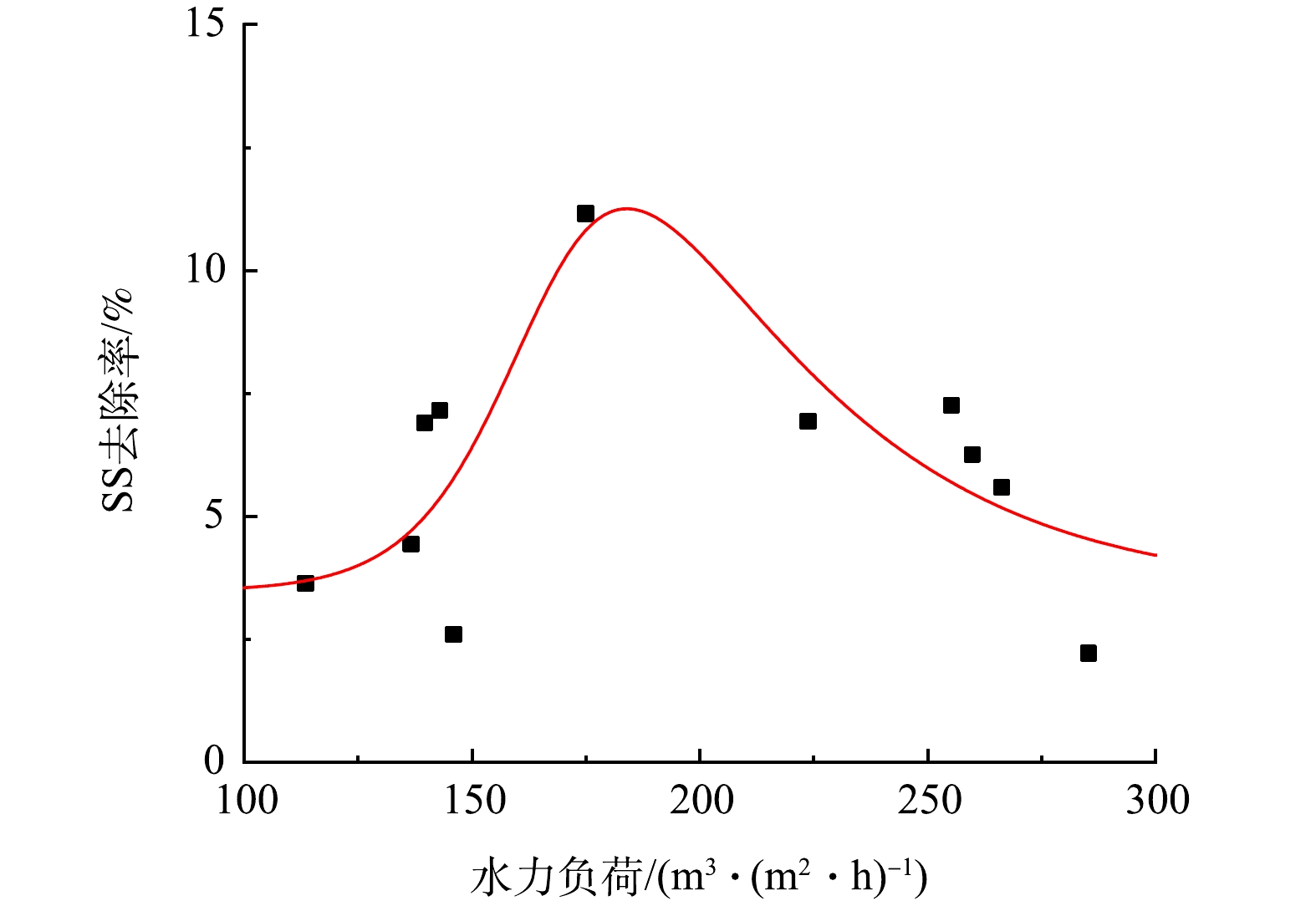

2)水力负荷。水力负荷是指单位面积浸没滤网在单位时间内处理的污水水量,是衡量旋转式带式过滤器污水处理能力的重要指标。为此,以水力负荷为评价指标,进一步考察其与SS去除率之间的关系,水力负荷根据式(4)进行计算。

式中:N为水力负荷,m3·(m2·h)−1;Q为进水流量,m3·h−1;b为滤网宽度,0.9 m。

水力负荷与SS去除率之间的关系见图7。当水力负荷处于150~250 m·h−1时,对应的SS去除率相对较高,均值为8.4%。当水力负荷为180 m·h−1时,SS去除率最佳,为12.5%;当水力负荷低于180 m·h−1时,SS去除率随着水力负荷的减少而降低。这是因为低水力负荷条件通常发生在进水流量较低时,此时的过滤时间普遍较短(低于5 s)。此外,实验时发现低水力负荷时的进水SS也较低,均值为157 mg·L−1,此时旋转式带式过滤器以机械过滤为主。当水力负荷超过180 m·h−1,随着水力负荷的增加,SS去除率表现为逐渐降低的趋势。这是因为此时的进水流量较高,滤网需要以较高的转速运转以满足污水处理量,过滤时间的减少导致了SS去除率的降低。可以发现,旋转式带式过滤器能够以相对较高的水力负荷实现污水中悬浮固体的去除,当控制其水力负荷处于较优范围时,其SS去除率可接近传统初沉池的15%~30%,可在最大限度保留进水中有机碳源的基础上,实现砂渣的有效分离。

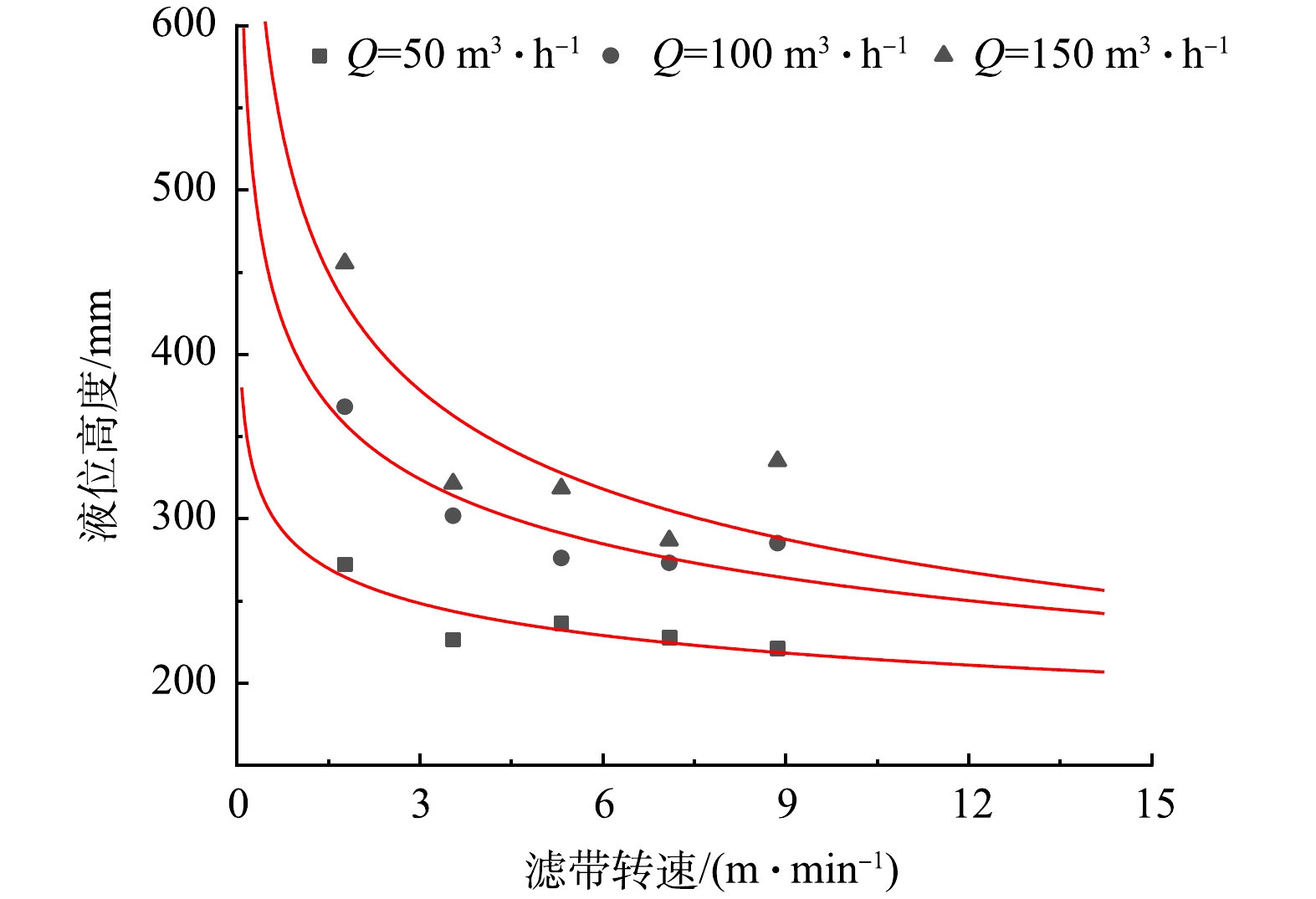

3)多参数相互关系。进一步分析可以发现,液位高度h、进水流量Q、滤带转速v是构成过滤时间和水力负荷这2个影响因素的核心参数。为此,在不同进水流量条件下,设置不同的滤网转速,并记录实验期间的液位高度,以考察液位高度h、进水流量Q、滤带转速v之间的相互关系,结果见图8。实验期间,进水SS处于150~250 mg·L−1。在滤带转速不变的前提下,实验设备进水端液位高度随进水流量的增加而增加,而当进水流量不变时,液位高度则随着滤带转速的加快而越来越低,且逐渐趋近于极限最低液位。

旋转式带式过滤器的过滤推动力来源于进水与出水的液位差(即水头损失),过滤阻力主要来源于滤网自身阻力和泥饼层阻力,其过滤原理可采用达西定律(式(5))表达。可以发现,该设备的污水处理能力与液位高度、滤网固有阻力及泥饼层阻力密切相关。当滤网转速不断增加,泥饼层形成时间随之降低,导致泥饼层贡献的阻力占比逐渐变小,滤网的过滤总阻力以自身固有阻力为主。此时,旋转式带式过滤器将以机械过滤的模式运行,且进水端液位高度将逐渐趋于一恒定值,这与图8中所展现的趋势相同。因此,在实际运行时可通过提升滤网转速来缓解进水浓度或进水流量的冲击,也可通过增加进水端液位高度、降低滤网转速来延长过滤时间,提升SS去除效果。

式中:Q为进水流量,m3·s−1;h0为出水端液位,m;Amesh为与污水接触的滤网面积,即bh/sinα,m2;μ为过滤液污水的动力黏度,kg·(m·s)−1;R0为滤网固有阻力,s2·kg−1;RS滤网上泥饼层阻力,s2·kg−1。

旋转式带式过滤器最初在国外常被用于代替初沉池,其运转模式为:降低处理能力以形成致密泥饼层,从而大幅度提升SS及COD的去除效果[1]。处理能力的降低通常与进水水质特性及预期的SS及COD去除率相关,通常为最大设计进水能力的10%~50%[17-19]。实验过程中曾尝试通过降低进水流量及滤网转速来形成致密的泥饼层,然而该操作形成的泥饼层较薄,对于污染物去除率的提升较为有限。由于国内污水厂进水SS及COD普遍偏低,且由于国内生活习惯,污水厂进水中易形成泥饼层的大颗粒杂质、纤维类杂质含量较低。图2所示的进水颗粒物粒径分布也证明了国内水质并不适合泥饼层的形成。总体而言,在国内水质情况下,旋转式带式过滤器更适合以机械过滤的模式运行,而非泥饼层过滤模式。

-

为明确了解进水中砂渣等难降解、不可降解杂质对生化系统效能的影响[2-4,7,11,14],基于德国排水技术协会提出的污泥产率公式,计算了不同进水VSS/SS条件下生化系统污泥产率、活性污泥挥发性悬浮固体比例f及污泥浓度MLSS的变化情况[20],计算公式见式(6)~(8)。

式中:YT为污泥总产率系数,kg·kg−1;YH为异养微生物的增殖率,kg·kg−1,范围为0.60~0.75 kg·kg−1,取0.70 kg·kg−1;YBH为异样微生物内源呼吸衰减部分,kg·kg−1;YISS为进水颗粒性无机物对应的污泥产率系数,kg·kg−1;YNVSS为进水惰性颗粒性有机物对应的污泥产率系数,kg·kg−1;YP,obs为除磷产生的污泥量,kg·kg−1,取0.08 kg·kg−1[21];BH为异养微生物内源呼吸速率,d−1,取0.08 d−1;θc为污泥龄,d,参照实验污水厂生化系统取15;FT为异养微生物生长温度修正系数,取1.072;ω为生化系统内悬浮的颗粒性无机物ISS的比例,取0.5[11];α为生化系统进水VSS/SS比值,取0.35~0.75;CSS,inf为生化系统进水悬浮固体质量浓度,mg·L−1,取进水SS均值201.3 mg·L−1;S0、Se为生化系统进水、出水可生物降解有机物的质量浓度 (以BOD5计) ,mg·L−1,参照实验污水厂水质数据,分别取70 mg·L−1及3 mg·L−1;αNV为生化系统进水颗粒性有机物VSS中惰性有机物比例,取0.32。

式中:M为污泥浓度,mg·L−1;MVSS,XH为污泥浓度中微生物贡献部分,mg·L−1;MISS,inf为污泥浓度中进水颗粒性无机物贡献部分,mg·L−1;MVSS,inf为污泥浓度中进水惰性颗粒性有机物贡献部分,mg·L−1;MISS,P为污泥浓度中除磷贡献部分,mg·L−1;τ为水力停留时间,h,参照实验污水厂生化系统取9.6 h;f为活性污泥挥发性悬浮固体比例。

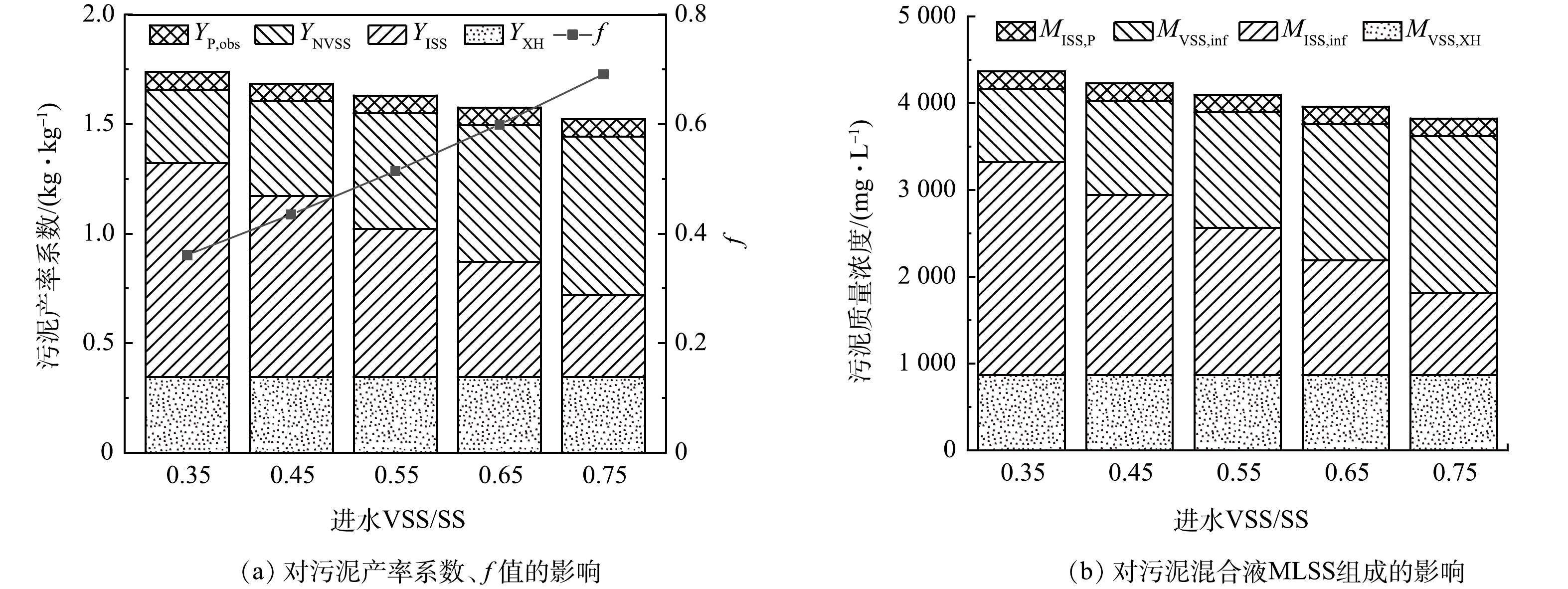

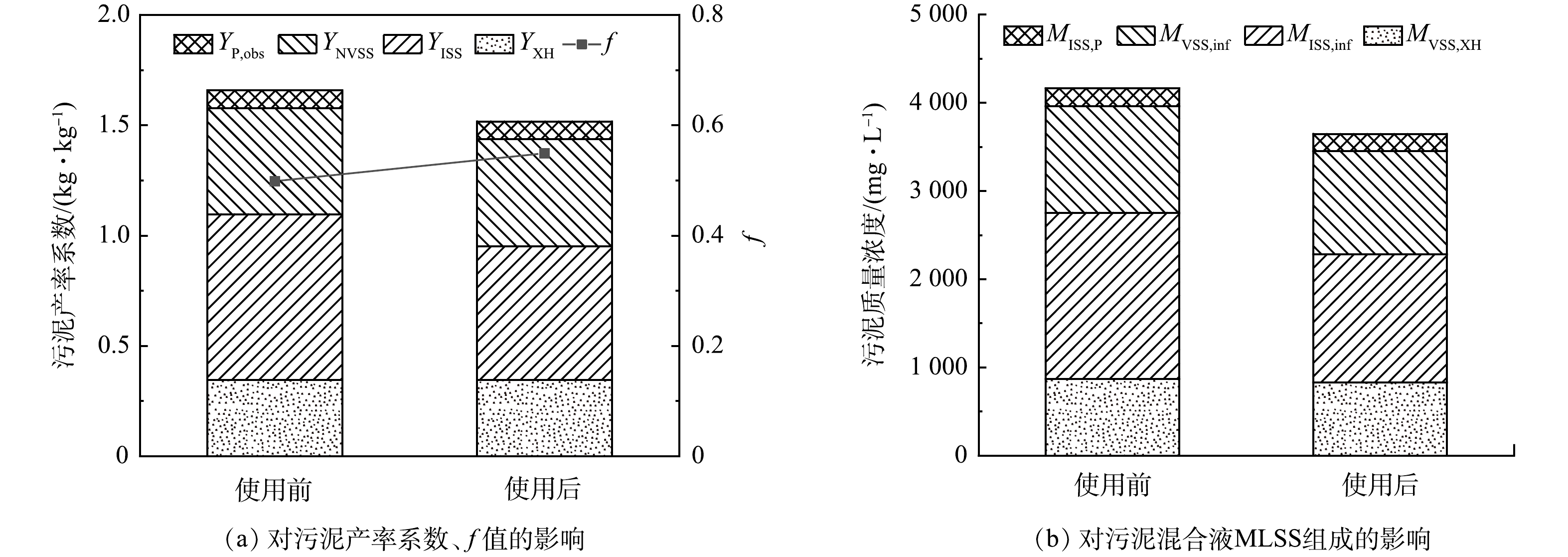

图9分别列出了进水VSS/SS对于生化系统污泥产率、f值及MLSS组成的影响。可见,进水VSS/SS的变化对于活性污泥f值的影响较大,随着进水VSS/SS的逐渐降低,f值呈直线下降趋势,VSS/SS每降低约13.3%,f值将随之降低12%。当进水VSS/SS降低至0.35时,f值仅为0.36,远低于活性污泥系统正常值。进水VSS/SS的降低还会导致污泥产率与污泥浓度的升高,当进水VSS/SS降低至0.35时,污泥产率系数将达到1.74 kg·kg−1,污泥质量浓度则高达4368 mg·L−1,相较于进水VSS/SS为0.65的正常水平,涨幅达到了10.3%。此外,高ISS将导致剩余污泥及污泥混合液中无机污泥比例显著增加,与进水VSS/SS为0.65时相比,进水VSS/SS降低至0.35时,无机污泥比例将增加58.1%,这也是导致活性污泥f值降低的主要原因。

由图9还可以看出,进水中惰性颗粒性有机物的含量对于生化系统活性污泥也有一定程度的影响,其占比的逐渐增加将导致剩余污泥与污泥混合液中惰性挥发性悬浮固体含量MLVSSinf显著增加,污泥混合液中约19%~47%均为此类污泥。此部分挥发性悬浮固体虽然是活性污泥支撑骨架的一部分,但由于其不能参与生化反应,而且还会阻碍微生物与氧气及底物的传质效率,将间接影响生化反应效果。可以发现,由进水砂渣等杂质贡献的无机悬浮固体MLISSinf与惰性挥发性悬浮固体MLVSSinf是活性污泥中的无效部分,不仅会挤占生化池内有效容积,降低系统效率,增加整体能耗,还会影响后续泥水分离与污泥资源化利用。因此,在预处理阶段尽可能地去除进水中的无机颗粒及惰性有机颗粒是非常有必要的。

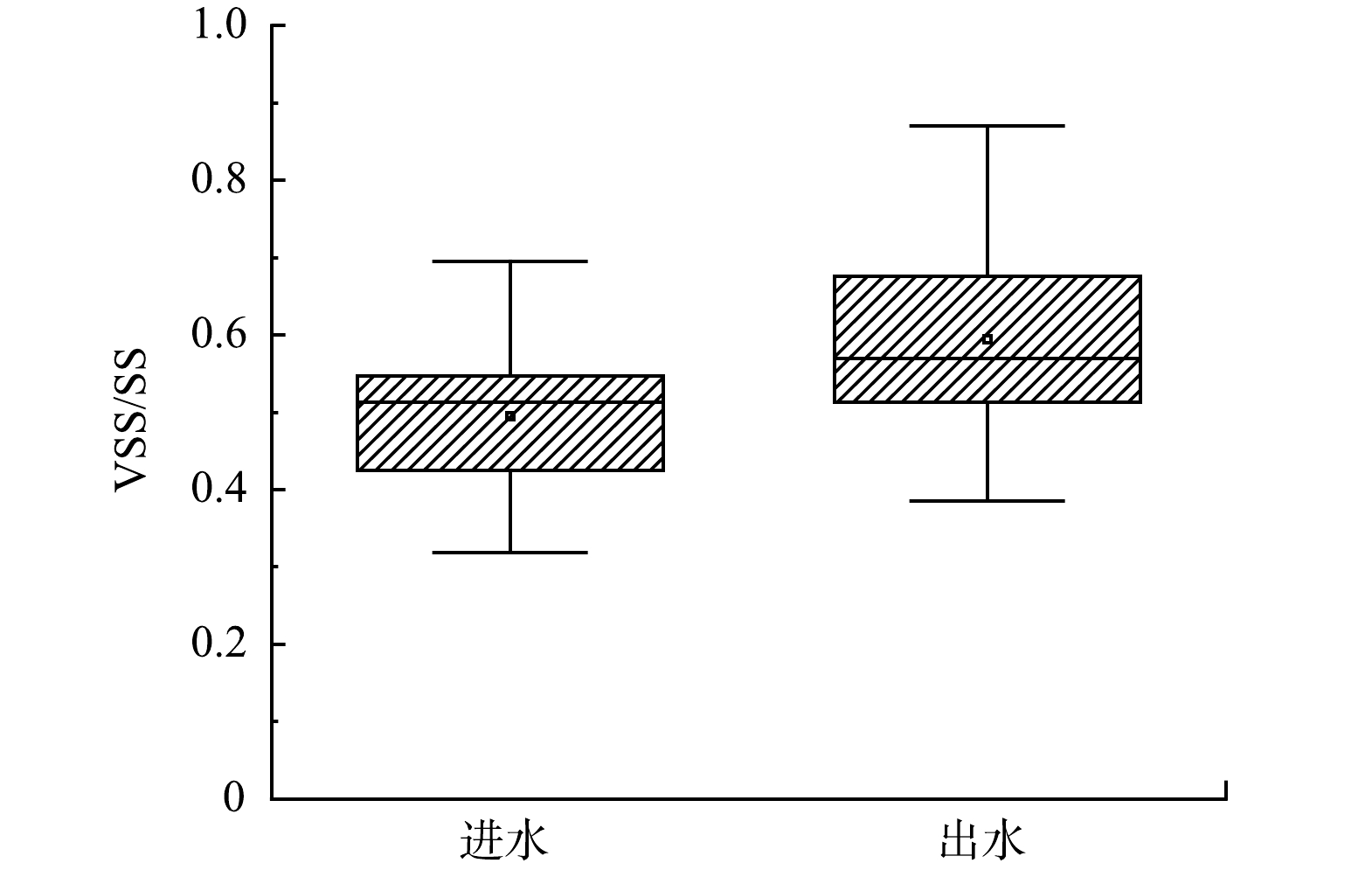

旋转式带式过滤器可有效分离出污水中大于200 μm的砂渣等颗粒物,且分离出的颗粒物以无机颗粒及惰性有机颗粒为主,因此,可有效降低生化系统进水中无机组分及惰性有机组分的含量。为进一步了解该设备对生化系统效能提升的实际效果,考察了其对污水VSS/SS的改善情况,结果见图10。旋转式带式过滤器进水VSS/SS平均值为0.50±0.10,低于0.60~0.80的正常范围[2],经处理后的出水VSS/SS提升至0.59±0.13,增幅为18.0%。

进一步以表3所列数据为基础,计算使用旋转式带式过滤器后对生化系统污泥产率、f值及MLSS组成的影响情况,结果见图11。使用旋转式带式过滤器后,生化系统污泥产率系数由1.66 kg·kg−1降低至1.52 kg·kg−1,混合液污泥质量浓度则由4 164 mg·L−1降低至3 647 mg·L−1,预期可降低8.4%的污泥产量及12.4%的混合液污泥浓度;活性污泥f值则由0.50升高至0.55,增幅达10%。此外,由进水无机组分贡献的MLISSinf由1 887 mg·L−1降低至1 453 mg·L−1,降低幅度达23.0%,而由进水惰性有机组分贡献的MLVSSinf则由1 208 mg·L−1降低至1 171 mg·L−1,降低幅度达3.1%。可以发现,旋转式带式过滤器以过滤原理同步去除了污水中的砂渣等杂质,其中砂等无机颗粒的去除可有效提升f值,而被去除的渣等有机颗粒主要由大量惰性颗粒性有机物和少量慢速可降解颗粒性有机物组成,该类杂质的去除虽然不能有效提升进水VSS/SS,但可改善微生物与氧气及底物的传质效率,降低污泥产量与无效污泥浓度。

-

1)旋转式带式过滤器对200 μm以上颗粒物的平均去除率达81.6%,对SS、COD及ISS的去除率分别为5.9%、4.2%及11.8%,污染物的去除主要依靠滤网机械过滤作用、网状结构拦截作用及泥饼层截留作用。

2)旋转式带式过滤器的过滤过程符合达西定律,过滤时间和水力负荷是影响处理效果的主要因素,当过滤时间大于5 s、水力负荷处于150~250 m·h−1时可取得较好的污染物去除效果。考虑国内水质情况,该设备适合在较高滤网转速下以机械过滤模式运行。

3)旋转式带式过滤器分离出的杂质以惰性有机颗粒及无机颗粒为主,可较好地保留污水中的有效碳源,预期可提升10%的活性污泥挥发性悬浮固体比例,降低8.4%的污泥产量及12.4%的混合液污泥浓度,同时可降低活性污泥中无效部分MLISSinf及MLVSSinf的比例,降低幅度分别为23.0%和3.1%。

旋转式带式过滤器强化生活污水预处理的评估优化

Evaluation and optimization of rotating belt filter for enhanced pretreatment of domestic sewage

-

摘要: 为探究适用于我国污水水质特点的强化预处理工艺,在贵阳某污水厂内搭建了旋转式带式过滤器生产性实验装置(4 000 m3·d−1)。针对实际生活污水,考察了其处理效果及相关的影响因素,核算了砂渣去除对生化系统效能提升的具体效果。结果表明:旋转式带式过滤器可同步去除污水中以砂渣为代表的惰性有机颗粒及无机颗粒,对粒径200 μm以上颗粒物的平均去除率达81.6%,预期可提升10%的活性污泥挥发性悬浮固体比例,降低8.4%的污泥产量及12.4%的混合液污泥浓度。过滤时间和水力负荷是影响处理效果的主要因素,当过滤时间大于5 s、水力负荷处于150~250 m·h−1时可取得较好的污染物去除效果。该设备可用于我国生活污水强化预处理,且适宜在较高转速下以机械过滤模式运行。Abstract: In order to explore the enhanced pretreatment process being applicable to the characteristics of sewage quality in China, a production test device (4 000 m3·d−1) of rotating belt filter (RBF) was built in a sewage plant in Guiyang. For the actual domestic sewage, the treatment efficiency and influencing factors of the RBF were investigated, and the specific effect of sand and slag removal on the improvement of biochemical system efficiency was calculated. The results showed that the RBF could simultaneously remove inert organic particles and inorganic particles represented by sand slag in sewage, and the average removal rate of particulates larger than 200μm could reach 81.6%. The RBF was expected to increase the proportion of volatile suspended solids in activated sludge by 10%, reduce the sludge production by 8.4% and the mixed liquor suspended solid by 12.4%. The filtering time and hydraulic load were the main factors affecting the treatment efficiency. When the filtering time was longer than 5s and the hydraulic load was between 150 m·h−1 and 250 m·h−1, a better performance on pollutions removal by the RBF could occur. The RBF can be used for the enhanced pretreatment of domestic sewage in China, and it is suitable to operate in the mechanical filtration mode at a higher speed.

-

表 1 旋转式带式过滤器对污染物的去除效果

Table 1. Pollutant removal efficiency by RBF

水样 SS/(mg·L−1) COD/(mg·L−1) ISS/(mg·L−1) 进水 201.3±89.1 141.5±49.2 101.6±35.1 出水 189.0±86.2 135.1±48.9 88.3±29.7 平均去除率/% 5.9 4.2 11.8 表 2 分离出的砂渣杂质有机物组分构成

Table 2. Organic matter composition of separated sand-slag impurities

有机物成分 含量/(g·kg-1) 占比/% 惰性颗粒性有机物Xl 294.42 77.63 慢速可降解颗粒性有机物Xs 84.76 22.35 (易降解+惰性)溶解性有机物S 0.061 0.02 表 3 旋转式带式过滤器对生化系统进水的改善情况

Table 3. Improvement of RBF influent of biochemical system

旋转式带式过滤器进出水 CSS,inf /(mg·L−1) S0 /(mg·L−1) α αNV 进水 201.3 70.0 0.50 0.322) 出水 189.0 67.11) 0.59 0.283) 注:1)去除率以COD平均去除率4.2%计;2)测试得到进水所含慢速可降解颗粒性有机物Xs为48 mg·L−1,惰性颗粒性有机物Xl为23 mg·L−1,对应αNV为0.32;3)实验得到旋转式带式过滤器Xs去除量为1.3 mg·L−1,Xl去除量为4.5 mg·L−1,计算得到αNV为0.28。 -

[1] TCHOBANOGLOUS G, BURTON F L, STENSEL H D. Wastewater Engineering: Treatment and Reuse(Fourth Edition)[M]. McGraw-Hill, 2005. [2] 曹业始, 郑兴灿, 刘智晓, 等. 中国城市污水处理的瓶颈、缘由及可能的解决方案[J]. 北京工业大学学报, 2021, 47(11): 1292-1302. doi: 10.11936/bjutxb2020040009 [3] 王洪臣. 关注城镇污水处理厂运营困境, 共同探寻破解之道[J]. 给水排水, 2019, 45(9): 1-3. [4] 吉芳英, 来铭笙, 何莉, 等. 细微泥沙粒径对活性污泥产率的影响及其计算公式[J]. 环境工程学报, 2016, 10(4): 1627-1632. doi: 10.12030/j.cjee.20160408 [5] 李佟, 崔春玥, 郝凤玲, 等. 曝气沉砂池除砂效果分析与优化研究[J]. 给水排水, 2017, 43(2): 45-48. doi: 10.3969/j.issn.1002-8471.2017.02.010 [6] 尹雷, 刘艇, 周文政, 等. 新型水力旋流除砂设备在西安市某污水厂的运行情况研究[J]. 节能与环保, 2021: 92-94. doi: 10.3969/j.issn.1009-539X.2021.05.035 [7] 侯锋. 地下式污水处理厂关键技术研究与工程实践[D]. 北京: 清华大学, 2017. [8] ODEGARRD H. Optimised particle separation in the primary step of wastewater treatment[J]. Water Science & Technology, 1998, 37(37): 43-53. [9] RUSTEN B, ODEGAARD H. Evaluation and testing of fine mesh sieve technologies for primary treatment of municipal wastewater[J]. Water Science & Technology, 2006, 54(10): 31-38. [10] 岳耀冬, 李军, 王昌稳, 等. 旋转带式预滤机除砂试验研究[J]. 中国给水排水, 2016, 3(23): 72-75. doi: 10.19853/j.zgjsps.1000-4602.2016.23.017 [11] 吉芳英, 周峰, 范剑平, 等. 降雨过程对污水处理厂无机颗粒物特性及活性污泥的影响[J]. 环境工程学报, 2016, 10(9): 4643-4648. doi: 10.12030/j.cjee.201601129 [12] MANSOUR-GEOFFRION M, DOLD P L, LAMARRE D, et al. Characterizing hydrocyclone performance for grit removal from wastewater treatment activated sludge plants[J]. Minerals Engineering, 2010, 23(4): 359-364. doi: 10.1016/j.mineng.2009.08.001 [13] LAGUNA A, OUATTARA A, GONZALEZ R O, et al. A simple and low cost technique for determining the granulometry of upflow anaerobic sludge blanket reactor sludge[J]. Water Science & Technology, 1999, 40(8): 1-8. [14] HE P J, LU F, ZHANG H, et al. Sewage sludge in China: Challenges toward a sustainable future[J]. Water Practice and Technology, 2007, 2(4): 83-90. [15] MSPERANDIO M, ETIENNE P. Estimation of wastewater biodegradable COD fractions by combining respirometric experiments in various So/Xo ratios[J]. Water Research, 2000, 34(4): 1233-1246. doi: 10.1016/S0043-1354(99)00241-9 [16] 柏小家. BioWin模拟软件在污水处理厂运行过程中的优化研究[D]. 昆明: 昆明理工大学, 2016. [17] RUSTEN B, RAZAFIMANANTSOA V A, ANDRIAMIARINJAKA M A, et al. Impact of fine mesh sieve primary treatment on nitrogen removal in moving bed biofilm reactors[J]. Water Science & Technology, 2016, 73(2): 337-344. [18] RAZAFIMANANTSOA V A, YDSTEB L, BILSTAD T, et al. Effect of selective organic fractions on denitrification rates using Salsnes Filter as primary treatment[J]. Water Science & Technology, 2014, 69(9): 1942-1948. [19] RUSTEN B, RATHNAWEERA S S, RISMYHR E, et al. Rotating belt sieves for primary treatment, chemically enhanced primary treatment and secondary solids separation[J]. Water Science & Technology, 2017, 75(11): 2598-2606. [20] 德国水资源、污水与固废管理协会. 一段式活性污泥法工艺设计规范(ATV-DVWK-A 131)[M]. 姚刚, 庞洪涛, 施汉昌, 译. 北京: 清华大学出版社, 2021. [21] 刘紫威. 利用ASM1模型分析进水颗粒无机物对污水厂运行的影响[D]. 扬州: 扬州大学, 2021. -

下载:

下载: