-

石油开采、运输以及贮存过程均会产生油田采出水,其具有含油量大、悬浮固体浓度高、有机物种类复杂[1-2]等特点。油田采出水处理处置不当会破坏生态环境并对人类健康造成巨大危害。对油田采出水进行深度处理,达到回注标准后回注,则既可避免油田采出水进入环境危害生物,也可避免水资源的大量浪费,因而成为近年来油田采出水处理处置领域的研究热点。

传统含油废水处理工艺一般有气浮、离子交换、吸附、混凝等[3-5]。然而由于油田采出水中乳化油的稳定状态,传统方法处理油田采出水达到回注标准难度大,往往需做进一步的精细处理。随着膜法水处理技术的发展,利用膜分离技术处理含油废水近年来应用日益广泛。利用膜技术处理油田采出水具有分离效果好、药剂投加量少、出水水质稳定、易于实现自动化控制等优点[6-8]。相较于有机膜,陶瓷膜以其强度高、耐腐蚀、耐高温、热稳定性好等特性[9-12],在膜技术处理油田采出水领域展现出更大的优势,但陶瓷膜处理油田采出水过程中,膜污染问题依然存在。由于油田采出水水质的复杂性,陶瓷膜过滤一段时间后会形成污垢,堵塞膜孔,导致过滤压力增大,膜通量下降,产水量降低[13-15],给陶瓷膜在油田采出水处理工程中的大规模应用造成了阻碍。合理优化陶瓷膜处理油田采出水系统运行控制工况,明确陶瓷膜处理油田采出水过程膜污染机理,开发更为高效的膜污染控制方法已成为陶瓷膜处理油田采出水领域亟待解决的关键问题。

本研究针对陶瓷膜处理油田采出水过程中存在的膜污染机理不明晰的问题,构建了陶瓷膜反应器,处理两级过滤后的实际油田采出水。通过四因素三水平正交实验,筛选出膜污染控制效果最优的运行控制工况。结合微观表征和膜阻力分析等手段,确定了造成陶瓷膜污染的主要污染物,揭示了油粒对陶瓷膜污染的微观机理,可为陶瓷膜在油田采出水处理及回用领域的推广应用提供参考。

-

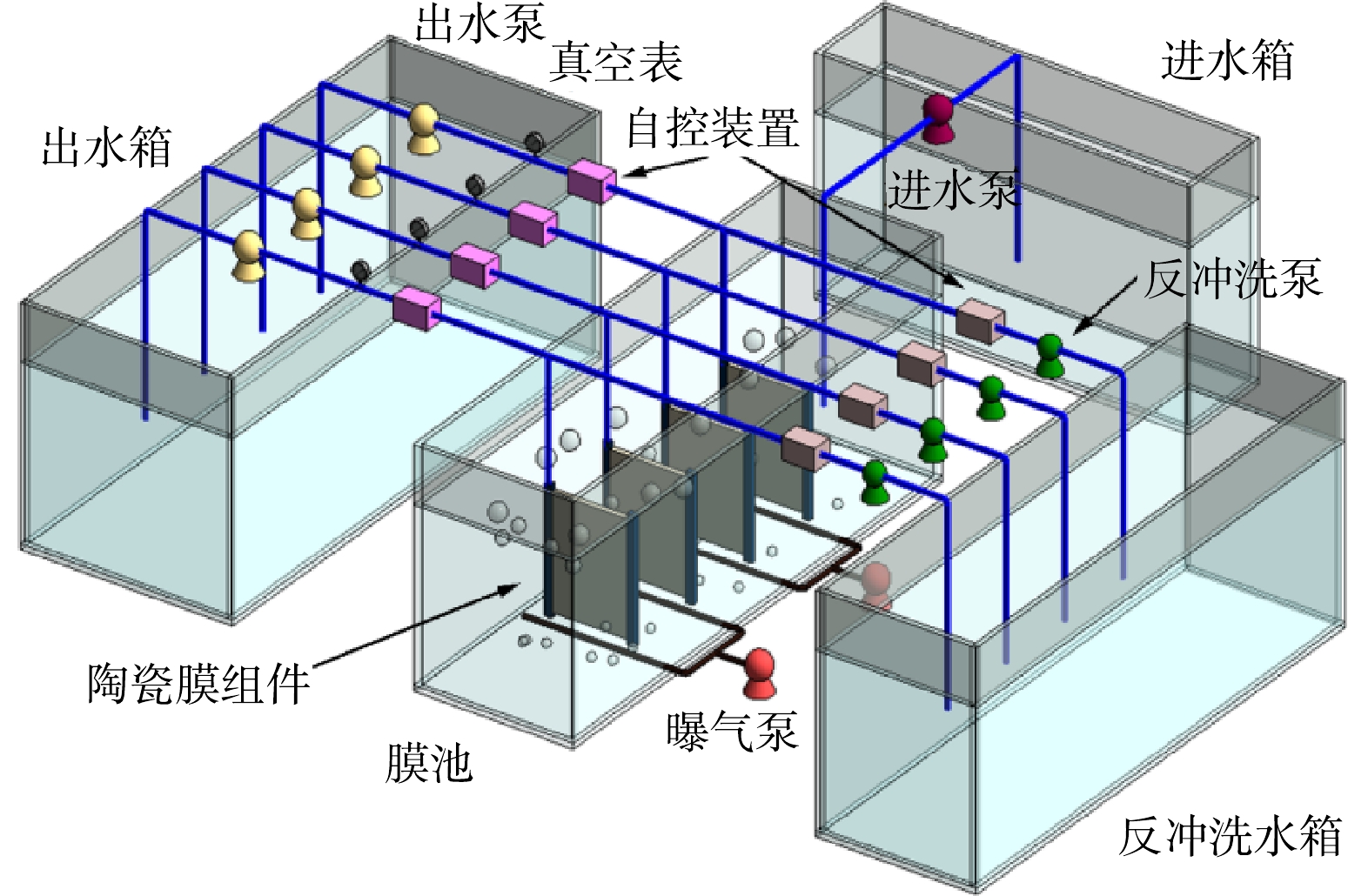

本研究采用的平板陶瓷膜处理油田采出水实验装置如图1所示。进水为取自胜利油田坨六站经2次除油罐出水的油田采出水,纯净水作为反冲洗用水。膜池的材质为PVC,有效容积为250 L,膜组件反应器及其相关配制置于膜池内,膜组件反应器内可同时运行4片平板陶瓷膜,通过气体流量计和膜组件底部的微孔曝气管对平板陶瓷膜表面进行定量曝气。陶瓷膜为购自山东某工业陶瓷研究院的同一批次全新平板陶瓷膜,膜材质陶瓷部分为Al2O3,集水部分为高分子聚乙烯,膜孔径为0.1 µm,有效过水面积为0.10086 m2, pH为2~12;实验以油田采出水为膜前原水,蠕动泵连接管路抽吸出水,通过量筒和真空表测定滤出液的体积和出水压力。平板陶瓷膜出水口使用三通分为抽滤系统和反冲洗系统,分别由自控装置控制运行。自控装置由电磁阀、计时器组成,通过自控装置控制蠕动泵的开关完成实验运行。

-

本实验用水采用胜利油田坨六站经核桃壳、双滤料两级过滤后出水的油田采出水:水温为22~25 ℃,pH为6.7~6.9,含油量为15~38 mg·L−1,悬浮固体含量为17~46 mg·L−1,粒径中值为2.5~3 µm。

-

在后续所有陶瓷膜处理油田采出水的实验中,出水含油量均在5 mg·L−1以下,SS<1 mg·L−1,粒径中值<1 μm,符合《碎屑岩油藏注水水质推荐指标及分析方法》(SY/T5329-2012)中A1级回注标准。这也验证了平板陶瓷膜处理油田采出水的优良效果。

-

1)含油量测定。按照《碎屑岩油藏注水水质推荐指标及分析方法》中测定含油量的方法配制标准油溶液,采用分光光度法测定,并绘制标准曲线。利用石油醚作为萃取剂,萃取油田采出水中的含油量,以石油醚为参比,测其在波长212 nm下的吸光度,根据式(1)计算含油量。

式中:

$ {\rho }_{0} $ 为含油量,mg·L−1;$ {m}_{0} $ 为标准曲线上对应的含油量,mg,$ {V}_{0} $ 为萃取水样体积,mL。2)膜通量测定。采用体积法进行平板陶瓷膜膜通量测定,自量筒量内取一定时间内通过一定膜面积的过滤液体积,根据式(2)计算膜通量。

式中:J为膜通量,L·(m2·h)−1;V为透过渗积物的体积,L;S为膜的有效过水面积,m2;t为过滤时间,h。

3)膜污染阻力分析。根据Darcy定律的过滤模型来确定平板陶瓷膜过滤过程中的阻力分布情况[16]。

式中:µ为料液粘度,Pa·s;Rt为膜污染过程中的总阻力,m−1;Δp为跨膜压差,Pa;Rm为膜本身的固有阻力,m−1;Ri为膜孔内污染阻力,m−1;Rc为浓差极化层阻力,m−1;Rg为当溶质在膜面富集形成的凝胶层阻力,m−1。

4)正交实验设计。本研究将运行控制因素优化作为实现膜污染有效控制的关键技术手段,确定了初始膜通量、过滤时间、水力反冲洗时间和曝气强度作为平板陶瓷膜运行调控的的关键因子[17-20],平均膜通量为响应值的四因素三水平正交实验。使用SPSS (statistical package for the social science) 对正交实验结果进行统计学分析,验证正交实验的结果。

5)分析手段。傅里叶变换红外光谱(fourier transform infrared spectroscopy,FTIR),检测未知物的官能团、测定化学结构、观察化学反应历程;扫描电镜(scanning electric microscopy,SEM),利用电子束扫描样品表面从而获得样品信息,了解物体表面微观结构;X射线能谱(X-ray energy dispersive spectrometer, EDS),检测元素发出的特征X射线的频率,用于分析污染层和膜表面的微观结构和元素组成。

-

平板陶瓷膜一般具有自身膜通量较高、机械强度高、耐高温耐腐蚀能力强的特点。掌握平板陶瓷膜的渗透特性利于控制后续的实验过程。

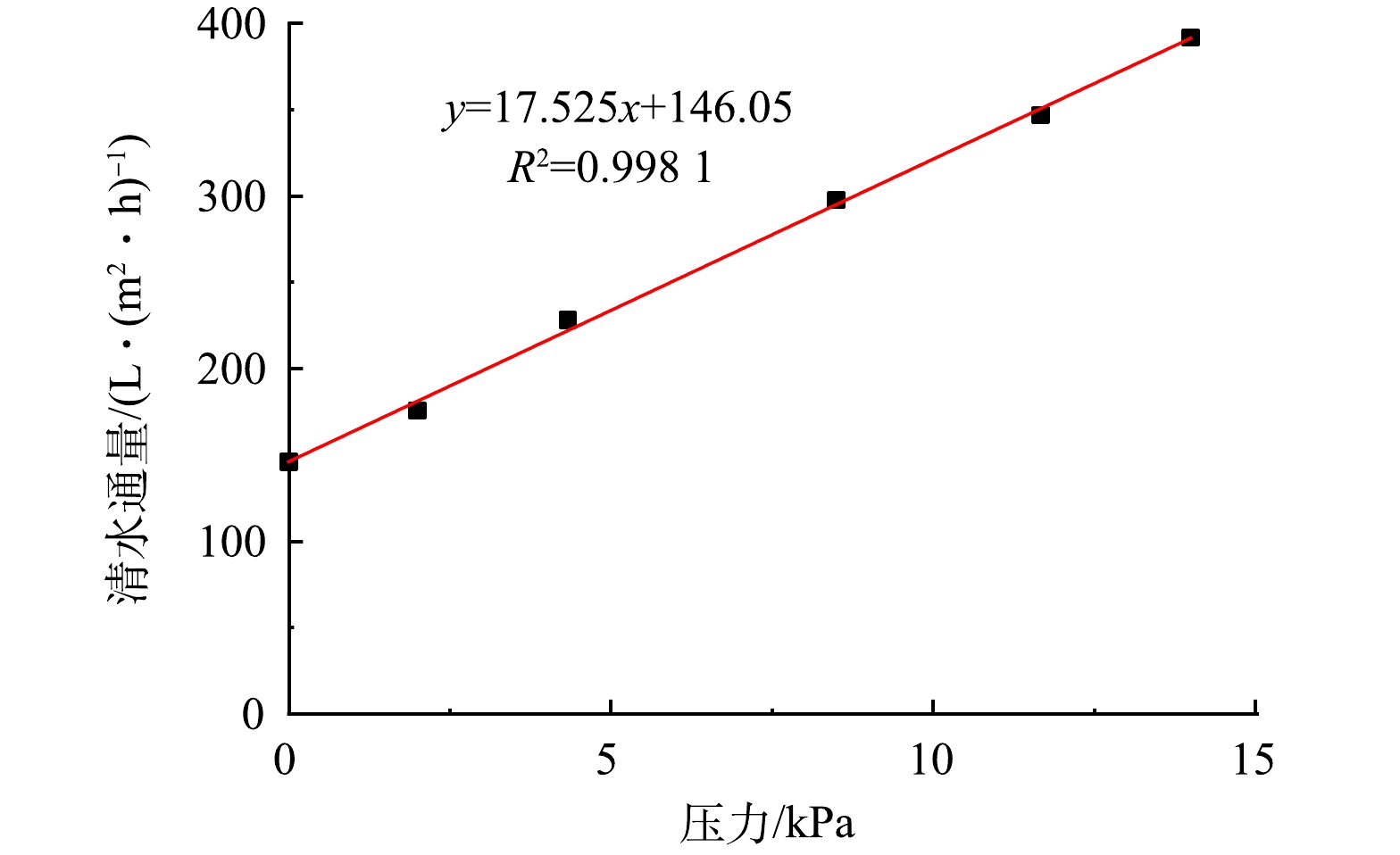

1)平板陶瓷膜清水通量测试。测定新膜抽滤蒸馏水的通量作为清水通量,调节蠕动泵转速,使实验装置在每个转速下持续运行30 min,记录平板陶瓷膜的出水量。将5 min出水量带入式(2)计算膜通量。管内压力与清水通量关系见图2。可以看出,在本实验条件下,平板陶瓷膜清水通量随管内压力增大而增加。当管内压力为15 kPa时,平均清水通量为408.93 L·( m2·h)−1。这说明平板陶瓷膜具有良好的过滤性能。

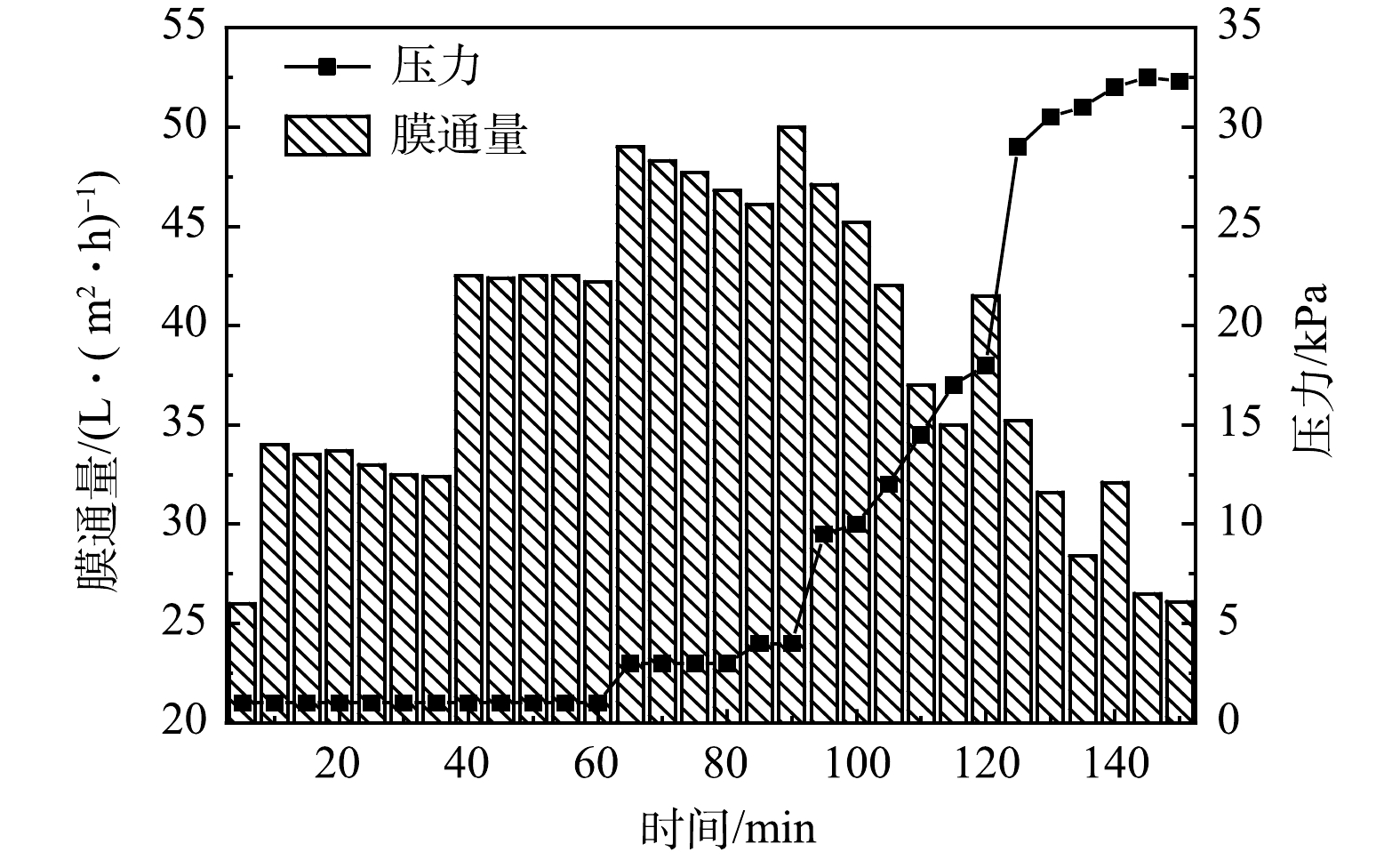

2)平板陶瓷膜临界通量测试。通过阶梯法来确定本实验条件下的临界通量:保持反应器在较低的通量J0运行一段时间,记录固定间隔(Δt)内该过程中跨膜压差的变化;提高膜通量J1,通量的增加值称为通量阶梯 (ΔJ=J1-J0),记录每个固定时间间隔(Δt)内过滤过程中跨膜压差的变化。重复以上步骤,不断提高膜通量,直至跨膜压差有突然的飞跃或者是在某阶梯间隔里跨膜压差不再稳定时为止,设此时的膜通量为JN+1 (N为实验中流量阶梯的增加次数),则JN为在该实验条件下允许保持跨膜压差恒定的最大膜通量,即为临界通量。

调节蠕动泵转速为30、40、50、60、70 r·min−1,使每个转速对应的压力梯度持续运行30 min。膜通量以5 min内滤出液的体积通过式(2)来计算。记录每5 min的压力和通量变化。在临界通量测试过程中,压力和膜通量变化如图3所示。前90 min内,平板陶瓷膜运行通量不高于50 L·(m2·h)−1。前60 min内,管内压力和膜通量基本保持一致,在第3个周期内,压力基本稳定,膜通量开始呈下降的趋势;在90 min之后的2个周期内,管内压力随时间增加急剧升高,且膜通量下降趋势加重,这说明当膜通量高于50 L·( m2· h)−1后,膜污染的速度较之前加快。此时,即便再次降低膜通量,膜压也不能恢复到原有的水平,这说明膜面开始形成滤饼层,即发生了不可恢复的膜污染。因此,确定本实验条件下平板陶瓷膜处理油田采出水的临界通量为50 L·( m2· h)−1。

-

1)正交实验。如前所述,本实验构建了以初始膜通量、过滤时间、水力反冲洗时间和曝气强度为影响因素,平均膜通量为响应值的四因素三水平正交实验。为了更全面地研究初始膜通量的影响,结合前期实验结果,初始膜通量选取大于、等于、小于临界通量3个水平,即30、50、80 L·(m2·h)−1,其通过调节蠕动泵的转速来实现;过滤时间3个水平值分别为10、15、20 min ;反冲洗时间分别选取30、60、90 min;曝气强度选取1、3、5 L·min−1。本实验采用相同的反冲洗强度,为400 mL·min−1。正交实验的因素水平见表1。

依次开展9种工况下的实验,每个工况同时运行2片同一批次的全新的陶瓷膜,并分别记录各自的管内压力及膜通量随时间的变化情况,最终取2片膜的平均膜通量均值作为该工况的平均膜通量,将15 L·( m2· h)−1作为此后所有实验的污染终点,以进行后续实验分析。

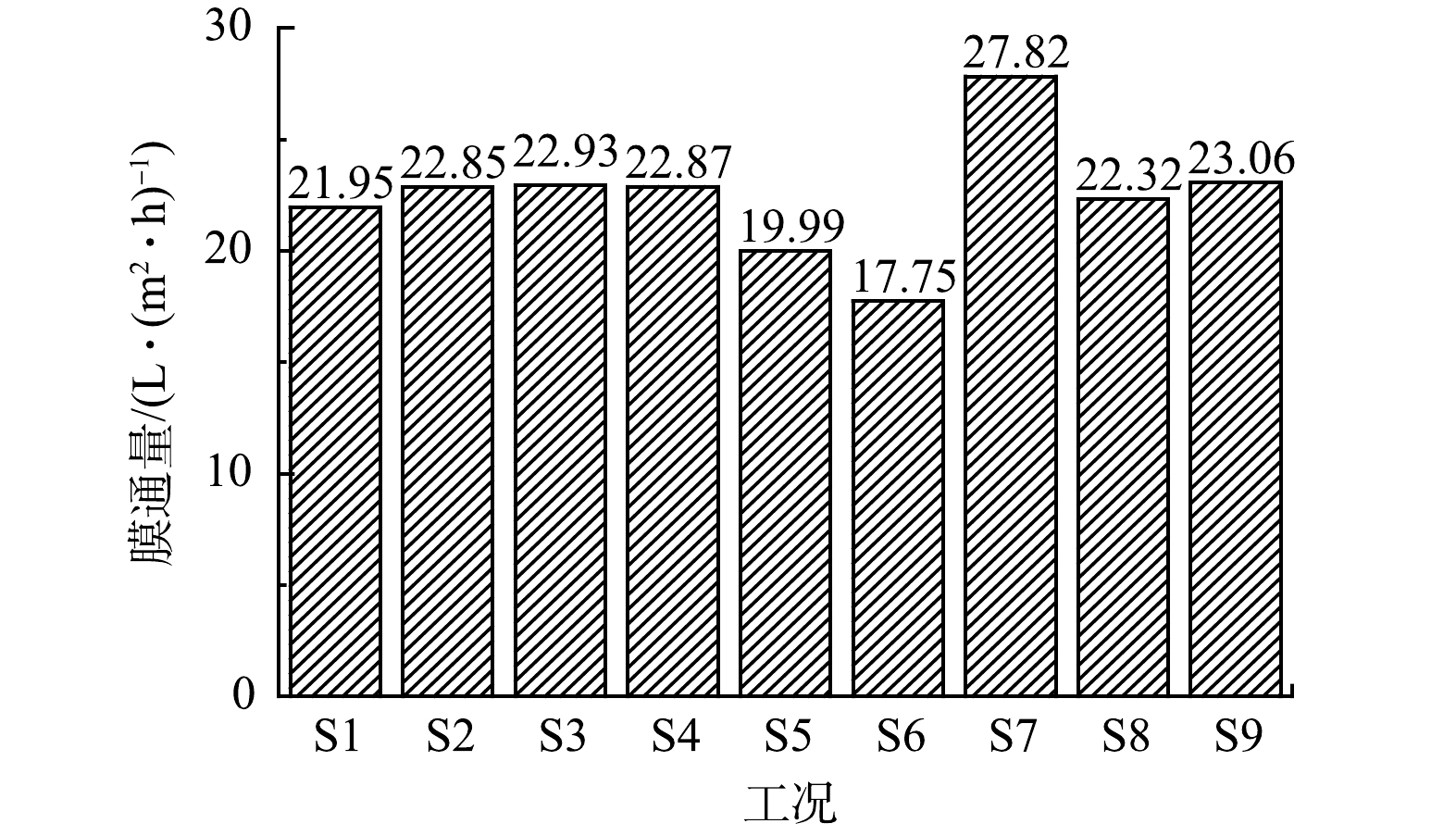

2)优化运行控制正交实验结果分析。不同工况下的平均膜通量结果如图4所示。可以看出,S7工况下的膜平均通量最大,为 27.82 L·(m2· h)−1,S6工况下膜的平均产水量最小,为 17.75 L·( m2· h)−1。各工况平均膜通量依次为S7>S9>S3>S4>S2>S8>S1>S5>S6,极差分析结果确定S7为平板陶瓷膜处理油田采出水最佳运行工况。

为验证实验结果的准确性,采用SPSS软件对正交实验数据进行分析[21-23]。如表2所示,对膜平均通量影响大小的显著性顺序为初始膜通量>反冲洗时间>过滤时间>曝气强度。其中,初始膜通量和反冲洗时间的影响较为显著。由表3可知,在初始膜通量80 L·( m2· h)−1,过滤时间10 min,反冲洗时间30 s,曝气强度3 L·min−1时可以获得更高的平均膜通量,与前述四因素三水平正交实验极差分析得出的最佳运行工况一致。

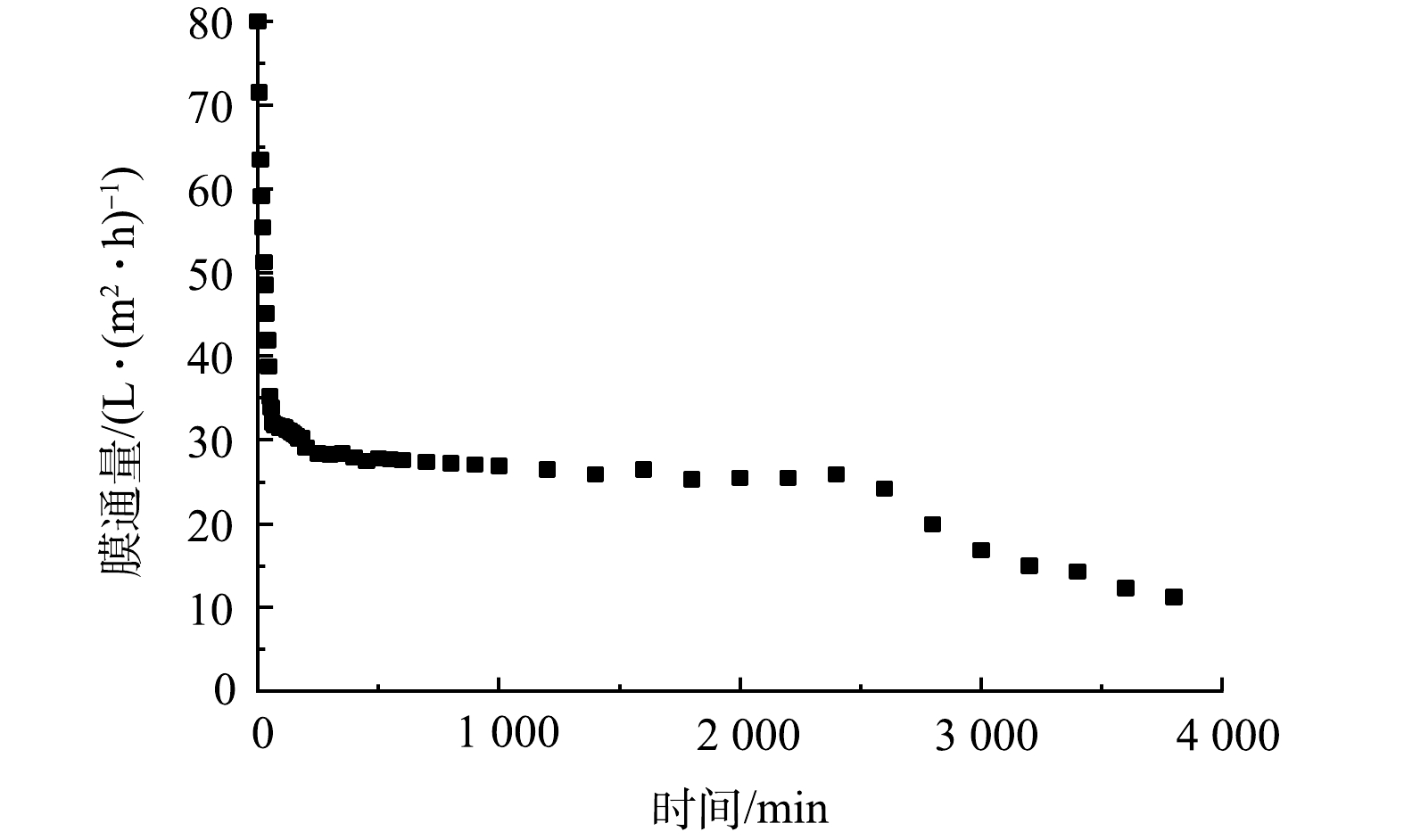

图5反映了最优工况S7下平板陶瓷膜处理油田采出水的通量曲线和平均通量。可以看出,在最开始的1 h内 通量衰减快,膜通量由80 L·(m2·h)−1迅速降至32.1 L·( m2· h)−1。此阶段膜污染形成的主要原因是浓差极化;在60~2 400 min,膜通量衰减速率开始减缓,平均膜通量基本稳定在27.82 L·( m2· h)−1附近,此时膜表面形成的滤饼层较稀疏,原水中的污染物颗粒仍然可以通过,因而对膜的过滤性能影响较小,并且水力反冲洗的水力冲刷作用能冲击掉稀疏的滤饼层上部分的污染物颗粒,因而效果显著,导致膜通量衰减缓慢;在2 400 min 之后,随着膜过滤过程的进行,滤饼层逐渐变得密实,此时水力反冲洗对通量恢复几乎没有效果;在3 300 min时,膜通量已经降低至14.87 L·( m2· h)−1,此时滤饼层已经成为泥饼层,对膜孔和表面的堵塞程度十分严重,此时的膜通量迅速下降,管内压力也迅速增大,仅依靠水力反冲洗已经不能恢复其通量,需要对其进行化学清洗。这说明即便在最优运行参数下,膜污染依然不可避免。因此,判定膜污染的主要成分以及考察膜的污染阻力分布对于阐明膜污染机制是必要的。

-

1)膜污染成分分析。采用能谱分析(EDS)对原水和平板陶瓷膜污染层进行了元素组成及含量对比表征,结果如表4所示。可以看出,原水层中Cl、Na元素含量较高,体现了油田采出水中无机盐含量很高的特点;C元素在原水和污染层中的占比均较大,污染层中O、Si、S元素较原水出现了富集,说明油田采出水中有机污染物含量较高。此外,污染层中含有Ba、Fe、 Ca、和Mg等无机金属元素。这说明无机金属离子也是导致膜污染的重要因素。

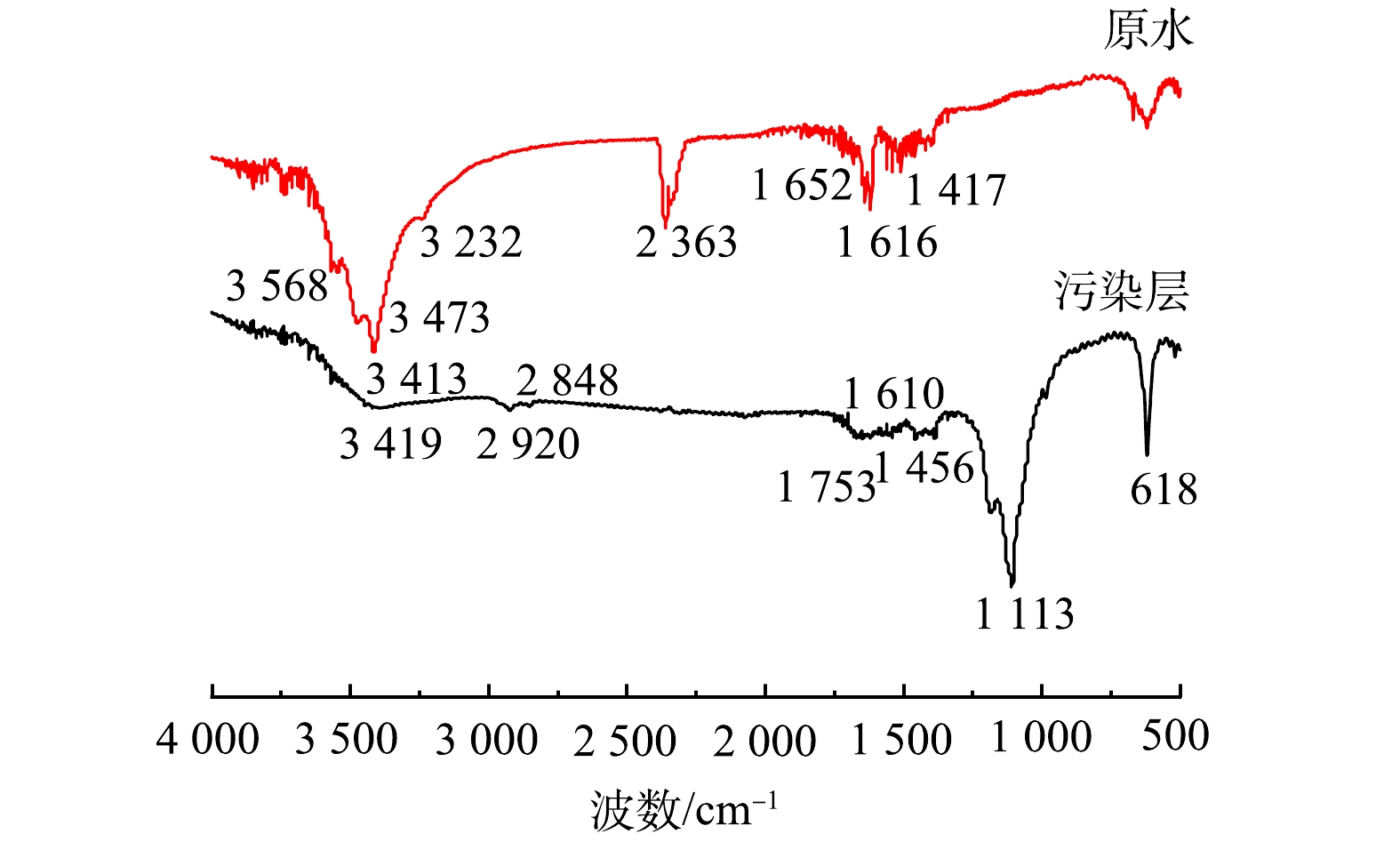

实验所用原水(即胜利油田坨六站经二级过滤后的油田采出水)和污染层(陶瓷膜处理油田采出水所形成的污染层)的红外谱图分析结果如图6所示。由图6(a)可见的红外谱图中,1 417cm−1为C-H及-CH2的变形吸收峰;1 616 cm−1处谱带伸缩振动表明芳环及杂芳环的存在;1 652 cm−1为–C=O的对称振动吸收,及3 232 cm−1处的伸缩振动确定为酰胺类的特征吸收;2 336 cm−1为CO2的弱吸收带;3 413 cm−1对应于游离仲酰胺的伸缩振动;3 568 cm−1和3 473 cm−1分别为羟基以游离态及二聚态形式的伸缩振动谱带。由此可以看出原水中污染物质主要以烃类、芳香族、酰胺类、醇类、羧酸类及胺类化合物的形式存在。由图6(b)可见,1 113 cm−1附近的伸缩振动3 419 cm−1附近的振动被判断为是醇类化合物;1 456~1 610 cm−1内2~3条谱带表明芳环及杂芳环的存在;1 753 cm−1附近出现的肩峰表明是游离态的羧酸;1 669 cm−1附近的振动为酰胺的振动;在2 920 cm−1 和 2 848 cm−1附近出现了2个特征吸收峰,其都是饱和烃基的C-H键。由此可推测,造成膜污染的主要物质是醇类、芳香族、胺类或酰胺类、羧酸类、烃类化合物。

2)膜污染阻力分析。实验中通过3次平行实验测定并计算各部分过滤阻力,陶瓷膜各部分过滤阻力及占总阻力比例的平均值如表5所示。由表5可见,在本条件下,平板陶瓷膜自身阻力Rm,即由膜自身性质决定的阻力,约占总阻力的24.5%;浓差极化层阻力Rc约占总阻力的8.1%,这部分阻力是可逆的,可通过优化运行参数来降低这部分阻力。膜孔内污染阻力Ri约占总阻力的39.7%,这部分阻力主要发生在膜滤开始阶段。凝胶层阻力Rg 约占总阻力的27.7%,这部分阻力是由于溶质吸附在膜面直至浓度达到饱和后沉积在膜表面所产生的,需要通过高强度的反冲洗或者化学清洗来去除。膜孔内阻力和凝胶层阻力占总阻力的65%以上,对过滤影响最大,尤其是膜孔内阻力,对膜污染起着主要作用。

-

1)正交实验得到的最优运行工况为初始膜通量80 L·(m2·h)−1,过滤时间10 min,反冲洗时间30 s,曝气强度3 L·min−1,此工况下平均膜通量为27.82 L·(m2·h)−1,出水水质满足回注要求;对结果进行方差分析,四因素的影响顺序为初始膜通量>反冲洗时间>过滤时间>曝气强度。

2)胺类或酰胺类、烃类、羧酸类、芳香族、醇类等有机化合物是造成陶瓷膜污染的主要污染物,Si、Fe、Ca、Mg、Ba等无机盐离子也是膜污染的重要组成部分。

3)陶瓷膜自身阻力、膜孔内污染阻力、浓差极化层阻力、凝胶层阻力分别占总阻力的24%、40%、8%、28%。膜孔内阻力和凝胶层阻力占总阻力的65%以上,对过滤效果影响最大。

平板陶瓷膜处理油田采出水运行控制优化及膜污染机理

Operation control optimization and membrane fouling mechanism of flat-sheet ceramic membrane treating oilfield produced water

-

摘要: 陶瓷膜凭借其机械强度高、化学稳定性好等优点,近年来在油田采出水处理领域得到了广泛的应用。针对陶瓷膜处理油田采出水膜污染控制这一核心问题,采用小试实验与模型分析相结合的方法,深入开展了陶瓷膜处理系统运行控制优化的研究,结合微观表征,阐明了陶瓷膜处理油田采出水膜污染机理。结果表明,陶瓷膜处理油田采出水最佳运行控制工况为:初始膜通量80 L·(m2·h)−1,过滤时间10 min,反冲洗时间30 s,曝气强度3 L·min−1;此条件下陶瓷膜可保持平均膜通量27.82 L·(m2·h)−1。原水和污染层的表征结果表明,胺类或酰胺类、烃类、羧酸类、芳香族、醇类等有机物化合物是造成陶瓷膜污染的主要有机物,Si、Fe、Ca、Mg、Ba等无机盐离子也是膜污染的重要组成部分;过滤过程中膜孔内阻力和凝胶层阻力对陶瓷膜膜污染形成起主导作用。Abstract: Ceramic membrane has been widely used in the field of oilfield produced water treatment in recent years because of its high mechanical strength, good chemical stability and other advantages. Aiming at the core issue of membrane pollution control in oilfield produced water treatment by ceramic membrane, the small-scale experiment and model analysis were used to deeply conduct the optimization research on the operation control of ceramic membrane treatment system. Combined with microscopic characterization, the membrane pollution mechanism in oilfield produced water treatment by ceramic membrane was clarified. The results showed that the optimal operating control conditions for oilfield produced water treatment by ceramic membrane were: initial membrane flux of 80 L·(m2·h)−1, filtering time of 10 min, backwashing time of 30 s, aeration intensity of 3 L·min−1. Under above conditions, the ceramic membrane could maintain an average membrane flux of 27.82 L·(m2·h)−1. The characterization results of raw water and pollution layer showed that amine or amide, hydrocarbon, carboxylic acid, aromatic, alcohol and other organic compounds were the main organics causing ceramic membrane pollution, and inorganic salt ions such as Si, Fe, Ca, Mg, Ba were also important components of membrane pollution; In the filtration process, both the resistances in the membrane pore and in the gel layer play a leading role in the formation of ceramic membrane fouling.

-

-

表 1 L9(34)正交实验设计表

Table 1. L9 (34) orthogonal experimental design

工况 因素 初始膜通量/

(L·(m2·h)−1)过滤时间/

min水力反冲

时间/s曝气强度/

(L·min−1)S1 30 10 60 1 S2 30 15 90 3 S3 30 20 30 5 S4 50 10 90 5 S5 50 15 30 1 S6 50 20 60 3 S7 80 10 30 3 S8 80 15 60 5 S9 80 20 90 1 表 2 运行控制因素方差分析表

Table 2. Analysis of variance of operating control factors

源 Ⅲ型平方和 df 均方 F Sig 修正模型 80.025a 8 10.003 15.956 1.83×10-4 截距 8986.489 1 8986.489 14334.423 3.07×10-7 初始膜通量 32.935 2 16.467 26.267 1.75×10-4 过滤时间 19.164 2 9.582 15.284 1.276×10-3 水力反冲时间 24.424 2 12.212 19.479 5.37×10-4 曝气强度 3.502 2 1.751 2.793 1.3836×10-2 误差 5.642 9 0.627 总计 9072.156 18 修正后总计 85.667 17 *注:R2=0.934(调整R2=0.876)。 表 3 单因素统计量

Table 3. Statistical analysis of average membrane fluxes corresponding to the operating control factors

运行控制因素 因素水平 各因素水平对应的平均膜通量统计值 算数平均值/ L·(m2·h)−1 标准误差 95%置信区间下限 95%置信区间上限 >初始膜通量 30.00 L·(m2·h)−1 22.675 0.323 21.944 23.406 50.00 L·(m2·h)−1 20.547 0.323 19.815 21.278 80.00 L·(m2·h)−1 23.810 0.323 23.079 24.541 过滤时间 10.00 min 23.787 0.323 23.055 24.518 15.00 min 21.812 0.323 21.080 22.543 20.00 min 21.433 0.323 20.702 22.165 水力反冲时间 30.00 s 23.185 0.323 22.454 23.916 60.00 s 20.697 0.323 19.965 21.428 90.00 s 23.150 0.323 22.419 23.881 曝气强度 1.00 L·min−1 21.733 0.323 21.002 22.465 3.00 L·min−1 22.760 0.323 22.029 23.491 5.00 L·min−1 22.538 0.323 21.807 23.270 表 4 原水和污染层的元素质量百分比

Table 4. Mass percentage of elements in raw water and contaminated layer

元素 元素质量百分比/% 原水 污染层 C 33.46 30.30 O 3.69 19.74 Cl 39.28 0.35 Si 0.03 0.46 N 0 0 K 0.35 0.07 Mg 0.63 0.14 Ca 1.56 0.80 Ba 0.27 37.00 Na 20.71 0.53 S 0.02 6.43 Fe 0 3.86 表 5 各部分污染阻力及所占比例的平均值

Table 5. Pollution resistance of each part and its average proportion

Rt

/(1011·m−1)比例

/%Rm

/(1011·m−1)比例

/%Ri

/(1011·m−1)比例

/%Rc

/(1011·m−1)比例

/%Rg

/(1011·m−1)比例

/%12.62 100.00 3.09 24.53 5.01 39.70 1.03 8.13 3.50 27.70 -

[1] 张华倩, 胡天宇. 分析油田采出水的特性及处理技术[J]. 中国石油和化工标准与质量, 2013, 33(8): 108. doi: 10.3969/j.issn.1673-4076.2013.08.105 [2] 刘长莉, 王宝鑫, 李娜, 等. 弱碱三元采出水ABR生物处理工艺研究[J]. 环境科学与技术, 2015, 38(S1): 198-204. [3] 高飞, 朱俊维, 曾凡震. 简述油田污水处理面临的问题及处理技术[J]. 石化技术, 2020, 27(7): 82-83. doi: 10.3969/j.issn.1006-0235.2020.07.046 [4] LI X, JIA Y, QIN Y, et al. Iron-carbon microelectrolysis for wastewater remediation: Preparation, performance and interaction mechanisms[J]. Chemosphere, 2021, 278: 130483. doi: 10.1016/j.chemosphere.2021.130483 [5] MA D, YI H, LAI C, et al. Critical review of advanced oxidation processes in organic wastewater treatment[J]. Chemosphere, 2021, 275: 130104. doi: 10.1016/j.chemosphere.2021.130104 [6] Fulazzaky M, Setiadi T, Fulazzaky M A. An evaluation of the oilfield-produced water treatment by the membrane bioreactor[J]. Journal of Environmental Chemical Engineering, 2020, 8(5): 104417. doi: 10.1016/j.jece.2020.104417 [7] PADAKI M, SURYA MURALI R, ABDULLAH M S, et al. Membrane technology enhancement in oil-water separation. A review[J]. Desalination, 2015, 357: 197-207. doi: 10.1016/j.desal.2014.11.023 [8] PABBY A K, SASTRE A M. State-of-the-art review on hollow fibre contactor technology and membrane-based extraction processes[J]. Journal of Membrane Science, 2013, 430: 263-303. doi: 10.1016/j.memsci.2012.11.060 [9] 王浩, 王宁, 李杰. 简析陶瓷膜的发展和应用[J]. 山东陶瓷, 2020, 43(6): 15-18. doi: 10.3969/j.issn.1005-0639.2020.06.004 [10] 张勇, 秦玉兰, 樊晓丽, 等. 平板陶瓷膜MBR工艺在农村污水处理中的应用[J]. 中国给水排水, 2021, 37(10): 120-125. [11] 张诗洋, 单历元, 廖松义, 等. 陶瓷膜在废水处理领域中的研究进展[J]. 工业水处理, 2021, 41(4): 31-36. [12] HE Z, LYU Z, GU Q, et al. Ceramic-based membranes for water and wastewater treatment[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2019, 578: 123513. doi: 10.1016/j.colsurfa.2019.05.074 [13] 张瑞君. 纳滤对聚驱采油废水的处理效能及膜污染研究[D]. 哈尔滨: 哈尔滨工业大学, 2014. [14] 冯晓娜, 熊若晗, 马文结, 等. 陶瓷超滤膜分离水中天然有机物的膜污染研究[J]. 给水排水, 2020, 56(S2): 136-141. doi: 10.13789/j.cnki.wwe1964.2020.S2.021 [15] ALRESHEEDI M T, BASU O D. Effects of feed water temperature on irreversible fouling of ceramic ultrafiltration membranes[J]. Journal of Water Process Engineering, 2019, 31: 100883. doi: 10.1016/j.jwpe.2019.100883 [16] BAI Z, ZHANG R, WANG S, et al. Membrane fouling behaviors of ceramic hollow fiber microfiltration (MF) membranes by typical organic matters[J]. Separation and Purification Technology, 2021, 274: 118951. doi: 10.1016/j.seppur.2021.118951 [17] 贾秀粉, 郭赟, 孙霞. 陶瓷超滤膜在含油废水处理中的应用及改造[J]. 节能, 2020, 39(6): 136-138. [18] ALRESHEEDI M T, BARBEAU B, BASU O D. Comparisons of NOM fouling and cleaning of ceramic and polymeric membranes during water treatment[J]. Separation and Purification Technology, 2019, 209: 452-460. doi: 10.1016/j.seppur.2018.07.070 [19] NINOMIYA Y, KIMURA K, SATO T, et al. High-flux operation of MBRs with ceramic flat-sheet membranes made possible by intensive membrane cleaning: Tests with real domestic wastewater under low-temperature conditions[J]. Water Research, 2020, 181: 115881. doi: 10.1016/j.watres.2020.115881 [20] TANUDJAJA H J, HEJASE C A, TARABARA V V, et al. Membrane-based separation for oily wastewater: A practical perspective[J]. Water Research, 2019, 156: 347-365. doi: 10.1016/j.watres.2019.03.021 [21] 应智霞, 施陈, 邹志文. 3种常见统计软件在生物统计学教学中的应用比较——以配对数据t-检验为例[J]. 安徽农学通报, 2021, 27(13): 197-199. doi: 10.3969/j.issn.1007-7731.2021.13.067 [22] 赵慧琴, 石立, 刘金山, 等. SPSS软件计算主成分分析的缺陷与纠正[J]. 统计与决策, 2020, 36(15): 56-59. doi: 10.13546/j.cnki.tjyjc.2020.15.011 [23] 赵慧琴, 朱建平. 如何用SPSS软件计算因子分析应用结果[J]. 统计与决策, 2019, 35(20): 72-77. doi: 10.13546/j.cnki.tjyjc.2019.20.015 -

下载:

下载: