-

对氯苯酚(4-chlorophenol, 4-CP)是一种具有高生物毒性且化学性质稳定的化工中间体[1]。欧洲环境署(European Environment Agency, ECA)已将氯酚列为优先控制污染物[2]。排入纸浆厂废水的加拿大苏必利尔湖中被检测到二氯酚和三氯酚的质量浓度分别为4 mg·L−1和13 mg·L−1,对水生生物毒性大。然而,现有的工业废水处理工艺(膜生物反应器工艺、离子交换法和膜分离法等)难以完全去除废水中的氯酚类污染物,会导致其随尾水流入自然环境中[3]。

人工湿地-微生物燃料电池(constructed wetland-microbial fuel cell, CW-MFC)作为一种将人工湿地(constructed wetland, CW)和微生物燃料电池(microbial fuel cell, MFC)相结合的新兴技术,其内部存在自然的氧化还原条件,能够利用MFC产生的电能以提高难降解有机物的去除效率[4]。有研究表明,CW-MFC对有机印染废水[5-7]、抗生素废水[8]和养殖废水[9-10]等均表现出良好的净化效果。YADAV等[11]首次将设计的单舱室CW-MFC应用于亚甲基蓝废水的治理,亚甲基蓝的去除率可达93.15%且具有15.73 mW·m−2的输出功率密度。为了进一步突破CW-MFC产电性能低的瓶颈,并且提升CW-MFC对化学需氧量(chemical oxygen demand, COD)、总氮(total nitrogen, TN)和氨氮(ammonia nitrogen, NH4+-N)等污染物的净化效果,研究者通过对反应器构型进行了改造升级,设计并探究了多种CW-MFC物理构型,包括堆叠构型(stacked CW-MFC)[12-13]、多级构型(multi-stage CW-MFC)[14-15]和模块化构型(modular CW-MFC)[16]对产电性能与污染物去除效果的影响。XU等[12]在分层连续流CW的基础上,创造了堆叠构型CW-MFC,其COD去除率为88.7%。有研究[17]表明,两极串联的CW-MFC比单一CW具有更高的污染物去除效果以及标准化能量回收率。REN等[14]将适用于高强度废水处理的垂直流CW和水平流CW与MFC分别耦合串联,构建了多极构型CW-MFC,COD、氨氮和总氮去除率分别为72%、59%和47%。TAMTA等[16]为减少土地占用面积并提高发电量,设计了模块化CW-MFC反应器用于处理高负荷(初始COD和NH4+-N分别为3 200 mg·L−1和30.21 mg·L−1)生活污水,COD和NH4+-N的去除率分别为98.5%和90.4%。

李氏禾(Leersia Hexandra Swartz)是本课题组前期研究发现的一种可修复4-CP污染水体的植物[18]。为将堆叠构型、多级构型和模块化构型CW-MFC应用于工程中,本研究构建了CW-MFC-A(堆叠构型)、CW-MFC-B(多级构型)和CW-MFC-C(模块化构型) 3种中试CW-MFC,并以李氏禾为湿地植物,探究了不同构型CW-MFC系统在不同4-CP浓度(0、20、40和60 mg·L−1)下对废水的净化效果、产电性能和李氏禾生理生化响应的影响。

-

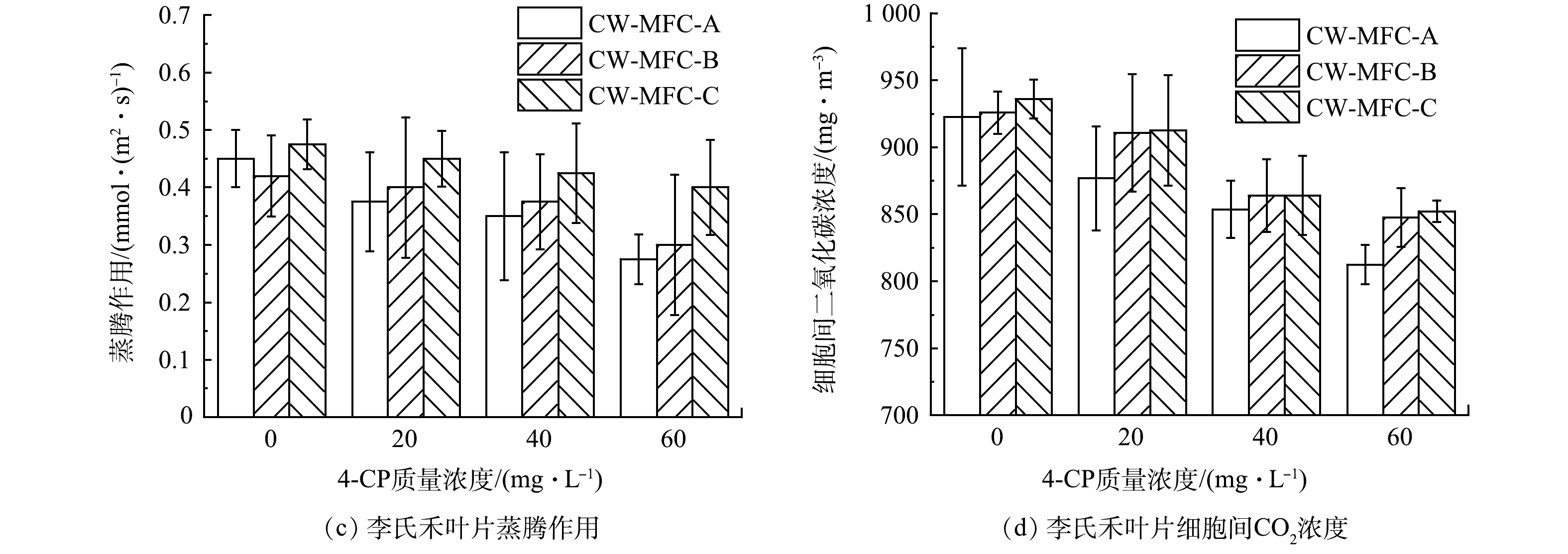

本研究使用的填料均为活性炭颗粒(粒径6~8 mm,购自益阳可臣贸易有限公司,中国),并通过1 mol·L−1的盐酸和1 mol·L−1的NaOH溶液浸泡24 h,以除去表面的油渍、金属离子污染物和附着的杂质,最后使用蒸馏水洗净。将作为阴极电子导流体的石墨电极棒(直径6 mm,北海碳素有限公司,中国)置于1 mol·L−1的盐酸中浸泡24 h,将作为阳极电子导流体的紫铜电极棒(直径6 mm)置于1 mol·L−1的硫酸中浸泡4 h,再使用蒸馏水洗净。不锈钢丝网(5目304不锈钢丝网,丝径0.6 mm)在使用前用1 mol·L−1硫酸浸泡4 h以除去表面钝化层,有助于微生物富集和降低电荷转移内阻[19]。将填料和电子导流体使用不锈钢网片包裹,然后采用尼龙扎带和钛丝进行固定,构成立体网笼电极(图1)。 CW-MFC-A、CW-MFC-B和CW-MFC-C的阴极体积分别为792、803和806 cm3;阳极体积分别为440、450和442 cm3。

-

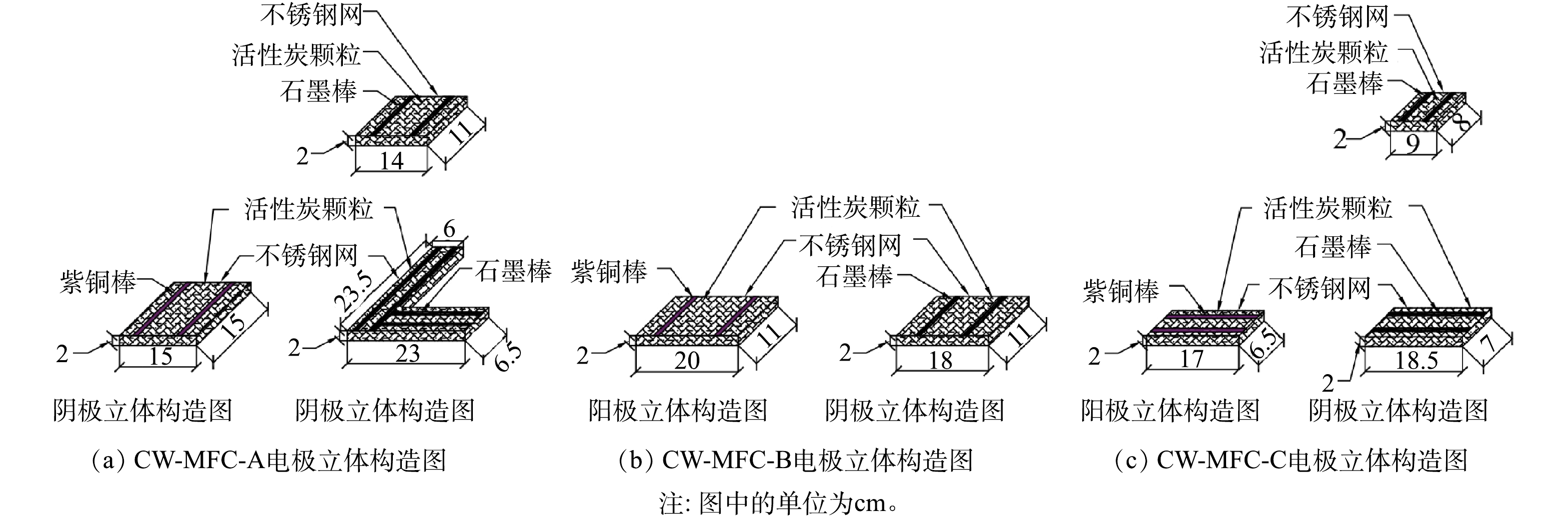

本研究中3种不同构型的CW-MFC装置材质均为有机玻璃,反应器容积为(20.37±0.27) L,有效体积为(6.12±0.10) L,其构造见图2。CW-MFC-A、CW-MFC-B和CW-MFC-C分别为堆叠构型、多级构型和模块化构型(含有6个区域),合成废水的流动方式均按照图2中箭头方向流动,并最终实现溢流出水。

各反应器内部均填充砾石作为连通层、承托层和填充层,以改善污水在反应器内的分布。阴阳电极间距均为15 cm。各反应器的阴极、阳极和2 000 Ω外接电阻由直径为1 mm的钛丝进行连接,连接点和接触液体的部分使用环氧树脂进行密封[14]。各反应器液面始终处于阴极下表面,以保证闭合回路和空气阴极的形成[19]。各反应器外壁均使用黑色胶带进行包裹,以防止藻类大量生长[20]。

-

污泥取自广西桂林市秀峰区燕京啤酒(桂林漓泉)股份有限公司污水处理厂厌氧池,取回后先使用营养液厌氧培养(1 L营养液的基本成分包括1 g CH3COONa、0.75 g NH4Cl、0.95 g KH2PO4·2H2O、7.5 g K2HPO4以及5 mL微量元素营养液,微量营养元素液的配置参考LIU等[21]的报道),共培养7 d。采用蠕动泵(BT101L DG10-2,保定雷弗蠕动泵有限公司,中国)将培养后的厌氧污泥同时从各反应器底部通入直至阴极下表面,以促使污泥与系统中砾石和电极材料等充分混合。在反应器静置2 d后,采用蠕动泵以3 d的HRT从各反应器进水阀门连续泵入合成废水。1 L合成废水的基本成分包括192.3 mg CH3COONa、107.69 mg NH4Cl、19.68 mg KH2PO4·2H2O以及5 mL微量元素营养液,调节pH至7.00±0.10[22]。向1 L合成废水中添加4-CP以配置不同浓度(0、20、40和60 mg·L−1)的合成废水。待各反应器运行至输出电压稳定时,视为启动成功[23]。每15 d种植30株预培养[18, 24]后具有相近生长状态的李氏禾。

-

4-CP的测定采用4-氨基安替比林法[18];COD、TN和NH4+-N的测定分别依据国标HJ/T 399-2007、HJ 636-2012和HJ 535-2009。每3 d从各反应器出水溢流处采集水样,重复3次。

产电电压采用万用表(F18B,福禄克测试仪器有限公司,中国)每8 h对各反应器外电阻两端电压进行测定。在实验结束反应器断开外接电阻后约20 h,接入可变电阻箱(ZX36,上海东茂电子科技有限公司,中国),采用万用表由高到低测定不同外电阻(9 000~100 Ω)下的阴、阳极电势以及输出电压[19, 25],电压稳定时间为30 min。同时,根据输出电压和阳极体积计算功率密度以绘制功率密度曲线。

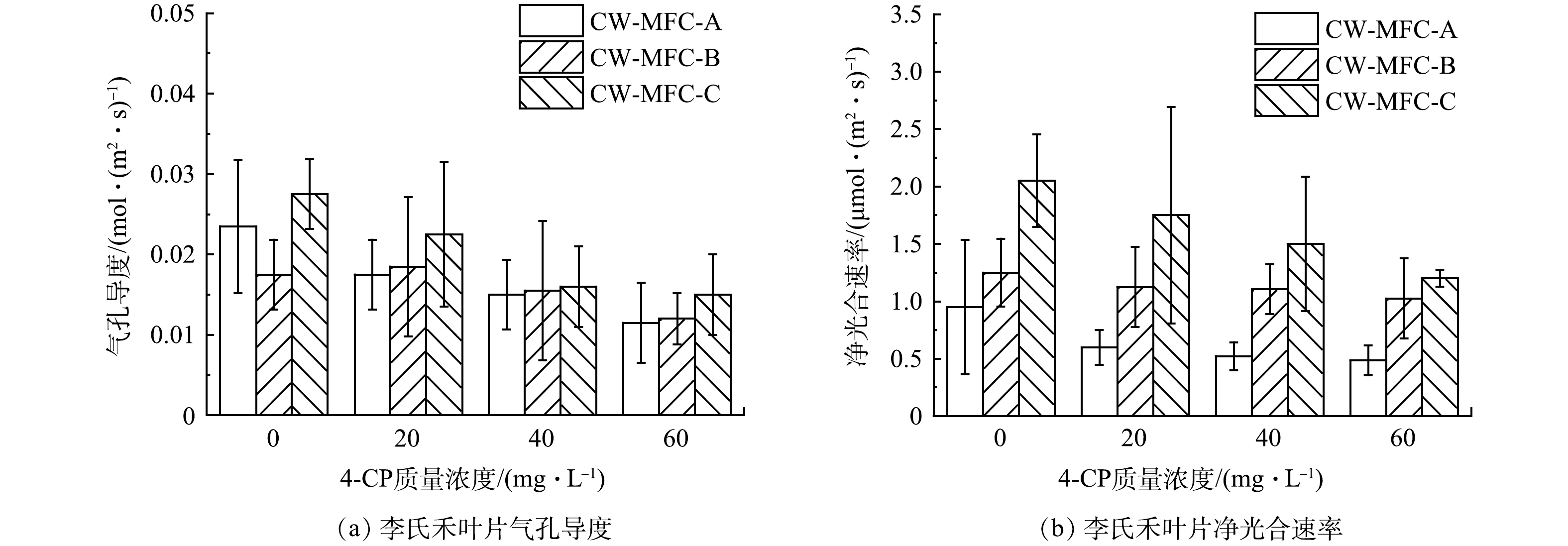

采用光合作用仪(3051D型,浙江托普仪器有限公司,中国)于实验结束时对李氏禾的净光合速率(net photosynthetic rate, Pn)、蒸腾速率(transpiration rate, Tr)、气孔导度(Cleaf)和细胞间二氧化碳浓度(CO2In)进行测定。采用直尺随机选取植株对株高进行测定[26]。植物生物量的测定参考刘昭君等[27]描述的方法。

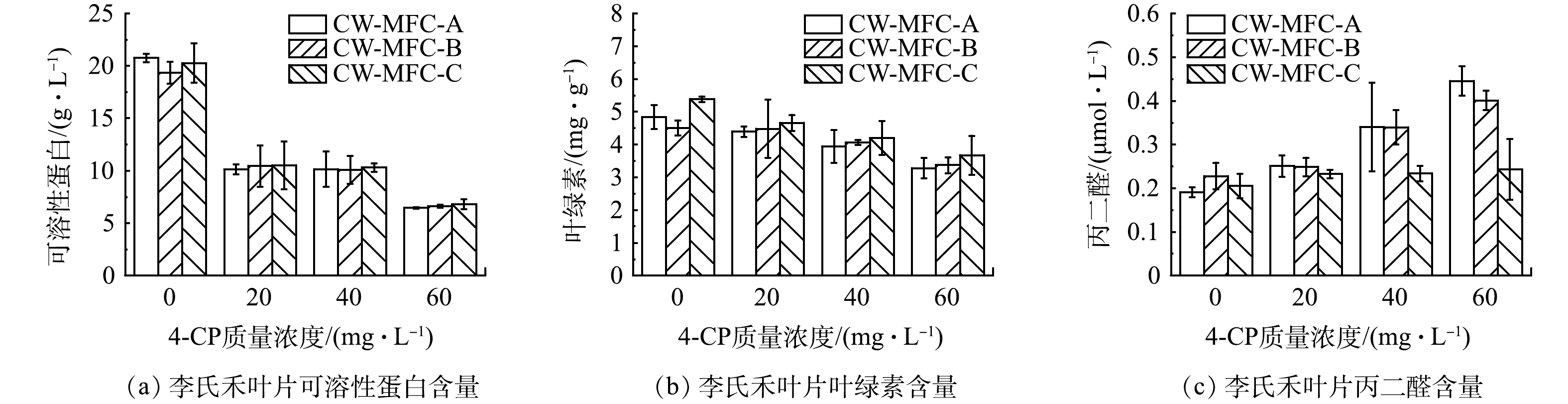

植物叶片中丙二醛(malondialdehyde, MDA)的测定参考刘昭君等[27]描述的方法;可溶性蛋白的测定参照试剂盒(A045-2-2,南京建成生物工程研究所,中国)中所描述的方法[28];叶绿素含量的测定采用乙醇提取法[27]。

-

如图3所示,3种反应器对4-CP和COD去除率随着4-CP浓度的增高而逐渐降低。这可能与4-CP对微生物的毒害效果有关,随着4-CP浓度的不断增加,微生物受到的毒害效应越强,进而导致4-CP和COD去除率的下降。CW-MFC-C相比于CW-MFC-A和CW-MFC-B在40 mg·L−1 4-CP时拥有更高的输出电压、更好的COD和4-CP的去除效果。这可能因为CW-MFC-C良好的产电性能有利于对4-CP和COD的去除[29]。

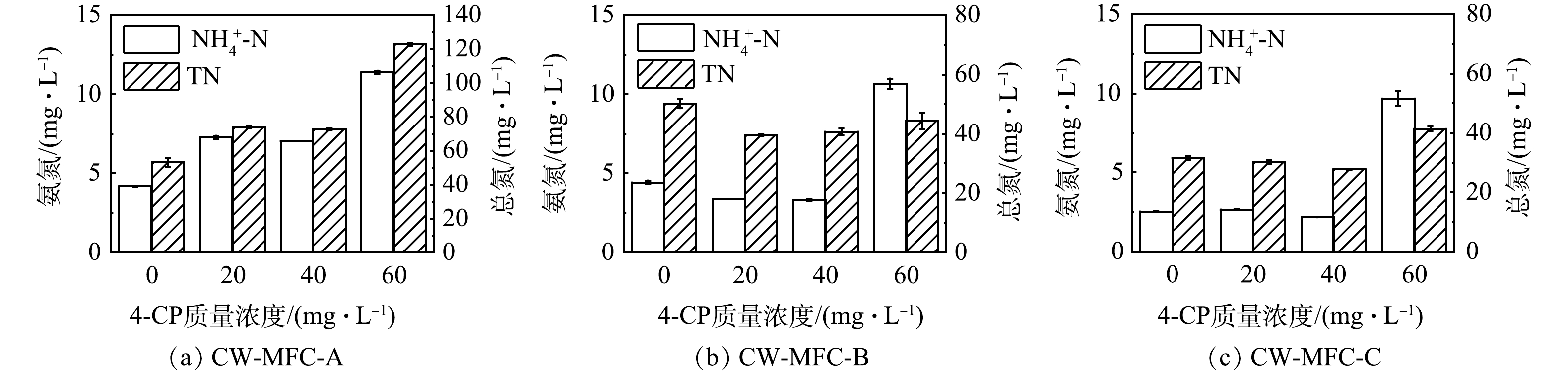

如图4所示,随着4-CP浓度的增高,3种反应器的NH4+-N去除率均在4-CP为40 mg·L−1时达到最高。这与3种反应器内进行硝化作用的微生物经过驯化均适应了环境有关。在4-CP为60 mg·L−1时,微生物受到的4-CP毒害效应增强,进而导致NH4+-N去除率下降。随着4-CP浓度的增高,3种反应器的出水TN浓度均较高。这可能是由于各反应器内的微生物进行了硝酸盐异化还原所致。ZHAO等[30]在上海吴淞炮台湿地中检测出异化硝酸盐还原菌Lacunisphaera和Sorangium。本课题组在前期研究的CW-MFC的微生物群落中也检测出了异化硝酸盐还原菌Closridium sps、Desulfovibrio sp、Pseudomonas sps和Klebsiella sp[19]。因此,尚需进一步通过微生物群落结构测定以揭示这些微生物是否仍存在于CW-MFC中。CW-MFC-C相比于CW-MFC-A和CW-MFC-B在40 mg·L−1 4-CP时具有更好的NH4+-N去除效果,这与CW-MFC-C具有更长的好氧路径、在相同有效容积下具有更多的舱室有关。这使得系统内的硝化细菌和亚硝化细菌能够获得良好的生存环境,也使得CW-MFC-C中的李氏禾生长状态好于CW-MFC-A和CW-MFC-B。而CW-MFC-A在4-CP为0~20 mg·L−1时,NH4+-N和TN含量的变化趋势与CW-MFC-B和CW-MFC-C不同,这与反应器内植物的生长状况有关。进一步对各反应器内李氏禾生理生化响应进行研究,发现CW-MFC-A的李氏禾生长状态不佳,这对系统脱氮有一定的影响。

-

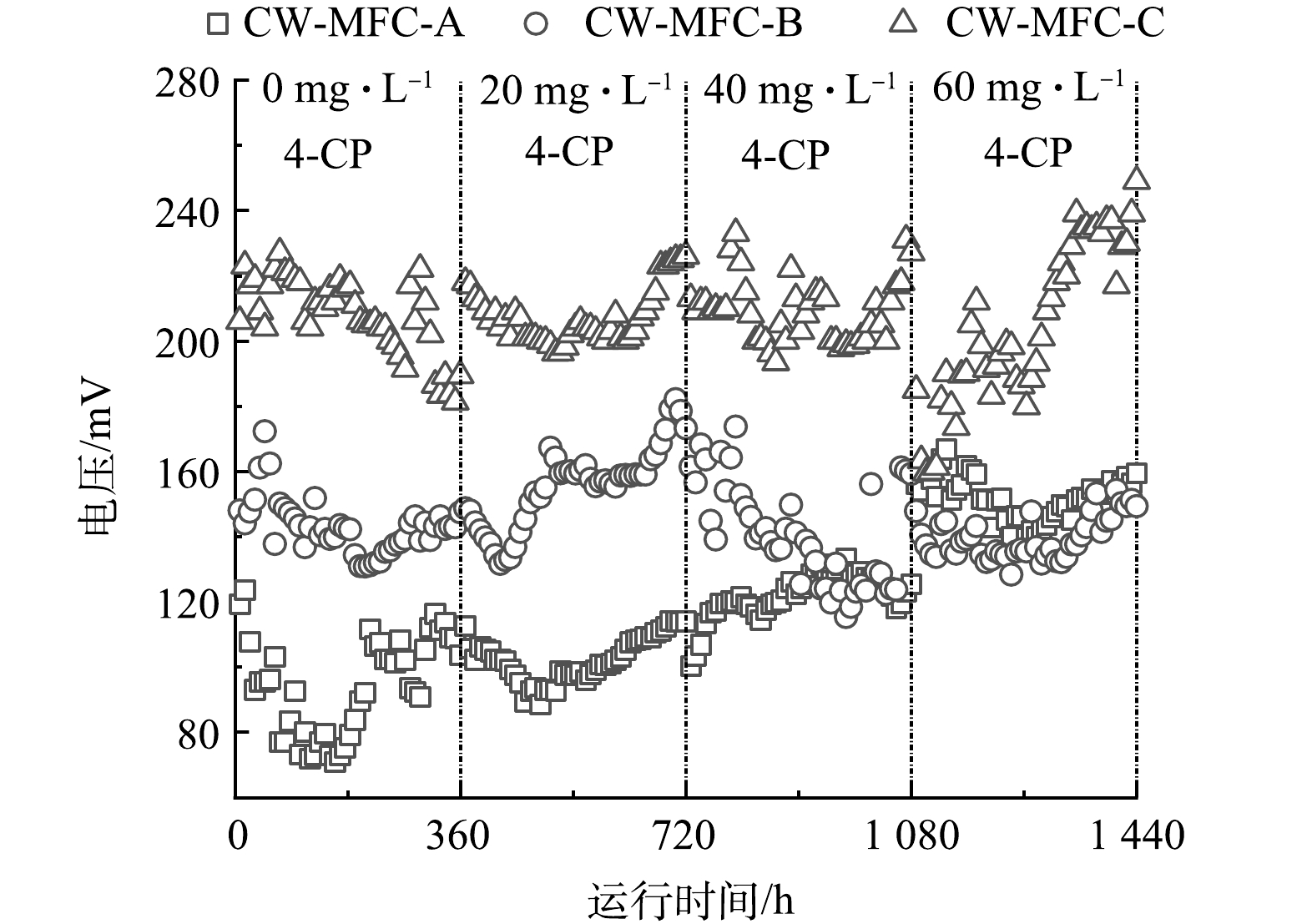

由图5可见,CW-MFC-A和CW-MFC-C在60 mg·L−1 4-CP下具有更高产电电压,分别为166.7 mV和249.0 mV。这与FANG等[31]的研究结果相似,表明在一定程度内通过提高4-CP浓度,可以提升系统产电电压。而CW-MFC-B在20 mg·L−1 4-CP下具有更高的产电电压,这可能是由于微生物随4-CP浓度增高受到的毒害效应越强。CW-MFC-C相比于CW-MFC-A和CW-MFC-B具有更高的产电电压,这是由于CW-MFC-C具有更好的废水净化效果,进而有利于产电微生物生长。

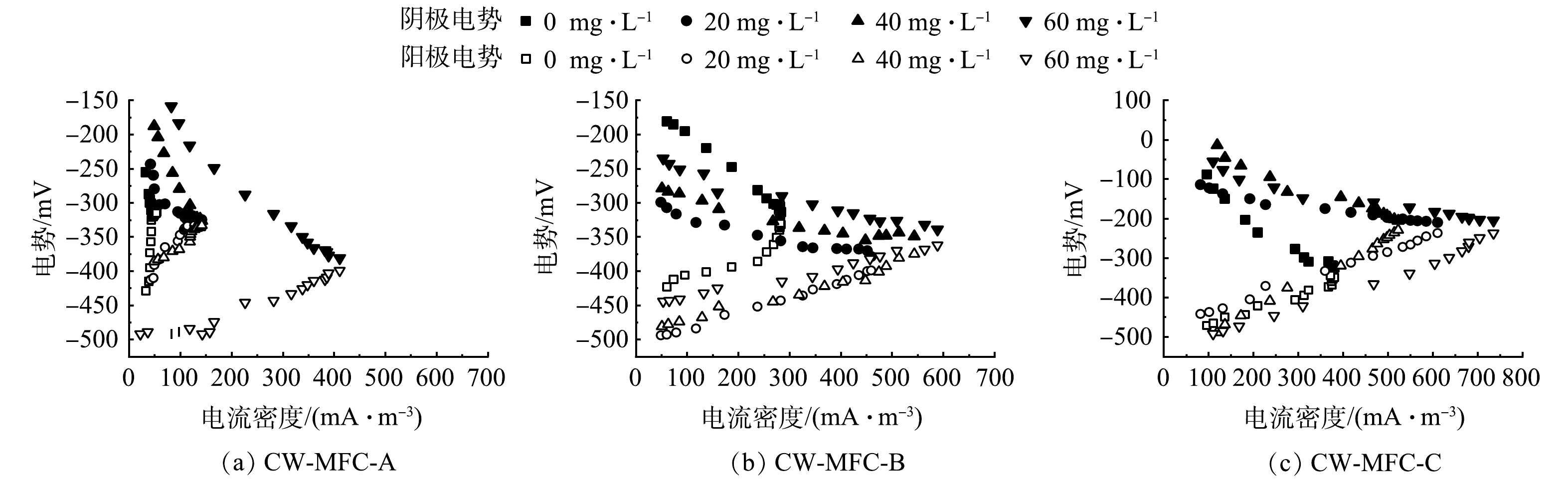

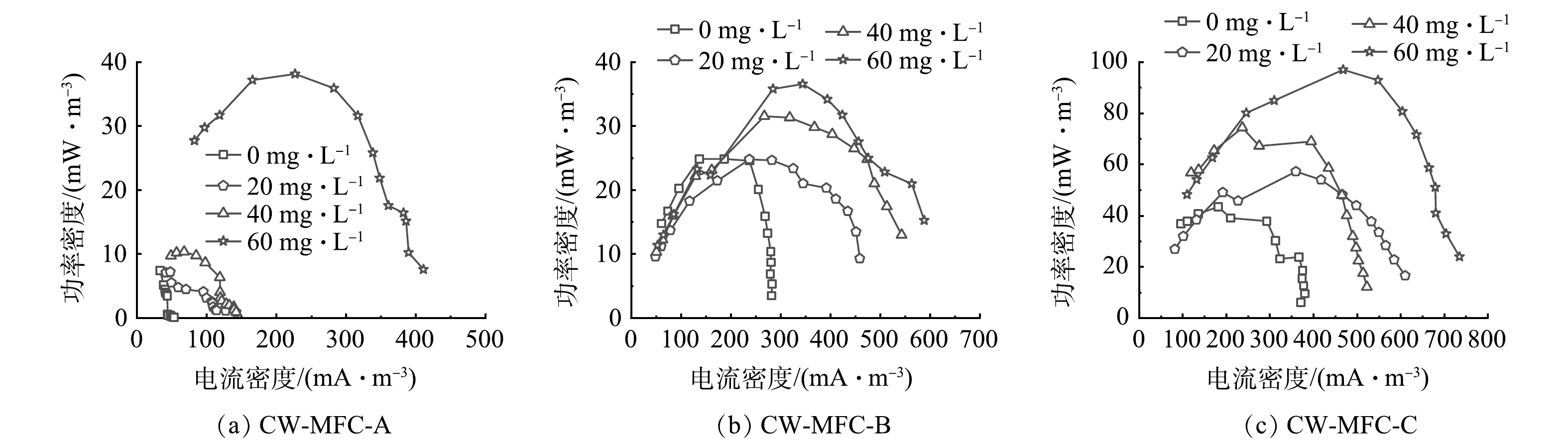

由图6和7可见,3种反应器在60 mg·L−1 4-CP下具有更高的电流密度和功率密度。这可能是随4-CP浓度不断增高,其在反应器内可电离出的氢离子浓度上升,从而提高了反应器内液体的电导率。随着4-CP浓度的升高,CW-MFC-B和CW-MFC-C反应器的阳极电势变化差异均比阴极大,但由于电阻值逐渐减小,导致电子流出阳极的速度变快,从而正电荷的累积使得阳极电势向正方向移动[19]。CW-MFC-C相比于CW-MFC-A和CW-MFC-B在相同4-CP浓度下具有更高的电流密度和功率密度。这可能是其4-CP去除率最高,微生物脱氯降解4-CP时产生了更多的氯离子,增加了反应器内电解质的离子浓度,从而提高了反应器内液体的电导率。当电流密度从0提升到200 mA·m−3时,在相同4-CP浓度下CW-MFC-C的阳极电势的变化幅度最小,表明CW-MFC-C具有更好的阳极性能和更稳定的阳极生物膜[19]。通过与其他已报道CW-MFC的产电性能进行比较,由表1可见,本研究中CW-MFC-C具有更好的产电性能。尽管典型的单舱室CW-MFC反应器构型仍是目前主流的物理构造形式,但模块化构型CW-MFC反应器应得到更多的关注。

-

李氏禾的生长状态与4-CP浓度有密切联系。由表2可知,李氏禾株高和生物量随着4-CP浓度的提升而下降。当4-CP质量浓度达到20 mg·L−1时,各反应器的李氏禾叶片无发黄;当4-CP质量浓度达到40 mg·L−1时,各反应器内李氏禾少量叶片表现出发黄的迹象;当4-CP质量浓度达到60 mg·L−1时,各反应器内李氏禾叶片枯黄较多、植株萎缩且部分叶片受到虫害。以上结果表明,李氏禾在高浓度4-CP胁迫下生长受到严重抑制,从而影响其对4-CP废水的净化效果,这与王超等[18]的研究结果相似。相比于CW-MFC-A和CW-MFC-B,CW-MFC-C系统内李氏禾的株高和生物量受4-CP胁迫影响的程度最小,这是由于CW-MFC-C的废水净化效果较好,从而使李氏禾受到的4-CP毒害胁迫作用最低。

叶绿素含量与植物光合作用能否正常进行息息相关,同时能间接反应植物受到的胁迫程度[36]。可溶性蛋白是反应植物体内酶系统稳定的重要指标,MDA能反映4-CP对植物的损害程度[37]。由图8看出,各反应器的李氏禾叶片中的可溶性蛋白和叶绿素含量随着4-CP浓度增高而下降。可溶性蛋白含量下降可能是李氏禾植株不断受到4-CP的胁迫,植株将合成的脂蛋白用于修复受损的植物细胞和组织造成的[18]。叶绿素含量下降是因为李氏禾植株在4-CP的持续胁迫下产生了过多的活性氧自由基(reactive oxygen species, ROS),导致叶片细胞膜质过氧化严重影响其叶绿素合成[36]。而各反应器的李氏禾叶片中MDA含量随着4-CP胁迫浓度增高而上升,表明4-CP浓度增加对李氏禾产生的毒害作用增大[18]。CW-MFC-C相比于CW-MFC-A和CW-MFC-B,其内的李氏禾随着4-CP浓度不断升高拥有更好的生化响应,这可能是其李氏禾生化指标受4-CP胁迫影响最小,并侧面验证了CW-MFC-C具有更强的废水净化效果。

植物光合作用通常受到诸多影响因素的限制,通过对种植在不同构型CW-MFC反应器内李氏禾的光合作用参数进行测定,可了解在各反应器内不同4-CP浓度下李氏禾光合作用的强弱。由图9可知,各反应器内种植的李氏禾叶片的Pn、Tr、Cleaf和CO2In参数均随着4-CP浓度的升高呈现不同程度的下降,其中Cleaf的下降幅度最为明显。导致植物光合作用下降的原因有气孔限制与非气孔限制,表明李氏禾光合作用可能与气孔有关[36,38]。CW-MFC-C相比于CW-MFC-A和CW-MFC-B,其内的李氏禾叶片的光合作用参数受4-CP胁迫影响最小,表明CW-MFC-C的李氏禾生长情况最好,在3种反应器中CW-MFC-C对废水具有最好的净化效果。

-

1) 3种构型反应器达到最佳废水净化性能的4-CP质量浓度为40 mg·L−1,在40 mg·L−1时,CW-MFC-C对4-CP的去除率为66.15%,优于CW-MFC-A(61.24%)和CW-MFC-B(65.02%)。

2) 3种构型反应器在4-CP为60 mg·L−1的条件下产电性能均为最高。CW-MFC-C在60 mg·L−1 4-CP时产电电压和输出功率密度分别为249.0 mV和96.9 mW·m−3,优于CW-MFC-A(166.7 mV和38.1 mW·m−3)和CW-MFC-B(182.1 mV和36.6 mW·m−3)。

3) 3种构型反应器内李氏禾的生长状态和生理生化响应指标均随4-CP浓度的升高而逐渐变差。CW-MFC-C在最高产电性能的4-CP浓度(60 mg·L−1)下,其李氏禾株高和生物量分别为45.30 cm和0.237 g·株−1,其叶片的可溶性蛋白、叶绿素、MDA、气孔导度、净光合速率、蒸腾作用和胞间CO2含量分别为6.81 g·L−1、3.67 mg·g−1、0.24 μmol·L−1、0.02 mol·(m2·s)−1、1.20 μmol·(m2·s)−1、0.40 mmol·(m2·s)−1和852.24 mg·m−3,其生长状态均好于CW-MFC-A和CW-MFC-B。

不同构型人工湿地-微生物燃料电池对废水中对氯苯酚的净化效果及产电性能的影响

Effect of the constructed wetland-microbial fuel cells with different configurations on the purification of 4-chlorophenol in wastewater and the power generation performance

-

摘要: 构建了堆叠构型(CW-MFC-A)、多级构型(CW-MFC-B)和模块化构型(CW-MFC-C)的中试人工湿地-微生物燃料电池(CW-MFC),且探究了不同构型CW-MFC在不同对氯苯酚(4-CP)浓度(0、20、40和60 mg·L−1)下对废水的净化效果、产电性能和李氏禾生理生化响应的影响。结果表明,CW-MFC-A、CW-MFC-B和CW-MFC-C在40 mg·L−1 4-CP下具有最好的废水净化效果,在60 mg·L−1 4-CP下具有最高的产电性能,CW-MFC-C比CW-MFC-A和CW-MFC-B具有更好的4-CP去除效果(66.15%)、更高的产电电压(249.0 mV)和功率密度(96.9 mW·m−3)。3种构型CW-MFC内李氏禾的生理生化响应指标均随4-CP胁迫浓度增加而变差。同时,CW-MFC-C在对应更高产电性能的4-CP浓度下(60 mg·L−1),其李氏禾株高和生物量分别为45.30 cm和0.237 g·株−1,其叶片的可溶性蛋白含量、叶绿素含量、丙二醛(MDA)含量、气孔导度(Cleaf)、净光合速率(Pn)、蒸腾速率(Tr)和胞间CO2浓度(CO2In)分别为6.81 g·L−1、3.67 mg·g−1、0.24 μmol·L−1、0.02 mol·(m2·s)−1、1.20 μmol·(m2·s)−1、0.40 mmol·(m2·s)−1和852.24 mg·m−3,其受4-CP胁迫影响程度均小于CW-MFC-A和CW-MFC-B。以上所构建的模块化构型CW-MFC可为治理4-CP废水提供参考。Abstract: Pilot-scale constructed wetland-microbial fuel cell(CW-MFC) was constructed in stacked, multi-stage and modular configurations, and their effects the on power generation performance, wastewater purification and physiological and biochemical response of Leersia Hexandra Swartz at different concentrations of 4-chlorophenol (0, 20, 40 and 60 mg·L−1) were studied. The results showed that for the CW-MFC-A, CW-MFC-B, and CW-MFC-C, the highest removal effect occurred at 40 mg·L−1 4-CP, and the highest power generation performance occurred at 60 mg·L−1 4-CP. Simultaneously, the CW-MFC-C reactor had better 4-CP removal effect(66.15%), higher power production voltage(249.0 mV) and power density(96.9 mW·m−3) than CW-MFC-A and CW-MFC-B. The physiological and biochemical response of L. Hexandra in all reactors became worse with increasing 4-CP stress concentration. Meanwhile, at the 4-CP concentration of 60 mg·L−1 with higher power-producing performance, the plant height and biomass in CW-MFC-C were 45.30 cm and 0.237 g·plants−1, respectively, the soluble protein content, chlorophyll content, MDA content, Cleaf , Pn, Tr, and CO2In of its leaves were 6.81 g·L−1, 3.67 mg·g−1, 0.24 μmol·L−1, 0.02 mol·(m2·s)−1, 1.20 μmol·(m2·s)−1, 0.40 mmol·(m2·s)−1 and 852.24 mg·m-3, respectively, and the extent of 4-CP stress in CW-MFC-C was less than that in CW-MFC-A and CW-MFC-B. Furthermore, the design of the L. Hexandra CW-MFC with modular configuration can provide a reference for the governance of 4-CP contaminated wastewater.

-

-

表 1 与其他已报道的CW-MFC在产电性能上的比较

Table 1. Compared with other reported CW-MFC on the power generation performance

表 2 李氏禾的株高和生物量

Table 2. Plant height and biomass of L. Hexandra

4-CP质量浓度/(mg·L−1) 株高/cm 生物量/(g·株−1) CW-MFC-A CW-MFC-B CW-MFC-C CW-MFC-A CW-MFC-B CW-MFC-C 0 46.6±0.38a 46.5±0.65a 46.4±0.65a 0.265±0.004a 0.266±0.002a 0.268±0.003a 20 45.9±0.58abc 46.1±0.23ab 46.1±1.66ab 0.246±0.002bcd 0.250±0.007bc 0.253±0.005b 40 45.1±0.69bc 45.6±0.48abc 45.6±1.14abc 0.236±0.010de 0.241±0.006cde 0.245±0.008bcd 60 44.8±0.71c 44.9±0.15c 45.3±0.60bc 0.222±0.010f 0.232±0.005ef 0.237±0.006de 注:表中结果为平均值±标准偏差(n=3);同列中相同英文字母表示差异显著(LSD,P<0.05)。 -

[1] 刘菲, 赵胜勇, 刘启龙. 高铁酸钾氧化处理对氯苯酚废水的研究[J]. 应用化工, 2021, 50(3): 684-686. doi: 10.3969/j.issn.1671-3206.2021.03.025 [2] WATKINS M, SIZOCHENKO N, MOORE Q, et al. Chlorophenol sorption on multi-walled carbon nanotubes: DFT modeling and structure–property relationship analysis[J]. Journal of Molecular Modeling, 2017, 23(2): 23-39. [3] 姚宏嘉, 陈星, 张玉, 等. 生物炭负载γ-MnO_2纳米复合材料活化过一硫酸盐降解对氯苯酚的性能及机理[J]. 环境工程学报, 2022, 16(6): 1833-1844. doi: 10.12030/j.cjee.202201078 [4] 李峰, 杨宝山, 王惠, 等. 开闭路运行模式下微生物燃料电池型人工湿地处理抗生素废水的效果及微生物群落响应[J]. 环境工程学报, 2021, 15(9): 3035-3045. doi: 10.12030/j.cjee.202105073 [5] PATEL D, BAPODRA S L, MADAMWAR D, et al. Electroactive bacterial community augmentation enhances the performance of a pilot scale constructed wetland microbial fuel cell for treatment of textile dye wastewater[J]. Bioresource Technology, 2021, 332: 125088. doi: 10.1016/j.biortech.2021.125088 [6] 赵联芳, 于雪晴, 路宗仁, 等. FeS对CW-MFC系统降解活性艳红X-3B效果及过程的影响[J]. 中国环境科学, 2022, 42(7): 3093-3102. doi: 10.3969/j.issn.1000-6923.2022.07.012 [7] FANG Z, SONG H L, CANG N, et al. Performance of microbial fuel cell coupled constructed wetland system for decolorization of azo dye and bioelectricity generation[J]. Bioresource Technology, 2013, 144: 165-171. doi: 10.1016/j.biortech.2013.06.073 [8] SONG H L, LI H, ZHANG S, et al. Fate of sulfadiazine and its corresponding resistance genes in up-flow microbial fuel cell coupled constructed wetlands: Effects of circuit operation mode and hydraulic retention time[J]. Chemical Engineering Journal, 2018, 350: 920-929. doi: 10.1016/j.cej.2018.06.035 [9] DOHERTY L, ZHAO Y, ZHAO X, et al. Nutrient and organics removal from swine slurry with simultaneous electricity generation in an alum sludge-based constructed wetland incorporating microbial fuel cell technology[J]. Chemical Engineering Journal, 2015, 266: 74-81. doi: 10.1016/j.cej.2014.12.063 [10] VILLASENOR J, CAPILLA P, RODRIGO M A, et al. Operation of a horizontal subsurface flow constructed wetland - Microbial fuel cell treating wastewater under different organic loading rates[J]. Water Research, 2013, 47(17): 6731-6738. doi: 10.1016/j.watres.2013.09.005 [11] YADAV A K, DASH P, MOHANTY A, et al. Performance assessment of innovative constructed wetland-microbial fuel cell for electricity production and dye removal[J]. Ecological Engineering, 2012, 47: 126-131. doi: 10.1016/j.ecoleng.2012.06.029 [12] XU L, ZHAO Y, WANG T, et al. Energy capture and nutrients removal enhancement through a stacked constructed wetland incorporated with microbial fuel cell[J]. Water Science and Technology, 2017, 76(1): 28-34. doi: 10.2166/wst.2017.168 [13] ZHANG S, YANG X L, LI H, et al. Degradation of sulfamethoxazole in bioelectrochemical system with power supplied by constructed wetland-coupled microbial fuel cells[J]. Bioresource Technology, 2017, 244: 345-352. doi: 10.1016/j.biortech.2017.07.143 [14] REN B, WANG T, ZHAO Y. Two-stage hybrid constructed wetland-microbial fuel cells for swine wastewater treatment and bioenergy generation[J]. Chemosphere, 2021, 268: 128803. doi: 10.1016/j.chemosphere.2020.128803 [15] SRIVASTAVA P, YADAV A K, GARANIYA V, et al. Electrode dependent anaerobic ammonium oxidation in microbial fuel cell integrated hybrid constructed wetlands: A new process[J]. Science of The Total Environment, 2020, 698: 134248. doi: 10.1016/j.scitotenv.2019.134248 [16] TAMTA P, RANI N, YADAV A K. Enhanced wastewater treatment and electricity generation using stacked constructed wetland–microbial fuel cells[J]. Environmental Chemistry Letters, 2020, 18(3): 871-879. doi: 10.1007/s10311-020-00966-2 [17] DOHERTY L, ZHAO Y. Operating a two-stage microbial fuel cell-constructed wetland for fuller wastewater treatment and more efficient electricity generation[J]. Water Science and Technology, 2015, 72(3): 421-428. doi: 10.2166/wst.2015.212 [18] 王超, 王义安, 林华, 等. 对氯苯酚胁迫下李氏禾的净化性能、生长状态及生理生化响应[J]. 应用与环境生物学报, 2022, 28(3): 662-667. doi: 10.19675/j.cnki.1006-687x.2021.01004 [19] 王义安, 张学洪, 郑君健, 等. 不同基质碳源下人工湿地微生物燃料电池的电化学性能及微生物群落结构[J]. 环境工程学报, 2021, 15(11): 3696-3706. doi: 10.12030/j.cjee.202108060 [20] ZHANG K, YANG S, LUO H, et al. Enhancement of nitrogen removal and energy recovery from low C/N ratio sewage by multi-electrode electrochemical technology and tidal flow via siphon aeration[J]. Chemosphere, 2022, 299: 134376. doi: 10.1016/j.chemosphere.2022.134376 [21] LIU S, SONG H, WEI S, et al. Bio-cathode materials evaluation and configuration optimization for power output of vertical subsurface flow constructed wetland: Microbial fuel cell systems[J]. Bioresource Technology, 2014, 166: 575-583. doi: 10.1016/j.biortech.2014.05.104 [22] WANG G, GUO Y, CAI J, et al. Electricity production and the analysis of the anode microbial community in a constructed wetland-microbial fuel cell[J]. RSC Advances, 2019, 9(37): 21460-21472. doi: 10.1039/C8RA10130B [23] WANG J, HE M-F, ZHANG D, et al. Simultaneous degradation of tetracycline by a microbial fuel cell and its toxicity evaluation by zebrafish[J]. RSC Advances, 2017, 7(70): 44226-44233. doi: 10.1039/C7RA07799H [24] LIU J, ZHANG X H, YOU S H, et al. Function of Leersia hexandra Swartz in constructed wetlands for Cr(VI) decontamination: A comparative study of planted and unplanted mesocosms[J]. Ecological Engineering, 2015, 81: 70-75. doi: 10.1016/j.ecoleng.2015.04.025 [25] SONAWANE J M, AL-SAADI S, SINGH RAMAN R K, et al. Exploring the use of polyaniline-modified stainless steel plates as low-cost, high-performance anodes for microbial fuel cells[J]. Electrochimica Acta, 2018, 268: 484-493. doi: 10.1016/j.electacta.2018.01.163 [26] 周品成, 刘希强, 康兴生, 等. 4种水生植物对兽用抗生素去除效果比较[J]. 华南农业大学学报, 2019, 40(6): 67-73. doi: 10.7671/j.issn.1001-411X.201901020 [27] 刘昭君, 林华, 王义安, 等. 磷肥种类对李氏禾富集铜、铬的影响及其生理响应[J]. 生态环境学报, 2021, 30(2): 412-419. doi: 10.16258/j.cnki.1674-5906.2021.02.022 [28] DENG Y, WANG W, YU P, et al. Comparison of taurine, GABA, Glu, and Asp as scavengers of malondialdehyde in vitro and in vivo[J]. NANOSCALE RESEARCH LETTERS, 2013: 8. [29] 袁玉杰, 赵亚乾, 付晶淼, 等. CW-MFC中的电子流及对废水处理的强化作用[J]. 中国给水排水, 2021, 37(16): 27-34. doi: 10.19853/j.zgjsps.1000-4602.2021.16.005 [30] ZHAO Y, BU C, YANG H, et al. Survey of dissimilatory nitrate reduction to ammonium microbial community at national wetland of Shanghai, China[J]. Chemosphere, 2020, 250: 126195. doi: 10.1016/j.chemosphere.2020.126195 [31] FANG Z, CAO X, LI X, et al. Electrode and azo dye decolorization performance in microbial-fuel-cell-coupled constructed wetlands with different electrode size during long-term wastewater treatment[J]. Bioresource Technology, 2017, 238: 450-460. doi: 10.1016/j.biortech.2017.04.075 [32] GUPTA S, NAYAK A, ROY C, et al. An algal assisted constructed wetland-microbial fuel cell integrated with sand filter for efficient wastewater treatment and electricity production[J]. Chemosphere, 2021, 263: 128132. doi: 10.1016/j.chemosphere.2020.128132 [33] SRIVASTAVA P, YADAV A K, MISHRA B K. The effects of microbial fuel cell integration into constructed wetland on the performance of constructed wetland[J]. Bioresource Technology, 2015, 195: 223-230. doi: 10.1016/j.biortech.2015.05.072 [34] OON Y L, ONG S, HO L, et al. Role of macrophyte and effect of supplementary aeration in up-flow constructed wetland-microbial fuel cell for simultaneous wastewater treatment and energy recovery[J]. Bioresource Technology, 2017, 224: 265-275. doi: 10.1016/j.biortech.2016.10.079 [35] 秦歌, 陈婧, 余仁栋, 等. 人工湿地-微生物燃料电池对高碳氮废水的强化净化和产电研究[J]. 湿地科学与管理, 2021, 17(4): 12-17. doi: 10.3969/j.issn.1673-3290.2021.04.03 [36] 覃辉, 林华, 徐虹, 等. 李氏禾对水体中Ni的富集特征及其光合生理响应[J]. 水处理技术, 2022, 48(7): 92-97. doi: 10.16796/j.cnki.1000-3770.2022.07.018 [37] ABID M, ALI S, QI L K, et al. Physiological and biochemical changes during drought and recovery periods at tillering and jointing stages in wheat (Triticum aestivum L. )[J]. Scientific Reports, 2018, 8(1): 4615. doi: 10.1038/s41598-018-21441-7 [38] 周蛟, 韩盼盼, 潘远智, 等. Cd胁迫对两种龙葵光合生理及叶绿素荧光特性的影响[J]. 农业环境科学学报, 2021, 40(1): 26-34. doi: 10.11654/jaes.2020-0818 -

下载:

下载: