-

选择性催化还原 (selective catalytic reduction, SCR) 脱硝技术因其效率高、成本低和选择性高等优势而被广泛应用于烟气脱硝[1-3]。尽管该技术解决了电力行业中高温烟气 (300 ℃以上) 脱硝的问题,但由于SCR催化剂活性温度较高、抗毒性能较差,无法处理非电力行业大量低温烟气 (120~300 ℃以下) 中的NOx[4-5]。因此,低温烟气SCR脱硝技术的研究热点为具有低活性温度和抗毒性能强的催化剂[2, 6-7]。尽管SCR催化剂的活性温度已低于120 ℃[8-9],但受成本、工艺等制约,相关催化剂难以在实际工业低温烟气脱硝工程中应用。目前,在工业上实际运行的低温SCR催化剂操作温度约为200 ℃[10-12],故反应温度是控制NOx转化率的首要因素。在SCR催化剂的活性温度区间内,催化剂的活性与反应温度成正比[13-15]。非电力行业的低温烟气脱硝反应器一般设置于烟气处理末端,即设置于脱硫除尘之后,烟气温度通常在100 ℃以下 (湿法脱硫可低于60 ℃) ,烟气温度远低于目前工业化SCR催化剂的活性温度区间。因此,脱硝反应器前会加装预热器,使烟气温度达到催化剂的活性温度区间。预热烟气进入反应器后会先将热量传递给催化剂,只有催化剂整体达到高活性温度,脱硝反应才会高效进行。

YANG等[16]采用将粉状活性金属组分涂覆在空白单体载体表面制备NH3-SCR蜂窝催化剂,并在250~350 ℃的温度下进行实验。结果表明,SCR脱硝反应主要在催化剂表面的微界面进行。因此,理论上讲,只要使SCR催化剂反应界面温度在其活性温度区间即可保证NOx高转化率,而无需将烟气整体温度升高。基于此,以催化剂颗粒为循环热载体,并利用旋流循环流化反应器可在无需整体加热的情况下实现NOx在催化界面的反应,从而达到降低能耗以去除NOx的目标。旋流流化反应器应用于气态污染物治理中。马良等[17-18]开发了新型旋流流化床反应器,用于活性炭吸附挥发性有机化合物,反应器在120 Pa压降下的吸附效率接近100%。同时,增加颗粒自旋转速度可在一定程度上提高吸附效率[19]。

基于以上原理,本课题组设计了一种低温SCR旋流循环流化反应器,以开发高温催化剂为循环热载体的低温烟气脱硝工艺。采用计算流体力学 (computational fluid dynamics, CFD) 与离散元方法 (discrete element method, DEM) 耦合的数值模拟方法[20-22],研究低温烟气与高温催化剂在反应器中的传热特性及脱硝可行性,以期为低温烟气脱硝提供参考。

-

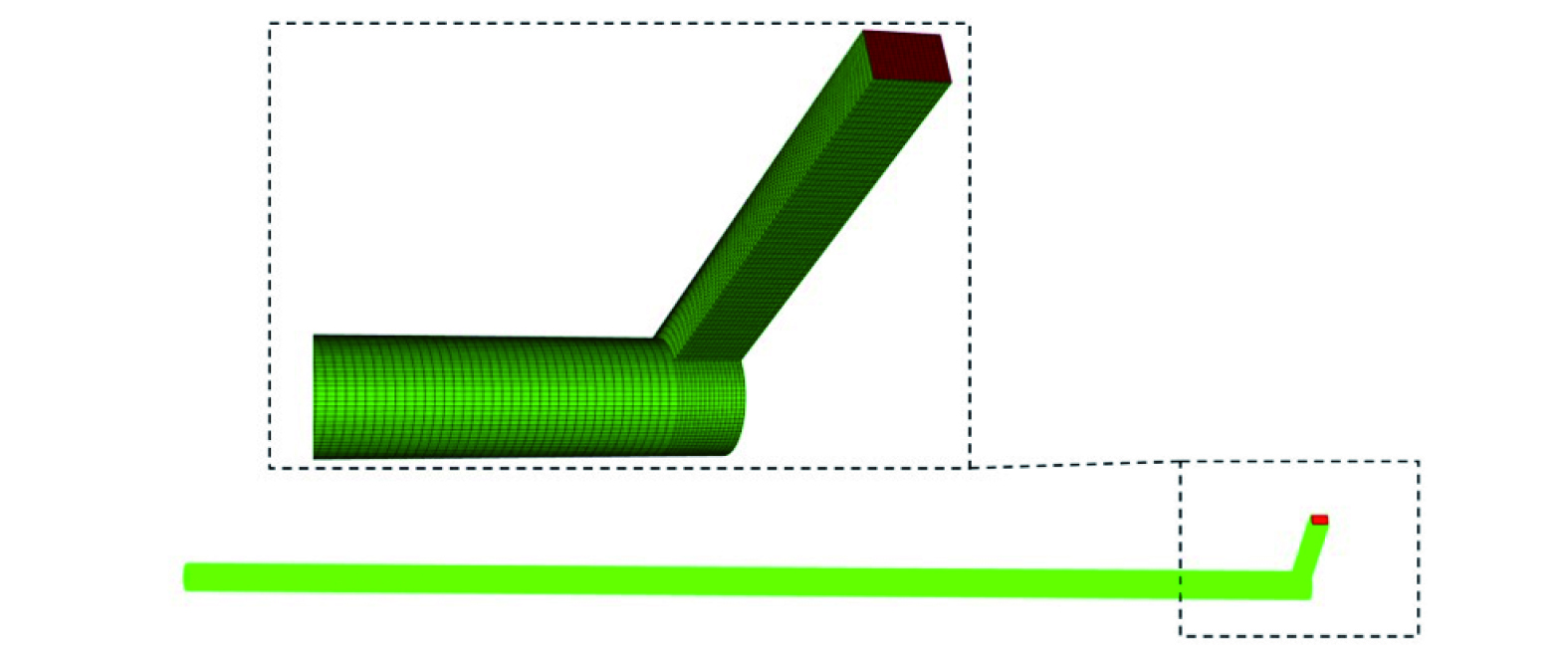

基于气态污染物旋流流化吸附器[17, 19],设计了一种用于低温烟气脱硝的旋流流化反应器。反应器的结构尺寸如表1和图1(a)所示,其圆柱形反应腔内径为25 mm,高度1 040 mm,底部为矩形切向入口,底部中心设置有圆柱形芯棒。工艺流程如图1(b)所示,低温烟气与氨气均匀混合后,经风机增压,通过气固喷射器携带高温催化剂进入旋流流化反应器。在旋流流化反应器中,烟气中的氮氧化物与氨气吸附于旋流自转催化剂的高温微界面,并进行脱硝反应。净化后的烟气携带降温后的催化剂颗粒从旋流流化反应器顶部出口排出进入气固旋流分离器,催化剂颗粒从旋流分离器底流口排出,进入加热储罐再生,净化烟气从旋流分离器溢流口排出。本文将针对烟气携带高温催化剂进入旋流流化反应器后的颗粒运动与传热过程进行模拟研究,探究烟气进口气速与温度、催化剂颗粒的进料速率、旋流流化反应器的结构参数等因素对催化微界面温度的调控机制。

-

采用计算流体力学与离散元法的耦合方法对旋流反应器内烟气与颗粒传热过程进行模拟研究。考虑到数值计算的经济性,旋流流化反应器内部流场采用当前应用最多的雷诺应力模型 (Reynolds stress model, RSM) [23-24]。RSM模型充分考虑了流线弯曲、张力的快速变化以及二次流的影响[25],大量研究证明该模型能非常好的预测旋流分离器内部旋转流场结构[26-27]。气体流场求解采用稳态计算,气固两相耦合模拟的求解过程采用瞬态计算。气体流场模拟的压力速度耦合采用SIMPLEC(Semi-Implicit Method for Pressure Linked Equation Consistent)算法,气固两相耦合模拟的压力速度耦合采用SIMPLE(Semi-Implicit Method for Pressure Linked Equation)算法[28]。因为模型采用六面体结构化网格,且网格和流动方向一致,所以其他守恒方程的离散化采用QUICK (Quadratic Upwind Interpolation of Convective Kinematics) 格式,以获得更高的精度。颗粒由旋流流化反应器的入口进入,颗粒初始速度与气相速度保持一致,EDEM仿真中的瑞利时间步长[20]计算公式为:

式中:rs是颗粒半径,m;ρ是颗粒密度,kg·m−3;G是剪切模量,GPa;v是泊松比。本模拟中EDEM采用的时间步长为2

$ \times $ 10−6 s (0.216TR) ,EDEM与CFD的时间步长比值设置为1∶50。模拟使用的催化剂活性温度区间是200~300 ℃,若采用烟气整体加热方式,需将低温烟气加热至300 ℃,所需热量为Q1。若采用旋流流化反应器,低温烟气从反应器切向入口至顶部出口升温所需热量为Q2。在不考虑其他热量损失的情况下,相比烟气整体加热,采用旋流流化反应器进行脱硝,从而减少烟气整体升温的节能效率。节能效率计算式见式 (2) 。

旋流流化反应器内催化剂颗粒滞留量Mr,其中q是催化剂颗粒的进料速率,Tr是催化剂颗粒在旋流流化反应器中的停留时间。滞留量的计算式见式 (3) 。

-

以图1 (a)所示旋流流化反应器从切向入口至顶部出口的内部空间为计算域,反应器切向入口处气体和颗粒采用“速度进口” (velocity inlet) ,速度方向垂直于入口平面,顶部出口设为“压力出口” (pressure outlet) 。旋流流化反应器切向入口流体流动近似于充分发展的管道流动,其湍流强度根据经验公式[29]进行计算。计算式见式 (4) 。

Rei是旋流流化反应器的入口特征雷诺数,计算公式为式 (5) 。

式中:ρg为进口气体的密度,kg·m−3;D为旋流流化反应器的直径,m;Uz为进口气体轴向速度,m·s−1。进口气速分别为5、7.5、10、12.5与15 m·s−1时,由公式4可得湍流强度分别为4.49、4.37、4.27、4.21与4.15。EDEM中颗粒相与壁面的参数设置如表2所示。催化剂设置为1 mm直径的均一球形颗粒。

-

旋流流化反应器计算域采用结构化网格,如图2所示。直角坐标系原点设置于旋流流化反应器底部中心处。该旋流流化反应器总共划分了 N1=520 500个六面体网格。为了验证模型网格无关性,另外对模型进行了加密网格划分,总数分别为 N2=766 260个和 N3=1 012 020个。选取旋流流化反应器高度为15 mm的截面上一条直径,利用其流体切向速度分布来验证模型网格无关性。以网格密度N1为基准,网格密度为N2和N3计算的切向速度平均误差分别为4.5%和8.1%,如图3所示。由于网格数量最多的N3模型模拟结果误差变大,故选择模拟结果较好,且计算时间消耗最少的N1网格密度进行模拟计算。

-

在不同进口气速条件下,从反应器进口到顶部出口单个催化剂颗粒的温度变化趋势如图4所示。随着进口气速的提高,催化剂颗粒的停留时间减小,进口气速Ui从5 m·s−1增至15 m·s−1的5个工况对应的颗粒停留时间分别为2.38、1.86 、1.58 、1.39 和1.27 s,到达反应器顶部出口的温度分别为499.2、484.3、471.5、460.5 和450.7 K。因此,在催化剂颗粒的进料速率为5 g/s的条件下,进口气速为10、12.5 和15 m·s−1 3个工况可使反应器出口催化剂温度依旧处于活性区间。当模拟进口气速为7.5 m·s−1,催化剂颗粒的进料速率为25 g·s−1时,此时催化剂出口温度能达到催化剂活性温度。

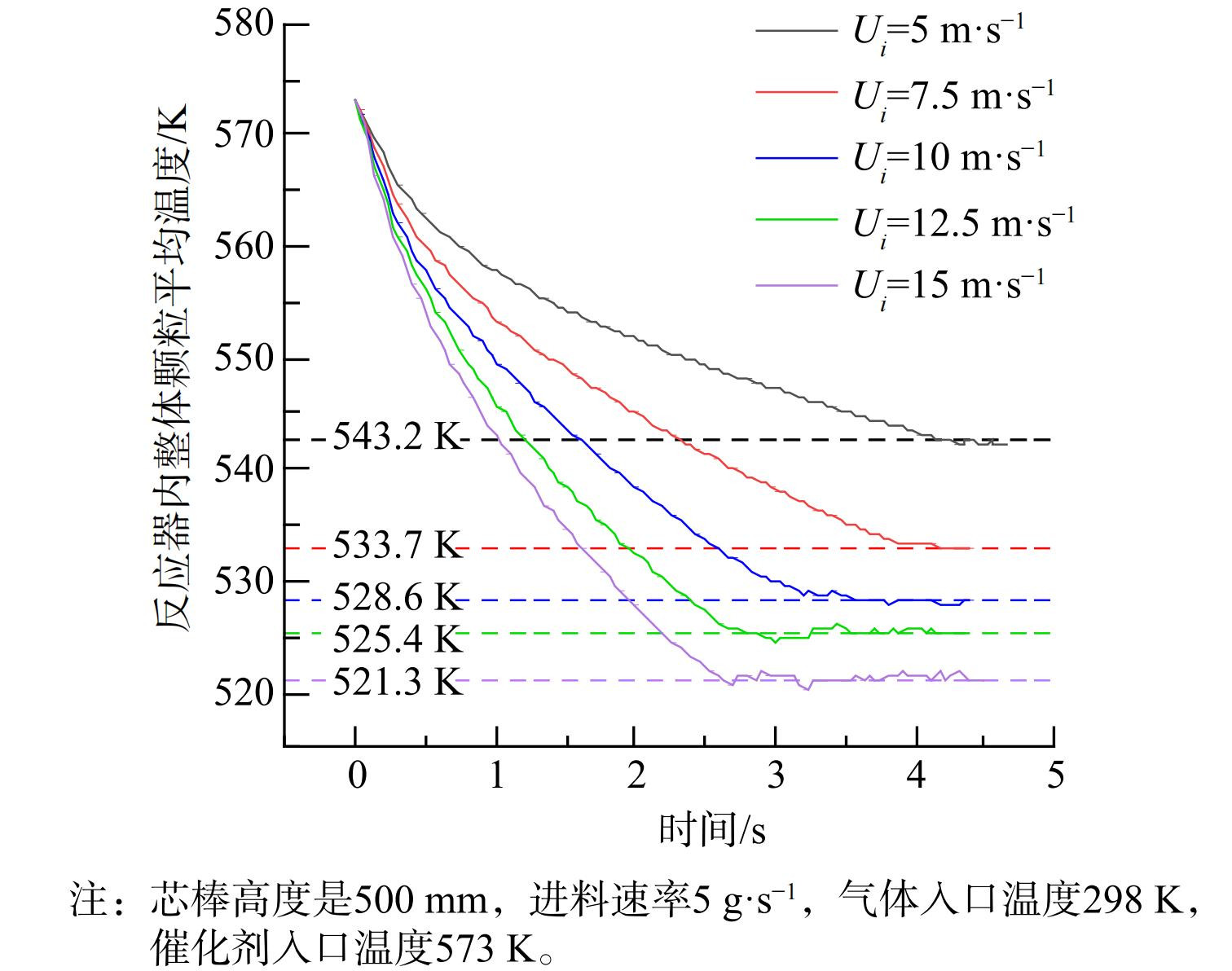

在不同进口气速条件下,从催化剂颗粒进入反应器开始,反应器内全部颗粒的平均温度变化趋势如图5所示。随着进口气速的增加,反应器内全部颗粒的平均温度达到稳定的时间逐渐减小 (分别为4.31、3.99、3.51、2.72 和2.54 s) ,且平均温度逐渐降低 (分别为543.2、533.7、528.6、525.4 和521.3 K) 。

进口气速显著影响低温烟气与催化剂颗粒在反应器内的传热时间,进而影响高温催化剂向低温烟气的总传热量,最终出口催化剂颗粒的出口温度随着进口气速Ui的升高而降低。

-

在不同的催化剂进料速率q下,从反应器进口到顶部出口单个催化剂颗粒的温度变化趋势如图6所示。随着催化剂进料速率的提高,催化剂颗粒的滞留时间缩短,催化剂到达反应器出口时,催化剂温度降低幅度减小。进料速率从5 g·s−1增至50 g·s−1的5个工况对应的颗粒停留时间分别为1.24、1.15 、0.97 、0.87 和0.79 s。在不同催化剂进料速率条件下,从催化剂颗粒进入反应器开始,反应器内催化剂颗粒的热交换率变化趋势如图7所示。随着催化剂进料速率增加,反应器内催化剂颗粒热交换率逐渐减小 (分别为0.098、0.071、0.053、0.045 和0.032 W) 。

随着催化剂颗粒进料速率q的提高,颗粒滞留时间缩短,热交换速率逐渐降低,故催化剂到达反应器出口的温度降低减小。

-

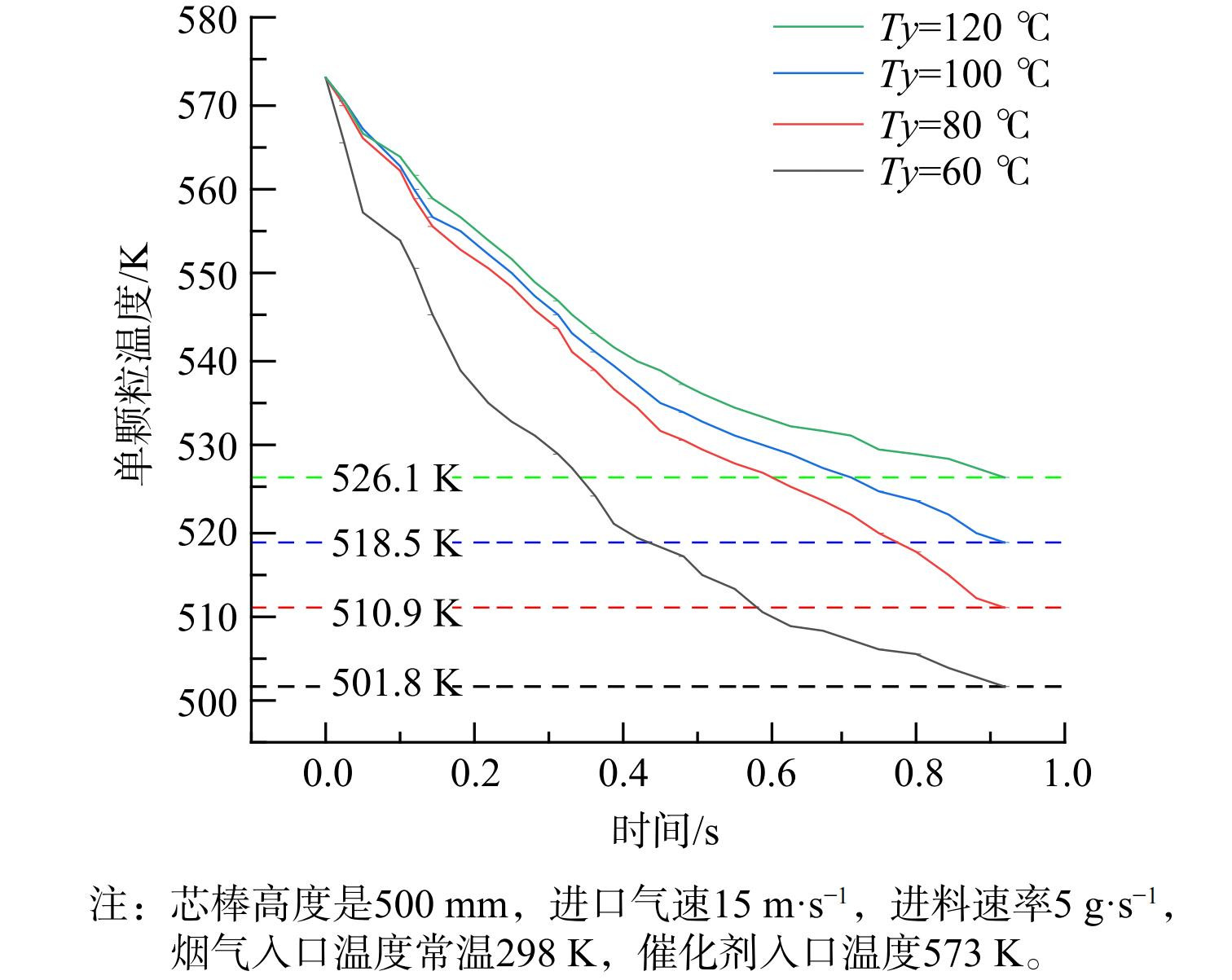

进口烟气温度的升高大幅提高了气体初始温度从而影响出口烟气温度。图8是旋流流化反应器整在不同进口烟气温度Ty下的气体温度分布,以及出口气体温度。反应器运行参数为:芯棒高度是500 mm,进口气速是15 m·s−1,催化剂入口温度573 K,催化剂进料速率是5 g·s−1,烟气入口温度分别是60、80、100和120 ℃。随着入口烟气温度提高,旋流流化反应器气体和催化剂温度差距较小,从而大大降低了热交换,出口催化剂温度升高。

反应器内催化剂颗粒的热交换率变化趋势如图9所示,随着进口烟气温度Ty的提高,进口烟气温度与催化剂颗粒的温差降低,热交换速率逐渐降低,从而催化剂到达反应器出口时,催化剂出口温度降低减小。

-

气体的进口速度Ui显著影响气体和催化剂颗粒在旋流流化反应器内的停留时间,不同进口气速Ui下旋流流化反应器内气体温度分布如图10所示。气体温度分布等值线呈现倒“V”形态,即中间温度低两边温度高。这是由于催化剂颗粒在流化床反应器中螺旋向上运动,在离心力作用下颗粒向壁面附近聚集,因此壁面附近颗粒与气体的热交换频繁,气体温度较高。而且高温颗粒向低温气体传热的主要区域为反应器环隙,反应器芯柱上部气体沿轴向温差较小。以图10(a)为例,在进口气速为5 m·s−1时,从反应器入口至环隙出口,气体温度从298 K升至约431 K,上升幅度为44.6%。从反应器内环隙出口至反应器顶部出口,气体温度从431 K升至448.6 K,上升幅度仅为4.0%。由此说明,旋流流化反应器内芯棒与壁面环隙内的传热量远大于芯棒上部反应腔。

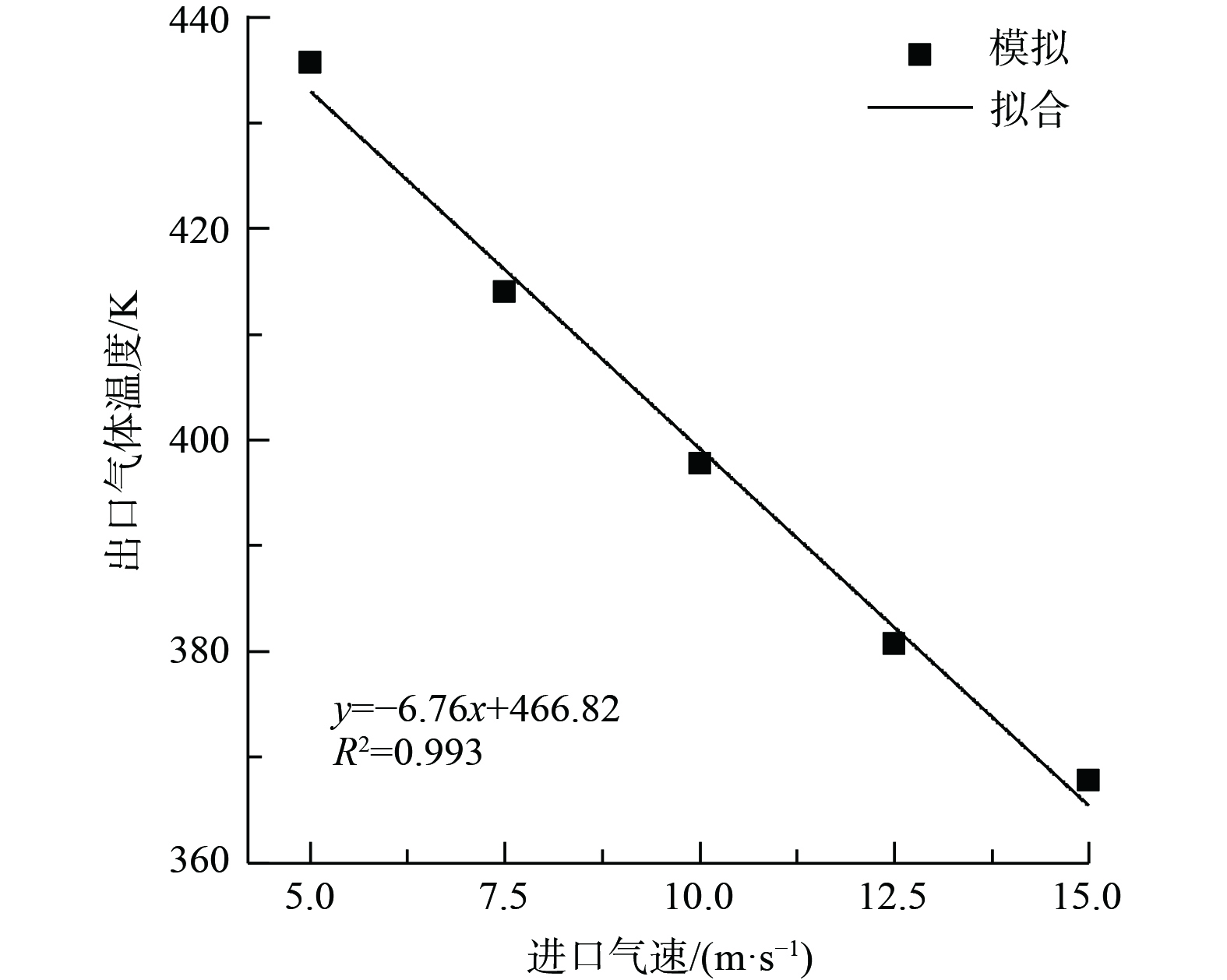

进口气速显著影响低温烟气与催化剂颗粒在反应器内的传热时间,进而影响高温催化剂向低温烟气的总传热量,最终出口气体的出口温度随着进口气速Ui的升高而降低。

根据式 (2) ,旋流反应器出口烟气的温度与烟气节能效率成反比,出口烟气温度越低节能效率越高。不同进口气速下反应器出口烟气温度如图11所示,气体出口温度与进口气速呈线性关系,进口气速每升高2.5 m·s−1,出口温度降低约16.7 ℃。这是由于进口气速增大,烟气在反应器内催化剂颗粒的换热时间减少,故导致出口烟气温度随进口气速增大而减小。

-

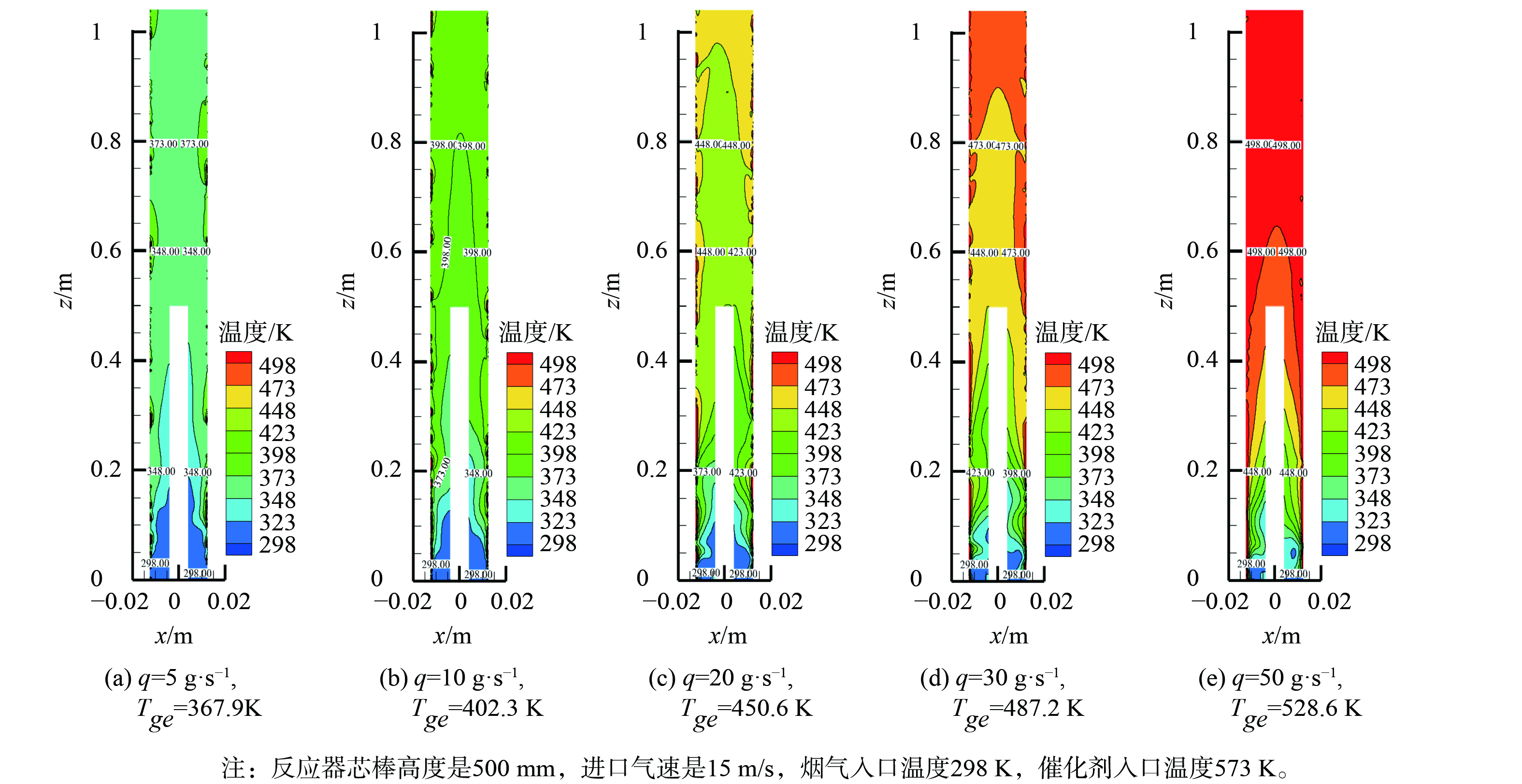

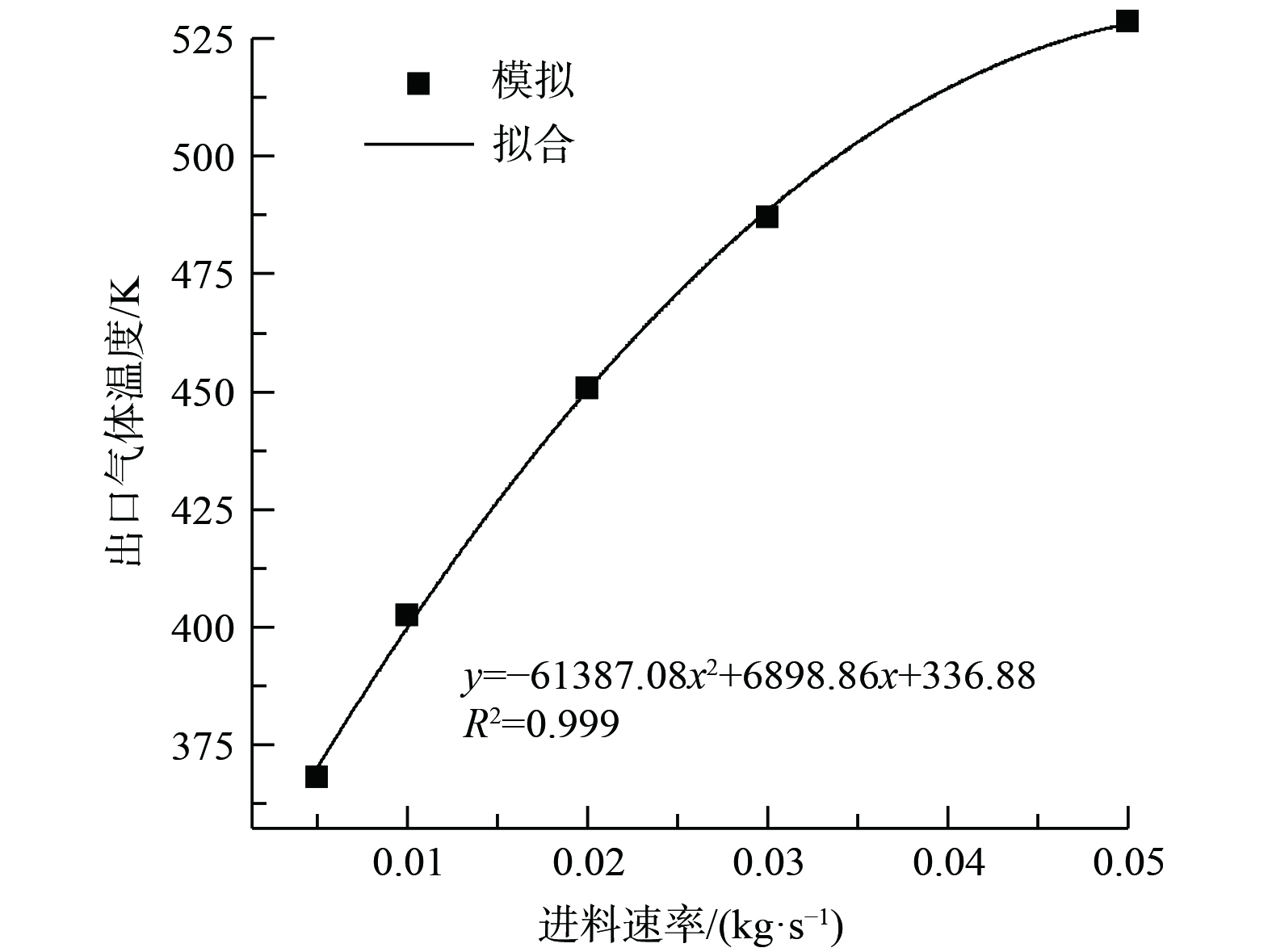

催化剂颗粒的进料速率q显著影响旋流流化反应器内催化剂颗粒的瞬时滞留量,进而影响气固两相的传热过程。在不同催化剂进料速率q条件下,旋流流化反应器内气体的温度分布如图12所示。高温颗粒向低温气体传热的主要区域仍然为反应器环隙,反应器芯柱上部气体沿轴向温差较小。如图12(a)所示,以进料速率5 g·s−1为例,从反应器入口至环隙出口,气体温度从298 K升至约348 K,上升幅度为16.7%。从反应器内环隙出口至反应器顶部出口,气体温度从348 K升至367.9 K,上升幅度仅为5.7%。随着催化剂颗粒进料速率提高,反应器内催化剂颗粒滞留量增加,从而增大传热面积,导致旋流流化反应器内气体平均温度呈现上升趋势。由式 (3) 和图6计算可得,颗粒的滞留质量分别为6.2、11.5 、19.4 、26.1 和39.5 g。旋流流化反应器出口气体温度与进料速率呈正相关,如图13所示。随着催化剂进料速率增大,出口气体温度逐渐接近催化剂温度,气体温度上升速率迅速衰减。当进料速率达到50 g·s−1,出口气体温度几乎不在上升。

随着催化剂颗粒进料速率q的提高,催化剂颗粒的滞留时间缩短,热交换速率逐渐降低,但是反应器内催化剂颗粒滞留量增加,从而增大传热面积,导致气体出口温度逐渐上升。

-

旋流流化反应器出口气体温度与进口烟气温度呈线性正相关,如图14所示。反应器入口烟气温度每升高20 ℃,出口气体温度升高约13.0 ℃。将入口烟气温度25 ℃带入图14线性拟合公式计算得到出口气体温度为367.7 K,对比图12 (a) 的出口气体温度367.9 K (入口温度25 ℃) ,误差仅为0.5 %。

-

1) 进口气速显著影响低温烟气与催化剂颗粒在反应器内的传热时间,进而影响高温催化剂向低温烟气的总传热量,最终反映为烟气出口温度的不同。随着催化剂进料速率的提高,催化剂颗粒的滞留时间缩短,催化剂到达反应器出口时,催化剂温度降低幅度减小。高温颗粒向低温气体传热的主要区域为反应器环隙,反应器芯柱上部气体沿轴向温差较小。当进口气速高于10 m·s−1时 (催化剂进料速率5 g·s−1) ,能保证催化剂出口温度高于催化活性温度200 ℃。在临界流化进口气速以上,升高催化剂进料速率可降低进口气速来保证催化剂出口活性温度。

2) 进料速率对于出口烟气温度影响最大。旋流流化反应器进口催化剂进料速率的增大,使反应器内高温催化剂颗粒累积量也增大,在相同进口气速下,低温烟气获得的能量多,反应器出口烟气温度则升高。随着进料速率由5 g·s−1到50 g·s−1,出口烟气温度变化在94.7 ℃到247.4 ℃。

3) 在本研究条件下,当气速为7.5 m·s−1,催化剂进料速率为25 g·s−1时,可保证反应器出口催化剂颗粒微界面温度不低于其活性温度,同时烟气出口温度达到最低。该工况下, 25 ℃的低温烟气经过反应器后达到221.9 ℃ (催化剂初始温度300 ℃) ,升温幅度为196.9 ℃。若该低温烟气直接加热至300 ℃,升温幅度达到275 ℃。不考虑其他热量损失的影响,相较烟气直接加热,旋流流化工艺的节能效率为28.4%。

低温烟气脱硝旋流流化反应器的传热特性

Heat transfer characteristics of low-temperature flue gas denitrification swirl fluidization reactor

-

摘要: 现行工业低温烟气脱硝技术需对烟气及整个反应系统进行整体加热以达到催化剂高效反应的温度,存在能耗高的问题。由于脱硝反应仅在高温催化颗粒的微界面上进行,提出以高温催化剂颗粒为循环热载体,利用旋流流化反应器使其与低温烟气中的氮氧化物快速接触,发生脱硝反应的新方法。通过CFD和DEM耦合计算,模拟研究了旋流流化反应器中高温催化剂颗粒和低温烟气间的传热特性。调控因素主要包括进口气速、进料速率、进口烟气温度。结果表明,在催化剂进料速率为25 g·s−1、进口气速为7.5 m·s−1 (空速81 000 h−1) 时,反应器出口催化剂平均温度可达200 ℃以上 (催化剂高效活性温度区间为200~300 ℃) ,对比直接加热低温烟气的方式,不考虑加热与传热过程热量损失,可直接节约能耗28.36 %。本研究对比低温烟气脱硝中整体加热烟气的方式,可为低温烟气脱硝技术的优化提供参考。Abstract: At present, for industrial low-temperature flue gas denitrification, the flue gas and the whole reaction system is heated to achieve the efficient reaction temperature of the catalyst, the overall energy consumption of whihc is high. Based on the denitrification reaction on the face of high-temperature catalytic particles, a new method for rapid reaction with nitrogen oxides in low-temperature flue gas in a cyclone fluidization reactor using high-temperature catalyst particles as the circulating heat carrier was proposed. Through the coupling calculation of CFD and DEM, the heat transfer characteristics between high-temperature catalyst particles and low-temperature flue gas in the cyclone fluidization reactor were simulated and studied, and the regulatory factors mainly included inlet gas velocity, feed rate and inlet flue gas temperature. The results showed that when the catalyst feed rate was 25 g·s−1 and the inlet gas velocity was 7.5 m·s−1 (airspeed 81 000 h−1), the average temperature of the catalyst outlet of the reactor could reach more than 200 °C (the efficient active interval of the catalyst was 200~300 °C). Compared with the direct heating of low-temperature flue gas, the direct energy consumption saving reached 28.36% without considering the heat loss in the heating and heat transfer process.

-

-

表 1 旋流流化反应器结构参数

Table 1. Geometric parameters of the cyclone

圆柱直径D/mm 柱高H/D 进口宽度a/D 进口高度b/D 芯棒直径De/D 芯棒高度S/H 25 41.6 0.4 0.6 0.32 0.5 表 2 EDEM中颗粒相与壁面参数

Table 2. Parameters of particle phase and wall in EDEM

物理位置 泊松比 密度/ (kg·m−3) 杨氏模量/Pa 恢复系数 静摩擦 动摩擦 颗粒相 0.45 2 760 1 $ \times $ 0.4 0.55 0.08 壁面 0.3 7 800 7 $ \times $ 0.25 0.3 0.04 -

[1] ZHANG J, LI X C, CHEN P G, et al. Research status and prospect on vanadium-based catalysts for NH3-SCR denitration[J]. Materials (Basel), 2018, 11(9): 2-15. [2] LIU H Z, TAN Q, JIANG X, et al. Comprehensive evaluation of flue gas desulfurization and denitrification technologies of six typical enterprises in Chengdu, China[J]. Environmental Science and Pollution Research, 2020, 27(36): 45824-45835. doi: 10.1007/s11356-020-10460-5 [3] XIONG S C, CHEN J J, LIU H, et al. Advances in the treatment of multi-pollutant flue gas in China's building materials industry[J]. Journal of Environmental Science (China), 2023, 123(01): 400-416. [4] ANTHONSAMY S B I, AFANDI S B, KHAVARIAN M, et al. A review of carbon-based and non-carbon-based catalyst supports for the selective catalytic reduction of nitric oxide[J]. Beilstein Journal of Nanotechnol, 2018, 9(1): 740-761. [5] WU Y, HU Z, ZHOU J-l, et al. Improvement in the resistance to KCl and PbCl2 synergistic poisoning of the commercial SCR catalyst by Ce(SO4)2 modification: A combined experimental and spin-polarized DFT study[J]. Journal of Environmental Chemical Engineering, 2023, 11(3): 2-11. [6] TAN W, WANG J, CAI Y, et al. Molybdenum oxide as an efficient promoter to enhance the NH3-SCR performance of CeO2-SiO2 catalyst for NO removal[J]. Catalysis Today, 2022, 397-399(01): 475-483. [7] HAN Q, JIN S, WANG J, et al. Insights to sulfur-resistant mechanisms of reduced graphene oxide supported MnOx-CeOy catalysts for low-temperature NH3-SCR[J]. Journal of Physics and Chemistry of Solids, 2022, 167(01): 2-17. [8] WU Z, JIN R, LIU Y, et al. Ceria modified MnOx/TiO2 as a superior catalyst for NO reduction with NH3 at low-temperature[J]. Catalysis Communications, 2008, 9(13): 2217-2220. doi: 10.1016/j.catcom.2008.05.001 [9] LAGUNA O H, ROMERO S F, CENTENO M A, et al. Gold supported on metal-doped ceria catalysts (M=Zr, Zn and Fe) for the preferential oxidation of CO (PROX)[J]. Journal of Catalysis, 2010, 276(2): 360-370. doi: 10.1016/j.jcat.2010.09.027 [10] 熊天龙, 李艳松, 刘琪琪, 等. 焦化行业烟气低温SCR脱硝中试研究[J]. 四川化工, 2016, 19(1): 52-55. doi: 10.3969/j.issn.1672-4887.2016.01.015 [11] 冀岗, 董卫杰, 李强, 等. 太钢烧结烟气氮氧化物超低排放技术研究[J]. 烧结球团, 2018, 43(2): 28-34. doi: 10.13403/j.sjqt.2018.02.031 [12] CHEN C, CAO Y, LIU S, et al. Review on the latest developments in modified vanadium-titanium-based SCR catalysts[J]. Chinese Journal of Catalysis, 2018, 39(8): 1347-1365. doi: 10.1016/S1872-2067(18)63090-6 [13] GAO X, LIU S, ZHANG Y, et al. Physicochemical properties of metal-doped activated carbons and relationship with their performance in the removal of SO2 and NO[J]. Journal of Hazard Materials, 2011, 188(1-3): 58-66. doi: 10.1016/j.jhazmat.2011.01.065 [14] GAO X, LIU S, ZHANG Y, et al. Low temperature selective catalytic reduction of NO and NO2 with NH3 over activated carbon-supported vanadium oxide catalyst[J]. Catalysis Today, 2011, 175(1): 164-170. doi: 10.1016/j.cattod.2011.03.058 [15] JIANG B Q, LIU Y, WU Z B. Low-temperature selective catalytic reduction of NO on MnOx/TiO2 prepared by different methods[J]. Journal of Hazard Materials, 2009, 162(2-3): 1249-54. doi: 10.1016/j.jhazmat.2008.06.013 [16] YANG J, MA H, YAMAMOTO Y, et al. SCR catalyst coated on low-cost monolith support for flue gas denitration of industrial furnaces[J]. Chemical Engineering Journal, 2013, 230(1): 513-521. [17] MA L, HE M Y, FU P B, et al. Adsorption of volatile organic compounds on modified spherical activated carbon in a new cyclonic fluidized bed[J]. Separation and Purification Technology, 2020, 235(1): 2-11. [18] MA L, SHEN Q S, LI J P, et al. Efficient gas-liquid cyclone device for recycled hydrogen in a hydrogenation unit[J]. Chemical Engineering & Technology, 2014, 37(6): 1072-1078. [19] MA L, XIANG G L, HUANG Y, et al. Effects of spherical adsorbent fluidization and self-rotation on removal of VOCs in a cyclonic fluidized bed[J]. Journal of Industrial and Engineering Chemistry, 2020, 85(01): 181-189. [20] CHU K W, WANG B, YU A B, et al. CFD-DEM modelling of multiphase flow in dense medium cyclones[J]. Powder Technology, 2009, 193(3): 235-247. doi: 10.1016/j.powtec.2009.03.015 [21] CHU K W, WANG B, XU D L, et al. CFD–DEM simulation of the gas–solid flow in a cyclone separator[J]. Chemical Engineering Science, 2011, 66(5): 834-847. doi: 10.1016/j.ces.2010.11.026 [22] FU P B, ZHU J Y, LI Q Q, et al. DPM simulation of particle revolution and high-speed self-rotation in different pre-self-rotation cyclones[J]. Powder Technology, 2021, 394(01): 290-299. [23] TIAN J Y, NI L, SONG T, et al. CFD simulation of hydrocyclone-separation performance influenced by reflux device and different vortex-finder lengths[J]. Separation and Purification Technology, 2020, 233(1): 2-15. [24] ZHANG Y, LIU Y, QIAN P, et al. Experimental investigation of a minihydrocyclone[J]. Chemical Engineering & Technology, 2009, 32(8): 1274-1279. [25] ZHANG Y, LIU P, GE J, et al. Simulation analysis on the separation performance of spiral inlet hydrocyclone[J]. International Journal of Coal Preparation and Utilization, 2021, 41(7): 474-490. doi: 10.1080/19392699.2021.1934828 [26] VAKAMALLA T R, MANGADODDY N. Numerical simulation of industrial hydrocyclones performance: Role of turbulence modelling[J]. Separation and Purification Technology, 2017, 176(1): 23-39. [27] RAZMI H, SOLTANI G A, MOHEBBI A. CFD simulation of an industrial hydrocyclone based on multiphase particle in cell (MPPIC) method[J]. Separation and Purification Technology, 2019, 209(1): 851-862. [28] 赵国智, 孔凡让, 占惊春, 等. 基于SIMPLE算法的湍流场数值模拟[J]. 水电能源科学, 2007, 25(3): 100-102. [29] BASSE N T. Turbulence intensity and the friction factor for smooth- and rough-wall pipe flow[J]. Fluids, 2017, 2(2): 2-13. -

下载:

下载: