-

电镀是当代工业产业链中不可或缺的环节,在机械、电子、航天等各个领域都有广泛的应用,而电镀行业产生的电镀废水经过处理后会产生含有重金属离子及有毒有害成分的电镀污泥[1]。一般情况下,电镀污泥只是进行简单填埋,甚至随意堆放,不仅对环境造成污染,也是对资源的一种浪费[2]。因此,开发一种经济有效的处理电镀污泥的方法是环境工程领域亟待解决的问题。将电镀污泥作为原材料制作烧结砖是一种潜在的重要处理方法,因为它既可以减少自然资源的消耗,又可以降低废弃物的处理成本。高温制备砖体时,电镀污泥中的重金属会与土中的硅、铝、铁等氧化物相互反应发生矿化作用,这在很大程度上降低了重金属从砖体内部转移到环境中的可能性,减少了对周围环境的污染[3]。然而掺加电镀污泥等固废可能会降低烧结砖的性能,例如李鹏飞[4]将电镀污泥作为材料制作陶粒时发现,随着电镀污泥的添加,陶粒的抗压强度下降,吸水性提高。这是由于电镀污泥中含有的水分及有机物在高温燃烧时挥发排出到材料外部,生成连通气孔,导致材料内部疏松,力学性能下降。作者在之前的研究中已发现,砖体内部的致密性与高温时产生液相的量密切相关,因此提高液相产生量是提高砖体力学性能及降低浸出风险的一种潜在方法[5]。玻璃在高温时能形成熔融液相,且黏度较大,使砖体内部各物质结合紧密,起到提高内部致密度的作用,同时其中的Na2O及非结晶成分能起到助熔剂的作用,在高温煅烧时使石英在较低的温度熔融从而进一步提高砖体内部液相产生量提高砖体的抗压等物理性能[6]。

通过添加玻璃粉对砖体性能进行改善是潜在的一种方法[7],但很少有研究关注玻璃粉粒径的变化对砖体性能的改善作用,本研究采用4种目数的玻璃粉,考察其对烧结砖物理和力学性能的影响,以及对重金属固定的作用。

全文HTML

-

本研究使用的电镀污泥来自江苏省常州市前黄电镀厂,该厂主要经营金属表面处理、电镀加工。电镀污泥中含有大量的铜锌铬镍等重金属。制作烧结砖主体的红土来自常州市的一家砖窑厂。砖体中添加的玻璃粉由实验室破碎玻璃器皿研磨制得,粉碎研磨后通过100目(150 μm)、300目(48 μm)、600目(23 μm)、800目(18 μm)的筛网过筛得到4种均匀粒度的废玻璃粉。

-

将取来的电镀污泥晒干后剔除其中较大杂质,用球磨机以400 r·min−1的转速研磨1 h,将研磨过后的电镀污泥与红土分别过200目的筛网。研究表明烧结砖中电镀污泥的合适添加量为10%[8],本研究将电镀污泥加入量提升至20%以考察玻璃粉对重金属浸出风险的影响。玻璃粉、红土及电镀污泥混合比例见表1。将混合后的土样放入行星球磨机用较小钢球二次研磨,转速为400 r·min−1,研磨时间1 h,使3种原料充分混合从而保证烧制过程中砖体的完好性。

称取40 g混合完全的粉末用实验室小型10 T粉末压片机压制成长宽高为50、30、35 mm的生砖,在压制前往模具中添加约1 mL水以增强砖块的塑性。将压制的砖块置于恒温干燥箱中以100 ℃的温度干燥24 h,最后将干燥完毕的砖块在马弗炉中按照5 ℃·min−1的升温速率升到950 ℃,并在此温度下保持3 h完成烧制,烧制结束自然冷却后取出。

-

对烧制得到的烧结砖进行抗压性能测定,每个样品都以1 MPa·s−1的速度垂直于受压面加荷,直至样品破碎,按照《烧结普通砖》(GB5101—2003)[9]中的抗压强度对砖体进行等级判定;按照《砌墙砖试验方法》(GB/T2542—2012)[10]中吸水率、显气孔率的试验方法对砖体进行物理性能试验研究;为了检测砖体内部有机物质的减少对砖体性能的影响,对砖体的烧失量进行检测。

-

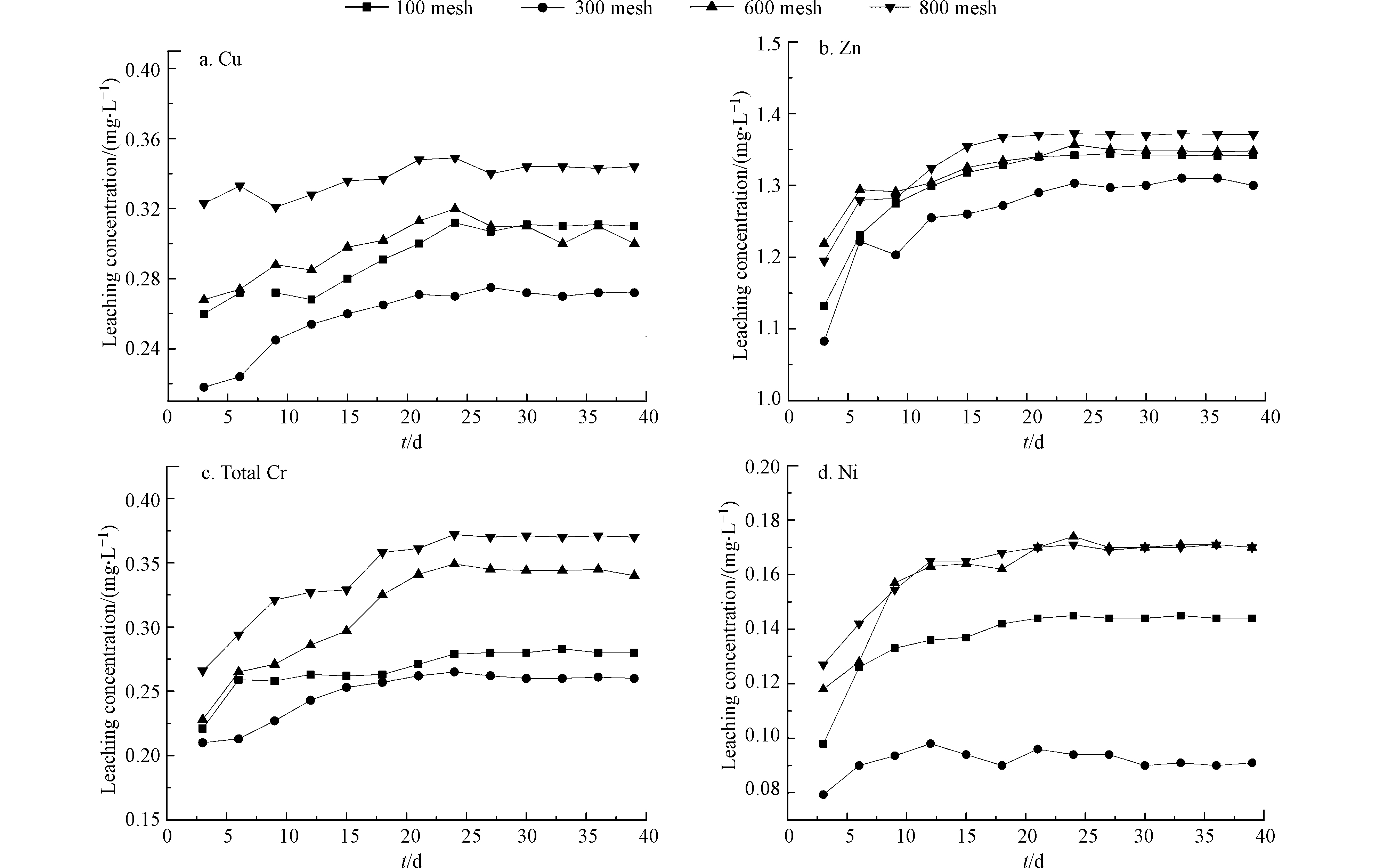

根据《固体废物浸出毒性浸出方法醋酸缓冲溶液法》(HJ/T300—2007)[11]对烧制好的烧结砖进行浸出实验研究,确定砖块中的重金属固化效果,醋酸法选用2#浸提剂(用试剂水稀释17.25 mL的冰醋酸至1 L,配置后溶液的pH值应为2.64±0.05),按照液固比20:1(L·kg−1)配置醋酸浸提剂。每隔3天取10 mL浸出水样,采用火焰原子吸收法测定浸出水样中铜、锌、铬、镍的浓度。

1.1. 试验样品来源

1.2. 实验程序

1.3. 砖体物理性能试验方法

1.4. 浸出毒性测试

-

采用X射线荧光光谱仪(XRF)对红土、玻璃粉和电镀污泥进行分析,结果见表2。Si、Al和Fe氧化物是红土的主要成分,电镀污泥中Fe2O3的含量较高,会使烧制后的砖体中生成钾钙长石等物质。钾钙长石具有较低的热膨胀系数和较好的机械性能,能提高材料的强度和化学稳定性[12],Fe2O3在高温中也易和铝、锌等金属氧化物的反应生成难溶于水的AB2O4型尖晶石化合物,这些化合物大多难溶,可降低重金属浸出毒性[13]。

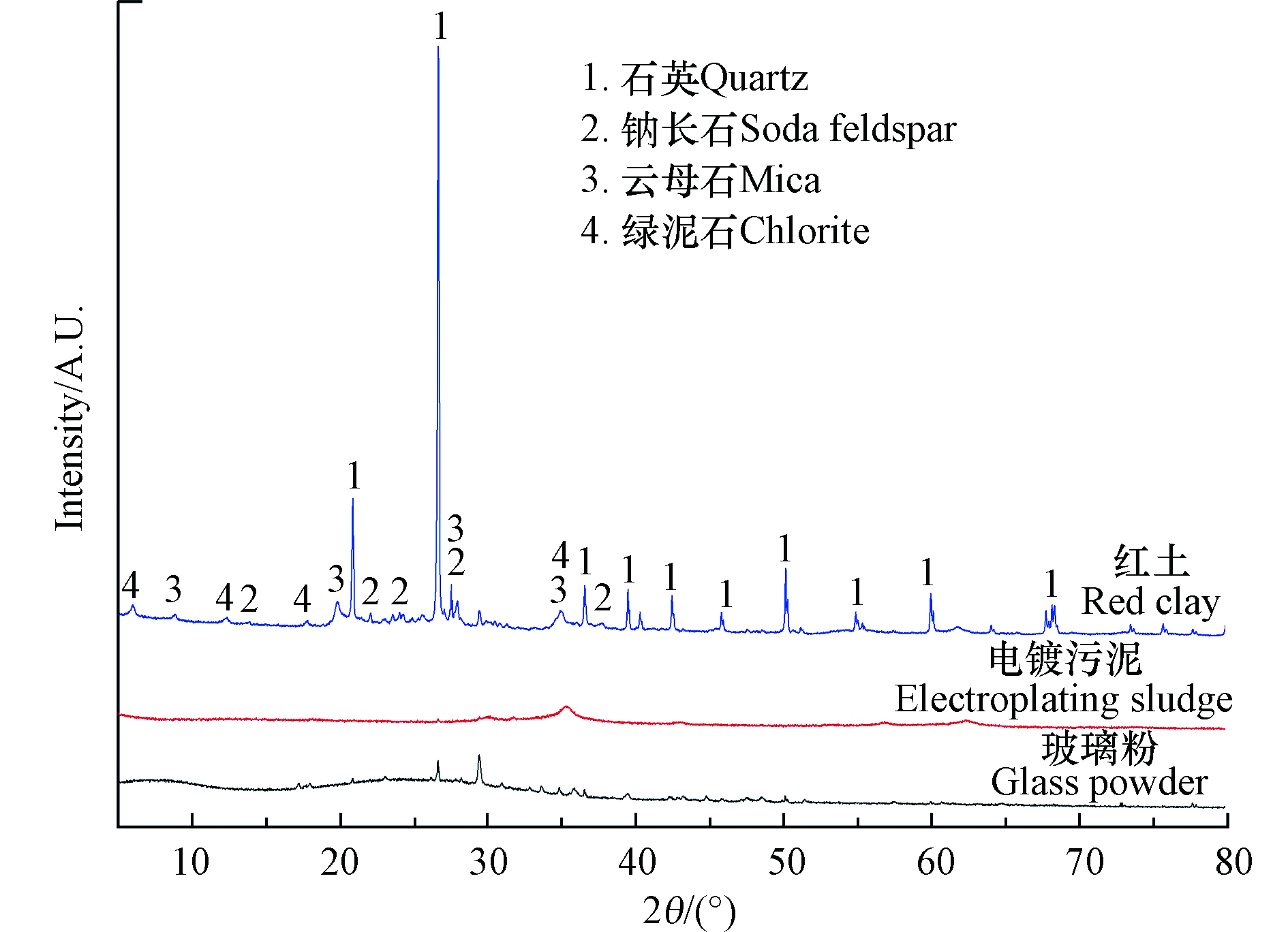

对3种原料采用XRD进行矿相分析,结果如图1所示,红土与玻璃粉中的物质以SiO2为主,研究指出SiO2对砖体的抗压强度等力学性能具有提升作用[14]。本次实验电镀污泥是经有机络合试剂沉淀处理得到,因此电镀污泥中碱金属和碱土金属含量较少。有研究认为高温时重金属在碱性环境下更容易蒸发,因此本实验使用的电镀污泥可以减少重金属在高温时的挥发,有利于重金属转化为稳定形态,从而降低浸出风险[15]。

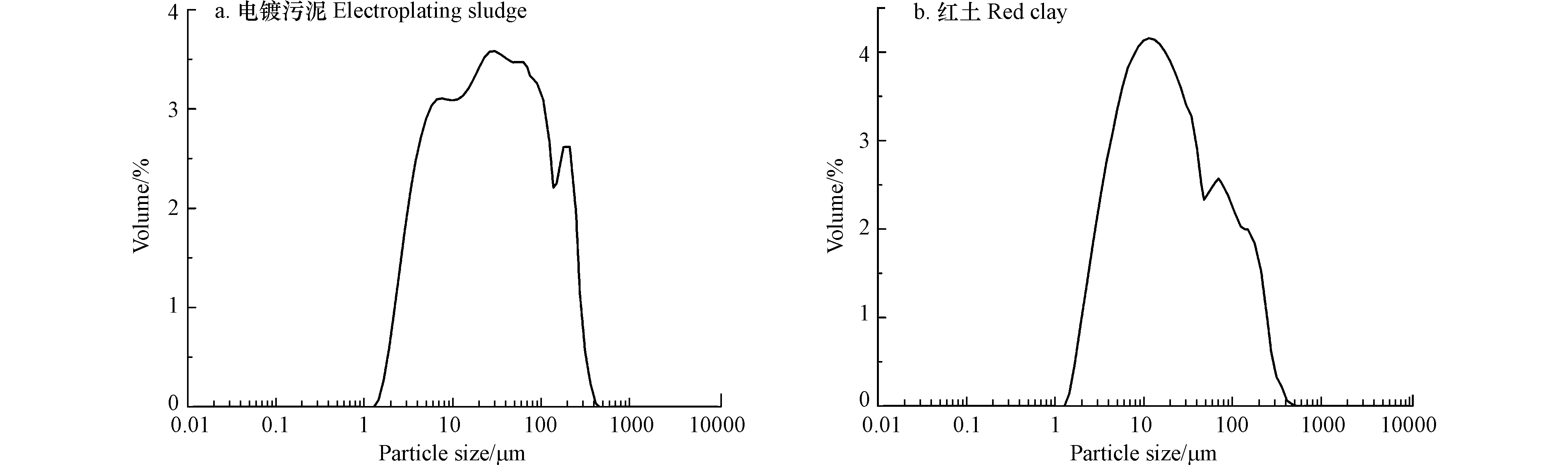

电镀污泥、红土与不同目数玻璃粉粒度分布如图2所示。从图2看出,电镀污泥与红土的粒径中值分别为22.56 μm、15.16 μm。4种目数的玻璃粉中,300目的玻璃粉与两种原料的粒径分布最为相似,且粒径分布较宽。

-

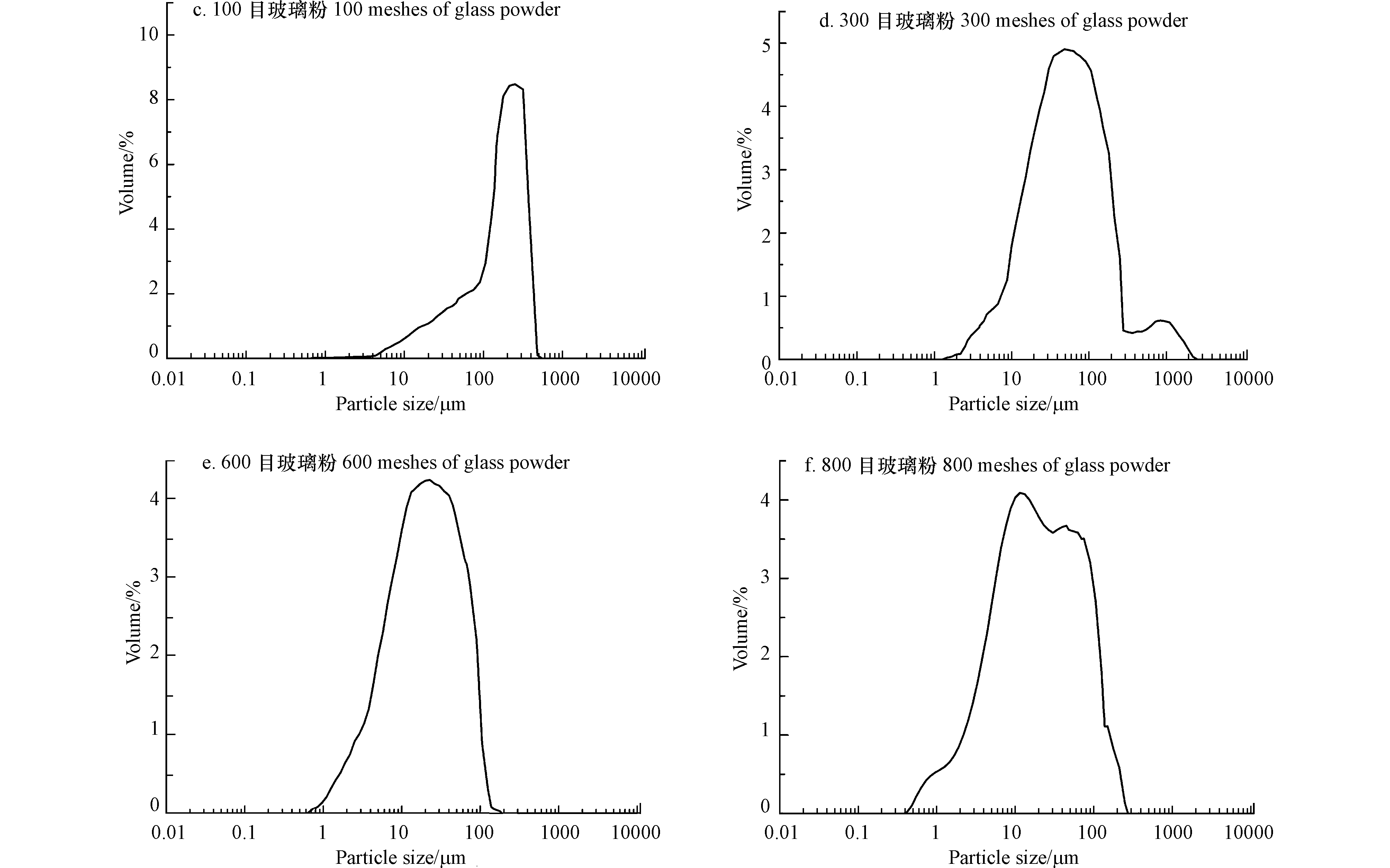

将烘干磨细的电镀污泥分别与红土、玻璃粉混合,然后压制成型、干燥、烧制得到烧结砖,烧制合格的砖体应无裂痕、无膨胀、颜色均匀。图3是制备好的烧结砖,砖体表面致密,有一层釉质形成,这是因为烧结砖表明的玻璃高温熔融,冷却后形成玻璃态物质,这些玻璃态物质均匀的覆盖在表面上,可以有效减少液体的侵入,对阻止重金属浸出转移会起到重要作用。

-

烧结砖的烧失量变化如图4所示,砖体的最大烧失量为3.48%,最小为2.48%。在相同目数的情况下,玻璃粉添加量越少,烧失量越大,这是由于玻璃粉本身的烧失量很小,所以砖体失重的主要原因是由于红土和电镀污泥中物理水、有机质及水合物的挥发和分解。在目数不同的情况下,添加300目玻璃粉的砖体烧失量最大,这是由于玻璃粉粒径与原料粒径相似,砖体内部各组分排列较为均匀,受热性能较好,因此烧失量大[16]。

图5(a)是砖体的线性收缩率图,通常优质砖的收缩率低于8%,本试验的砖体都基本符合这一标准。当玻璃粉目数相同时,随着玻璃粉增加,砖体的线性收缩率逐渐增大;当目数不同且满足优质砖的标准时,添加300目玻璃粉的烧结砖线性收缩率最大,达到−7.55%。收缩率的变化是由于砖体在高温下烧结成型时,内部有机物和水分被蒸发排除,砖体内部留下较多的孔隙,玻璃粉在高温时熔融,成为高温液相,流入砖体内部的孔隙中,在液体应力的作用下使砖体内部各物质之间结合紧密,导致砖体体积收缩[17]。当砖体中含有大量的玻璃粉时,高温时产生的熔融液相多,因此添加较多玻璃粉的砖体线性收缩率较大;当添加玻璃粉粒径过小时,由于3种原料之间存在粗糙度的差异,导致三者无法充分熔融包裹,局部熔融液相产生量较少,产生的黏性也较小,因此砖体内部收缩也就小。当添加的玻璃粉粒径过大,玻璃粉熔点较高,部分未融化,产生的熔融液相少,线性收缩就小。

图5(b)和(c)是砖体的显气孔率和吸水率,随着玻璃粉的添加,吸水率和显气孔率都有所下降,添加300目玻璃粉的砖体显气孔率和吸水率最小,分别达到10.07%和7.72%。

吸水率是检验砖体耐久性的重要指标之一,根据《烧结普通砖》(GB5101—2003)中对非严重风化区的黏土砖标准,吸水率不大于19%,此次试样都满足要求[9]。砖体中孔洞产生的原因是原材料中水分的蒸发以及碳酸盐等物质在高温烧结过程中分解放出CO2气体,不利于砖体的致密化[18]。添加100目玻璃粉的砖体在4种砖体中孔洞率和吸水率较大,这是由于在高温时,较大粒径的玻璃粉被包裹在砖体内部,一部分不能完全熔融,其本身还是呈现玻璃粉的固体形态,占据一定的内部体积;而当玻璃粉目数与原材料相当时,高温熔融液相流入砖体内部孔洞,形成更多闭孔;粒径过小时,红土、电镀污泥与玻璃粉之间为不完全包裹,3种材料之间产生一定的空隙,在成砖过程中产生连通孔洞,再加上粉末粒径越小,热阻越小,在较低的温度下即可吸收与大粒径颗粒在较高温度下吸收的相同热量,因此烧结过程中液相出现早,砖体的表面先形成釉质层,导致表层气孔较早关闭,砖体内部的气体不能及时排出,砖体的显气孔率和吸水率较大[19]。在相同烧结条件下,采用较宽粒径分布的原料制备的砖体致密化程度高、显气孔率低,这也很好地解释了本次实验采用300目的玻璃粉在提升砖体性能方面的优越性[20].

图5(d)是砖体的密度变化示意图,随着玻璃粉目数的增加,砖体的密度先变大再变小,添加300目玻璃粉的砖体密度最大,达到2.01 g·cm−3;而当玻璃粉目数相同时,添加玻璃粉数量越多,砖体的密度就越大,这和线性收缩率、显气孔率、吸水率的变化一致。

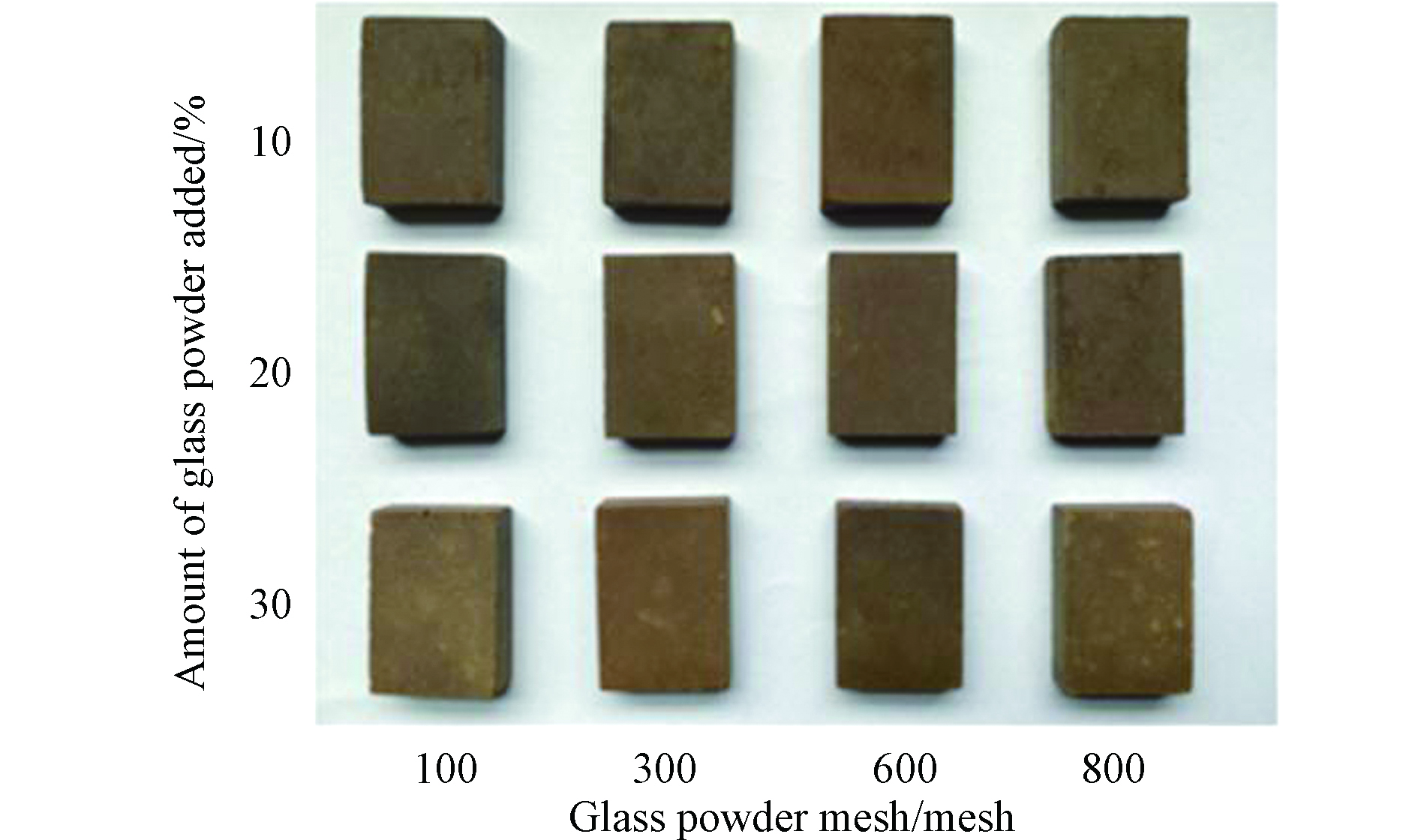

抗压强度是建筑材料的重要指标,中国建筑材料标准(GB/T2542—2012)要求烧结砖的抗压强度必须大于10 MPa,图6显示了砖体抗压强度的变化,本研究制备的所有砖都符合要求。抗压强度随着玻璃粉的添加而增大,最大达到50.24 MPa,砖体的抗压强度与孔隙率密切相关,抗压强度的变化与孔隙率的变化一致,在添加300目玻璃粉时,砖体的抗压性能最好。一般来说,对于不同粒径的原料,在相同的压力条件下,平均粒径较小原料的初坯密度会更低,孔隙率会更高,随着温度和压力的上升,坯体的致密度会逐渐增大,而本次实验砖体致密度的提升很大一部分原因是由于砖体内玻璃相的形成,废玻璃在熔化过程中形成的液相可以增强原材料之间的连接性,提高抗压强度[21-22]。形成的玻璃相的粗细对砖体内部致密程度的影响不一,较粗玻璃相表面光滑且比表面积大,与砖体内部颗粒之间摩擦力小,粘结性差,因此砖体内部较为松散,而较细玻璃相表面会形成多棱角和裂纹,与周围颗粒之间形成较大的摩擦力,结合力就越大,但过小粒径玻璃粉因其更大的比表面积会使其形成的晶粒粗化,不利于砖体内部的致密化[23]。

-

图7所示为含有不同目数玻璃粉的烧结砖的微观结构变化,其中添加300目玻璃粉的烧结砖微观结构变得致密均匀,气孔数量明显减少,砖体内部形成光滑的微观结构,内部大部分被玻璃相包裹,表明玻璃相填充了裂缝和气孔,这与显气孔率和吸水率的变化一致。

表3和表4为烧结砖的比表面积与平均孔径,随着玻璃粉目数的增加,砖体内部的比表面积与孔径先减小再增大;而在添加相同目数的玻璃粉时,砖体内部的比表面积与平均孔径随着玻璃粉添加量的增大而减小,即内部孔隙减少,这与SEM观察到的现象一致。添加300目玻璃粉的砖体的比表面积和平均孔径在4种玻璃粉中最小,分别为0.46 m2·g−1,3060 nm,是由于较宽粒径分布的原料在烧结过程中得到小孔的机会更大,相对于较窄粒径分布的原料制备砖体,得到小孔的数量就会更多,导致平均孔径减小[24]。

-

图8是砖体粉末XRD分析图,分析表明掺加玻璃粉和电镀污泥的烧结砖中主要有3种物相,分别是石英、尖晶石及长石。随着玻璃粉添加量的增多,石英的特征峰强度降低,长石和尖晶石的特征峰强度明显增强,长石的形成表明SiO2的熔化和液相的形成,长石的形成也与玻璃粉的添加密切相关。长石的熔点较低,通常作为覆盖陶瓷表面的釉料及粘结剂,能起到降低砖体比表面积和孔隙率的作用,从而减少砖体内部物质与外界的接触,起到降低重金属浸出毒性的作用[25]。尖晶石结构的化学式通常是AB2O4(A是二价金属,B是三价金属),尖晶石结构具有良好的化学稳定性,不易与酸碱溶液反应,通常用于固定重金属,起到降低重金属浸出毒性的作用[26]。玻璃粉的加入增加了尖晶石的特征峰的强度,说明玻璃粉的加入有利于ZnCr2O4、ZnAl2O4、CuAl2O4等尖晶石的形成和生长,有利于降低电镀污泥砖对环境造成的风险。

用电镀污泥制砖,最为关注的问题是其中有害金属对周围环境的影响,中国政策不允许在建筑材料制造过程中引入危险废物,在这种情况下采用《危险废物鉴别标准浸出毒性鉴别》(GB5085.3—2007)[27]评估重金属的释放行为,以检验有害重金属的长期浸出风险,图9是添加玻璃粉为30%的烧结砖4种重金属的浸出浓度随时间变化的曲线图。

当浸出量稳定时,300目玻璃粉烧结砖中Cu2+、Zn2+、总Cr、Ni2+这4种重金属浓度为:0.27、1.3、0.26、0.09 mg·L−1,《危险废物鉴别标准浸出毒性鉴别》(GB5085.3—2007)中浸出毒性鉴别标准值Cu2+、Zn2+、总Cr、Ni2+的浓度分别为100、100、15、5 mg·L−1,浸出液中重金属的浓度远低于标准值。当玻璃粉的添加量达到30%时,重金属的浸出浓度较低,这是由于玻璃粉的添加对重金属的固化起重要作用,砖体内部更加致密,使得浸出液与砖块内部的接触面积减少,重金属浸出风险由此降低[28]。另外,从SEM图像上显示了大量玻璃相的形成,玻璃粉在烧制过程中融化并形成液相,形成的液相减少了重金属与Al2O3或Fe2O3在高温下的接触面积,改善了重金属与Al2O3和Fe2O3之间的传质,最后冷却成为玻璃相,从而有限减少了重金属的释放[29]。因此,玻璃相的包裹导致砖体与浸出液接触面积的大幅降低可能是重金属浸出浓度下降的主要原因。

2.1. 原料表征

2.2. 添加玻璃粉对污泥烧结砖性能的影响

2.2.1. 添加玻璃粉对污泥烧结砖性能的影响

2.2.2. 显微结构与孔隙结构

2.3. 重金属浸出风险评估

-

(1)添加玻璃粉制作污泥烧结砖可以显著提高砖体的各项性能,添加与原料目数相近的玻璃粉时,效果更好,当掺加30%质量分数的300目玻璃粉时,线性收缩率−7.55%、显气孔率达到10.07%、吸水率达到7.72%。

(2)玻璃粉的加入提高了污泥烧结砖的抗压强度,砖体的最大抗压强度达到50.24 MPa。

(3)玻璃粉的加入降低了污泥砖的比表面积、平均孔径,最小达到0.46 m2·g−1、3060 nm。

(4)重金属的浸出风险表明,玻璃粉的加入降低了重金属的浸出风险,浸出液中重金属浓度小于国家限定标准值,因此是一种安全可行的方法。

下载:

下载: