-

合成染料在诸多行业中被广泛应用,如纺织、皮革、印染、化妆品、造纸等[1-2]。但是,大多数染料及其降解产物具有毒性[3],在进入环境后对生态系统产生威胁。孔雀石绿(MG)是一种常见的阳离子染料[4],极易溶于水,在水环境中不易被降解,具有高毒素,致畸、致癌、致突变等危害[5-6]。目前,常见的处理含染料废水的方法包括吸附、膜处理、絮凝和高级氧化等[7]。但是,传统的吸附和絮凝等方法只能将水溶液中的染料转移到吸附剂中,容易造成二次污染问题[8-9]。而高级氧化法对反应条件要求相对严格,一般在酸性条件下进行,反应后需要对废水进行二次处理[10-11]。膜分离技术成本相对较高,一般在实际应用中很少使用[12]。

近年来,纳米零价铁(nZVI)作为一种新型材料在污染物去除中得到了广泛的应用[13]。nZVI具有高还原性,易制得且价格低廉,对持久性有机污染物以及重金属等污染物都有较好的处理效果。但是nZVI易团聚,且极易被氧化,导致反应活性降低[14-16]。近年来的研究发现,将nZVI负载在多孔吸附介质,如生物炭(BC)、活性炭(AC)和膨润土等成为一种有效的将nZVI分散并保持其反应活性的方法[17-20]。有研究表明,nZVI-AC在吸附染料方面有较好的作用,使用0.5 g·L−1的吸附剂可去除99.41%的MG;通过玉米秸秆在500 ℃的高温下热解制备生物炭,然后制备nZVI-BC磁性复合材料在20 min后对MG染料的去除效率高达99.9%;一种新型复合材料可循环多壁碳纳米管/凹凸棒石负载纳米级零价铁(nZVI/MWCNTs/APT),用于去除阳离子染料MG,在反应90 min时对MG的去除率可达98.9%[21-23],由此可见纳米铁与炭的结合对染料去除效果较好。但是,目前使用的大部分负载介质的颗粒都较小,一部分容易进入环境中,不利于回收利用,且容易产生二次污染问题。此外,在实际水处理过程中,常见的去除工艺包括人工湿地、生物滤池以及反应器技术等,需要使用的材料具备一定的承压能力。因此,需要开发一种具备一定颗粒大小以及强度的材料,以方便应用于实际处理过程。

为了提高nZVI的处理效率,避免其快速氧化、团聚和二次污染等不足,本研究通过液相还原法,将nZVI负载于活性炭粉末(PAC)后,添加高岭土并在高温下烧制,对负载后的材料进行硬化,制备了具有一定强度的硬质纳米零价铁/炭颗粒(nZVI/PAC)。利用单因素实验优化了制备条件,对比了与纯nZVI造粒和纯活性炭造粒对MG的去除差异,探究了初始pH、MG初始浓度、nZVI/PAC投加量以及反应温度对去除结果的影响,并研究了MG的反应动力学以及反应机理,为开发粒状nZVI/PAC材料作为填充材料应用于实际水处理提供了参考。

全文HTML

-

采用液相还原法[24],以PAC(粒径为32目)为载体,在负载nZVI后,利用高岭土作为黏合剂,制备硬质nZVI/PAC。具体方法为:称取一定量FeSO4·7H2O溶于30 %的乙醇溶液中,配置浓度为0.5 mol·L−1的溶液。将一定质量比的PAC和高岭土加入FeSO4·7H2O溶液中,电动搅拌20 min使其混合均匀。随后往溶液中通入高纯氮气20 min,用于隔绝氧气,同时通过恒压漏斗滴加同体积1 mol·L−1的KBH4溶液,控制滴加速度为1滴每秒左右,控制氮气流速为0.04—0.06 m3·h−1,反应过程中持续搅拌。反应过程如反应式(1)所示:

反应完成后将混合液经抽滤后,用脱氧去离子水洗涤3次,再用脱氧无水乙醇洗涤3次,再次抽滤后加入1 %质量比的壳聚糖增加混合物的黏度,加入1%质量比的碳酸铵用于在材料烧制过程中形成内部孔隙。通过手工将混合材料造粒,保持粒径10 mm左右,在氮气保护下,于40 ℃下烘干,随后放入管式炉中,通入氮气经高温烧制后,得到改性硬质nZVI/PAC颗粒。

通过单因素实验优化nZVI/PAC的制备条件。在最高温度为800 ℃,保温时间2 h的条件下,添加40 %质量比的高岭土后,制备了铁碳比分比为2∶1、4∶1、6∶1和8∶1的nZVI/PAC颗粒,以获得最佳铁碳比。在最佳铁碳比条件下,制备了高岭土质量比分别为20 %、30 %、40 %和50 %的nZVI/PAC颗粒,得到最佳的高岭土添加比例。随后,通过改变最高烧制温度为400、600、800、1000 ℃,改变保温时间为0.5、1、2、4 h,优化了材料制备的烧制温度和保温时间。管式炉的升温条件为:0—500 ℃的升温速率为5 ℃·min−1,500—800 ℃的升温速率为10 ℃·min−1,800—1000 ℃的升温速率为5 ℃·min−1。

-

nZVI颗粒和PAC颗粒与上述nZVI/PAC颗粒的制备方法基本一致。在最佳制备条件下,只使用nZVI和只使用PAC与高岭土混合造粒后制备的材料分别为nZVI颗粒和PAC颗粒。

-

利用全自动物理吸附仪(3H-2000PM2)进行了比表面积(BET))的测定;利用微机控制电子万能实验机(C45.105)对材料的抗压强度进行了测试;利用扫描电子显微镜(FEI Inspect F50(FSEM))和透射电子显微镜(FEI G2 F20)对材料的微观形貌进行了表征;使用能谱扫描(EDS)分析了材料的元素分布;利用X射线衍射仪(Bruker D8 ADVANCE A25X)分析了材料的晶体形态(XRD);利用傅里叶变换红外光谱仪(Thermo Fisher Nicolet Is5)测定了材料的表面官能团;利用热重分析仪(STA 2500)在氮气环境下以材料制备时相同的升温条件,得到了材料的TG-DSC曲线。

-

首先比较了不同条件下制备的nZVI/PAC颗粒对孔雀石绿的去除效果。称取1.0 g材料加入到0.1 L浓度为0.1 g·L−1的孔雀绿溶液中。溶液的初始pH 4.4,反应温度为25 ℃,根据去除效果选取最佳造粒条件。选取最佳制备条件后,使用nZVI/PAC颗粒、nZVI颗粒、PAC颗粒考察了不同材料对孔雀石绿的去除结果。取1.0 g不同材料放入0.1L浓度为0.1 g·L−1的孔雀石绿溶液中,反应温度为25 ℃,溶液初始pH 4.4。

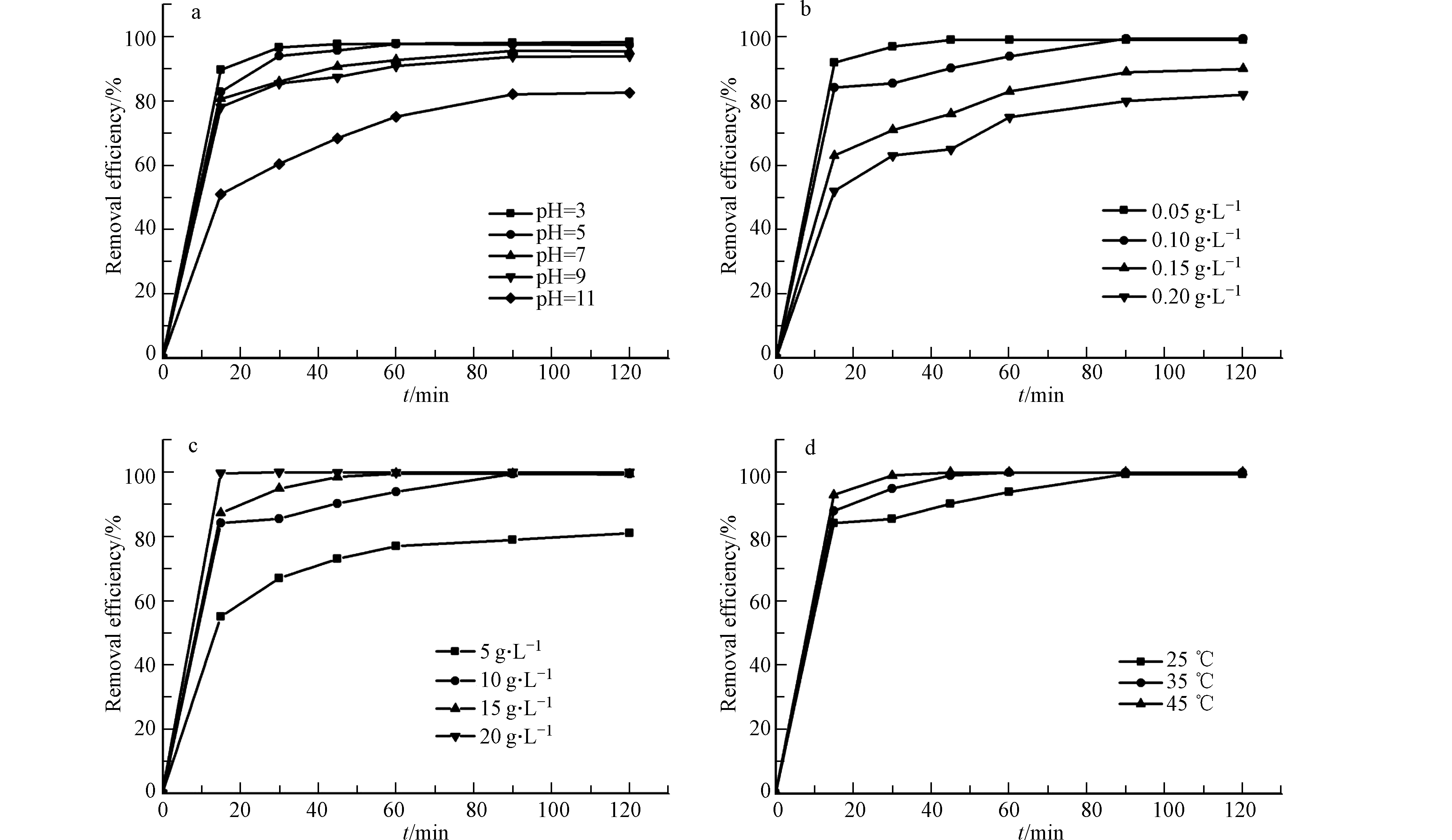

选取nZVI/PAC颗粒考察了初始pH、孔雀石绿初始浓度、材料投加量以及反应温度对去除结果的影响。使用0.1 mol·L−1的HCl和NaOH溶液调节溶液初始pH值分别为3、5、7、9、11,nZVI/PAC颗粒投加量为5 g·L−1,MG浓度为100 mg·L−1,反应温度为25 ℃。

改变孔雀石绿初始浓度为50、100、150、200 mg·L−1,溶液pH4.4,nZVI/PAC颗粒投加量为5 g·L−1,反应温度为25 ℃。

改变nZVI/PAC颗粒投加量为5、10、15、20 g·L−1,溶液pH 4.4,MG浓度为100 mg·L−1,反应温度为25 ℃。

改变反应温度为25、35、45 ℃,nZVI/PAC颗粒投加量为5 g·L−1,MG浓度为100 mg·L−1,反应温度为25 ℃。

各组实验均在150 mL锥形瓶中进行,恒温水浴振荡器转速为150 r·min−1,在设置的时间点取样。水样经0.45 μm有机微孔滤膜过滤后,利用紫外可见分光光度计在λmax=613 nm处测定MG的浓度。

孔雀石绿的去除率计算公式为:

式中,R为染料的去除效率(%);C0、Ct为染料初始和t时刻的浓度(mg·L−1)。

1.1. 材料制备

1.1.1. nZVI/PAC颗粒的制备

1.1.2. nZVI颗粒与PAC颗粒的制备

1.2. 材料表征

1.3. 孔雀石绿的去除实验

-

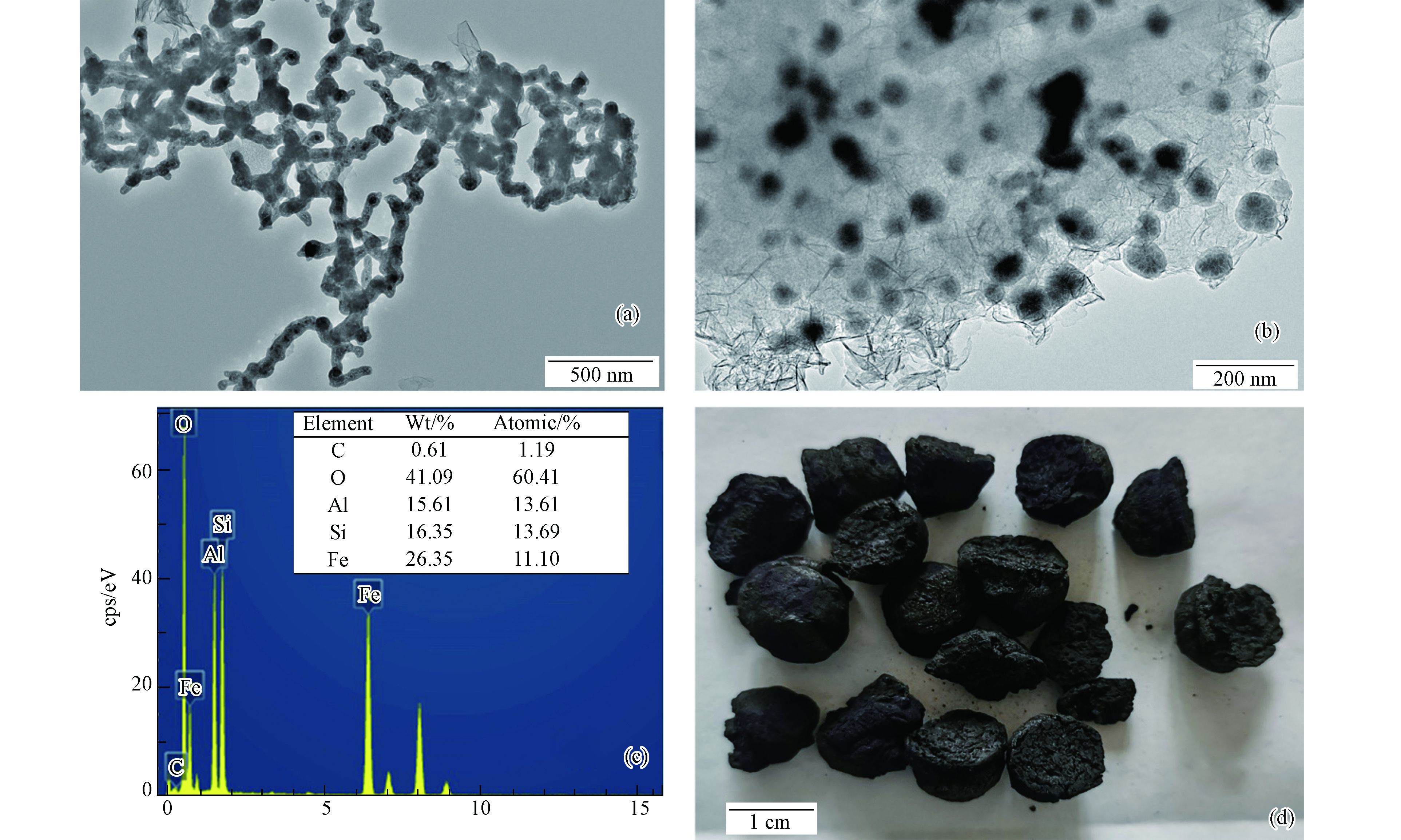

图1为未负载的纳米零价铁(nZVI)、活性炭负载纳米零价铁颗粒(nZVI/PAC)的透射电镜图及nZVI/PAC的能谱图。如图1(a)所示,未负载的纳米零价铁颗粒整体呈链状分布,且有一定的团聚现象,这可能是纳米零价铁较大的比表面积导致的颗粒间的相互吸引。在通过活性炭负载并造粒之后,如图1(b)所示,nZVI颗粒在材料中分布较为均匀,且对颗粒间的团聚现象起到了改善作用。比表面积的测试结果也证实了这一点,nZVI/PAC的比表面积为25.5 m2·g−1,显著高于纯nZVI造粒的8.4 m2·g−1。同时,nZVI颗粒被包裹在材料内部,在一定程度上保护了纳米零价铁不被氧化。图1(c)显示,nZVI/PAC主要含有C、O、Al、Si、Fe等元素,进一步说明nZVI在材料中稳定存在。

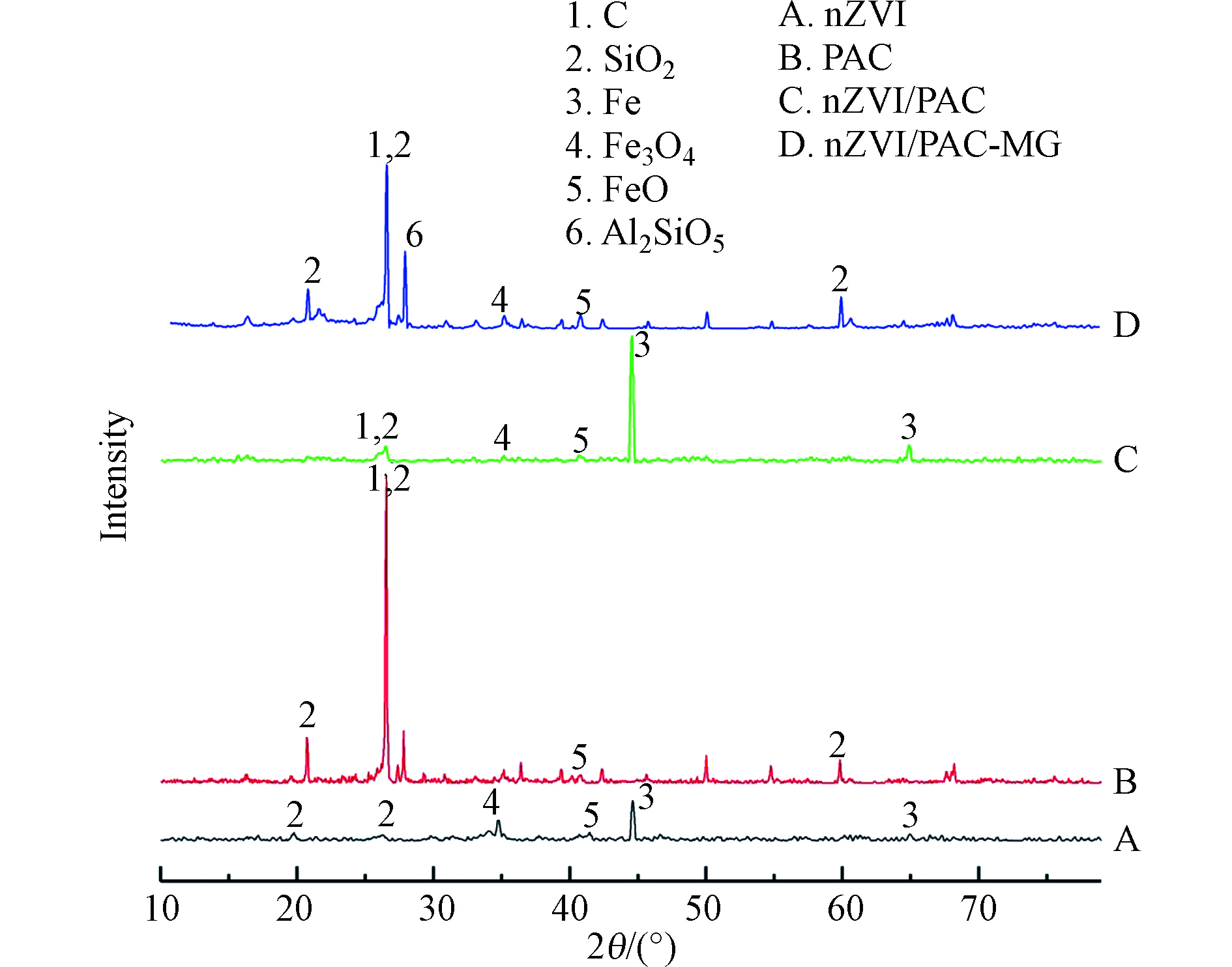

nZVI造粒、PAC造粒、nZVI/PAC造粒以及反应后的nZVI/PAC材料的XRD分析如图2所示。PAC造粒在26.55°处出现了明显的碳峰,nZVI造粒在2θ=44.62°处有明显出峰,该点对应α-Fe的特征衍射峰。而nZVI/PAC同时存在这两个特征峰,说明材料中同时存在活性炭和纳米零价铁。此外,在nZVI材料中出现了Fe的氧化物的特征峰,说明在材料的制备过程中,纳米零价铁发生了氧化,而nZVI/PAC材料则有效避免了这一点。在反应后的nZVI/PAC中,α-Fe的特征衍射峰消失,而增加了Fe的氧化物的特征峰,表明了在反应过程中材料中的纳米零价铁的变化过程。

-

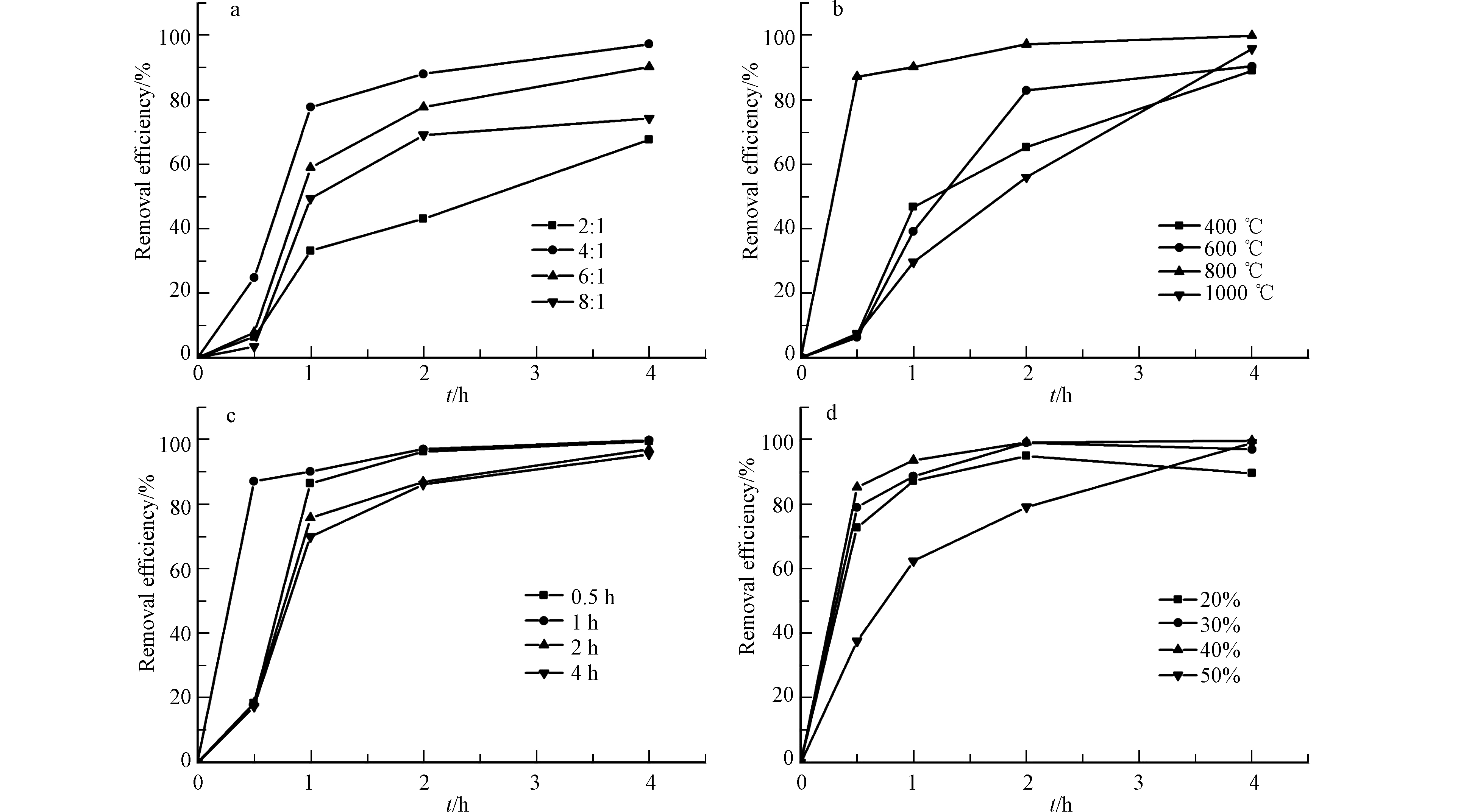

在材料制备的条件优化过程中,不同条件下制备的nZVI/PAC颗粒材料对孔雀石绿的去除结果如图3所示。

nZVI在MG的去除中起到关键作用,因为nZVI作为还原活性位点可以有效降解MG。由图3a可以看出,当铁碳比为2:1时,nZVI/PAC对孔雀石绿的去除率较低,这是因为材料中的nZVI较少,不足以提供足够的还原位点降解MG。而随着材料中nZVI比例的提升,对MG的去除呈现出先上升后下降的趋势。因为随着nZVI含量的增加,材料中的PAC不足以将其完全分散,造成了nZVI的聚集,导致有效还原位点的减少。当铁碳比为4:1时,达到了对MG的最佳去除效果。

高岭土添加量会影响nZVI/PAC的成型与强度[25],但是过多的高岭土会导致材料有效成分减少,不利于长期反应。如图3d所示,在高岭土添加量质量比为40%时,在4 h的反应时间内,nZVI/PAC对MG的去除率达到100%。同时,也保证了材料的强度。因此,最佳高岭土添加量选择40%。

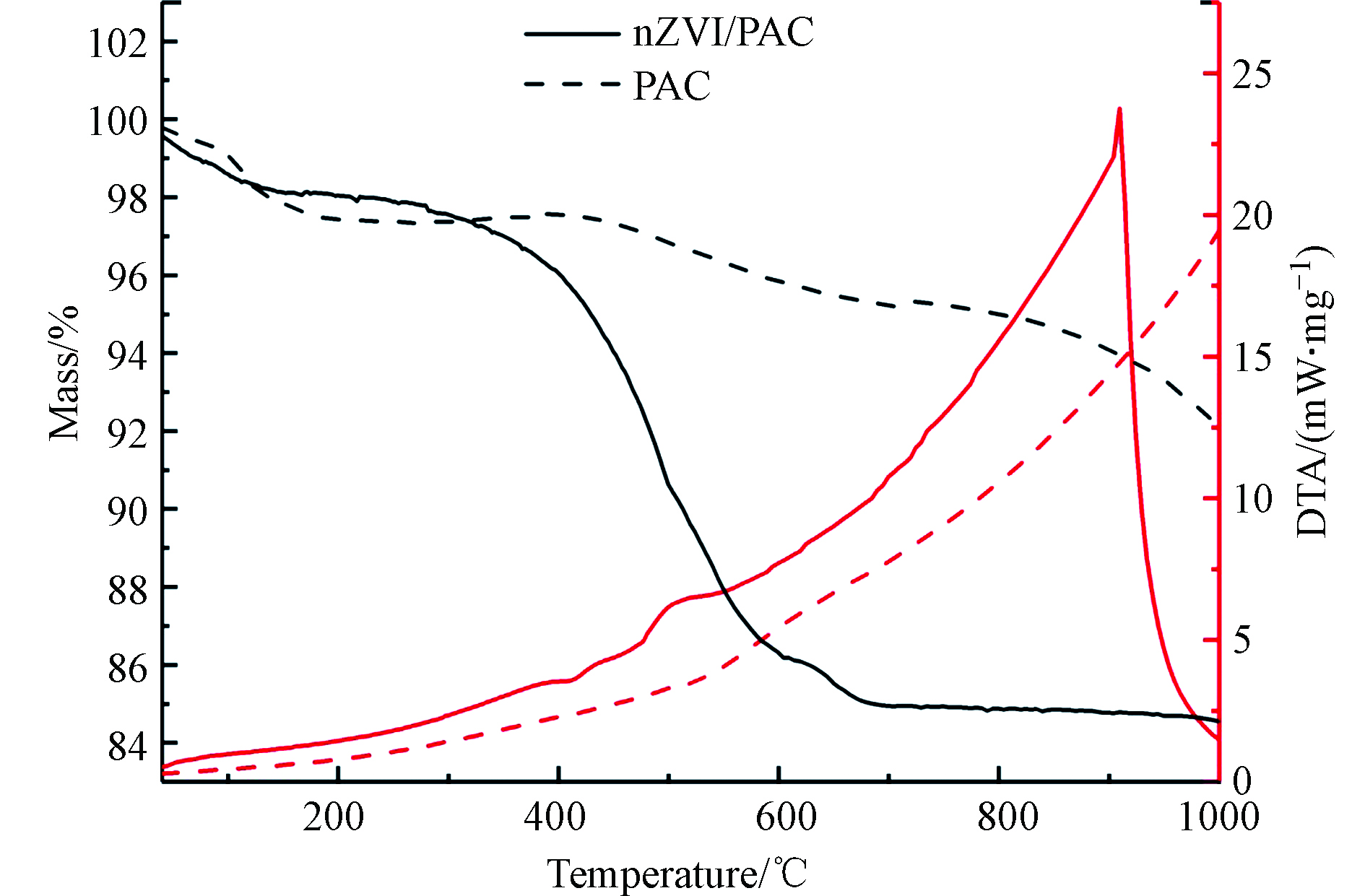

烧制温度会影响材料的强度以及结构,材料中的高岭土在升温过程中发生脱水、分解以及析出新晶相等变化,从而影响材料的最终形态[26]。温度较低时,高岭土脱水在内部形成孔隙,导致比表面积增加。如图3b所示,在烧制温度为400—800 ℃时,随着温度升高,制得的nZVI/PAC材料对MG的去除率也升高,因为材料的比表面积随着失去的水分增加而增加。而当烧制温度达到1000 ℃时,高岭土的晶体结构发生改变,产生收缩使材料空隙减少。同时,温度过高也容易导致nZVI的氧化,因此导致此温度下制得的nZVI/PAC材料对MG的去除率降低。考虑到材料的强度以及去除效果,选取800 ℃作为最佳烧制温度。

如图3c所示,材料的保温时间对MG最终去除结果的影响较小,选取保温时间为1 h作为最佳保温时间。综上所述,的nZVI/PAC材料的最佳制备条件为:铁碳比为4:1,添加高岭土质量比为40%,煅烧温度为800 ℃,保温时间为1 h,最终制得的nZVI/PAC具有较高的强度以及对MG的高去除率。

烧制温度会影响材料的强度以及结构,材料中的高岭土在升温过程中发生脱水、分解以及析出新晶相等变化,从而影响材料的最终形态。结合热重分析结果,如图4所示,在温度较低时,高岭土脱水在内部形成孔隙,随着温度继续升高,高岭土发生分解,这些都导致材料的比表面积增加。如图3b所示,在烧制温度为400—800 ℃时,随着温度升高,制得的nZVI/PAC材料对MG的去除率也升高,因为温度升高时,高岭土分解更彻底。而当烧制温度达到1000 ℃时,高岭土的晶体结构发生改变,产生收缩使材料空隙减少。同时,温度过高也容易导致nZVI的氧化,因此导致此温度下制得的nZVI/PAC材料对MG的去除率降低。而且经过烧制之后,nZVI/PAC颗粒具备了一定的抗压强度,如表1所示,随着温度的升高,材料的抗压强度也随之升高。当烧制温度为800 ℃时,颗粒材料对MG的去除率较高,且材料的浸水后抗压能力达到1.241 MPa,满足人工湿地等工程应用要求,因此选取800 ℃作为最佳烧制温度。

-

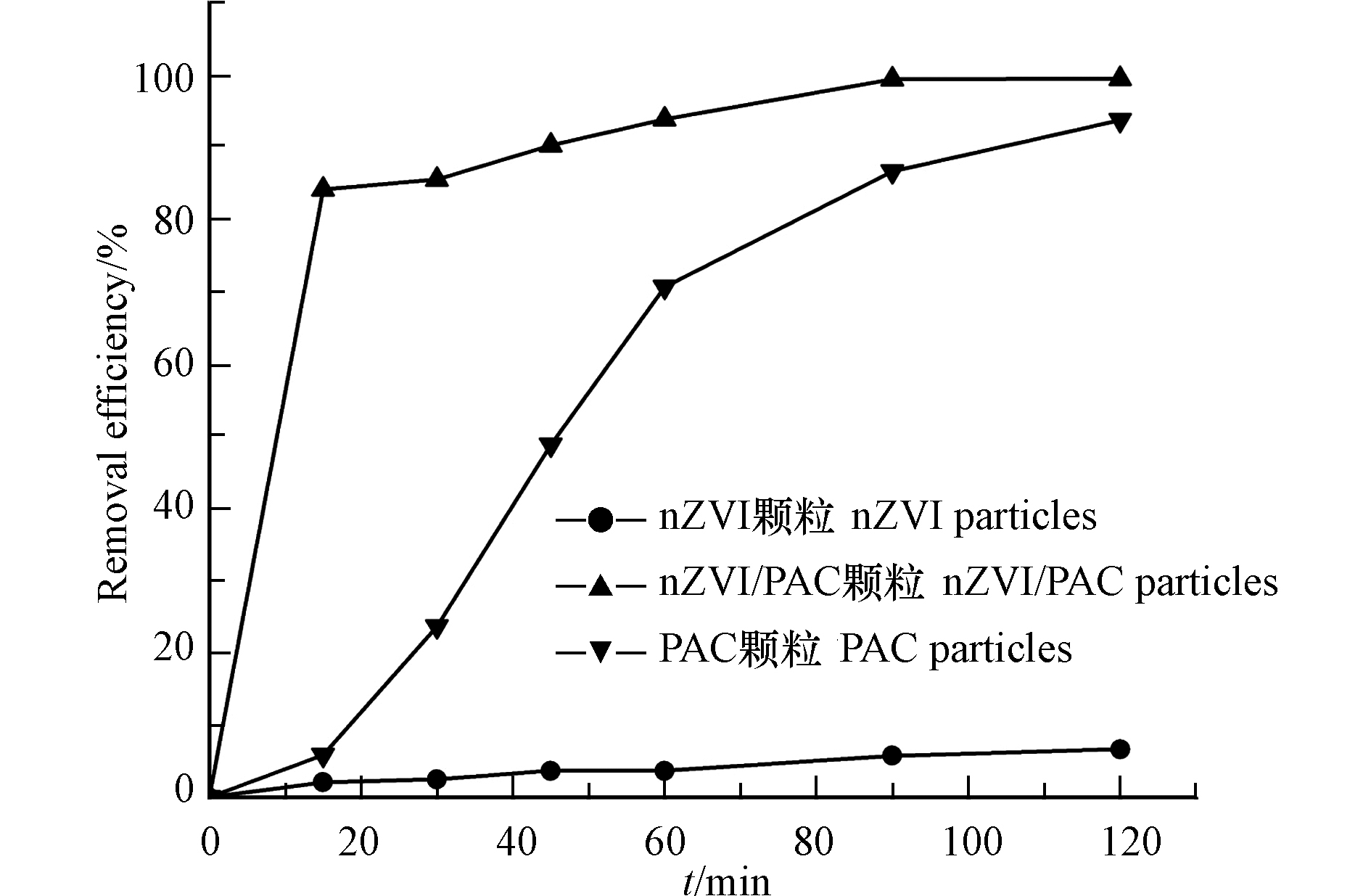

3种不同材料对MG的去除效果如图5所示。在120 min的反应时间内,nZVI、PAC和nZVI/PAC对MG的去除率分别为70.3%、6.6%、93.8%和99.5%。采用转移的热处理方法对材料的再生性能进行了初步评估,将吸附到饱和后的材料置于200 ℃通氮烘箱中烘至恒重,利用同样的条件重复进行6次实验后,nZVI、PAC和nZVI/PAC对MG的去除率达到2.4%、70.6%和87.5%,表明了该复合材料对MG染料废水的重复使用性能优良。用100 nm铁粉造粒成本每500 g为1000元,而纳米零价铁/活性炭复合材料价格每500 g为172元,从成本上来讲,所制备的复合材料比注射nZVI低很多,从效果上来讲,单纯的纳米零价铁易氧化而失活。活性炭负载nZVI显著提高了对MG的去除效果,且在反应15 min后,nZVI/PAC对MG的去除效果达到了84.2%。这是因为活性炭的吸附作用增加了MG和nZVI的接触,加快了MG的还原反应。而PAC材料只能通过吸附作用去除MG,导致了去除效率较低,也容易产生吸附饱和,利用纳米零价铁的还原性,使得铁碳在反应过程中形成微电解作用,在实际应用工程中去除污染物更长久。nZVI材料对MG的去除率仅为6.6%,这是由于nZVI容易产生团聚现象[27],导致材料的比表面积较小,同时也不利于还原反应的进行。总体而言,活性炭能有效避免nZVI发生团聚,同时活性炭提供的吸附能力能加快nZVI与MG的还原反应,最终保障了nZVI/PAC对MG的高效去除。

-

如图6a所示pH对nZVI/PAC去除MG的影响。MG的去除率随pH的增加而降低,这是因为随着pH的增加,水中的OH−会与MG产生竞争性吸附。同时,OH−与nZVI结合后,生成的氧化物和氢氧化物使nZVI表面钝化,阻止了nZVI与MG的还原反应,从而导致溶液中MG的去除率降低。

图6b显示了不同初始浓度对MG去除效果的影响。MG的去除率随着MG初始浓度的增加而降低,在120 min的反应时间内,当MG初始浓度由0.05 g·L−1增加至0.2 g·L−1时,MG的去除率从99.8 %降至82.3 %。因为nZVI/PAC投加量一定时,其吸附能力和活性位点固定,MG浓度升高时使得活性位点不足。在初始的60 min内,溶液中MG的去除较快,这是由于MG被快速吸附到材料表面的吸附位点上。而随着反应的进行,表面的吸附位点逐渐减少,反应逐步向孔道内部扩散,但表面生成的铁氧化物阻碍了这一过程,导致MG去除的减缓。

如图6c所示nZVI/PAC投加量对MG去除的影响。在nZVI/PAC投加量高于10 g·L−1之后,MG的最终去除率达到了99 %以上。随着nZVI/PAC的增加,材料提供的的吸附位点和总比表面积增加,加快了MG的去除速率,在反应15 min后,nZVI/PAC投加量为10、15、20 g·L−1的反应体系中,MG的去除率分别达到了84.2 %、87.3 %和99.7 %。

温度对MG去除的影响如图6d所示。随着温度的升高,MG的去除速率升高。当温度从25 ℃升高至45 ℃时,反应平衡时间从90 min减少至30 min。这是因为温度升高时,MG分子的动能增加,加强了分子扩散,加快了MG与nZVI的碰撞速率。

-

采用准一级动力学模型和准二级动力学模型对实验数据进行拟合,其结果如表2所示。相比之下,准二级动力学模型更好地描述了MG的去除过程,不同MG浓度下准二级动力学模型的拟合相关系数R2达到了0.98以上。说明化学吸附是MG去除过程中的主要控制步骤[24]。

-

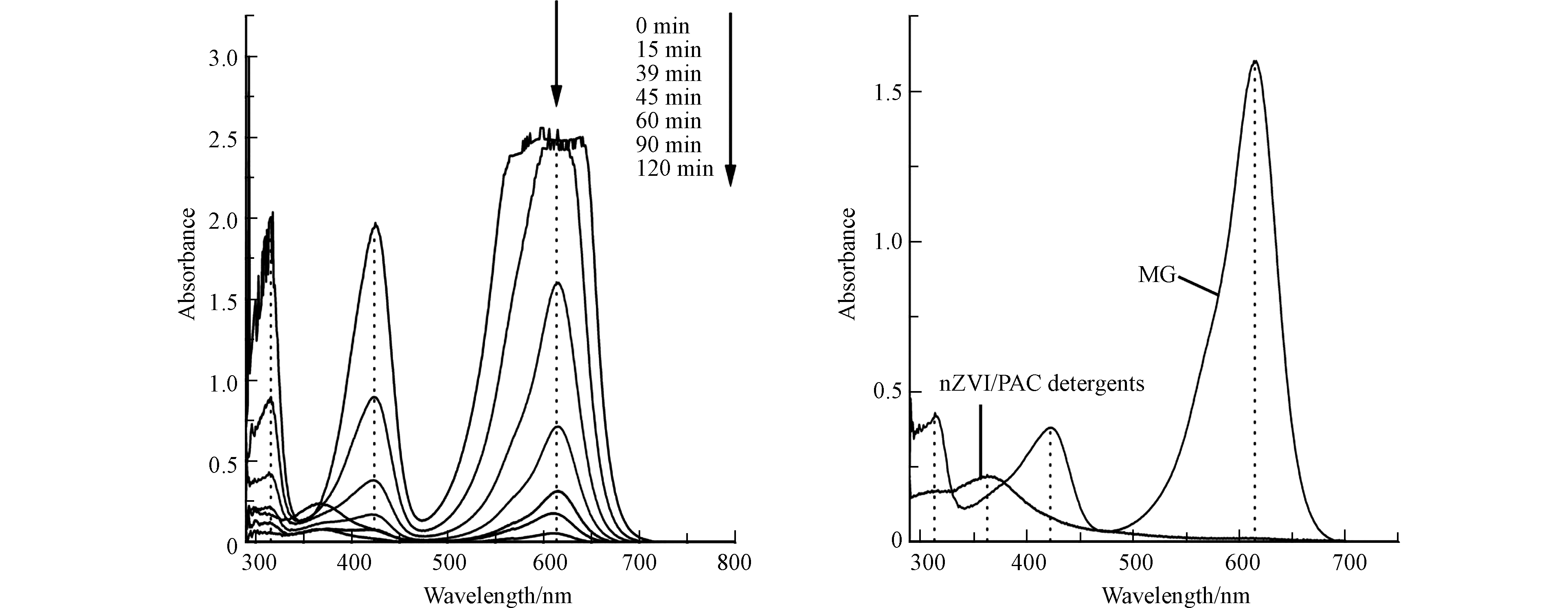

为进一步分析nZVI/PAC对MG的去除机理,对不同反应时间MG水溶液进行了UV-vis光谱分析,结果如图7所示。MG在可见光区的312 nm、425 nm和613 nm处有明显的吸收峰,其中最大吸收峰位于613 nm处,这是由—C=N—、—C=C—和所连芳香环共轭产生的。随着反应进行,吸收峰迅速减弱,并在反应120 min后基本消失。说明溶液中的MG逐渐被吸附,最终被去除。

取反应平衡后的nZVI/PAC颗粒,使用去离子水反复冲洗,收集洗液进行了UV-vis光谱分析,其结果如图7所示。与MG的吸收曲线相比,洗涤液中MG的特征吸收峰完全消失,并在363 nm处产生了新的吸收峰,说明了新物质的生成,进一步说明MG被nZVI还原。总体而言,在nZVI/PAC去除MG的过程中,当MG被吸附到材料表面后,nZVI与水或者H+反应得到的H自由基使MG的偶氮键断裂,破坏了MG的发色基团和共轭结构,使MG染料脱色并从溶液中去除。

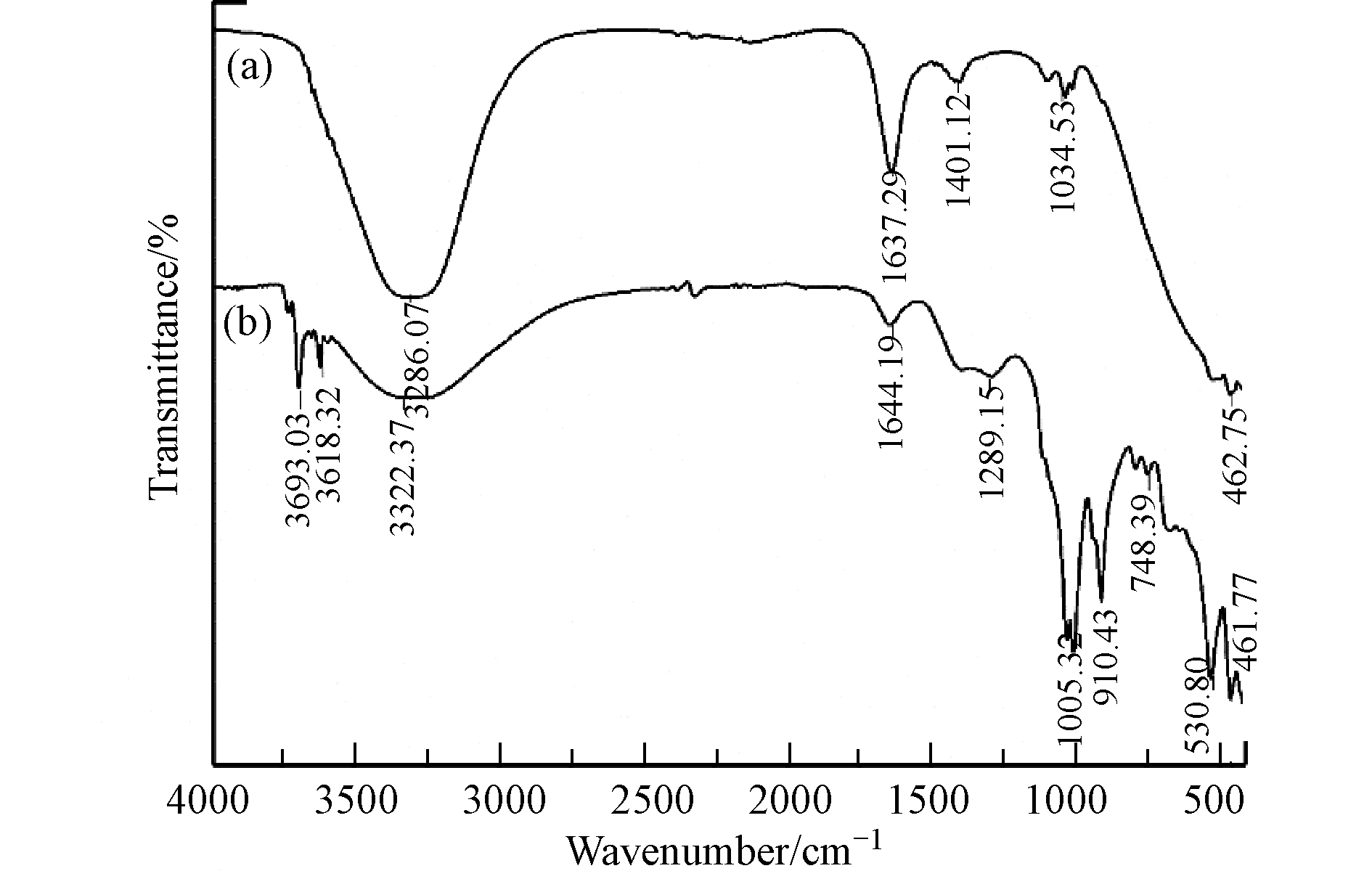

nZVI/PAC反应前后的红外谱图如图8所示。在反应后,nZVI/PAC的O—H伸缩振动由3322 cm−1移至3286 cm−1,是由于水分子间的氢键对峰位和峰强产生影响,使O—H伸缩振动频率向低波数方向移动。同时在3618 cm−1和3693 cm−1出现了新的吸收峰,这是由C—H的伸缩振动和O—H的生成。1637 cm−1处的特征峰对应于芳香族C=C的伸缩,748 cm−1处的特征峰代表苯环的C—H面外弯曲振动,并说明其为单取代反应。反应后材料在1005 cm−1和910 cm−1的特征峰主要由γ(C—H)的面外变形和C—O键形成。反应前后材料的红外光谱变化说明MG去除过程中生成了新的化合物。结合UV-vis光谱和红外光谱分析,nZVI/PAC对MG的去除反应过程为:

2.1. 材料的表征

2.2. 孔雀石绿的去除实验

2.2.1. 不同制备条件下的nZVI/PAC对孔雀石绿的去除

2.2.2. 不同材料对孔雀石绿的去除实验

2.2.3. nZVI/PAC去除孔雀石绿的影响因素

2.3. 动力学研究

2.4. 孔雀石绿的去除机理

-

(1)采用液相还原法制备了硬质nZVI/PAC颗粒材料,其最佳制备条件为:铁碳比为4:1,添加高岭土质量比为40%,煅烧温度为800 ℃,保温时间为1 h,最终制得的nZVI/PAC具有较高的强度以及对MG的高去除率。

(2)制备的nZVI/PAC材料对nZVI具有较好的分散作用,且提高了nZVI的抗氧化能力。

(3)MG的去除率随PH和MG初始浓度的降低而升高,随nZVI/PAC投加量和温度的增加而升高。

(4)准二级动力学模型很好地描述了MG的去除反应的动力学。进一步的研究表明,nZVI/PAC对MG的去除机理主要为nZVI破坏了MG的发色基团和共轭结构,使MG染料脱色并从溶液中去除。本研究为nZVI材料应用于实际水处理提供了参考。

下载:

下载: