-

纳滤(nanofiltration, NF)是一种介于超滤和反渗透之间的压力驱动型膜分离过程. 孔径约为1 nm,对二价及多价离子具有较高的截留率,对一价离子截留率低,适用于分离体系中含有相对分子质量为几百的有机物及二价、多价离子. 近年来,纳滤膜已从常规的污水处理体系,逐步向有机溶剂、高温、耐氯、自清洗等特种分离应用方向发展.

对于纳滤膜而言,超滤基膜性质、反应单体种类和浓度、聚合时间、热处理温度等均会对致密层结构(thin film composite, TFC)产生影响,进而影响复合膜结构性能[1-3]. 一般来说,具有使用价值的超滤基膜应具有孔径分布均匀、亲水性好、耐高温、耐溶剂、力学强度优良等特点. 2018年浙江大学张林教授团队在《Science》期刊上发表了一种具有特殊“脊谷状图灵(Turing)结构”的复合纳滤膜[4],详细介绍了控制得到高渗透通量、高截留率TFC致密层表面界面聚合反应机理,表明水相单体从基膜孔内迁移至界面聚合反应区域速度主要受“反应-扩散”机制控制.

目前商业化复合膜所使用基膜多以聚砜(PSf)或聚醚砜(PES)为成膜聚合物,采用浸没沉淀相转化(NIPS)法制备. PSf和PES基膜耐高温性能、亲水性能较差,且其膜孔径相对较大、孔径分布相对较宽,此皆不利于制备高性能复合膜. 虽无机膜对苛刻环境的耐受性较优异,但其制备成本较高且加工难度较大限制了其应用,因此,开发耐热性能优异的有机纳滤膜,将进一步拓展复合膜的应用领域. 此外,温度增加会降低水溶液黏度并加快水分子扩散速度从而提升复合膜通透性能. 故耐热有机复合膜的开发不仅可拓展有机复合膜的应用领域,也可使工业余热在得到充分利用的基础上提高复合膜通透性能[5]. 为获得耐热性能优异的有机纳滤膜,目前多数研究通过采用耐热性能优异的聚合物材料如聚醚酮类、聚酰亚胺类、聚芳醚酰胺类等为膜材料制备多孔基膜,然后采用界面聚合工艺制备耐热有机复合膜,并取得了可观效果[6]. 然而此类材料制备工艺比较复杂,价格较高,限制了耐热有机纳滤膜的开发与应用.

聚对苯二甲酰对苯二胺(PPTA)是一种高性能聚芳酰胺大分子,其纤维制品被称为“Kevlar(凯夫拉)”,在我国被称为“对位芳纶或芳纶1414”,是世界三大高性能纤维之一. 其主链含有大量苯环和亲水性酰胺基团,分子间作用力强,结晶度高,带有较强的电负性,这些特性赋予了PPTA材料高强高模、耐高温、耐酸碱、耐有机溶剂等优良性能[7-9]. 随着高性能对位聚芳酰胺全球市场的急速发展和市场需求量显著增加,多品种对位芳纶纤维、水处理膜、锂电隔膜及复合材料新一轮技术开发正在加速推进,但国产高性能芳纶纤维及其下游产品研发由于各种复杂原因仍发展缓慢,其产品性能稳定性、成本、规模及应用水平方面与日本和美国等发达国家相比竞争力较弱、差距明显,特别是高性能对位芳纶分离膜材料仍是空白,尚无国产化对位芳纶膜材料问世.

因此,本文以涤纶无纺布作为增强支撑体,PPTA超滤膜为多孔基膜,以无水哌嗪(PIP)为水相单体,1,3,5-苯三甲酰氯(TMC)为油相单体,采用界面聚合制得 PPTA/PA复合纳滤膜. 研究界面聚合过程中水相单体浓度、油相单体浓度、热处理温度等条件对 PPTA/PA复合纳滤膜结构与染料脱盐性能的影响,为苛刻环境下精细膜分离的应用提供了一种新型高性能高分子分离膜材料.

-

PPTA树脂(比浓对数黏度5—6 dL·g−1),中化高性能纤维材料有限公司. 无水哌嗪(PIP,AR),1,3,5-苯三甲酰氯(TMC,AR),浓硫酸(H2SO4,98%),氯化钠(NaCl),硫酸钠(Na2SO4),硫酸镁(MgSO4), 氯化钙(CaCl2), 上海泰坦科技股份有限公司. 刚果红染料(CR,Mw=696.68 g·mol−1),曙红Y染料(EY,Mw=691.9 g·mol−1),亚甲基蓝(MB,Mw=373.9 g·mol−1), 上海国药化学试剂有限公司.

-

以涤纶无纺布增强PPTA超滤膜为多孔基膜,采用界面聚合法(IP)制备PPTA/PA复合纳滤膜. 首先,将PPTA超滤基膜置于一定浓度的 PIP水相溶液中浸泡一段时间后取出,随后,再将其浸入TMC正己烷油相溶液中再反应一段时间. 然后,将所得初生复合纳滤膜取出,置于一定温度下热处理8min以进一步构建膜表面致密层结构. 最后,将处理后的PPTA/PA复合纳滤膜保存在浓度为1%NaHSO3水溶液中待用.

在PPTA/PA复合纳滤膜制备中有众多因素可影响到复合膜的性能,其中对聚合反应条件的选择为制备性能良好的PPTA/PA复合纳滤膜的关键,因此,本文主要对 PIP 浓度、TMC 浓度、热处理温度等3个主要因素进行探究,以选取较优的制膜条件. 如表1所示.

-

采用扫描电子显微镜(SEM, Phenom XL, 荷兰)对膜表面形貌进行观察,测试前对膜样品表面进行喷金处理.

-

采用傅里叶变换红外分析仪(FTIR, WDF-530, 中国)测试膜表面的官能团,测试波长范围为4000—400 cm−1.

-

采用自动倾斜型接触角测量仪(SDC-350H, 中国)测试膜表面静态接触角. 在室温条件下,每次将5 µL纯水滴在膜样品表面直至液滴无明显变化,每个样品测试3次取平均值.

-

采用固体Zeta电位分析仪(SurPASS, Anton Paar, 奥地利)测试膜表面荷电性. 在常温下,用1 mmol·L−1 氯化钾(KCl)溶液作为背景电解质,设置合适的膜表面间距后,测试膜表面不同pH值(3—10)下的Zeta电位. 测试期间采用浓度为0.1 mol·L−1的HCl和NaOH来调节KCl溶液的pH值.

采用液体Zeta电位仪(ZS90, Malvern, 英国)测试染料溶液的Zeta电位,染料的浓度为100 mg·L−1.

-

在室温0.6 MPa下测定PPTA/PA复合纳滤膜对染料(CR, EY和MB)及无机盐(Na2SO4、MgSO4、CaCl2和NaCl)的截留效果,其中染料与无机盐的浓度分别为100 mg·L−1和1000 mg·L−1. 在测试前,PPTA/PA复合纳滤膜在0.6 MPa下预压30 min. 采用紫外可见分光光度计(UV-1801)及电导率仪(DDS-307A)测试并计算溶液截留前后染料与无机盐的浓度. 通过式(1)和式(2)分别计算PPTA/PA复合纳滤膜的渗透通量和截留率:

其中,V为渗透滤液通量体积(L), A为膜测试有效面积(m2),t为运行时间(h).

其中,R为截留率(%), Cf为进料液浓度(mg·L−1),Cf为过滤液浓度(mg·L−1).

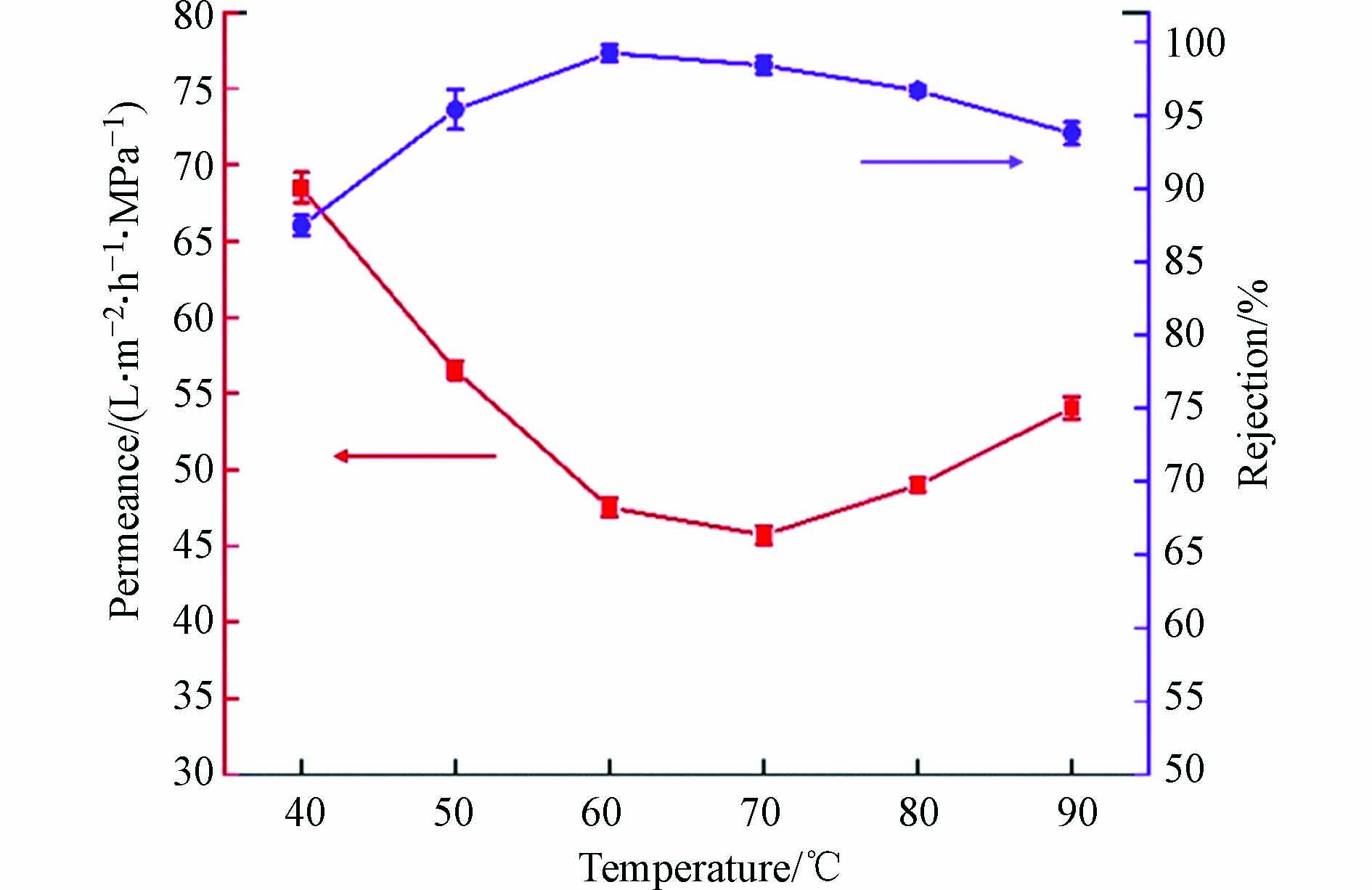

另外,为了评价PPTA/PA复合纳滤膜的热稳定性,分别在25 ℃至90 ℃的温度范围内测量100 mg·L−1 CR和1000 mg·L−1 NaCl及Na2SO4染料/盐溶液渗透滤液通量和截留率.

-

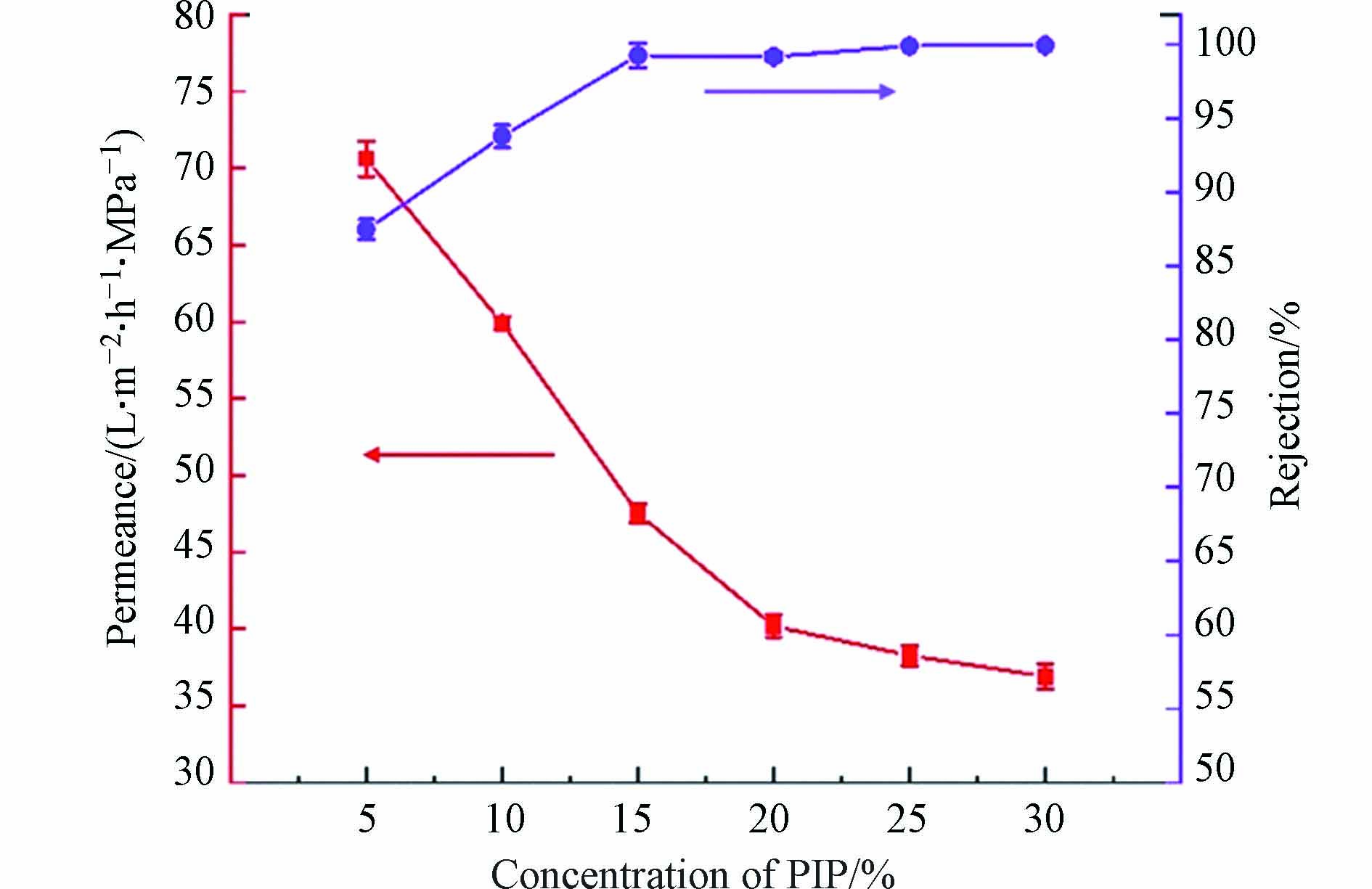

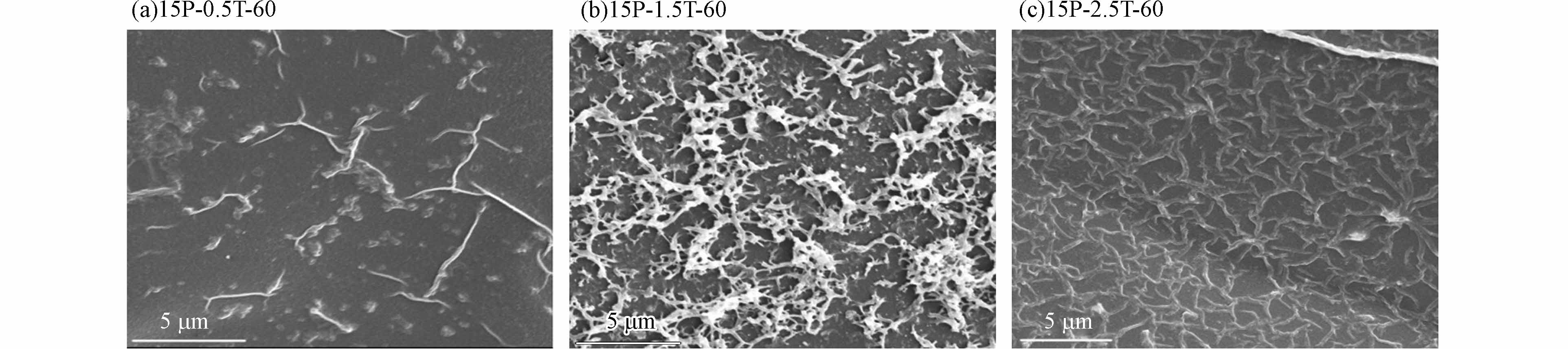

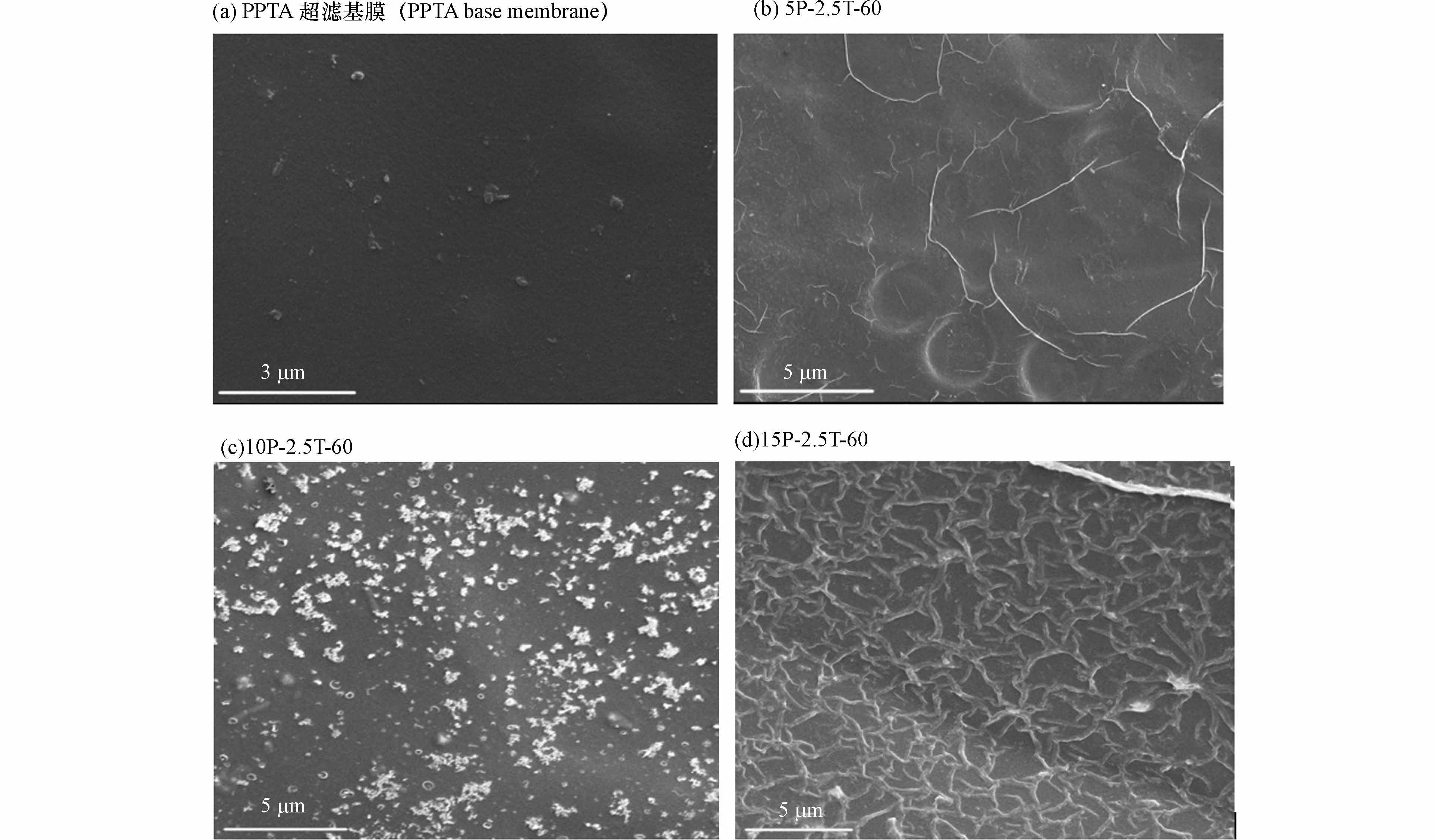

图1为PIP浓度对PPTA/PA复合纳滤膜表面形貌影响,图2为PIP浓度对PPTA/PA复合纳滤膜渗透通量与Na2SO4截留率影响. 图1(a)为前期研究所得PPTA超滤基膜[10-12],其表面形貌呈现光滑致密结构. 随着水相单体PIP浓度从5%wt增加到15%wt,膜表面出现从“点状”向“条纹脊谷状”转变的趋势,且如图2所示,PPTA/PA复合纳滤膜渗透通量显著下降,而Na2SO4截留率大幅上升;当水相单体PIP浓度超过15%wt时,PPTA/PA复合纳滤膜渗透通量略有降低,而截留率几乎保持不变. 这是因为界面聚合反应主要发生在有机相一侧,受水相单体PIP向水/油两相界面反应扩散速率控制[13]. 当水相单体PIP浓度较低时,扩散至水/油两相界面反应区域的PIP数量较少,导致PIP和TMC之间反应交联度较低,形成结构相对较薄且疏松的PA分离层,所得复合纳滤膜渗透通量较高而截留率较低,反之,则形成结构相对致密的PA分离层. 当PIP浓度超过一定值后,形成更高交联度的PA分离层,阻碍了水相单体PIP向水/油两相界面反应区域扩散,导致所得复合纳滤膜渗透通量略有下降,而截留率几乎保持不变. 此时,水相单体PIP浓度的增加对复合纳滤膜结构与性能无明显影响.

-

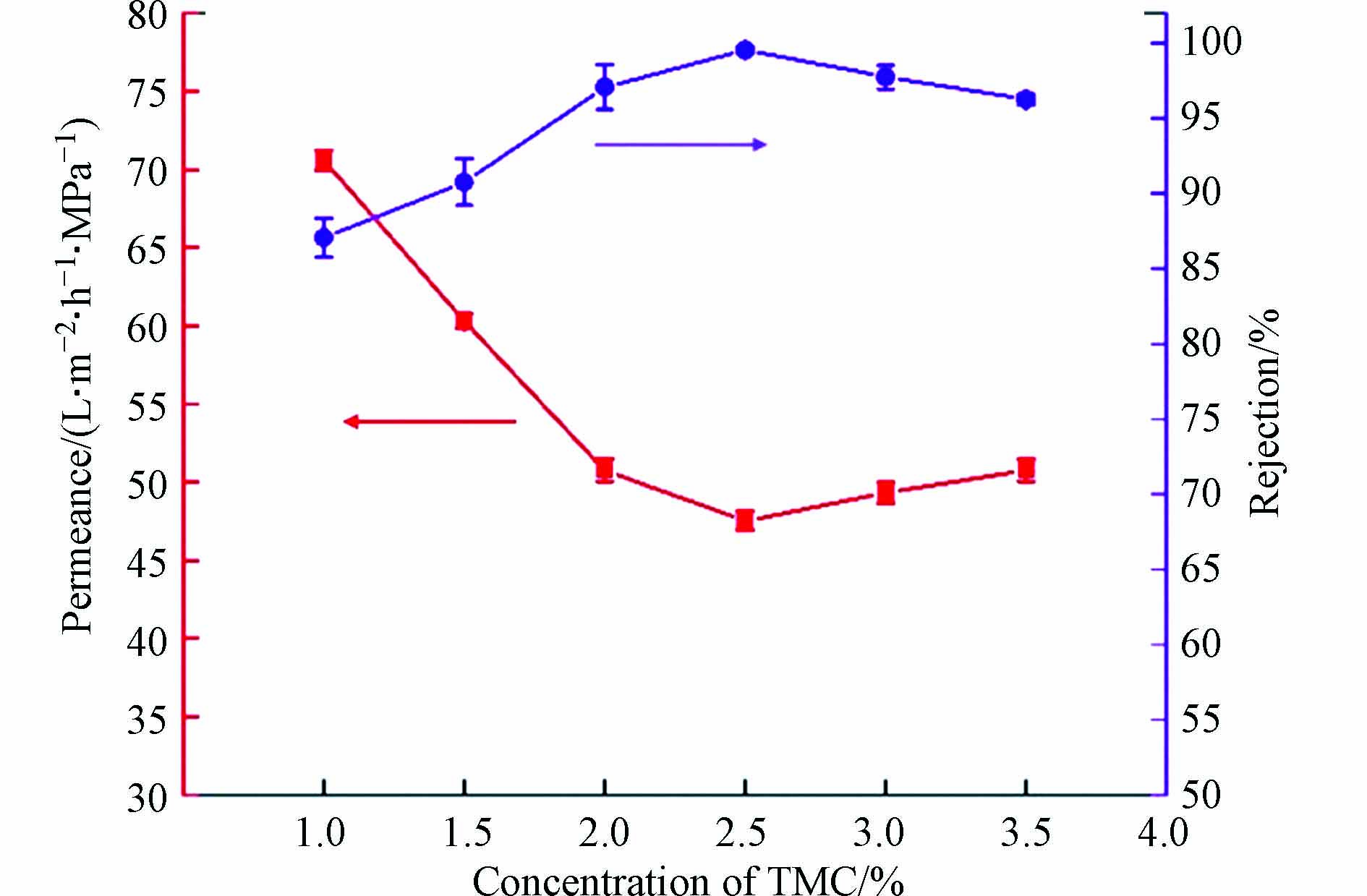

图3为TMC浓度对PPTA复合纳滤膜表面形貌影响,图4为TMC浓度对PPTA复合纳滤膜渗透通量与Na2SO4截留率影响. 如图所示. 当油相单体TMC浓度从1%wt增加到3.5%wt时,PPTA/PA复合纳滤膜渗透通量随油相单体TMC浓度的增加先下降后上升,而Na2SO4截留率随油相单体TMC浓度的增加先上升后下降. 当油相单体TMC浓度为2.5%wt时,截留率达到最大值. 这是由于当TMC浓度增加时,界面聚合反应交联度增加,形成更加致密的表面层结构. 而当油相单体TMC浓度超过一定值后,会导致界面聚合反应过快,使水相单体PIP快速消耗,而PA分离层中未反应的酰氯基团易水解转化为羧酸基团而失去活性,导致水/油两相界面反应区域形成的PA分离层结构变得疏松;其次,残余的油相单体TMC也易发生副反应而转化为亲水性较强的羧酸基团[14-16],从而导致PA分离层表面结构稳定性降低,亲水性增加.

-

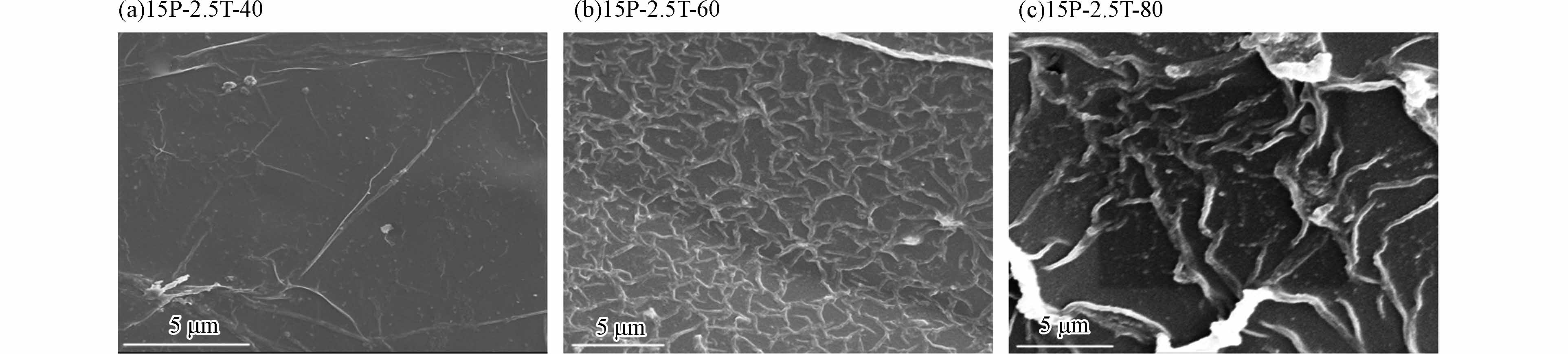

图5为热处理温度对PPTA/PA复合纳滤膜表面形貌影响,图6为热处理温度对PPTA/PA复合纳滤膜渗透通量与Na2SO4截留率影响. 如图所示,热处理温度对PPTA/PA复合纳滤膜性能的影响与油相单体TMC浓度对PPTA/PA复合纳滤膜的影响相似. 热处理温度升高增加了聚酰胺分子链段的运动,降低聚酰胺的黏性,加快水相单体PIP的扩散速率,导致水相单体PIP向水/油两相界面反应区域扩散数量增加,使得形成的聚酰胺分子量和交联度提高,复合纳滤膜的渗透通量下降而截留率上升. 另外,高热处理温度也会影响膜表面分离层结构规整性,出现结构缺陷 [17-18].

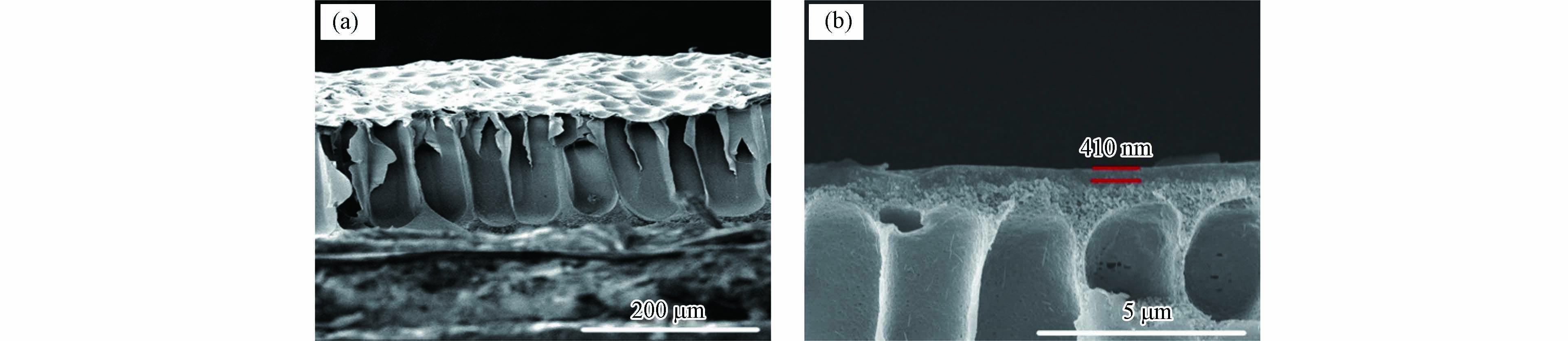

图7为PPTA超滤基膜与PPTA/PA复合纳滤膜横截面结构,如图所示,与基膜横截面相比,复合纳滤膜表面存在一层因PIP和TMC发生界面聚合反应而生成的PA分离层. PPTA/PA复合纳滤膜PA层厚度分别约为410 nm. 由于PPTA基膜的亲水性较优,PPTA超滤基膜可以吸附更多的PIP单体,因此,在界面聚合过程中,PPTA基膜可以提供更多的PIP单体参与界面聚合反应,所得PA层厚度较高.

综合前述探究,PPTA/PA复合纳滤膜的较优工艺条件为:水相单体PIP浓度(15%wt),油相单体TMC浓度(2.5%wt),水相浸泡时间为2 min,油相浸泡时间为45s,热处理温度为60 ℃和热处理时间为8 min.

-

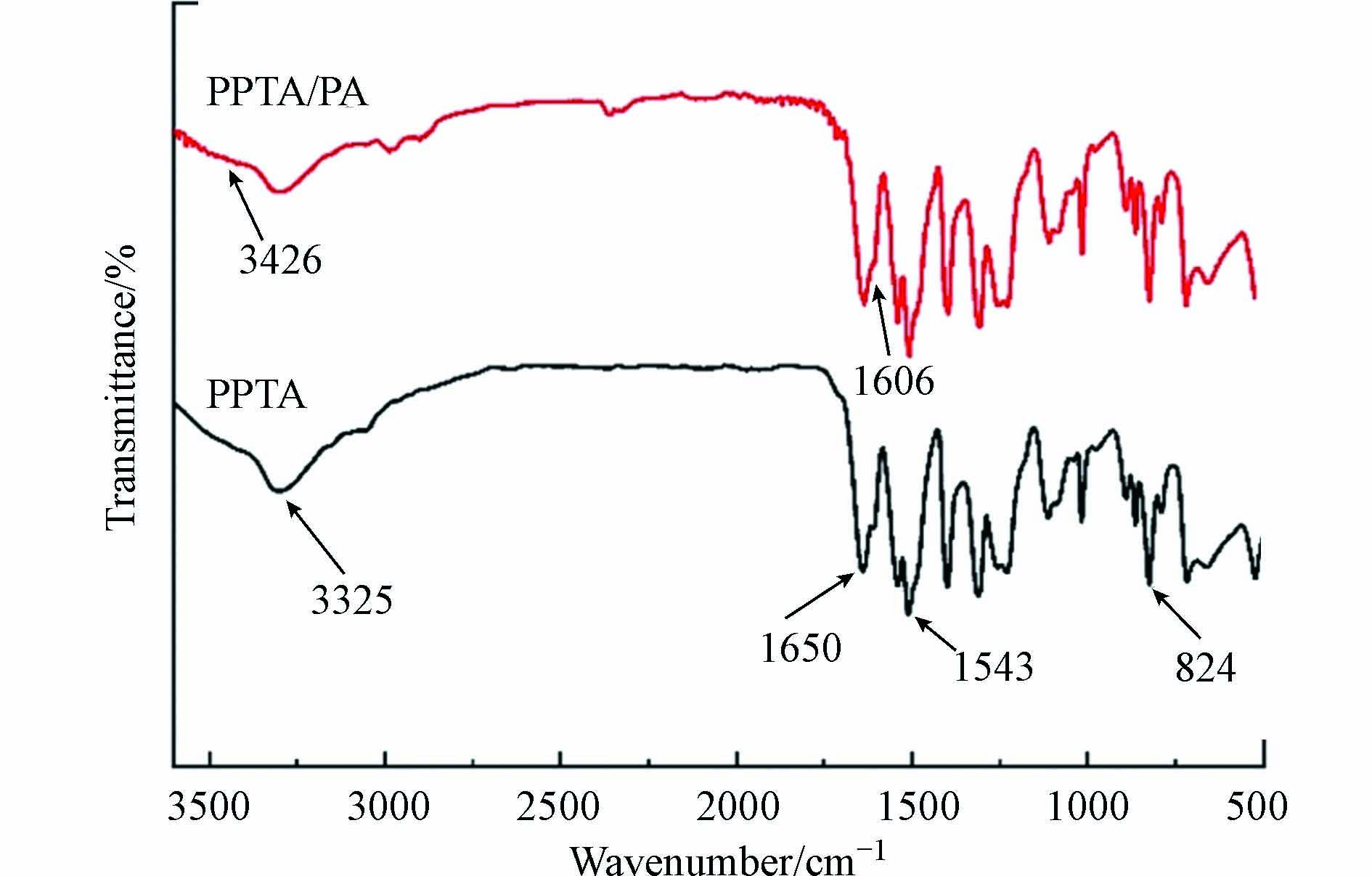

图8为PPTA基膜及PPTA/PA复合纳滤膜的FTIR谱图,由图可见,在824、1543、1650、3325 cm−1位置的吸收峰依次是对位取代苯、C=O拉伸振动、N—H弯曲振动和—NH2拉伸振动吸收峰[19-20]. 与PPTA基膜相比,PPTA/PA复合纳滤膜在1606 cm−1处出现了新的吸收峰(C=O拉伸振动). PPTA基膜和PPTA/PA复合纳滤膜在3325 cm−1处显示出相同的峰值(—NH拉伸振动). 然而,PPTA/PA复合纳滤膜的峰值强度低于PPTA基膜的峰值强度,表明PPTA基膜表面形成了一层聚酰胺分离层,影响了PPTA基膜的峰值强度. 另外,在3426 cm−1处出现的宽带吸收峰与O—H拉伸振动有关,表明羧基基团被引入到复合纳滤膜的表面分离层中. 引入的羧基基团主要来自于界面聚合反应过程中TMC部分酰氯基团的水解. 综上所述,这也说明成功制备了PPTA/PA复合纳滤膜.

-

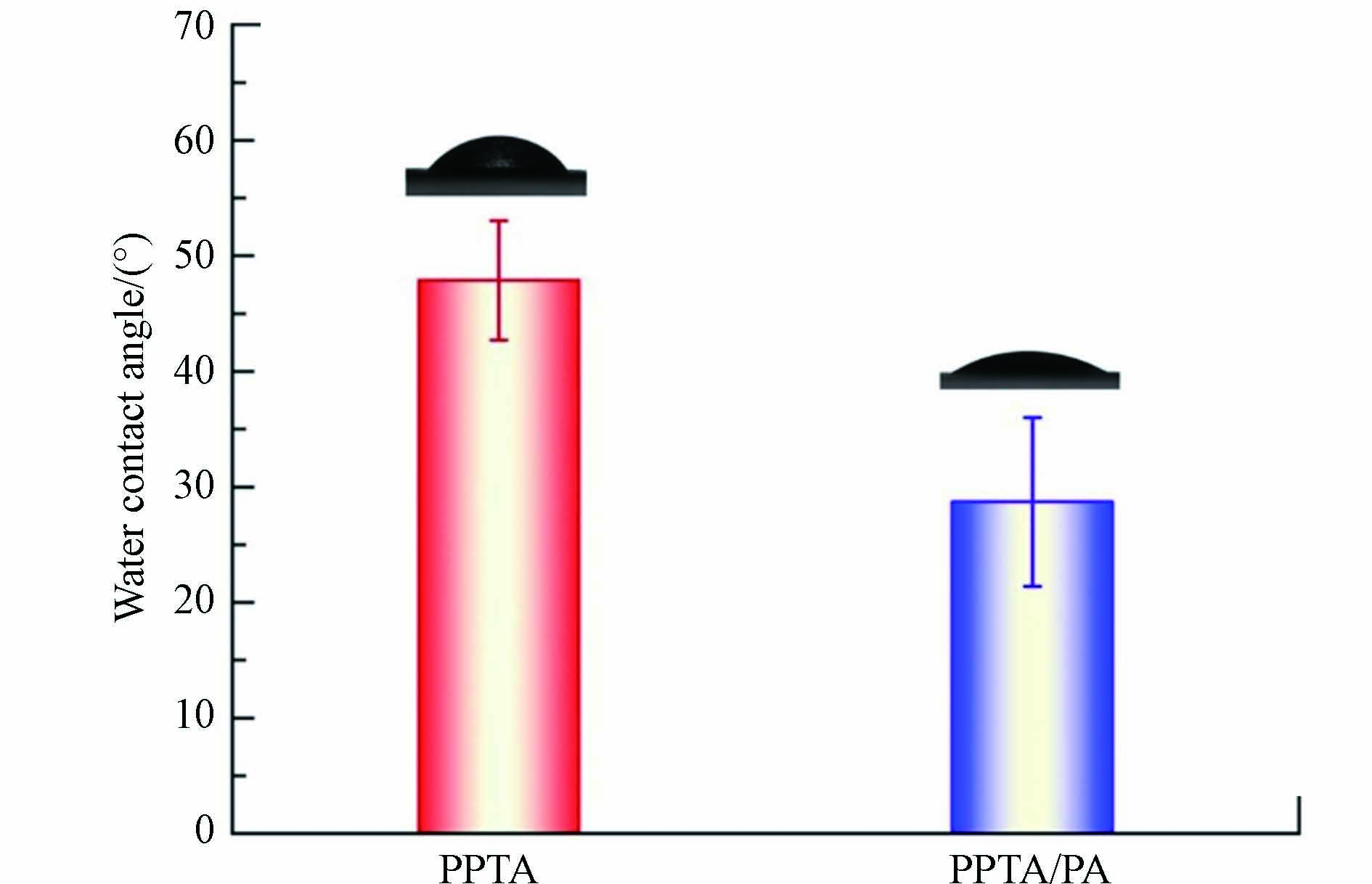

图9为PPTA基膜与PPTA/PA表面水接触角测试结果. 如图所示,PPTA基膜的接触角为47.9°,表现出良好的亲水性,这主要是PPTA大分子具有大量的亲水基酰胺键. 与PPTA超滤基膜相比,PPTA/PA复合纳滤膜的接触角为29.2°,这是由于界面聚合所得致密层也为亲水性聚酰胺分离层,与此同时,膜表面TMC中未反应的酰氯水解产生了亲水性羧基. 此外,膜表面形成的“脊谷型”结构,增大了膜表面粗糙度,即增加了表面接触面积,三者协同作用进而实现PPTA/PA复合纳滤膜亲水性提高.

-

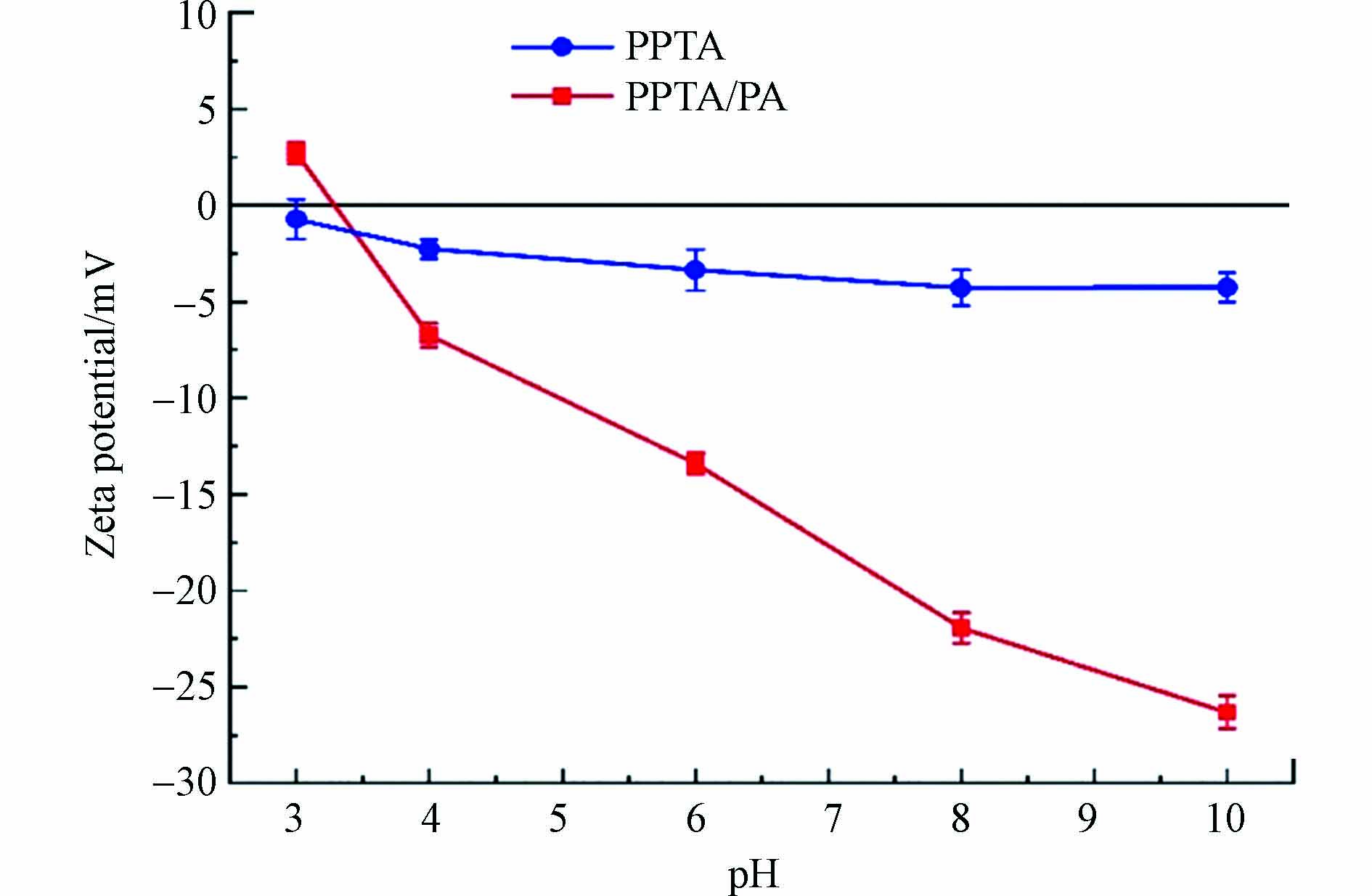

膜表面Zeta电位是表征道南效应对带电染料溶液分离作用的重要指标. 在纳滤过程中,纳滤膜在不同的pH值下呈现出不同的表面荷电特性,从而影响膜的性能. 图10为PPTA/PA复合纳滤膜表面Zeta电位与pH关系变化曲线,如图所示,PPTA/PA复合纳滤膜的等电点约为3.2. 当pH<3.2时,由于PPTA/PA复合纳滤膜表面大量氨基发生质子化,导致了其表面呈正的电性Zeta电位;当pH>3.2时,PPTA/PA复合纳滤膜表面呈负电性Zeta电位,这可能是因为氨官能团的去质子化和膜表面未反应的TMC酰氯基团水解为电负性羧酸基团[21].

-

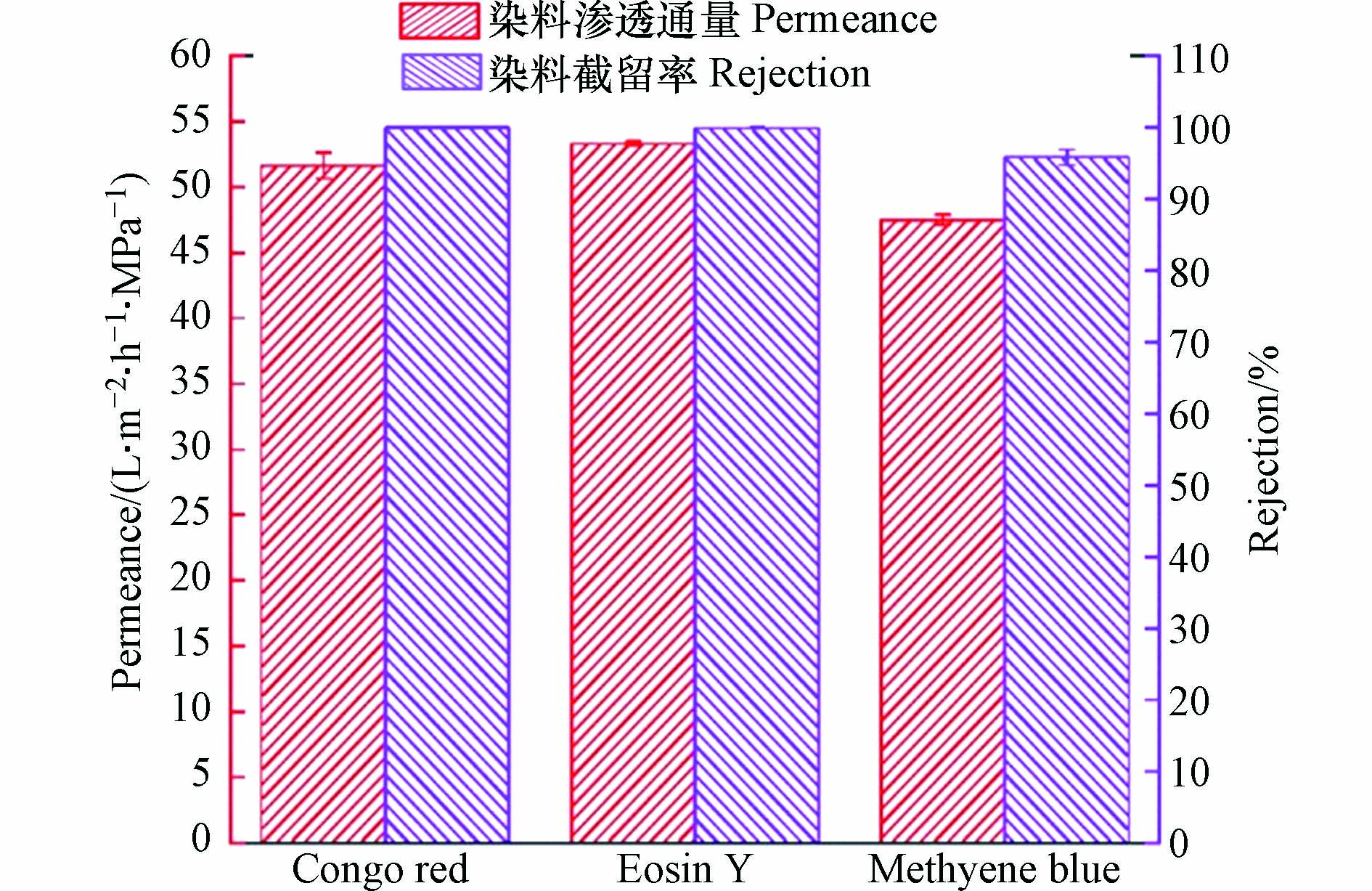

如图11所示,PPTA/PA复合纳滤膜对CR(99.9%)和EY(98.9%)呈现较高的截留率,然而,对MB的截留率略低(95.8%). 这是由于PPTA/PA复合纳滤膜对带有同种负电性的CR和EY染料分子的排斥力更强,截留效果更好. MB染料分子中含有正基团,导致染料溶液呈轻微正的Zeta电位. 与CR和EY相比,PPTA/PA复合纳滤膜对MB的截留率和渗透通量较低,这可能是因为正电基团的存在,膜表面对MB染料分子产生一定的吸附作用,增加了跨膜阻力,从而导致相对较低的渗透通量.

-

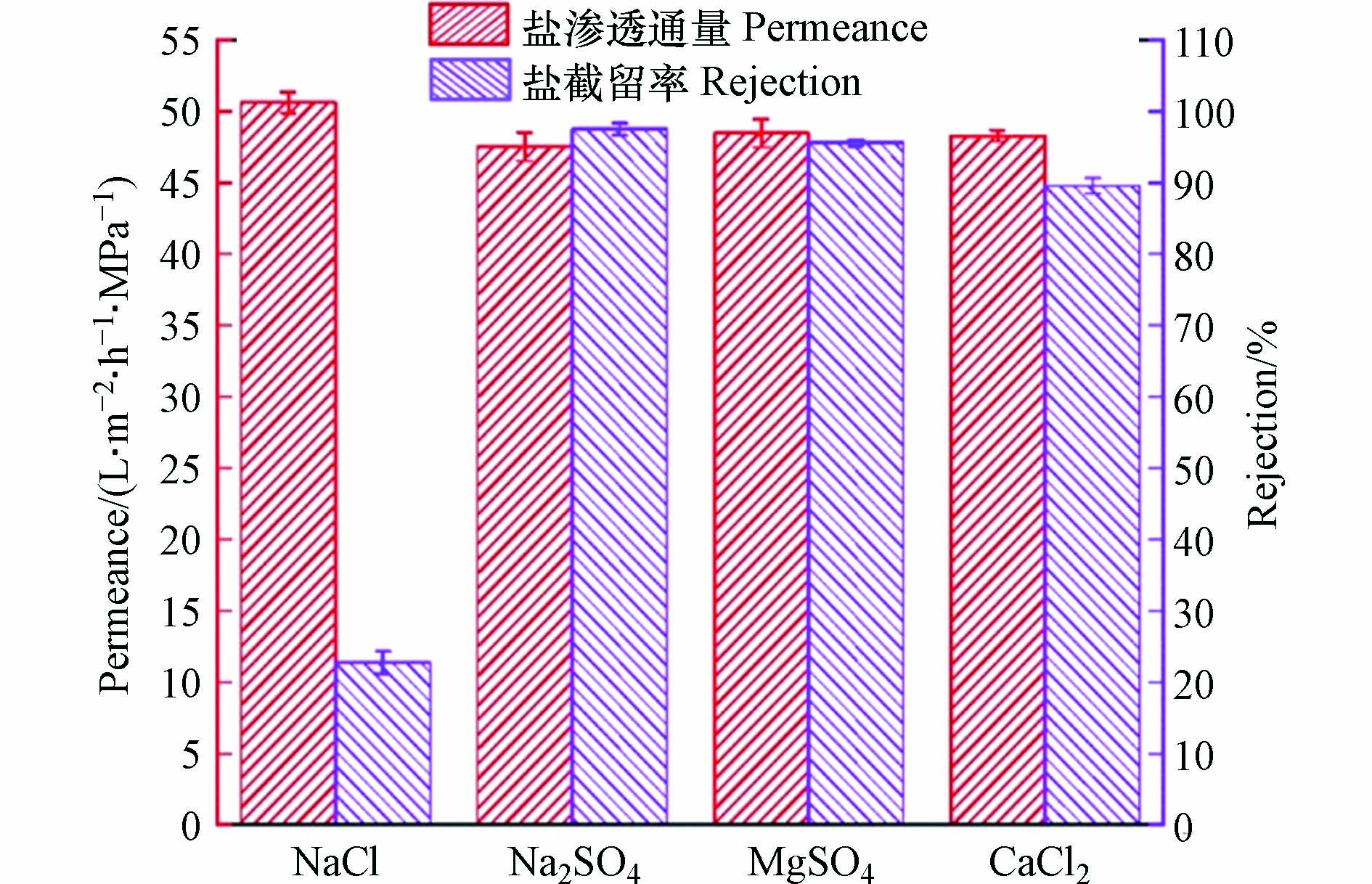

图12为PPTA/PA复合纳滤膜对无机盐溶液的渗透通量和截留效果。由图12可见,PPTA/PA复合纳滤膜对不同价态的阴离子和阳离子表现出不同的截留特性,其截留率顺序为:Na2SO4 (97.5%)> MgSO4 (95.6%) > CaCl2 (89.6%) > NaCl (22.7%). 这与其他文献中报道的带负电的NF膜一致. 一般来说,无机盐截留率可能与电荷、孔径和离子扩散系数有关. 根据道南效应,带负电荷的膜对较高化合价的阴离子的排斥力高于低价阴离子,即SO42- > Cl-. 相反,结合电中和要求,具有较低化合价的阳离子将促进保留. 另外,复合纳滤膜对CaCl2的截留率较高,而对NaCl的截留率较低的原因是Na+的水合半径(0.36 nm)小于Ca2+(0.41 nm),且扩散系数较高. 因此,所得PPTA/PA复合纳滤膜对无机盐表现出不同的截留行为,这是通过孔径筛选和电荷排斥之间的协同效应实现的[22].

-

图13为不同温度下,PPTA/PA复合纳滤膜对CR/Na2SO4及CR/NaCl分离性能的影响。由图13可见,当运行温度由常温25 ℃升至高温90 ℃时,PPTA/PA复合纳滤膜的渗透通量显著提升,对刚果红盐溶液渗透通量可达50 L·m−2·h−1·MPa−1以上,CR与Na2SO4的截留率几乎保持稳定,可达99%左右,这与前述结果趋势相一致,说明PPTA/PA复合纳滤膜具有良好的热稳定性能. 而NaCl截留率略有下降. 其原因在于温度升高使聚合物在溶液中柔韧性增加,并改善了NaCl的渗透性. 与此同时,渗透通量显著增加是因为溶液黏度的降低和水分子运动增加. 因此,通过适当提高运行温度,可以显著提高PPTA/PA复合纳滤膜渗透通量并减少膜污染.

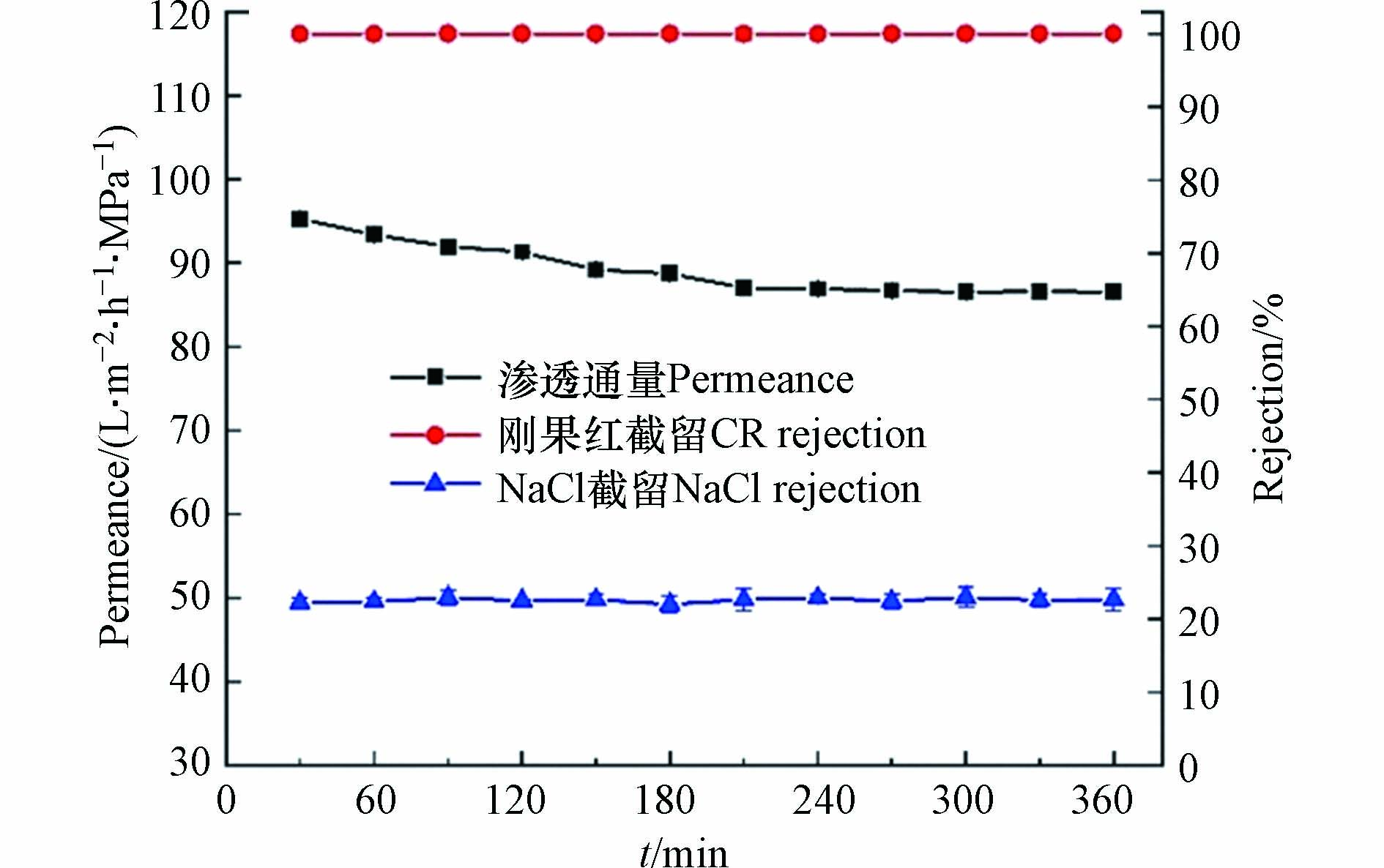

为了进一步研究PPTA/PA复合纳滤膜长期热稳定性,选择CR/NaCl染料溶液体系作为过滤介质,在80 ℃温度下连续运行360 min,测定PPTA/PA复合纳滤膜长时间高温染料脱盐性能,结果如图14所示,CR/NaCl染料溶液渗透通量可保持在80 L·m−2·h−1·MPa−1以上,可有效实现高温染料脱盐,对CR染料截留率保持在99%以上,在连续运行360 min内几乎保持稳定而渗透通量略有下降,表明PPTA/PA复合纳滤膜具有良好的膜孔尺寸稳定性和抗污染性. PPTA/PA复合纳滤膜优异的耐热性能得益于PPTA基膜优异的耐热性能和力学性能. 因此,PPTA/PA复合纳滤膜在高温运行条件下可保持相对稳定的渗透通量和染料脱盐截留率.

-

本文以亲水性PPTA超滤膜为基膜,采用界面聚合法制得PPTA/PA复合纳滤膜,确定了最优界面聚合工艺条件,研究了界面聚合工艺对复合纳滤膜性能的影响. 结果表明PPTA复合纳滤膜表面形成了典型的“脊谷状”条状表面结构,对二价盐离子具有较高的脱盐性能,其顺序为Na2SO4 (97.5%)> MgSO4 (95.6%) > CaCl2 (89.6%) > NaCl (22.7%),同时对带负电CR染料(截留率为99.9%)和EY染料(截留率为98.9%)呈现较高的截留率,表现出高效分离染料和无机盐性能. 当运行温度由常温25 ℃升至高温90 ℃时,PPTA/PA复合纳滤膜的渗透通量明显增加,渗透通量可达50 L·m−2·h−1·MPa−1以上,同时刚果红染料与Na2SO4截留率几乎稳定在99%左右,其可在80 ℃温度下较长时间保持稳定运行,表现出良好的高温纳滤性能.

对位芳香族聚酰胺复合纳滤膜制备及高温纳滤性能

Preparation and thermal resistance performance for PPTA composite nanofiltration membrane

-

摘要: 本文以对位芳香族聚酰胺(PPTA)超滤膜为基膜,无水哌嗪(PIP)与1,3,5-苯三甲酰氯(TMC)分别作为水相单体和油相单体,采用界面聚合法制得高通量耐热PPTA/PA复合纳滤膜. 研究了反应条件对PPTA/PA复合纳滤膜高温纳滤性能影响,观察了复合纳滤膜表面形貌与致密层结构,考察了渗透通量、耐热性以及抗污染等性能. 结果表明,当PIP浓度为15%wt,TMC浓度为2.5%wt,热处理温度和时间分别为60 ℃和8 min时,所得PPTA/PA复合纳滤膜对不同染料分子截留率可达95%以上,对二价盐截留率可达90%以上. 在高温条件下,所得PPTA/PA复合纳滤膜表现出优良的染料脱盐性能,在刚果红染料与Na2SO4截留率保持在99%的同时,渗透通量可达50 L·m−2·h−1·MPa−1以上.Abstract: In this paper, high flux heat-resistant PPTA/PA composite nanofiltration membranes were prepared by interfacial polymerization using para-aromatic polyamide (PPTA) ultrafiltration membrane as the base membrane and Piperazine (PIP) and trimesoyl chloride (TMC) as the aqueous and oil phase monomers, respectively. The effects of interfacial polymerization on the high-temperature nanofiltration performance of PPTA/PA composite nanofiltration membranes were investigated. The surface morphology and dense layer structure of the composite nanofiltration membranes were observed, and the permeance, heat resistance and anti-pollution properties were investigated. The results showed that when the PIP concentration was 15%wt, the TMC concentration was 2.5%wt, the heat treatment temperature and time were 60 ℃ and 8 min, respectively, the PPTA/PA composite nanofiltration membrane could retain more than 95% of rejection for different dye molecules and more than 90% of rejection for divalent salts, Under high temperature conditions, the obtained PPTA/PA composite nanofiltration membranes exhibited excellent dye desalination performance, and the permeate flux could reach more than 50 L·m−2·h−1·MPa−1 while the rejection rate of Congo red and Na2SO4 remained at 99%.

-

Key words:

- PPTA /

- interfacial polymerization /

- nanofiltration membrane /

- heat-resistance.

-

-

表 1 PPTA/PA复合纳滤膜样品制备参数

Table 1. The parameter of PPTA/PA NF membranes

膜样品

SamplesTMC/ % wt

ConcentrationPIP浓度/ % wt

Concentration热处理温度/℃

Thermal treatment15P-0.5T-60 0.5 15 60 15P-1.0T-60 1.0 15 60 15P-1.5T-60 1.5 15 60 15P-2.0T-60 2.0 15 60 15P-2.5T-60 2.5 15 60 15P-3.0T-60 3.0 15 60 5P-2.5T-60 2.5 5 60 10P-2.5T-60 2.5 10 60 20P-2.5T-60 2.5 20 60 25P-2.5T-60 2.5 25 60 30P-2.5T-60 2.5 30 60 15P-2.5T-40 2.5 15 40 15P-2.5T-80 2.5 15 80 -

[1] PENG L E, YANG Z, LONG L, et al. A critical review on porous substrates of TFC polyamide membranes: Mechanisms, membrane performances, and future perspectives [J]. Journal of Membrane Science, 2022, 641: 119871. doi: 10.1016/j.memsci.2021.119871 [2] WANG K P, WANG X M, JANUSZEWSKI B, et al. Tailored design of nanofiltration membranes for water treatment based on synthesis-property-performance relationships [J]. Chemical Society Reviews, 2022, 51(2): 672-719. doi: 10.1039/D0CS01599G [3] CHEN M X, XIAO C F, WANG C, et al. Preparation and characterization of a novel thermally stable thin film composite nanofiltration membrane with poly (m-phenyleneisophthalamide) (PMIA) substrate [J]. Journal of Membrane Science, 2018, 550: 36-44. doi: 10.1016/j.memsci.2017.12.040 [4] TAN Z, CHEN S F, PENG X S, et al. Polyamide membranes with nanoscale Turing structures for water purification [J]. Science, 2018, 360(6388): 518-521. doi: 10.1126/science.aar6308 [5] HU L J, ZHANG S H, HAN R L, et al. Preparation and performance of novel thermally stable polyamide/PPENK composite nanofiltration membranes [J]. Applied Surface Science, 2012, 258(22): 9047-9053. doi: 10.1016/j.apsusc.2012.05.153 [6] LIANG S M, XU G Y, JIN Y, et al. Annealing of supporting layer to develop nanofiltration membrane with high thermal stability and ion selectivity [J]. Journal of Membrane Science, 2015, 476: 475-482. doi: 10.1016/j.memsci.2014.12.003 [7] WANG C, XIAO C F, HUANG Q L, et al. A study on structure and properties of poly(p-phenylene terephthamide) hybrid porous membranes [J]. Journal of Membrane Science, 2015, 474: 132-139. doi: 10.1016/j.memsci.2014.09.055 [8] ZSCHOCKE P, STRATHMANN H. Solvent resistant membranes from poly-(p-phenylene-terephthalamide) [J]. Desalination, 1980, 34(1/2): 69-75. [9] SINGH T J, SAMANTA S. Characterization of kevlar fiber and its composites: A review [J]. Materials Today:Proceedings, 2015, 2(4/5): 1381-1387. [10] 赖星, 王黎明, 王纯, 等. 聚吡咯/凯夫拉中空纤维复合纳滤膜的制备及其染料脱盐性能 [J]. 环境化学, 2023, 42(4): 1239-1248. doi: 10.7524/j.issn.0254-6108.2021112101 LAI X, WANG L M, WANG C, et al. Fabrication of polypyrrole/kevlar hollow fiber composite nanofiltration membrane for dye desalination [J]. Environmental Chemistry, 2023, 42(4): 1239-1248(in Chinese). doi: 10.7524/j.issn.0254-6108.2021112101

[11] WANG C, XIAO C F, CHEN M X, et al. Unique performance of poly(p-phenylene terephthamide) hollow fiber membranes [J]. Journal of Materials Science, 2016, 51(3): 1522-1531. doi: 10.1007/s10853-015-9473-3 [12] FU M J, WANG C, SUN G W, et al. Controllable preparation of acid and alkali resistant 3D flower-like UiO-66-NH2/ZiF-8 imbedding PPTA composite nanofiltration membrane for dye wastewater separation [J]. Journal of Water Process Engineering, 2022, 50: 103320. doi: 10.1016/j.jwpe.2022.103320 [13] AN Q F, LI F, JI Y L, et al. Influence of polyvinyl alcohol on the surface morphology, separation and anti-fouling performance of the composite polyamide nanofiltration membranes [J]. Journal of Membrane Science, 2011, 367(1/2): 158-165. [14] SONG Y J, SUN P, HENRY L L, et al. Mechanisms of structure and performance controlled thin film composite membrane formation via interfacial polymerization process [J]. Journal of Membrane Science, 2005, 251(1/2): 67-79. [15] BUCH P R, JAGAN MOHAN D, REDDY A V R. Preparation, characterization and chlorine stability of aromatic–cycloaliphatic polyamide thin film composite membranes [J]. Journal of Membrane Science, 2008, 309(1/2): 36-44. [16] WEI X Z, KONG X, SUN C T, et al. Characterization and application of a thin-film composite nanofiltration hollow fiber membrane for dye desalination and concentration [J]. Chemical Engineering Journal, 2013, 223: 172-182. doi: 10.1016/j.cej.2013.03.021 [17] PRAKASH RAO A, JOSHI S V, TRIVEDI J J, et al. Structure–performance correlation of polyamide thin film composite membranes: Effect of coating conditions on film formation [J]. Journal of Membrane Science, 2003, 211(1): 13-24. doi: 10.1016/S0376-7388(02)00305-8 [18] HAN R L, ZHANG S H, HU L J, et al. Preparation and characterization of thermally stable poly(piperazine amide)/PPBES composite nanofiltration membrane [J]. Journal of Membrane Science, 2011, 370(1/2): 91-96. [19] ALSALHY Q F. Hollow fiber ultrafiltration membranes prepared from blends of poly (vinyl chloride) and polystyrene [J]. Desalination, 2012, 294: 44-52. doi: 10.1016/j.desal.2012.03.008 [20] SHI Q, NI L, ZHANG Y F, et al. Poly(p-phenylene terephthamide) embedded in a polysulfone as the substrate for improving compaction resistance and adhesion of a thin film composite polyamide membrane [J]. Journal of Materials Chemistry A, 2017, 5(26): 13610-13624. doi: 10.1039/C7TA02552A [21] MI Y F, WANG N, QI Q, et al. A loose polyamide nanofiltration membrane prepared by polyether amine interfacial polymerization for dye desalination [J]. Separation and Purification Technology, 2020, 248: 117079. doi: 10.1016/j.seppur.2020.117079 [22] WEI X Z, WANG S X, SHI Y Y, et al. Application of positively charged composite hollow-fiber nanofiltration membranes for dye purification [J]. Industrial & Engineering Chemistry Research, 2014, 53(36): 14036-14045. -

下载:

下载: