-

随着我国经济的发展与科技的进步,在保障经济发展的同时,环境问题逐渐被重视起来。已有研究表明,在产生雾霾天气的多种因素中,仅工业污染排放就占35%,燃煤电厂占10%。而在工业生产中产生的高温烟气、腐蚀性气体中,超细颗粒排放是产生可呼吸性粉尘的主要原因之一[1-2]。传统的袋式除尘器因为除尘效率高、发展较早、研究较为成熟,被广泛用于工业企业中,如焦化厂、炼铁厂、炼钢厂、炭黑厂、火力发电站等[3-4]。由于传统滤袋材料的限制,高温烟气须先被降温至滤料承受范围内(<280 ℃),再进行除尘。这种处理方式不仅不利于余热能源的利用,且长期处于较高温的环境下,还会影响滤袋的再生利用,产生烧袋和糊袋现象[5-6]。

与传统滤袋材质不同,金属滤袋由不锈钢材质制备,具有耐高温性,其可过滤的烟气温度高达400 ℃,使用铁铬铝材质制备的金属滤袋温度甚至可达1 000 ℃[7-8]。用金属滤袋替代传统滤袋处理高温烟气,不仅可以提升余热资源的利用率,降低滤袋的破损率,还可以减少后续设备的磨损。苏娜等[9]指出,金属纤维毡滤袋相比于现有的滤料,具有耐高温、透气性好、压力损失小、耐腐蚀、易于加工成型等优异的性能,将会被越来越广泛地应用在高温烟气除尘行业。孙鹏等[10]认为,金属纤维烧结毡有着优异的透气性能,其过滤效率可达到99.99%,排放浓度小于3.6 mg·m−3,可满足国家现行最严格的排放标准。

此外,清灰效果也是影响除尘器推广应用的重要因素。前期研究表明,传统袋式除尘器的清灰效果主要受滤袋大小、喷吹口孔径大小、喷吹高度和喷吹压力等因素的影响[11-12]。国内外常用脉冲喷吹对滤袋进行清灰的处理[13]。YAN等[14]通过实验证明,最大侧壁压力峰值更能反映清灰过程。LI等[15]的研究也显示喷吹压力越大,侧壁压力峰值越大。HUMPHRIES等[16]的研究表明,侧壁压力峰值要大于300 Pa才可以除去滤袋上60%的粉尘。王沁淘等[17]的研究显示,当最大侧壁峰值压力大于5 282 Pa时,脉冲清灰过度,导致滤袋破损。综上分析,可认为当侧壁压力峰值为300~2 500 Pa时,才会对滤袋产生有效地清灰。但针对金属滤袋脉冲喷吹压力分布影响因素的研究鲜有报道。

本研究针对金属滤袋开展了脉冲喷吹实验,研究脉冲喷吹高度、脉冲喷吹压力以及脉冲喷吹孔径对金属滤袋清灰压力分布的影响。同时,将所测得的喷吹压力分布规律与传统滤袋和滤筒的压力分布规律进行对比,为金属滤袋的后续研究提供参考。

全文HTML

-

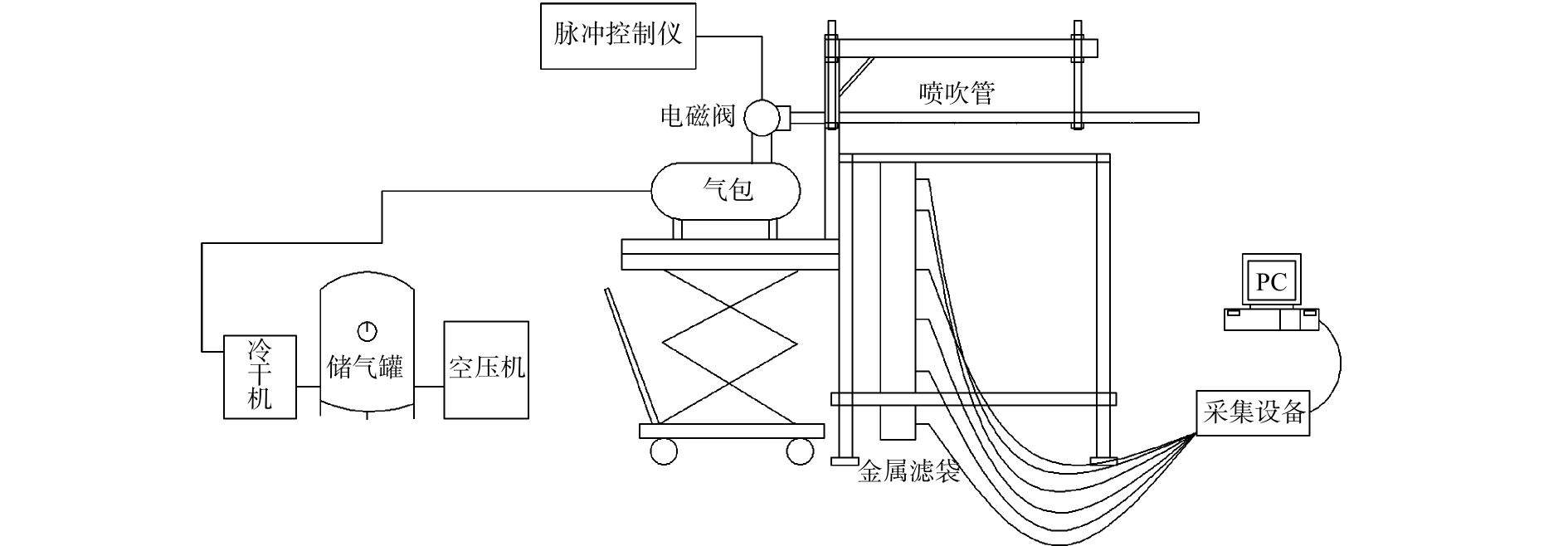

图1为搭建的脉冲喷吹实验平台,主要由脉冲喷吹设备和数据采集设备2个部分组成。脉冲喷吹设备包括UDI8A-7型螺杆空压机、DMF-Z-25直角型电磁脉冲阀、SXC-8A1脉冲仪、容积为40 m3的气包和5支不同喷吹孔径的喷吹管。数据采集设备包括SY7709型电荷放大器、USB-8512E型便携式数据采集仪和6支QSY8115型压电压力传感器。

-

本研究选用316 L不锈钢材质、过滤孔径10 μm、孔隙率80%、透气性120 L·(min·dm2)−1、ϕ130 mm×2 000 mm的金属滤袋作为研究对象。分别在距滤袋口的80、200、600、1 000、1 400和1 800 mm 处安置电压力传感器。在表1中的开孔1处进行脉冲喷吹实验。压力传感器通过电荷放大器和采集设备将压力参数转换为电流值。通过电压力转换公式,得出每个高度的侧壁压力值P1~P6。为保证参数的准确性,每组喷吹实验至少进行5次实验,读取值后取平均值。

-

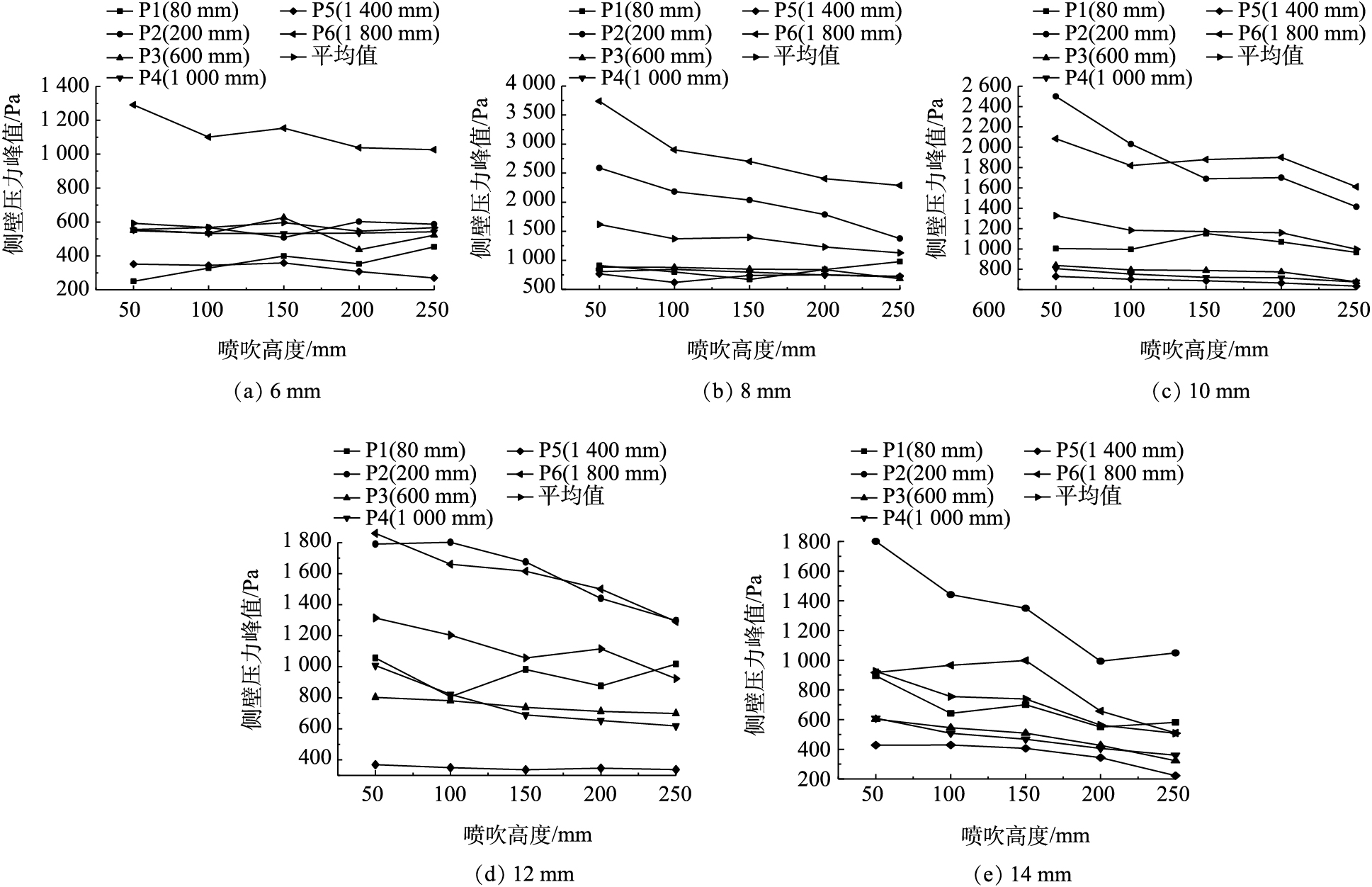

1)喷吹距离对清灰压力分布的影响实验。本实验使用图1的实验平台升降设备,改变喷吹孔距金属滤袋口的距离。通过压力表改变喷吹压力,进行每个喷吹高度下的各喷吹距离的实验,并读取、计算出P1~P6的侧壁压力峰值。其中脉冲宽度为80 ms。选取喷吹压力为0.2、0.3、0.4、0.5和0.6 MPa进行对比实验。选取6、8、10、12和14 mm的不同喷吹孔径的喷吹管进行规律变化研究。因实验数据获取只针对脉冲单次喷吹,单次采集,故不考虑脉冲间隔参数以及喷吹时间的影响。

-

2)喷吹孔径对清灰压力分布的影响实验。本实验采用图1的实验平台升降设备,通过改变不同孔径的喷吹管来进行孔径对清灰压力分布的影响实验。针对各喷吹孔径的最优喷吹距离(依次为50、100、150、200和250 mm),读取、计算出P1~P6的侧壁压力峰值,脉冲宽度为80 ms,选取喷吹压力0.5 MPa进行对比实验。其中使用6、8、10、12和14 mm不同孔径的喷吹管进行对比研究(编号依次1、2、3、4、5,见表1),每支管开孔数量为6个,从靠近气包开始编号,依次为开孔1~6。根据靳爽等[12]和童庆等[18]的研究,为保证管内均匀射流,远离气包的开孔口要比近气包的孔口小0.5~1 mm。因实验数据获取只针对脉冲单次喷吹,单次采集,故不考虑脉冲间隔参数以及喷吹时间的影响。

1.1. 实验装置

1.2. 实验方法

-

对金属滤袋在5种喷吹压力(0.2~0.6 MPa)下进行对比实验测试。当喷吹压力为0.2~0.4 MPa时,喷吹孔径为6、12和14 mm的P5(1 400 mm)的压力不能满足最低清灰要求的300 Pa,并且压力的改变会引起气流量大小的改变。为保证实验控制条件一致,故只选择0.5 MPa压力下的实验数据进行分析(见图2)。如图2(a)所示,在喷吹孔径为6 mm的条件下,大多数测点的侧壁压力峰值随着喷吹距离的增大呈现先增大再减小的趋势。个别点在150 mm处并非峰值,但与最大值压力差值不到100 Pa。在喷吹孔径为8 mm(图2(b))和10 mm(图2(c))的条件下,随着喷吹距离的增大,大多数测点的侧壁压力峰值呈现降低的趋势。在200 mm和150 mm时,其侧壁压力峰值并非最大值,但是评判脉冲喷吹的效果是压力的均衡性。在8 mm和10 mm的喷吹孔径下,喷吹距离在50 mm和100 mm下,P2(200 mm)或P6(1 800 mm)的侧壁压力峰值超过了2 500 Pa,且与其余部位的压力峰值差距太大。而在喷吹孔径为8 mm时,P1(80 mm)的侧壁压力峰值呈现先降低后上升的趋势,在喷吹距离为150 mm时,其压力达到最低值。故在8 mm和10 mm的喷吹孔径下,其最优喷吹距离分别为200 mm和150 mm。而喷吹孔径为12 mm(图2(d))和14 mm(图2(e))的条件下,喷吹距离在50 mm时,其压力最大不到2 000 Pa,所以最优喷吹距离均为50 mm。随着喷吹孔径的增大,最优喷吹距离呈现逐渐减小的趋势,与滤筒除尘器脉冲喷吹最优喷吹距离的趋势[15, 19]一致。

由图2可知,随着孔径的变大,侧壁压力峰值最大的点从P6(1 800 mm)变为P2(200 mm)。在喷吹孔径为10 mm和12 mm时,P6和P2的数值最大差距仅400 Pa。根据射流理论,这是由于脉冲喷吹孔径较小时气流扩散角度不大造成的。气流到达底部后,由于金属滤袋底部为封闭空间,射流速度瞬间变为零,动压转换为静压。静压作用于底部P6(1 800 mm)的侧壁,所以其侧壁压力峰值较大。而随着孔径的增大,气流扩散角度也变大,同时由于金属的滤袋的透气性较好,所以P2(200 mm)的压力随之变大。无论喷吹孔径如何变化,在P3(600 mm)和P4(1 000 mm)处的压力相差不大(最大差距仅196 Pa,最小差距不足7 Pa),P5(1 400 mm)处的喷吹压力最小。故金属滤袋的中、下部(距滤袋口600~1 400 mm)将是清灰困难的区域。

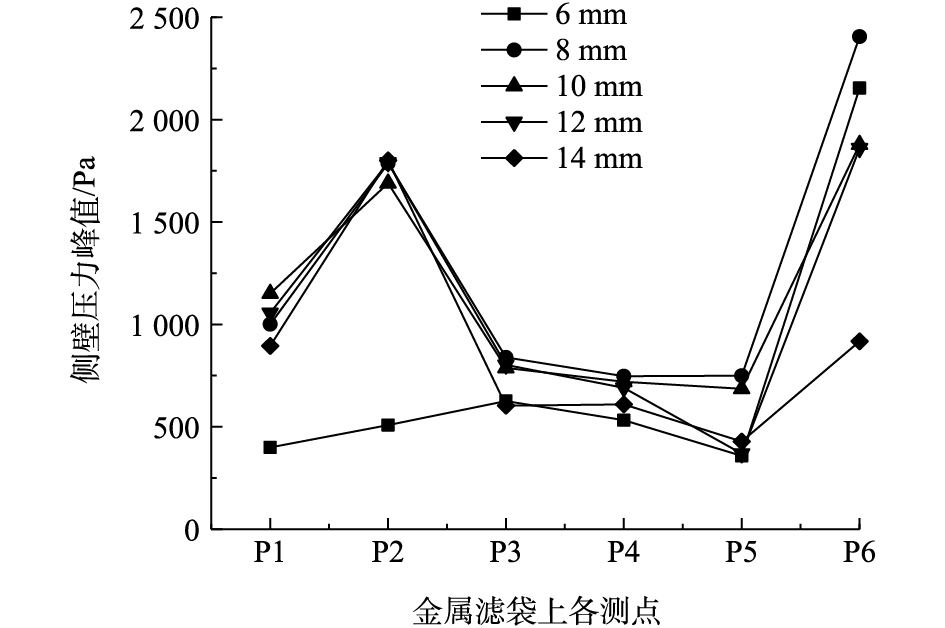

在同一喷吹压力(0.5 MPa)下,不同喷吹孔径有不同的最佳喷吹距离。因此,在各自最佳喷吹距离的条件下,本研究对喷吹孔径与清灰压力分布的关系进行深入分析。

-

图3为各喷吹孔径在最佳喷吹距离的条件下,当喷吹压力为0.5 MPa时的不同测点的侧壁压力峰值。由图3可以看出,喷吹孔径为8 mm时,在不同测点测得的侧壁压力峰值均大于其余4个喷吹孔径,除了P1(80 mm)点小于10 mm和12 mm孔径。这是因为脉冲喷吹孔径较大时,压缩空气从喷吹孔瞬间喷出,形成一股高速气流,喷嘴周围产生了低压区域,压力转换为动力,诱导产生了二次气流。当诱导气流向下运动时,滤袋壁阻碍气流发散,动压转换为静压,侧壁受到的压力增大,因此,产生10 mm和12 mm测点(P1)侧壁压力峰值较大的现象。在金属滤袋的整体压力分布中,中、下部(600~1 400 mm)处较为均匀,呈逐步降低的趋势,底部(1 800 mm)和上部(200 mm)压力较大。这是因为随着气流不断向下运动,由于金属滤袋的高透气性,气流在运动过程中扩散到滤袋外,并在气流运动过程中,与滤袋壁面接触产生摩擦,消耗一部分动能,因此,侧壁压力峰值随着距离的增加而减小,中部的侧壁压力较为均匀。金属滤袋底部压力较大的原因是:由于金属滤袋底部是全封闭的,当压缩气流运动到滤袋底部时,气流速度瞬间变为零,气体向四周扩散,动压转换为静压。这股发散开的气流和主导气流共同作用使滤袋底部压力变大。此外,P5(1 400 mm)的侧壁压力均小于其他测点,这将是清灰困难的区域。

表2为不同喷吹孔径的侧壁压力峰值标准差。由表2可看出,各喷吹孔径标准方差均很大(>0.4),说明金属滤袋的各测点的侧壁压力峰值的差距较大。14 mm喷吹孔径的标准方差最小,表明其气流分布与别的孔径相比较为均匀。但是由于其侧壁压力较小,所以其虽然稳定但清灰效果却不佳。而8 mm和10 mm的标准方差差距并不是很大,仅为0.017。在此情况下,应优先考虑所有测点中较弱势区域的数值大小。根据表3列出的P3(600 mm)、P4(1 000 mm)、P5(1 400 mm)这3个较弱点的侧壁压力峰值的对比,可以看出,8 mm测点的侧壁压力峰值均大于10 mm,故8 mm为金属滤袋的最佳喷吹孔径。

-

金属滤袋由金属毡纤维制备,与传统滤袋的柔性结构不同,其为刚性结构,所以它的除尘效果以及侧壁压力分布规律与传统纤维滤袋有不同。将本研究的结果与毕远霞等[20]研究的ϕ130 mm×2 000 mm传统纤维滤袋进行对比分析,选取同为0.5 MPa压力下的数据。毕远霞等[20]选取的上、中、下的3个点分别为P1(375 mm)、P2(1 085 mm)和P3(1 800 mm),分别与本研究选取的P2(200 mm)、P4(1 000 mm)和P6(1 800 mm)进行对比。由比较可知,传统纤维滤袋的侧壁压力峰值自上而下呈现逐渐增大的趋势,而金属滤袋呈现的是下部>上部>中部的趋势。根据CHOI等[21]的研究,金属过滤原件比陶瓷过滤原件的压降小6倍。可知金属滤袋的透气性极佳。而根据射流原理,滤袋滤料的透气性会影响射流的扩散,从而影响滤袋整体的侧壁压力峰值的分布。透气性较好的滤袋会让更多的射流穿透过滤袋发散出去。因此,透气性更好的金属滤袋的中部的侧壁压力峰值会小于上部。底部的侧壁压力峰值较大的原因则是,当主要的射流到达底部时,因为滤袋底部均为封闭空间,所以气流速度瞬间变为零,气体向四周发散,动压转换为静压,导致底部侧壁压力峰值较大。

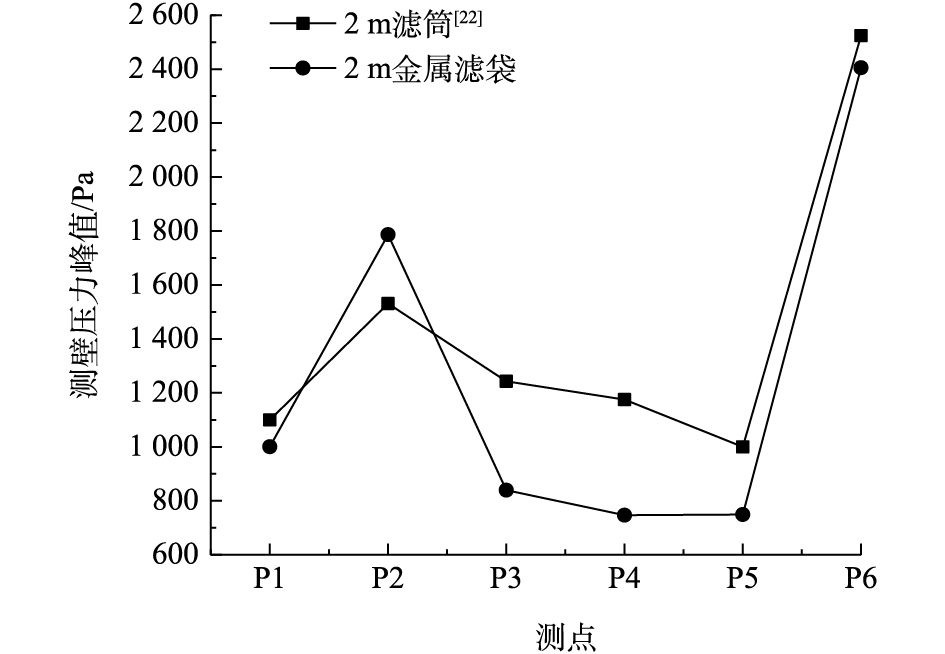

金属滤袋不同于传统滤袋的柔性结构,金属滤袋从结构上更像半刚性结构的滤筒。将本研究的结果与王岩[22]研究的ϕ147 mm×2 000 mm的滤筒进行对比分析,结果如图4所示。其中,2 m滤筒数据为喷吹孔径12 mm、喷吹压力0.5 MPa的各点侧壁压力峰值,测点的布置为P1(100 mm)、P2(200 mm)、P3(600 mm)、P4(1 000 mm)、P5(1 400 mm)、P6(1 800 mm);金属滤袋数据是在喷吹孔径8 mm、喷吹压力0.5 MPa的各测点的侧壁压力峰值。

由图4可以看出,2 000 mm金属滤袋的侧壁压力分布规律与2 000 mm滤筒相似。2 m的金属滤袋和滤筒均呈现自上到下先增大再减小再升高,底部的压力为最大值的规律。不同的是,与滤筒比较,金属滤袋的中、下部(距滤袋口600~1 400 mm)侧壁压力峰值较低,顶部(距滤袋口100 mm)的压力大于中、下部(距滤袋口600~1 400 mm),上部(距滤袋口200 mm)的压力与顶部(距滤袋口80 mm)以及中、下部(距滤袋口600~1 400 mm)的差距较大。其原因是,当射流进入滤袋后,气流向外扩散,从而上部的侧壁压力增大。部分未扩散的气流沿着滤袋壁面向下移动。金属滤袋的透气性较好,其向下的气流较少,故上部和中、下部的侧壁压力差距较大。

2.1. 喷吹距离对清灰压力分布的影响

2.2. 喷吹孔径对清灰压力分布的影响

2.3. 金属滤袋与传统纤维滤袋和滤筒侧壁压力峰值分布规律对比研究

-

1)根据金属滤袋在6、8、10、12和14 mm的不同喷吹孔径以及50、100、150、200和250 mm的不同喷吹距离、在0.5 MPa的脉冲喷吹压力下的侧壁压力峰值,可以看出,随着孔径的增大,侧壁压力峰值最大部位由下部(距滤袋口1 800 mm)向上部(距滤袋口200 mm)转化。各喷吹孔径的最佳喷吹距离依次是150、200、150、50和50 mm,具有由大变小的趋势。

2)金属滤袋在各喷吹孔径的最佳喷吹距离以及0.5 MPa的喷吹压力的条件下,喷吹孔径并非越小越好。金属滤袋的各部分压力分布较为不均匀,其标准方差均大于0.41。在喷吹孔径大于12 mm之后,各点的侧壁压力峰值下降明显。喷吹孔径小于8 mm后,上部的侧壁压力峰值下降显著,8 mm为最佳脉冲喷吹孔径。

3)金属滤袋具有透气性好的特性,它不同于传统纤维滤袋的侧壁压力峰值自上而下逐渐增强的趋势,金属滤袋呈现的是下部>上部>中部的趋势。在喷吹距离为200 mm、喷吹压力为0.5 MPa、喷吹孔径为8 mm时,金属滤袋在P1(80 mm)、P2(200 mm)、P3(600 mm)、P4(1 000 mm)、P5(1 400 mm)、P6(1 800 mm)的侧壁压力峰值分别为1 000、1 686、839、746、749和2 005 Pa。金属滤袋的中、下部(距滤袋口600~1 400 mm)清灰将是未来金属滤袋清灰的重点关注部位。

下载:

下载: