-

在油田和炼油厂的生产、储运以及含油污水处理过程中,会产生大量含油污泥。妥善处理与处置含油污泥,避免造成环境污染一直是油田和环保部门非常重视的问题[1]。含油污泥主要分为落地油泥、罐底油泥和炼油厂油泥。沉积在储罐罐底的油泥会直接影响油品质量,所以罐底的定期清理必不可少[2]。传统的射流清洗方法会造成水资源浪费,使用化学清洗剂可能造成二次污染。而气泡清洗法具有低能耗和自身清洁的特点,为罐底油泥的去除与清洗提供了新的手段。

气泡清洗法已被广泛应用在金属表面清洗、瓷器清洗等固体表面清洗领域。张学发等[3]验证了微气泡在金属脱脂应用上的可行性和优越性;CHAHINE等[4]建立了空化气泡清洁表面颗粒的力学模型;黄河等[5]的研究验证了气泡清洗瓷器表面的安全性。除了实验验证和应用研究,很多学者也对气泡清洗过程和机理做过论证。TUZIUTI[6]研究了微米级气泡清洗表面油脂的过程;YAMASHITA等[7]发现空化气泡的物理作用是去除材料表面附着颗粒的主要因素;REUTER等[8]研究了单个气泡去除玻璃表面附着颗粒机理;MAEKAWA等[9]认为微小气泡的上浮并带走油脂是固体表面清洗的机制之一。以上研究都表明气泡清洗在固体表面清洗领域具有应用潜力。

为明确气泡清洗技术在罐底底泥清洗中的应用情况,本研究考察了气泡尺寸差异对固体表面清洗效果的影响。通过搭建玻璃表面油污气泡清洗可视化实验装置,设计了可产生多种尺寸分布的气泡发生器,以研究不同尺寸气泡对固体表面粘附性污染物清洗效果的差异,并分析清洗时间、距离和角度等参数对清洗效果的影响,以期为高效处理油泥污染问题提供参考。

全文HTML

-

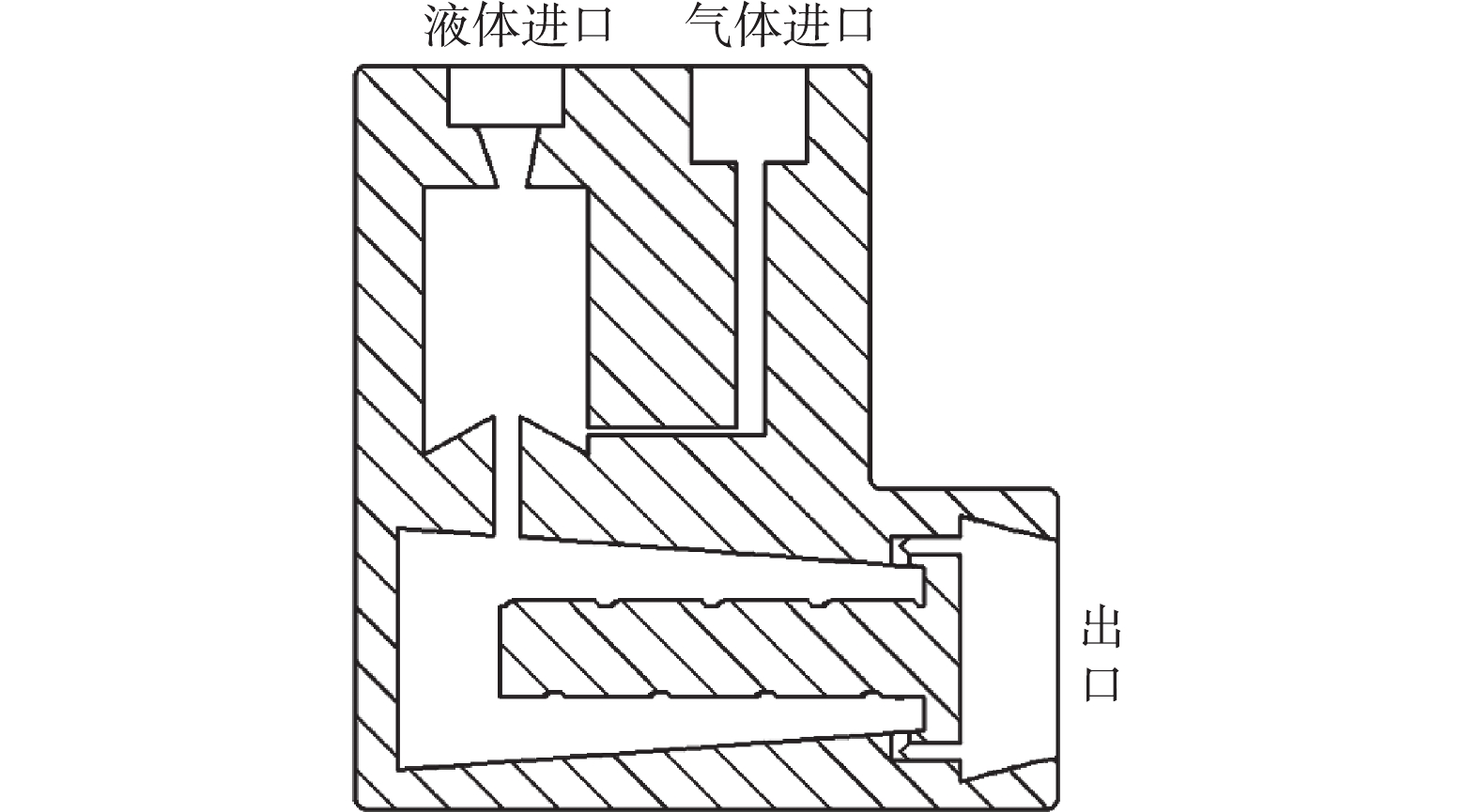

常用的气泡产生方法有加压溶气法和流体剪切法[10]。加压溶气法的原理是在对流体加压使气体过饱和溶解后,突然释放压力使气体以微小气泡的形式逸出,产生的气泡尺寸一般在100 μm以下[11];流体剪切法是依靠湍流剧烈的剪切力在气液流体中产生气泡,比较常见的是文丘里式和涡流式[12-13],产生的气泡尺寸大约为数百微米[14]。本研究参考现有气泡发生的方法和原理,优化设计了气泡发生器。发生器的主要结构包括文丘里结构的入口部分和具有中心圆柱的旋流腔(见图1),通过调节气泡发生器的气液比产生不同尺寸的气泡。

图1为实验采用的自制气泡发生器的结构示意图。气泡发生器的尺寸为58 mm×26 mm×61 mm,使用树脂材料3D打印技术制作完毕供实验使用。水通过水泵送至气泡发生器左侧的液体入口,空气通过空气压缩机送至右侧的气体入口。入口部分的文丘里结构能够使流体在以不同气液比例进入喷头时实现稳定混合;气液流体向下一起进入下部的旋流腔体,依靠旋流作用,部分空气在中心螺旋圆柱的表面被挤压,压力增大使更多空气溶入水中,并在出口处因突然释压以微小气泡形式析出,未溶解的部分空气也因流体剪切力被分割为气泡形态,从而实现调节进气和进水的比例获得不同尺寸范围的气泡。

-

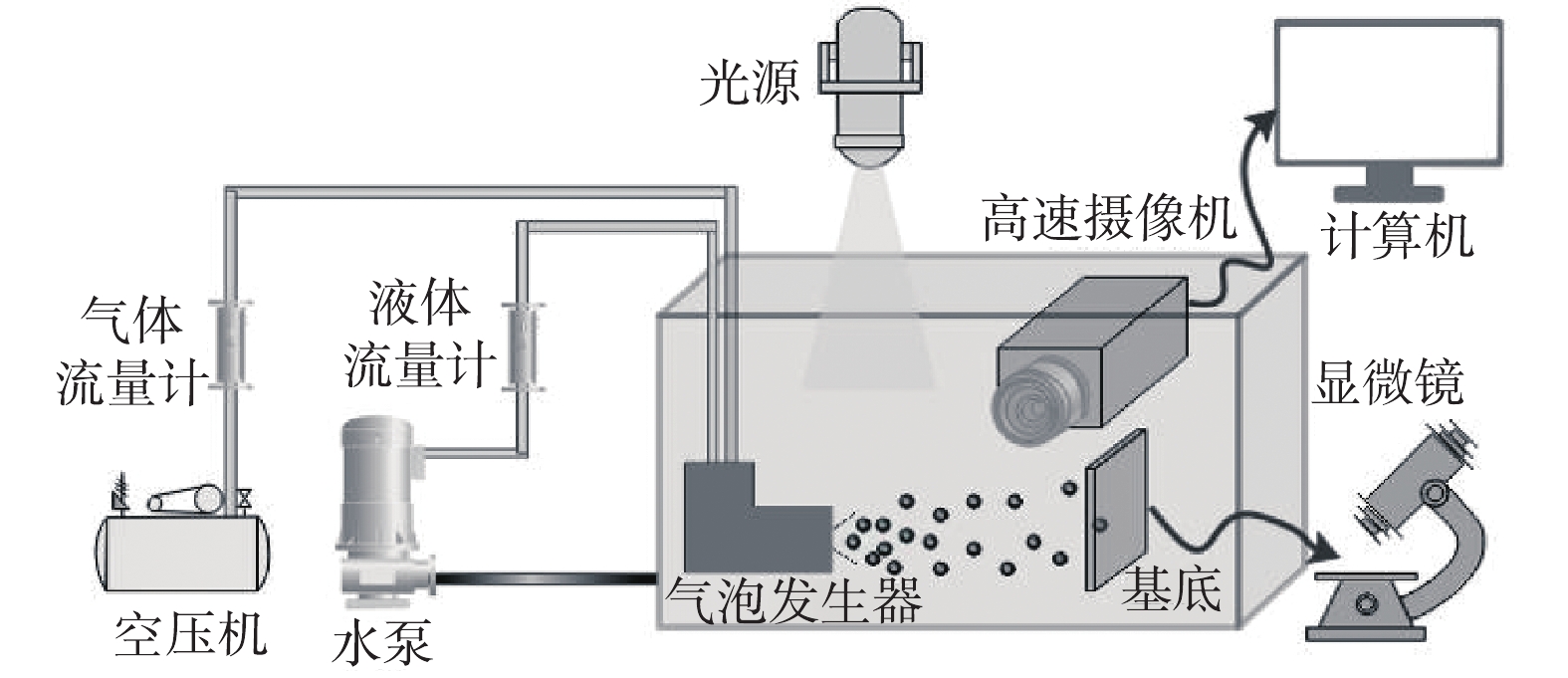

本研究搭建了气泡对玻璃表面油脂及颗粒污染物的可视化清洗实验装置(见图2)。污染物是黏度为0.350 Pa·s的硅油和粒径为5~50 μm的二氧化硅颗粒的均匀混合物。水经过水泵(江苏威乐泵业科技有限公司YE2-80M1-2,中国)通过气泡发生器进入水箱,再由水箱出口回到水泵,形成循环。水箱为玻璃材质,尺寸为40 cm×30 cm×30 cm,边壁挂有槽,用于固定微气泡发生喷头的位置和放置带有污染物的基底,水槽距离底部17 cm,距离水面8 cm。涂有污染物的玻璃基底放在气泡发生器出口的正前方,通过调整基底到气泡发生器出口处的距离和基底的倾斜角度来研究不同因素对清洗效果的影响。控制液体流量保持2.500 L·min−1不变,调节进气流量从0.125 L·min−1至1.000 L·min−1,从而研究不同气液比下产生的不同尺寸气泡对清洗效果的影响。通过高速摄像机拍摄产生的气泡图像,使用MATLAB软件统计气泡尺寸分布,并通过显微镜观察清洗前后玻璃表面污染物的变化。

-

通过图像方法[14]测量气泡尺寸。使用配有微透镜(AF Micro-Nikkor,60 mm,f / 2.8D)的高速相机(Photron Fastcam SA-X2,日本)记录气泡的运动,并通过定位摄像机焦点位置的标尺来测定每个实验的长度像素。由于气泡边界清晰,可将气泡分离成单独和重叠的气泡,用MATLAB分析图像获得气泡的几何尺寸[15],然后再根据图像分析结果统计出不同操作条件下产生的气泡尺寸分布情况。

污染物清洗效果的测量分析分为直接观测和称重量化两个部分。在清洗前后使用显微镜(上海光学仪器一厂XSP-8CA,中国)直接观察基底上的污染物。由于污染物中混有二氧化硅颗粒,可以直观地表征污染物的残留量、分布和位置变化。每次实验时,在同一基底上涂抹0.100 0 g污染物,误差控制在1%以内,并在每次清洗前后用电子天平称出污染物质量,按照式(1)计算去除率。

式中:R为去除率;m清洗前为清洗前玻璃基底上污染物的质量,g;m清洗后为清洗后玻璃基底上残留污染物的质量,g。

1.1. 气泡发生器

1.2. 实验装置

1.3. 测量与分析方法

-

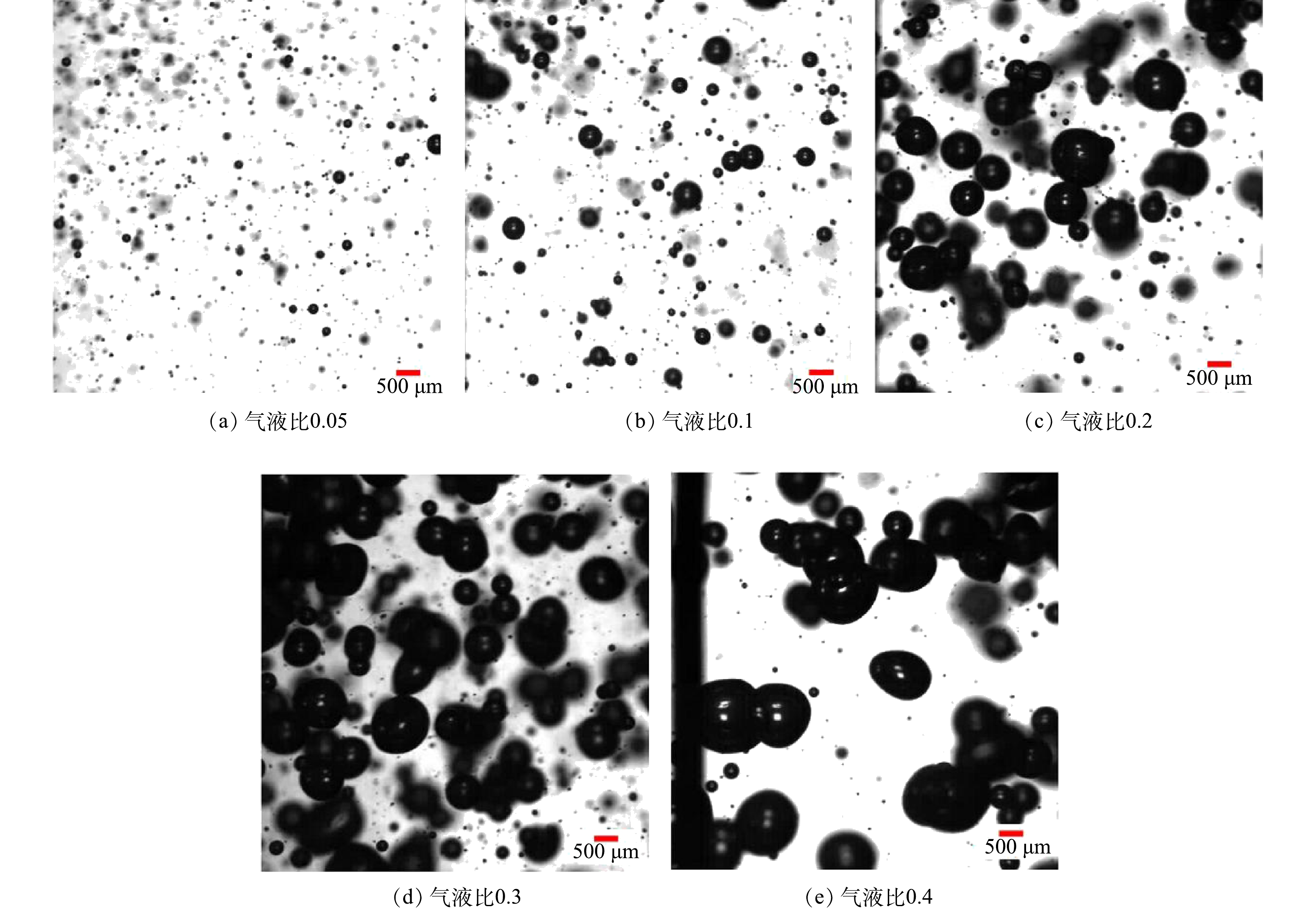

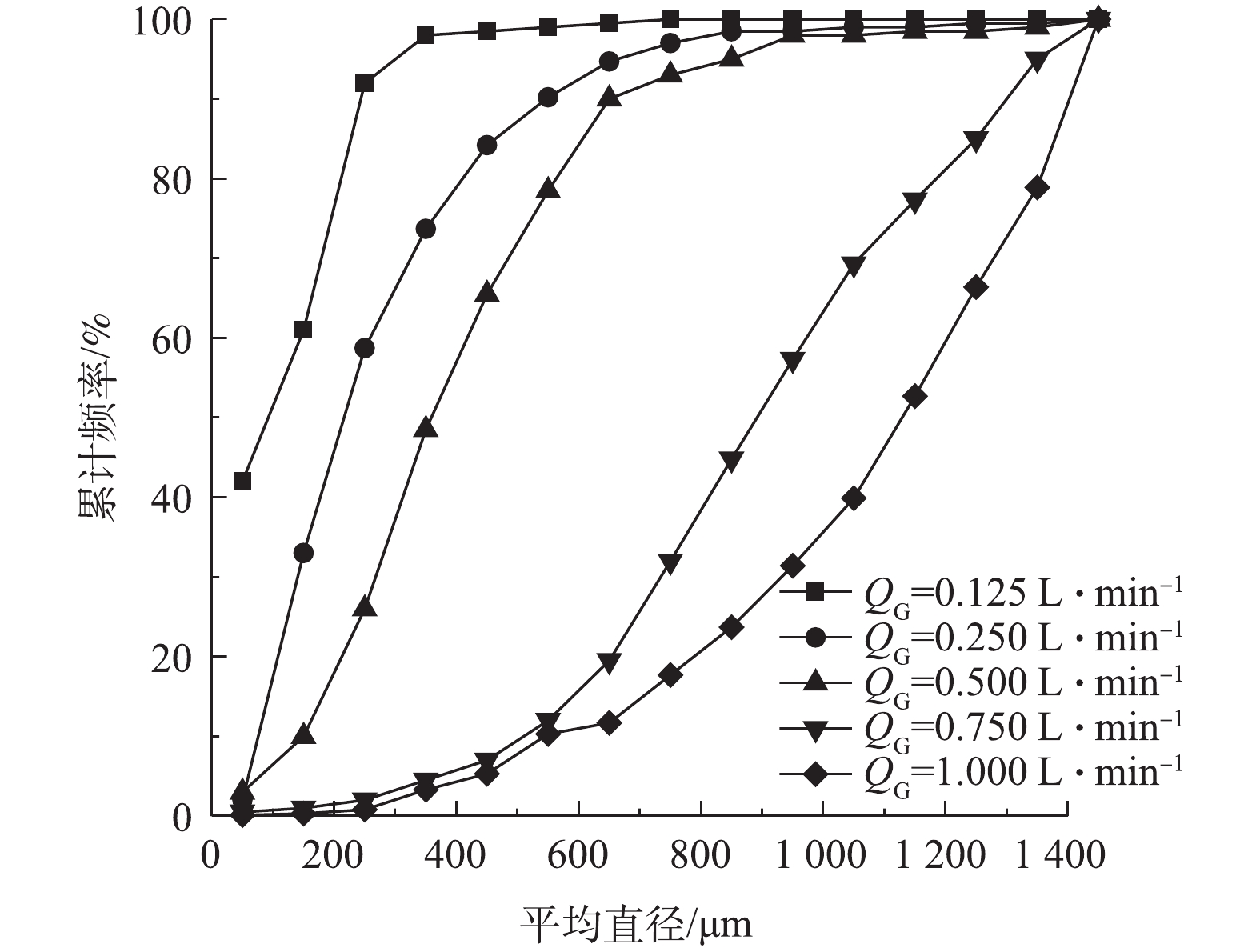

在相同液体流量下,进气流量控制在0.125~1.000 L·min−1进行实验,产生的气泡经高速摄像拍摄后图像如图3所示,气泡的尺寸分布数据见图4。由图3和图4可见,随着气液比的增大,气泡尺寸也逐渐增大;当气液比为0.05时,气泡尺寸较小,平均尺寸小于100 μm;随着气量的增加,大气泡从无到有,并且逐渐增多,而微小气泡的数量变化不大。当进气量较小时,进入喷头的气体在旋流作用下被挤压在中心实体圆柱表面,增大的压力使其溶于水中,并在出口常压释放时以微气泡的形态析出,此类气泡尺寸一般为数十微米[16]。然而,由于溶解度和固定接触面积的限制,只有一定量的气体能够溶入水中。随着进入喷头的气量增大,剩余气体被高速流体剪切为气泡,此类气泡尺寸较大,并随操作条件的变化而变化。根据该结果,当气液比为0.05~0.4时,可分别得到平均尺寸约为80、250、500、800及1 200 μm的不同尺寸气泡分布状态。这一结果可为后续实验对清洁效果的对比提供控制参数。

-

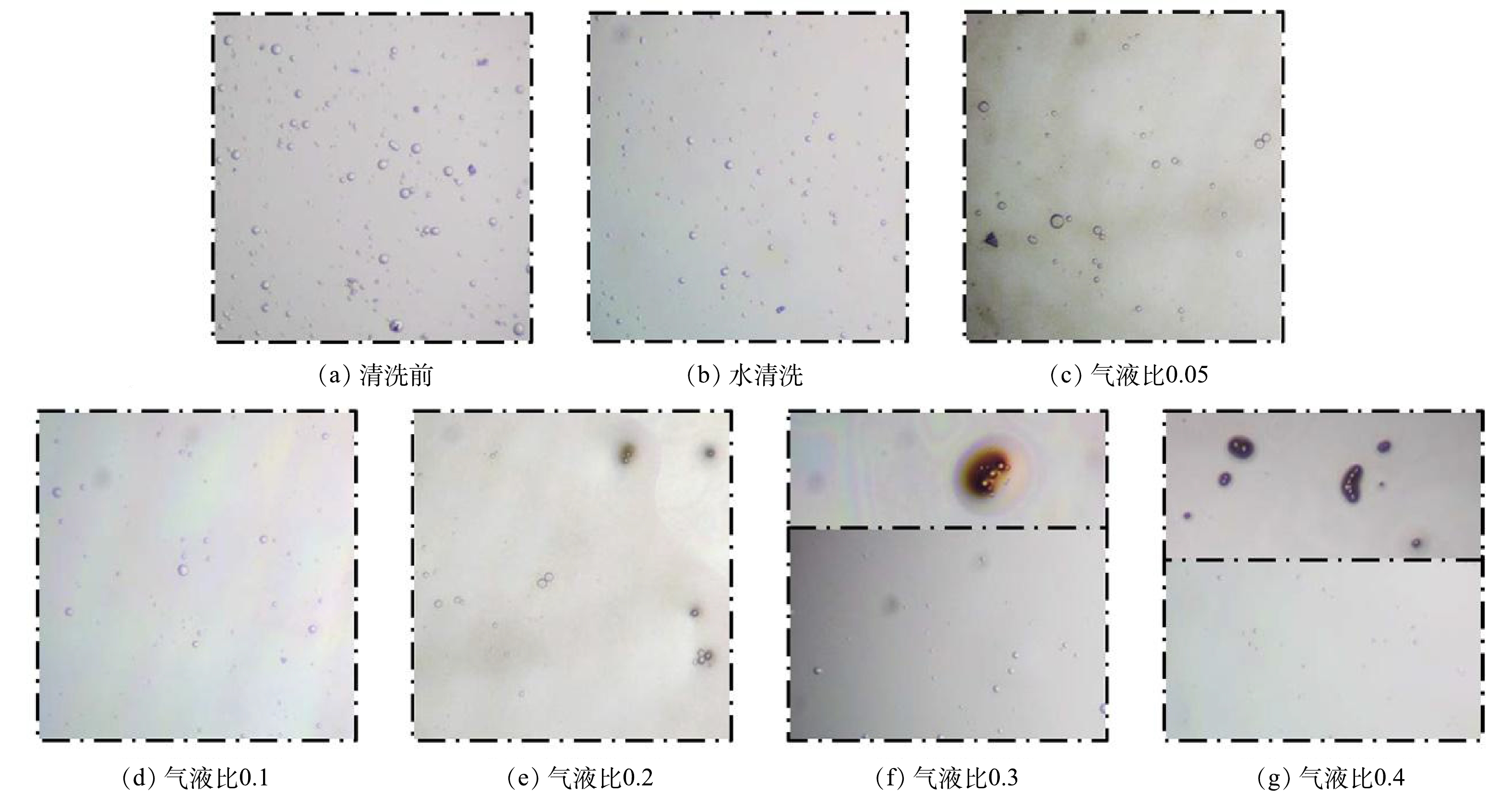

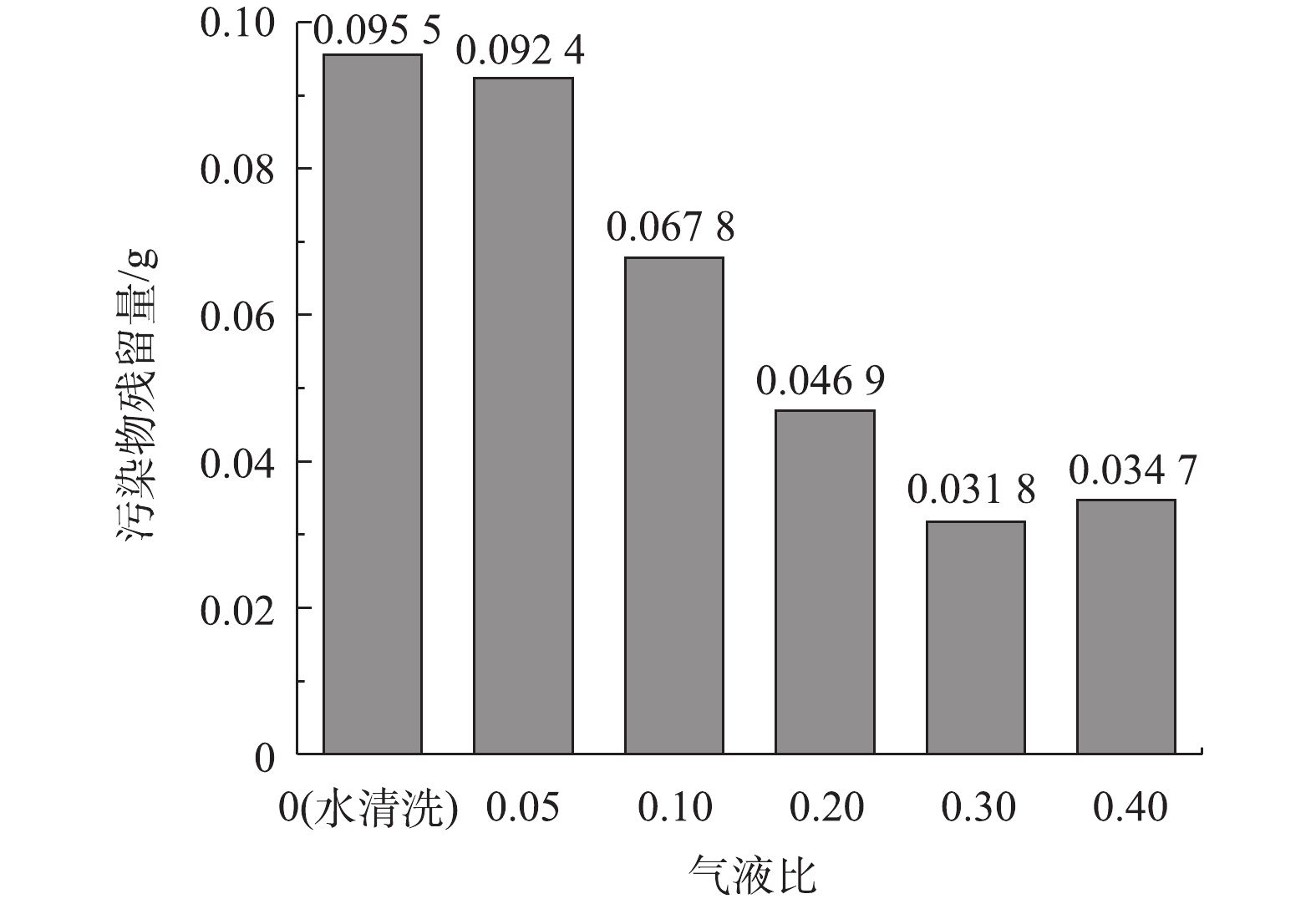

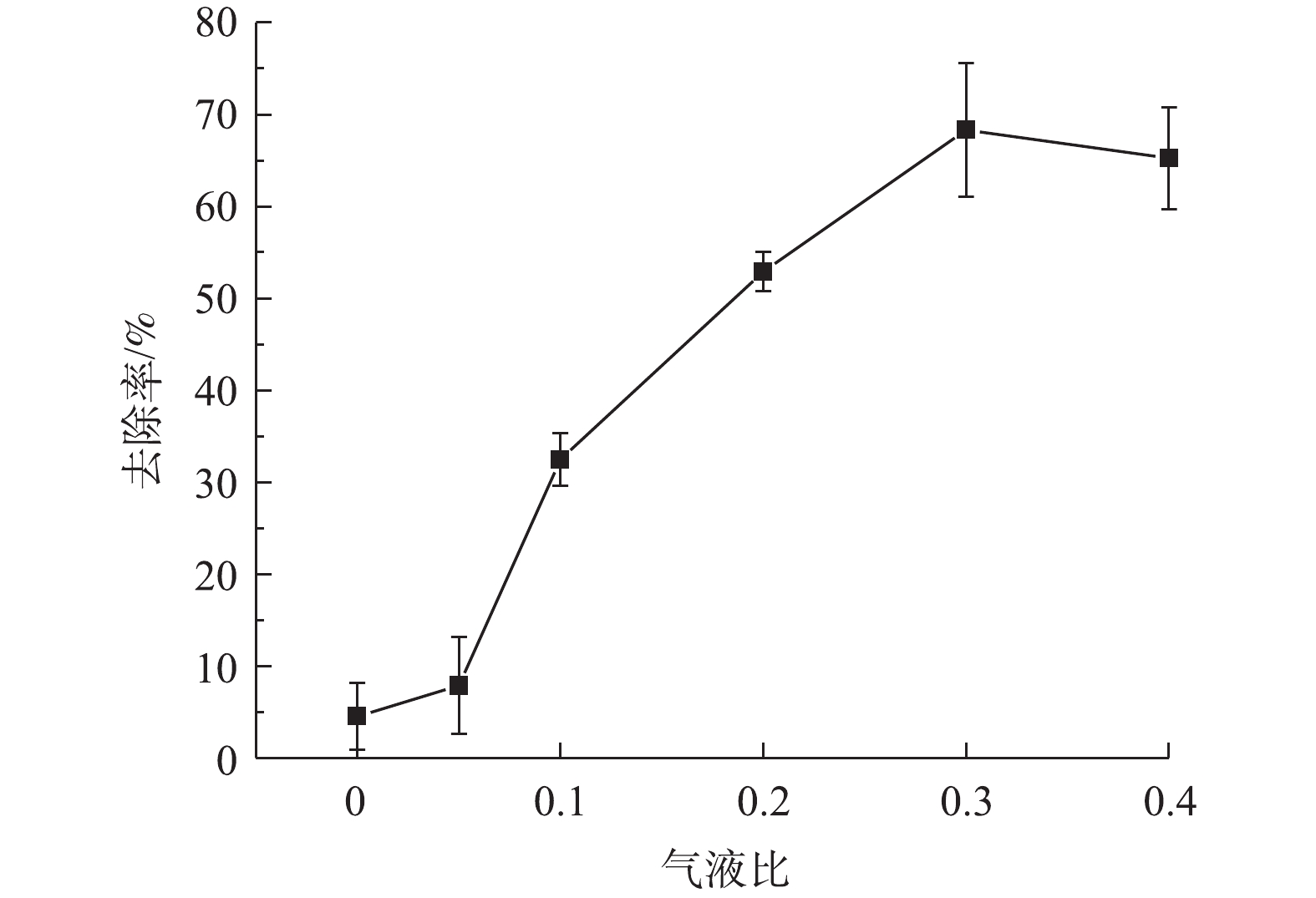

当控制清洗时间为60 s、液体流量为2.5 L·min−1时,在与水流垂直的方向放置基底玻璃片,并使之与气泡发生喷嘴出口相距10 cm,每次实验固定初始污染物为0.100 0 g,考察污染物的清洗效果。图5为不同气液比下,清洗前后污染物在玻璃载片上残留样貌的显微镜图像;图6为清洗后玻璃载片上污染物的残留量。当仅使用水流清洗时,污染物仍残留0.095 5 g,且通过对比清洗前后的显微镜照片可知,污染物样貌并无明显变化;当调节气液比为0.05时,清洗效果与仅用水清洗时的效果相近,污染物残留量仅降低到0.092 4 g;当调节气液比为0.1时,污染物残留降低到0.067 8 g,清洗效果有明显提升;而当气液比大于0.2时,玻璃基底上开始出现部分清洁区域,并且因硅油减少而使油膜变薄,未被去除的颗粒物在流体冲击作用下形成污染物聚集;当气液比为0.3和0.4时,玻璃基底表面出现大部分清洁区域,污染物质量降低到0.035 0 g以下,所以在这2种工况下玻璃基底上油污清洗的强化作用很明显。

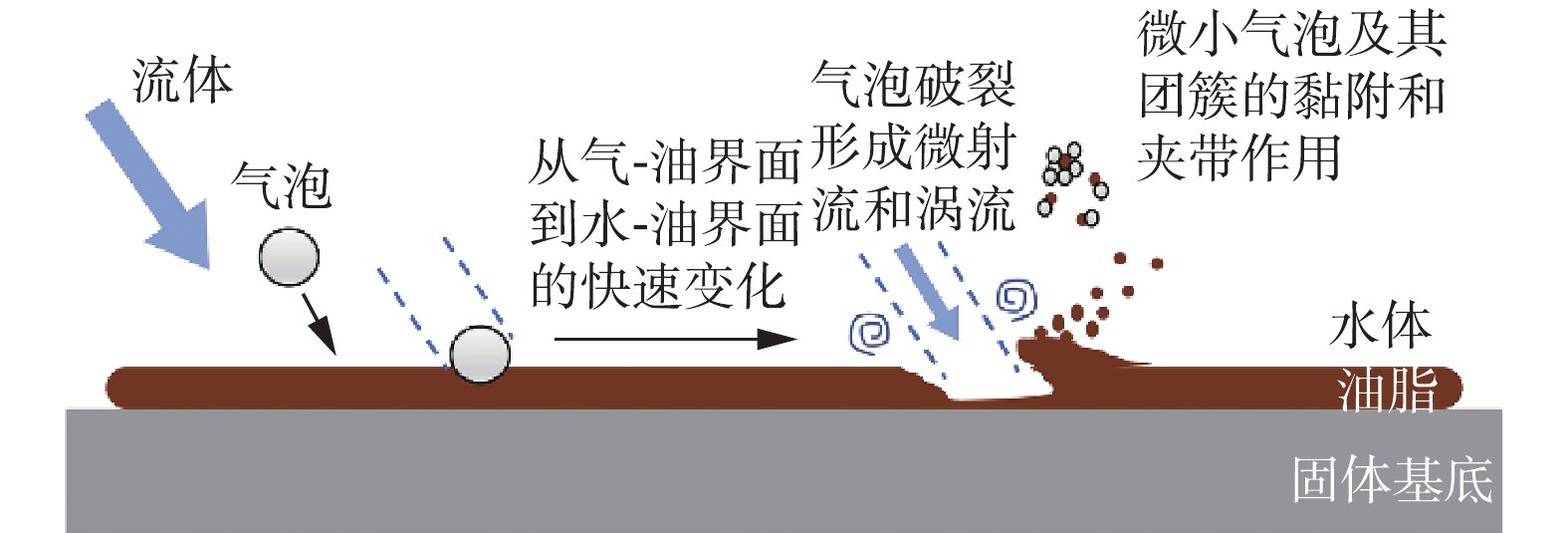

通过对气泡清洗玻璃基底上污染物去除率的计算,可以更直观地观察气泡尺寸差异的影响(见图7)。水清洗的去除效率仅为4.5%,加入平均直径为80 μm的微小气泡后,对去除效率的影响也非常有限,去除率仅为7.8%。然而,随着气泡尺寸的增加,去除率也随之逐步提高。平均尺寸为800 μm的气泡对污染物的清洗效果最好,去除效率达到了68.3%。而气液比为0.4时,气泡平均尺寸为1 200 μm,去除率却略低于800 μm的气泡。分析其原因,可能是由于此时的气泡更大,但数量相对减少,更容易破裂和上浮,在玻璃基底上的作用范围相对减小。根据实验现象和结果,结合现有研究分析,气泡清洗固体表面油脂的过程和机制如图8所示。流体夹带气泡接触油脂层,气泡流动引起气水界面快速变化[6],当较大气泡溃灭时,形成微小水射流并在周围形成涡流[8,17]。根据FOLDYNA等[18]的研究,与连续的液体射流相比,一滴或一团液体撞击目标会产生更高的冲击压力,从而对油脂带来额外冲击并促使其脱落;另外,尺寸微小的气泡具有比表面积大、表面带负电荷等特性,能够粘附脱落的油脂[3],与尾流夹带作用携带的油脂一起上浮[19],最终完成清洗去除过程。

-

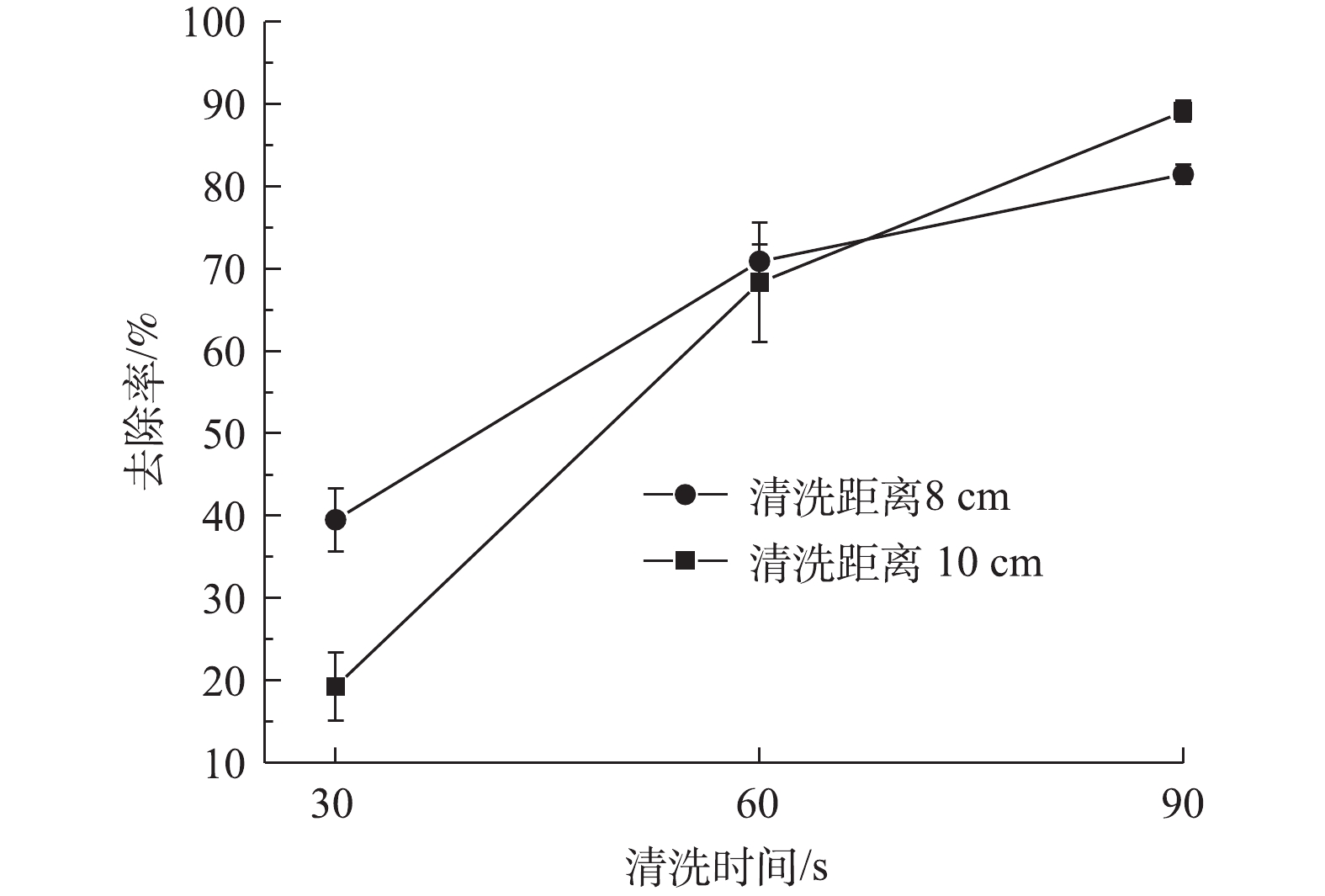

在相同操作条件下,产生的气泡在不同位置有不同的尺寸分布,且处理时间的变化也会影响对污染物的去除,所以又进一步研究了清洗距离和时间对清洗效果的影响。实验条件为,控制气体流量至0.750 L·min−1,即保持气液比为0.3固定不变,每次实验固定初始污染物为0.100 0 g,分别把玻璃基底放置于距离气泡发生器出口8 cm和10 cm处,并分别处理30、60和90 s。表1为不同实验条件下,清洗后玻璃基底上污染物残留量;图9为不同清洗时间和距离条件下的去除率。结果表明,随着清洗时间的增加,去除效果是增强的。当处理时间固定在30 s时,清洗距离为8 cm的条件下,去除效率为39.5%,高于清洗距离为10 cm的去除率(19.1%);而当处理时间为60 s时,清洗距离为8 cm的条件下去除效率提高至71.0%,而清洗距离为10 cm条件下去除效率也有较大提升,两者相差仅2.8%;当处理时间增加至90 s时,清洗距离10 cm条件下去除效率达到89.0%,反而高于8 cm距离条件下的81.4%。分析其原因,距离10 cm处的气泡分布更为分散,作用范围更大,在处理时间更充足的情况下会累积更好的清洗效果。由此说明,继续增加处理时间也不能较大幅度地提升清洗效果,而气泡清洗作用是有距离限制的,即在其他反应条件不变的情况下,存在一个最佳清洗距离,所以在清洗过程中应选择合适的清洗距离和时间。

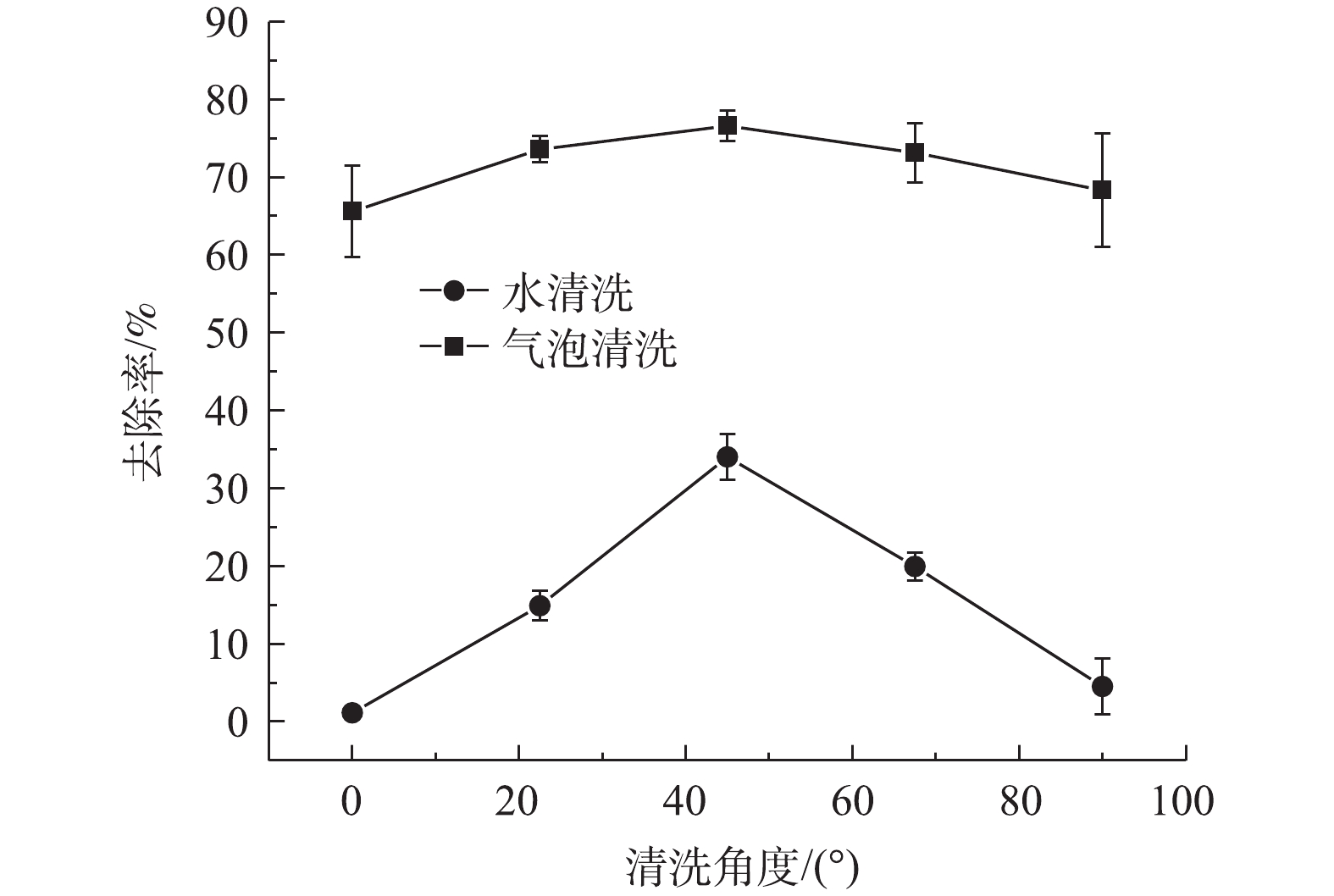

另外,基底放置的角度对清洗效果也有影响。玻璃基底表面与清洗水流流动方向的夹角即清洗角度。清洗角度为0°,即指玻璃片平行于水流方向放置;清洗角度90°,即指垂直于水流方向放置。控制气液比为0.3、清洗距离为10 cm、清洗时间为60 s不变,分别在清洗角度为0°、22.5°、45.0°、67.5°和90.0°时进行实验。清洗后玻璃表面污染物残留量如表2所示,去除率如图10所示。结果显示,不管是水清洗还是气泡清洗,当清洗角度设置为45°,都获得了更好的清洗效果。尤以水清洗的对比更为明显,当放置角度为0°和90°时,去除效率均不到5.0%;而放置角度为45°时,去除效率提高至35.0%。因此,为便于污染物从表面去除,应将基底按特定角度放置。

2.1. 气液比对气泡尺寸分布的影响

2.2. 气泡尺寸对清洗效果的影响

2.3. 清洗参数对清洗效果的影响

-

1)调节气泡发生器的入水气液比,可以得到不同尺寸的气泡。当比值在0.05~0.4内调节时,利用高速摄像机和图像处理软件可测得气泡的平均尺寸为80~1 200 μm。

2)设置清洗距离为10 cm,在与水流垂直的方向放置基底,在清洗时间为60 s、液体流量为2.5 L·min−1的条件下,采用单独水洗和微小气泡清洗2种方式对污染物的去除率均不到10%,且清洗效果随气泡尺寸的增大而增强。当气液比为0.3,即气泡平均尺寸约为800 μm时,清洗效果最好,污染物的去除率达到68.3%。

3)当处理时间为较短的30 s时,清洗距离选择8 cm,清洗效果更好;而当处理时间为较充足的90 s时,由于清洗距离为8 cm处的气泡更为分散,作用范围更大,该条件下气泡清洗效果更好。另外,当把基底放置在与水流方向呈45°夹角时,清洗效果最好。

下载:

下载: