-

纳滤(NF)膜是一种分离尺度介于超滤膜和反渗透膜之间的新型压力驱动分离膜[1-2]。由于其操作压力低、条件温和、分离效率高,已在海水脱盐、药物分离、食品加工以及水处理等领域得到广泛应用[3-4]。然而,随着应用的深入,膜处理的环境越来越复杂(如高温、高压),对膜材料提出了更高的要求[5]。与大多数只能在50 ℃下使用的商业化膜相比,耐高温纳滤膜可用于处理各种热流体,无需严格的温度控制,生产率将大大提高[6]。特别是在高温操作条件下,提高运行温度有助于提高膜通量和减少膜污染,这对能量回收和降低成本具有重要意义[7]。因此,开发具有热稳定性的纳滤膜具有重要意义。

凯夫拉(PPTA)具有优异的机械强度、热稳定性以及化学稳定性,是制备超滤膜的合适材料,可用于某些极端条件,如高温废水处理[8-9]。然而,PPTA具有高结晶度,难溶于大部分常规溶剂,制备条件苛刻,在膜领域的相关研究较少[10-11]。Nakura等[12]与Zschock等[13]以PPTA为成膜聚合物分别制备了PPTA超滤膜,前者研究了PPTA成膜条件,渗透性能;后者研究了膜的耐溶剂性能。然而,所得膜分离精度上仍需要进一步完善。Wang等[10]以PPTA为原料制备了PPTA中空纤维膜,所得膜表现出优异的耐热性和抗污染性能,但力学性能较差。此外,PPTA中空纤维膜仅为超滤膜,对于染料、无机盐等物质的分离性能仍有待进一步提高。因此,为了提高膜的分离精度,有必要对PPTA超滤膜进一步改性。

聚吡咯(PPy)具有良好的亲水性、优异的热稳定性、易于聚合,被广泛应用于改善膜的性能[14-15]。目前,电化学聚合法和化学气相沉积法(CVD)是两种常用的PPy合成方法。相较于电化学聚合法,化学气相沉积法操作简单,控制因素相对较少[16-17]。Shao等[18]以过硫酸铵为氧化剂,在水解聚丙烯腈(PAN-H)超滤膜表面原位聚合PPy分离层以制备复合纳滤膜,所得复合纳滤膜对异丙醇的渗透通量为12.1 L·m−2·h·MPa−1,对孟加拉玫瑰红的截留率为99.0%。Liu等[19]采用化学气相沉积法,制备了PVDF/PPy复合纳滤膜,所得膜抗污染性能明显提高。Ji等[20]采用氧化石墨烯(GO)对聚偏氟乙烯(PVDF)超滤膜进行亲水改性,随后采用化学气相沉积法在其表面原位聚合PPy分离层以制备PVDF/GO/PPy复合纳滤膜。与PVDF超滤膜相比,复合纳滤膜亲水性改善,同时对带负电染料具有较高的截留率(˃98.5%)。虽然复合纳滤膜亲水性好、分离精度高及抗污染性好,然而其分离过程都在常温条件下进行,关于气相沉积PPy制备的复合纳滤膜热稳定性研究,鲜有报道。

本文以PPTA为成膜聚合物,PPTA纤维编织管为增强体,采用干-湿法纺丝技术制备同质增强型PPTA 中空纤维膜。随后,通过化学气相沉积法(CVD)在膜表面原位聚合PPy分离层以进一步修饰膜结构,并对所得复合纳滤膜结构和染料脱盐的分离性能进行了研究,为纳滤膜在更高运行温度下处理染料废水提供一定的理论和实验依据。

-

凯夫拉(PPTA,纤维级),苏州兆达特纤科技有限公司;PPTA中空纤维编织管(纤维级),中化高性能纤维材料有限公司;浓硫酸(H2SO4)、N,N-二甲基乙酰胺(DMAc)、聚乙二醇(PEG,Mw=2000 Da),分析纯,上海泰坦科技股份有限公司;吡咯(Py)、亲水二氧化硅(SiO2)、硫酸钠(Na2SO4)、硫酸镁(MgSO4)、氯化钙(CaCl2)、氯化钠(NaCl)、三氯化铁(FeCl3),分析纯,上海阿拉丁生化科技股份有限公司;刚果红(CR,Mw=696.68 g·mol−1)、亚甲基蓝(MB,Mw=373.90 g·mol−1)、曙红Y(EY,Mw=647.89 g·mol−1),分析纯,国药集团化学试剂有限公司;去离子水(实验室自制)。

-

傅里叶变换红外光谱仪,WDF-530型,北京北分瑞利分析仪器有限公司;场发射扫描电子显微镜,Phenom XL型,上海复纳科学仪器有限公司;原子力显微镜,Bruker Dimension Icon型,布鲁克(北京)科技有限公司;固体表面Zeta电位仪,SurPASS型,奥地利Anton Paar公司;液体Zeta电位仪,ZS90型,英国Malvern公司;水接触角测试仪,SDC-350H型,东莞市晟鼎精密仪器有限公司。

-

采用干-湿法纺丝技术制备同质增强型PPTA中空纤维膜。首先,将PPTA树脂和亲水SiO2无机粒子置于真空烘箱(-0.1 MPa,100 ℃)中干燥12 h以移除水分。然后,将上述干燥后的PPTA树脂和亲水SiO2无机粒子与浓硫酸按照1.5:0.5:88比例加入250 mL三口圆底烧瓶中,并在70 ℃恒温水浴中搅拌至充分溶解,形成透明黄色粘稠状混合物。然后,向体系中加入20 g PEG致孔剂,继续搅拌待其充分溶解,经真空脱泡后形成均相铸膜液。随后,将铸膜液加入料釜中,铸膜液经喷丝头与PPTA中空纤维编织管同时挤出,均匀涂敷于纤维编织管外表面,在导丝辊的牵引下,经空气浴后,浸入到凝固浴中固化成形,制得同质增强型PPTA中空纤维膜。然后,经卷绕辊收集后置于去离子水中浸泡,后保存在去离子水中待用。

-

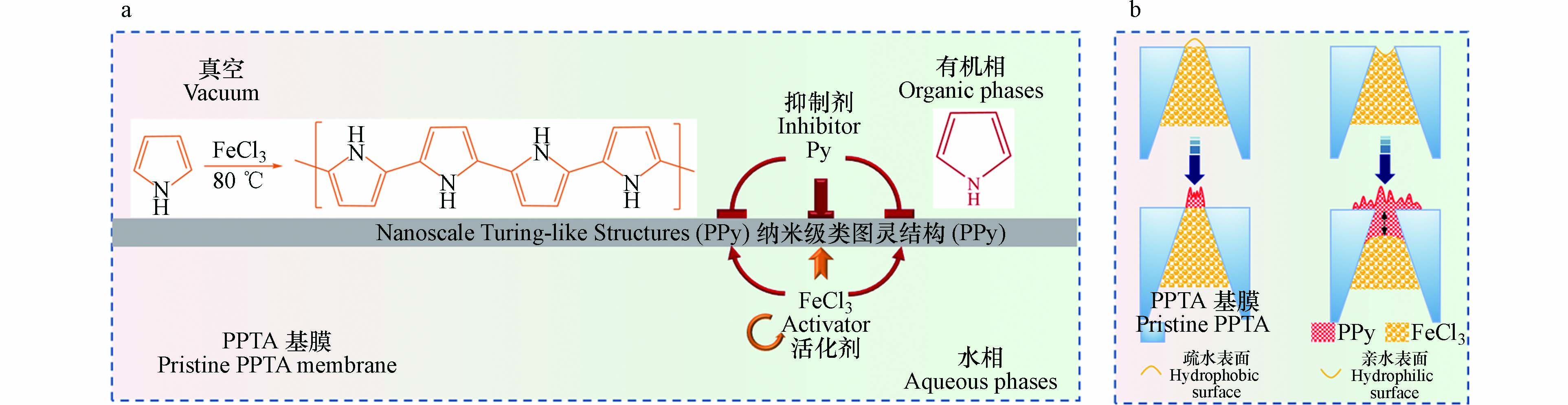

采用化学气相沉积法(CVD)制备PPy/PPTA中空纤维复合纳滤膜,其制备工艺如图1所示。首先,将PPTA基膜浸入质量分数为50%的FeCl3溶液中30 min,取出并用滤纸将基膜表面残余水分除去。将其放置在充满吡咯(Py)气相单体的真空干燥反应器中,以FeCl3为氧化引发剂,在基膜表面进行原位聚合形成疏松致密的PPy分离层。后将反应的膜放置于80 ℃鼓风干燥箱中进一步反应30 min,以稳定膜结构。最后,用去离子水清洗膜以去除未反应的FeCl3溶液,并在空气中晾干得到PPy/PPTA 中空纤维复合纳滤膜。

-

采用上海复纳科学仪器有限公司的Phenom XL场发射电子扫描显微镜(SEM)观察膜样品的形貌结构。膜样品经冷冻干燥处理后,用导电胶粘贴在铝板上,测试前进行喷金处理。采用德国Bruker Dimension Icon原子力显微镜(AFM)观察膜样品表面的粗糙度。采用北京北分瑞利分析仪器有限公司的WDF-530傅里叶变换红外光谱仪(FTIR)对膜样品表面化学结构进行分析,扫描范围为400—4000 cm−1。采用奥地利Anton Paar 的Sur PASS固体表面Zeta电位仪测试分析样品膜表面的电位,以测定复合纳滤膜的荷电性质,测试pH范围为3—10。采用英国马尔文ZS90液体表面Zeta电位仪测试分析染料溶液的电位,以测定染料溶液的荷电性质。采用东莞市晟鼎精密仪器有限公司的SDC-350H水接触角测试仪测定水滴在样品膜表面的静态接触角。微注射器液滴量为5 μL,每个膜样品随机选5个位置进行测试,取其平均值。

采用实验室自制的错流过滤装置在室温0.6 MPa操作压力下,测定PPy/PPTA中空纤维复合纳滤膜对染料和无机盐的分离性能,其中染料和无机盐的浓度分别为100 mg·L−1和1000 mg·L−1。测试之前,在室温0.6 MPa操作压力下对复合纳滤膜进行预压处理30 min,使膜通量达到稳定状态。每个膜样品在相同条件下平行测定3次,取其平均值。采用紫外可见分光光度计和电导率仪分别测试过滤前后染料和无机盐的浓度。根据公式(1)和公式(2)分别计算出复合纳滤膜的水通量(J)和截留率(R)。

式中,J为渗透通量(L·m−2·h−1),V为渗透液的体积(L);A为膜的有效面积(m2);t为渗透时间(h)。

式中,Cf和Cp分别为截留前后溶液的浓度(mg·L−1)。

-

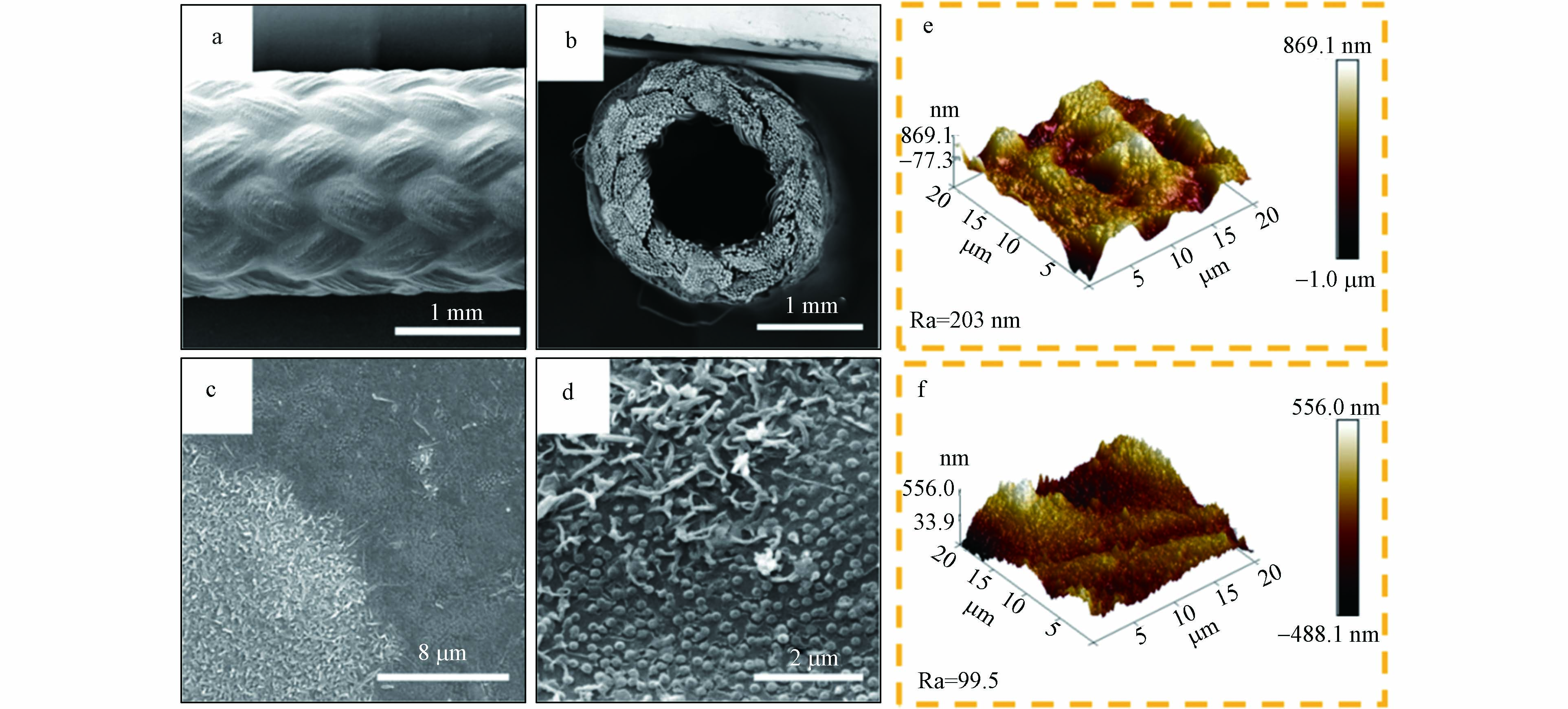

图2为PPTA基膜及PPy/PPTA中空纤维复合纳滤膜表面形貌图。PPTA基膜表面分离层较薄,分离层紧密包裹着PPTA纤维编织管(图2a, b)。这是由于铸膜液浸入水中时发生瞬时液-液相分离[21]。为了进一步提高膜表面电荷和分离精度,经PPy气相沉积后,膜表面形成了与Tan等[22]研究的图灵结构相似,并均匀分布在整个膜表面(图2c)。如图2d所示,这两种结构通常由球形或条状组成,两者单独存在或交联一起。这与Ji和Li等[20,23]之前研究相对均匀的PPy分离层不同,膜表面呈现球形颗粒,这可能支撑层亲疏水有关。

图灵结构的形成需要满足抑制剂的扩散系数必须远大于活化剂的扩散系数,导致“局部活化和横向抑制”, 这是扩散驱动不稳定性的基础[22,24]。本研究以FeCl3为活化剂,Py单体为抑制剂,当含有活化剂的PPTA基膜表面与抑制剂接触时,聚合反应开始。由于Py单体在水中的溶解度很小,聚合反应主要发生在两相界面反应区的有机侧。最初,活化剂在反应区与局部可用的抑制剂反应。随着聚合反应的继续进行,聚合反应扩散至反应区深处(有机相)。最后,在PPTA基膜的孔口区域形成交联PPy分离层。当反应体系满足活化剂和抑制剂扩散系数的适当差异时,导致扩散驱动的不稳定性,并产生球状和条状结构(图3a)。此外,活化剂的弯月面在PPTA基膜的亲水孔中呈凹形(图3b)。因此,在亲水性支撑膜的孔隙深处形成更多的PPy,从而减缓了活化剂扩散速率[25,26]。随着活化剂不断从亲水孔喷入有机相(真空),膜表面逐渐形成了一层PPy分离层,该分离层进一步延缓了活化剂的扩散速率(图3b)。在反应过程中,活化剂被限制在PPTA载体的表面纳米级孔内,其中物理阻碍抑制了活化剂扩散,从而减缓了其扩散速率[26]。

为了证实膜表面形态的变化,使用原子力显微镜(AFM)测量了PPTA基膜和PPy/PPTA中空纤维复合纳滤膜表面粗糙度。如图2e所示,PPTA基膜的表面相对粗糙,PPTA基膜的表面分离层紧密包裹着PPTA中空纤维编织管,导致膜表面不均匀。经PPy气相沉积后,膜表面形成了球形或相互连接条状结构,PPy/PPTA中空纤维复合纳滤膜表面粗糙度略有下降(图2f)。可能是由于这些球形或相条状结构平滑了PPTA中空纤维编织管与表面分离层之间的脊谷与沟壑,这与扫描电镜观察结果一致。因此,结果进一步表明,PPy分离层是在PPTA基膜上形成的。

-

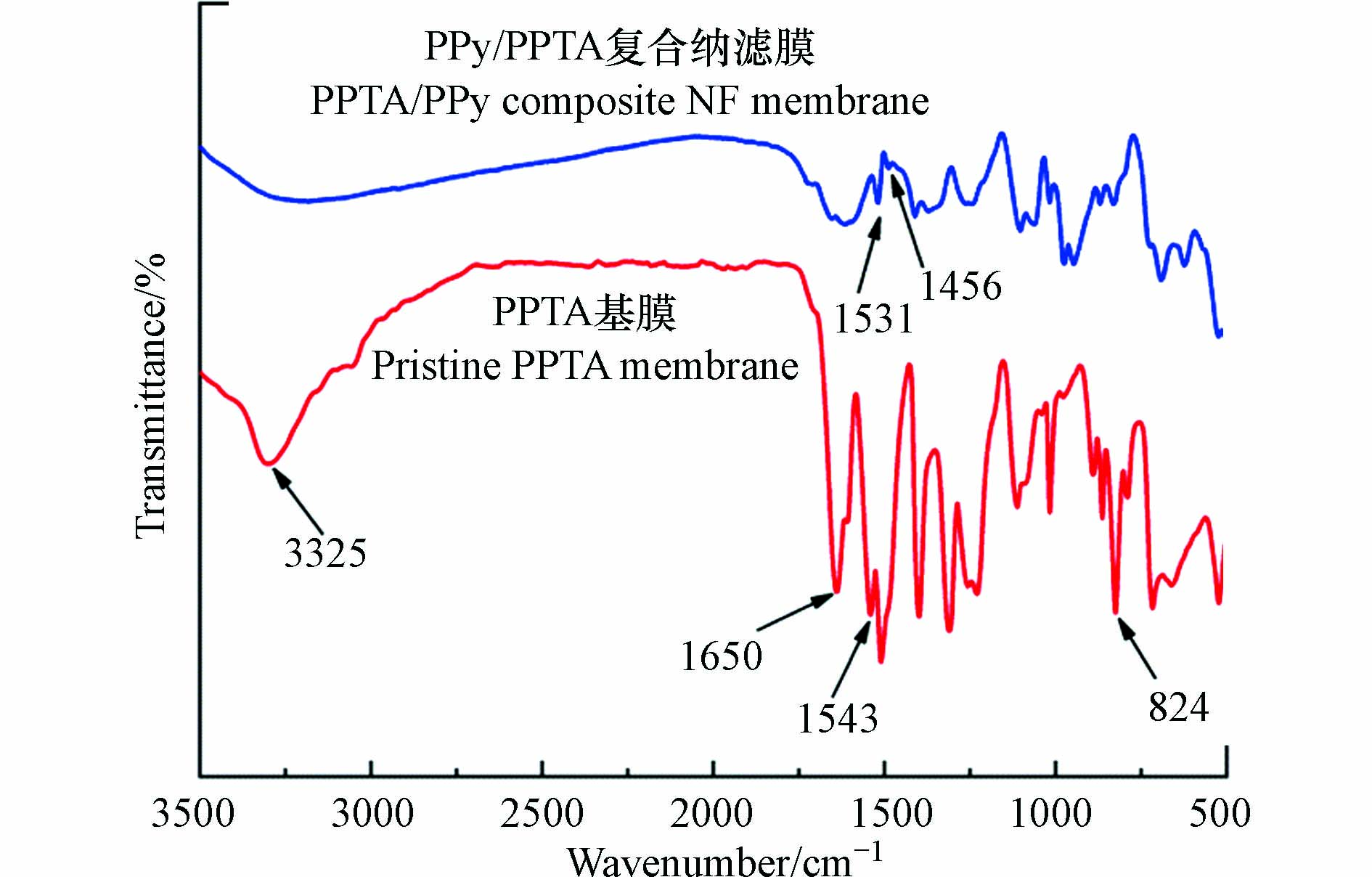

图4为PPTA基膜及PPy/PPTA中空纤维复合纳滤膜的红外光谱图。与PPTA基膜相比,经PPy气相沉积后的PPy/PPTA中空纤维复合纳滤膜,在1531 cm−1和1456 cm−1两处出现了新的吸收峰,这些新的吸收峰主要是由吡咯环的振动造成的[27-28]。此外,PPy/PPTA中空纤维复合纳滤膜表面没有观察到PPTA基膜的吸收峰,表明PPTA基膜表面已被PPy分离层完全覆盖住,由此也证明成功制备了PPy/PPTA中空纤维复合纳滤膜。

-

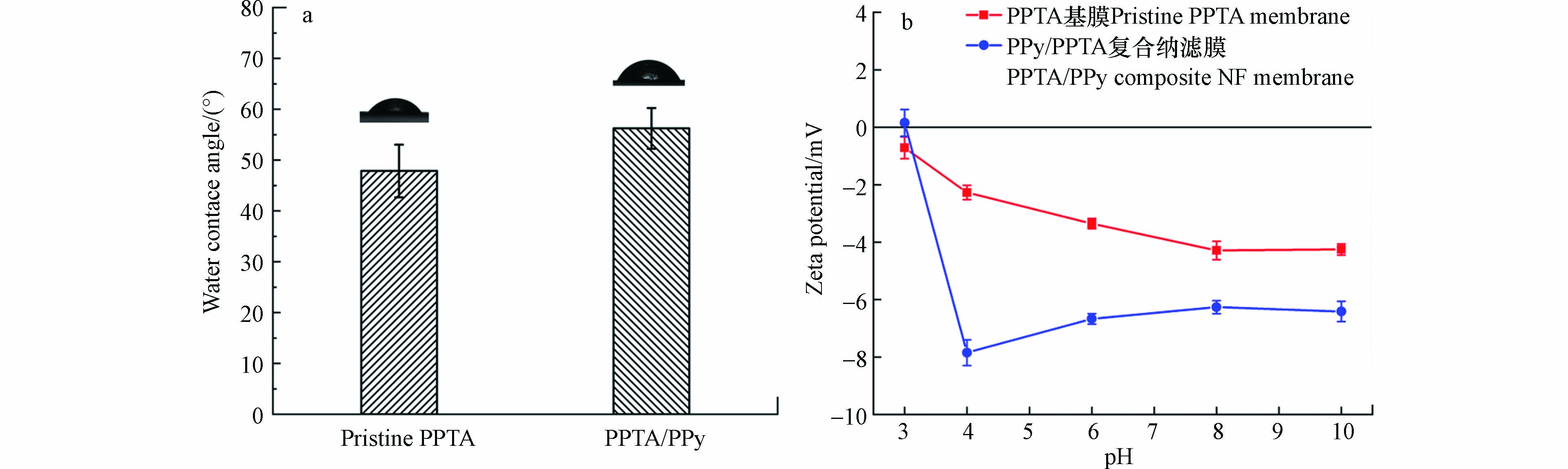

膜表面亲水性是影响渗透性能及抗污染性能的关键因素。一般来说,膜表面亲水性可以通过接触角表征[29-30]。图5a为PPTA基膜和PPy/PPTA中空纤维复合纳滤膜的接触角。PPTA基膜的接触角为47.9º,亲水性较好。PPy在膜表面聚合后,由于良好的亲水性和较大的表面粗糙度,膜仍然表现出较小的接触角。因此,PPy/PPTA中空纤维复合纳滤膜具有良好的亲水性,有利于提高膜的抗污染能力。

在纳滤过程中,纳滤膜在不同pH值下呈现出不同的表面荷电特征,进而影响膜的性能。图5b为PPy/PPTA中空纤维复合纳滤膜的Zeta电位随pH值的变化曲线,由图可见,PPy/PPTA中空纤维复合纳滤膜的等电点为3.2。当pH<3.2时,复合纳滤膜表面呈正的Zeta电位,当pH>3.2时,复合纳滤膜表面呈负的Zeta电位,这与大多数商用纳滤膜表面在中性pH下呈现负荷电性相一致[31]。与PPTA基膜相比,PPy/PPTA中空纤维复合纳滤膜的Zeta电位明显改善,呈现负的Zeta电位。一般来说,PPy的结构具有弱碱性阴离子交换基团,随着pH值的增加,该基团可能被去质子化,从而导致复合纳滤膜呈现较明显的负Zeta电位[32-33]。

-

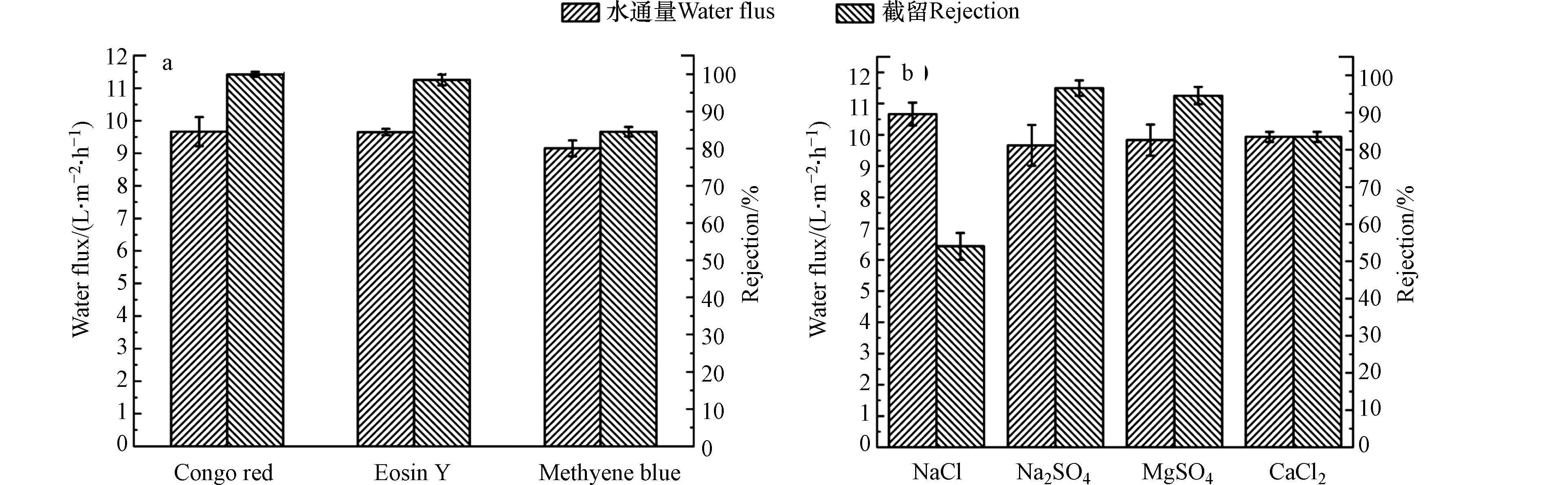

如图6a所示,PPy/PPTA中空纤维复合纳滤膜对不同价态的阴离子和阳离子表现出不同的截留特性,其截留率由高到低依次为:

${\rm{R}}_{{\rm{Na}}_2{\rm{SO}}_4} $ (93.59%)>${\rm{R}}_{{\rm{MgSO}}_4} $ (91.58%) >${\rm{R}}_{{\rm{CaCl}}_2} $ (83.45%) > RNaCl (54.04%),呈现较高的截留率。这与其他文献中报道的带负电的纳滤膜一致[34]。不同的截留率可以用纳滤膜的分离机理来解释,包括Donnan效应和筛分效应[35-36]。根据Donnan效应,带负电的膜表面对二价负离子(SO42−)的排斥力高于一价负离子(Cl−)。相反,结合电中和要求,具有较低化合价的阳离子将促进保留。此外,复合纳滤膜对CaCl2的截留率较高,但对NaCl的截留率较低。这主要是由Na+的水合半径(0.36 nm)小于Ca2+(0.41 nm),且扩散系数较高造成的[30]。因此,所得PPy/PPTA中空纤维复合纳滤膜对荷电物质的截留是Donnan效应和筛分效应两种机制协同作用的结果。如图6b所示,PPy/PPTA中空纤维复合纳滤膜对刚果红(99.95%)和曙红Y(98.82%)呈现较高的截留率,然而,对于亚甲基蓝的截留率较低(85.91%)。PPy/PPTA中空纤维复合纳滤膜对带电染料的分离也可以用Donnan效应和筛分效应来解释[28,37]。刚果红和曙红Y染料分子中都含有带负电荷基团,可能导致这两种染料溶液呈负的Zeta电位。由于Donnan效应和筛分效应的影响,复合纳滤膜对刚果红和曙红Y溶液的排斥力更强,截留效果更好[17]。亚甲基蓝染料分子中含有正基团,可能导致染料溶液呈轻微正的Zeta电位。与刚果红和曙红Y相比,复合纳滤膜对亚甲基蓝的截留率和通量都较低,截留率较低主要是由染料分子量的差异,膜表面电荷的变化对染料截留率的影响有限。而通量较低可能是由于正基团的存在,膜对亚甲基蓝有一定的吸附作用,增加了跨膜的运输阻力,导致相对较低的通量[20]。

此外,还详细研究了染料与无机盐浓度分别对PPy/PPTA中空纤维复合纳滤膜分离刚果红/NaCl混合物的影响,结果如图7所示。如图7a所示,其中NaCl浓度为1000 mg·L−1,随着刚果红浓度从100 mg·L−1增加到1000 mg·L−1,刚果红截留率保持稳定,而水通量略有下降。这是因为膜表面存在浓差极化,染料分子沉积在膜表面形成滤饼层,增加了过滤阻力[38-39]。此外,由于盐离子与带电染料分子耦合,NaCl的截留率略微增加[40]。图7b为NaCl浓度对PPy/PPTA中空纤维复合纳滤膜分离刚果红/NaCl混合物的影响,其中刚果红浓度为100 mg·L−1。随着NaCl浓度从1000 mg·L−1增加到10000 mg·L−1,刚果红截留率保持稳定,而NaCl截留率和水通量下降。这是因为膜驱动力的降低导致水通量的降低,而Na+的静电屏蔽效应的增强降低了NaCl截留率[41]。

-

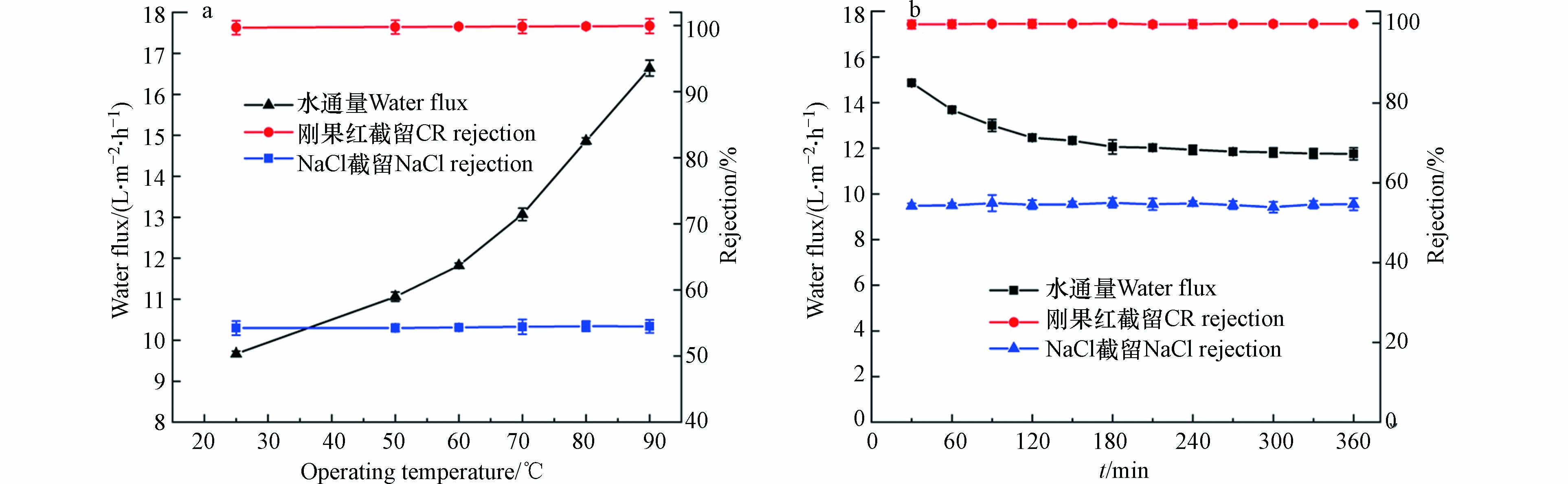

在复合纳滤膜运行过程中,运行温度会对复合纳滤膜分离性能产生一定影响。图8a为运行温度对PPy/PPTA中空纤维复合纳滤膜分离性能影响。由图8a可见,当运行温度从25 ℃升高至90 ℃时,PPy/PPTA中空纤维复合纳滤膜的水通量明显增加,刚果红的截留率几乎保持稳定,而NaCl截留率轻微下降。NaCl截留率轻微下降主要是由温度升高使溶液中的聚合物柔性增加造成的,从而导致NaCl的渗透性发生轻微变化[4]。在实验温度范围内,膜的水通量随温度升高而增大,这是由于水在氢键作用下以缔合体形式存在,这种缔合体的大小取决于温度,提高料液温度,可使水的缔合体尺寸变小,使得水的缔合体更容易在压力作用下透过膜,导致透过通量上升[42]。同时,膜的水通量与温度的关系可由阿伦尼乌斯(Arrhenius)方程解释[43-45],这主要是由溶液粘度的降低、溶剂扩散系数及聚合物链活性增大造成的[7]。因此,通过适当提高运行温度,可以较明显提高PPy/PPTA中空纤维复合纳滤膜水通量并减少膜污染。

为进一步研究PPy/PPTA中空纤维复合纳滤膜的长期热稳定性,选择刚果红/NaCl水溶液体系作为过滤介质,在80 ℃运行温度下连续运行360 min,测定PPy/PPTA中空纤维复合纳滤膜的分离性能,结果如图8b。由图8b可见,刚果红和NaCl的截留率在连续运行360 min内几乎保持稳定而水通量略有下降。水通量略有下降可能是由于染料分子在膜表面沉积导致轻微膜污染所致,表明PPy/PPTA中空纤维复合纳滤膜具有良好的结构稳定性和抗污染性能。这主要是由PPTA基膜优异的热稳定性和高机械性能引起的。随着运行温度的升高,PPTA基膜能够抵抗孔隙膨胀[46]。此外,PPTA基膜的亲水性改善了PPTA基膜与表面功能层的结合,有利于PPy/PPTA中空纤维复合纳滤膜的热稳定性[47]。

-

以同质增强型PPTA中空纤维膜为基膜,采用化学气相沉积法在基膜表面原位聚合PPy分离层,成功制备出具有类图灵结构的PPy/PPTA中空纤维复合纳滤膜。在室温0.6 MPa下,PPy/PPTA中空纤维复合纳滤膜对各种无机盐的截留率依次为RNa2SO4 (93.59%) > RMgSO4 (91.58%) > RCaCl2 (83.45%) > RNaCl (54.04%),表现出较高的脱盐性能,同时对带负电染料表现出较高的截留率(˃98.82%)。此外,PPy/PPTA中空纤维复合纳滤膜具有优异的热稳定性,膜通量在运行温度从25 ℃升高到90 ℃时较明显的增加,而截留率几乎保持稳定。综上所述,制备的PPy/PPTA中空纤维复合纳滤膜在处理高温染料废水中显示出巨大潜力。

聚吡咯/凯夫拉中空纤维复合纳滤膜的制备及其染料脱盐性能

Fabrication of polypyrrole/kevlar hollow fiber composite nanofiltration membrane for dye desalination

-

摘要: 以同质增强型凯夫拉(PPTA)中空纤维膜为基膜,吡咯(Py)和三氯化铁(FeCl3)分别为反应单体和活化剂,采用化学气相沉积法制备了结构稳定、可控的聚吡咯(PPy)/PPTA中空纤维复合纳滤膜。采用FTIR、SEM、AFM、接触角测定仪以及固体表面Zeta电位仪对基膜和PPy/PPTA中空纤维复合纳滤膜的微观形貌、化学组成、亲水性、表面荷电性进行了表征。结果表明,经PPy气相沉积后,PPy/PPTA中空纤维复合纳滤膜表面形成具有图灵结构特征的分离层,并均匀覆盖膜表面。在0.6 MPa室温下,PPy/PPTA中空纤维复合纳滤膜具有较高的的脱盐性能,其顺序为

${R_{{\rm{N}}{{\rm{a}}_2}{\rm{S}}{{\rm{O}}_4}}} $ (93.59%) >${R_{{\rm{MgS}}{{\rm{O}}_4}}} $ (91.58%) >${R_{{\rm{CaC}}{{\rm{l}}_2}}} $ (83.45%) > RNaCl (54.04%),同时对带负电染料表现出较高的截留率(˃98.82%)。当运行温度从25 ℃升高到90 ℃时,PPy/PPTA中空纤维复合纳滤膜的水通量较明显增加,而截留率几乎保持稳定,表现出优异的热稳定性,为纳滤膜在更高运行温度下处理染料废水提供指导。Abstract: A stable and controllable polypyrrole (PPy)/kevlar (PPTA) hollow fiber composite nanofiltration (NF) membrane with homogeneous reinforced PPTA hollow fiber membrane as the substrate was successfully prepared by chemical vapor deposition method. Pyrrole (Py) and ferric chloride (FeCl3) were used as reaction monomers and activators, respectively. The micro-morphology, chemical composition, hydrophilicity and surface charge of the pristine PPTA membrane and PPy/PPTA hollow fiber composite NF membrane was characterized by FTIR, SEM, AFM, contact angle analyzer, and solid surface Zeta potentiometer. The results showed that the surface of PPy/PPTA hollow fiber composite NF membrane formed a separation layer with Turing structure characteristics after PPy vapor deposition, and it evenly covered the membrane surface. At 25 ℃, 0.6 MPa, the as-prepared PPy/PPTA hollow fiber composite NF membrane exhibited not only a superior rejection (˃98.82%) for negatively charged dyes, but also an excellent salt rejection in the order as:${R_{{\rm{N}}{{\rm{a}}_2}{\rm{S}}{{\rm{O}}_4}}} $ (93.59%) >${R_{{\rm{MgS}}{{\rm{O}}_4}}} $ (91.58%) >${R_{{\rm{CaC}}{{\rm{l}}_2}}} $ (83.45%) > RNaCl (54.04%). When the operating temperature increased from 25 °C to 90 °C, the water flux of PPy/PPTA hollow fiber composite NF membrane increased significantly, while the rejection remained almost stable, showing excellent thermal stability. It provided guidance for NF membrane to treat dye wastewater at higher temperature. -

-

图 2 SEM形貌图

Figure 2. SEM images of (a) pristine PPTA membrane,(b) Cross-section of pristine PPTA membrane,(c) PPy/PPTA hollow fiber composite NF membrane,and (d) enlarged outer surface of PPy/PPTA hollow fiber composite NF membrane,and AFM images of the outer surface of (e) pristine PPTA membranes and (f) PPy/PPTA hollow fiber composite NF membrane

图 3 (a)化学气相沉积法形成“类图灵”结构的示意图;(b)PPTA基膜孔结构和化学气相沉积过程形成PPy分离层的概念模型[26]

Figure 3. (a) Schematic diagram of “Turing-like” structure formed by chemical vapor deposition method; (b) Conceptual model illustrating the role of pristine PPTA membrane pore structure and PPy separation layer formed by chemical vapor deposition method[26]

-

[1] 林亚凯, 汪林, 唐元晖, 等. 中空纤维纳滤膜制备方法的研究进展 [J]. 膜科学与技术, 2020, 40(3): 128-135. doi: 10.16159/j.cnki.issn1007-8924.2020.03.017 LIN Y K, WANG L, TANG Y H, et al. Research progress in preparation of hollow fiber nanofiltration membranes [J]. Membrane Science and Technology, 2020, 40(3): 128-135(in Chinese). doi: 10.16159/j.cnki.issn1007-8924.2020.03.017

[2] CAO X L, YAN Y N, ZHOU F Y, et al. Tailoring nanofiltration membranes for effective removing dye intermediates in complex dye-wastewater [J]. Journal of Membrane Science, 2020, 595: 117476. doi: 10.1016/j.memsci.2019.117476 [3] WU C R, ZHANG S H, YANG D L, et al. Preparation, characterization and application of a novel thermal stable composite nanofiltration membrane [J]. Journal of Membrane Science, 2009, 326(2): 429-434. doi: 10.1016/j.memsci.2008.10.033 [4] HAN R L. Formation and characterization of (melamine-TMC) based thin film composite NF membranes for improved thermal and chlorine resistances [J]. Journal of Membrane Science, 2013, 425/426: 176-181. doi: 10.1016/j.memsci.2012.08.017 [5] PENDERGAST M M, HOEK E M V. A review of water treatment membrane nanotechnologies [J]. Energy & Environmental Science, 2011, 4(6): 1946. [6] HAN R L, ZHANG S H, HU L J, et al. Preparation and characterization of thermally stable poly(piperazine amide)/PPBES composite nanofiltration membrane [J]. Journal of Membrane Science, 2011, 370(1/2): 91-96. [7] HU L J, ZHANG S H, HAN R L, et al. Preparation and performance of novel thermally stable polyamide/PPENK composite nanofiltration membranes [J]. Applied Surface Science, 2012, 258(22): 9047-9053. doi: 10.1016/j.apsusc.2012.05.153 [8] 王纯. 对位芳香族聚酰胺多孔膜制备及性能研究[D]. 天津: 天津工业大学, 2016: 8-86. WANG C. Preparation and properties of para aromatic polyamide porous membrane. Tianjin: Tianjin Polytechnic University, 2016: 8-86 (in Chinese)

[9] 赖星, 王纯, 肖长发, 等. 芳香族聚酰胺分离膜制备方法及应用进展 [J]. 纺织学报, 2021, 42(10): 172-179. doi: 10.13475/j.fzxb.20201203808 LAI X, WANG C, XIAO C F, et al. Progress in preparation and application of aromatic polyamide separation membrane [J]. Journal of Textile Research, 2021, 42(10): 172-179(in Chinese). doi: 10.13475/j.fzxb.20201203808

[10] WANG C, XIAO C F, CHEN M X, et al. Unique performance of poly(p-phenylene terephthamide) hollow fiber membranes [J]. Journal of Materials Science, 2016, 51(3): 1522-1531. doi: 10.1007/s10853-015-9473-3 [11] WANG C, XIAO C F, HUANG Q L, et al. A study on structure and properties of poly(p-phenylene terephthamide) hybrid porous membranes [J]. Journal of Membrane Science, 2015, 474: 132-139. doi: 10.1016/j.memsci.2014.09.055 [12] NAKURA K, KAMIZAWA C, MATSUDA M, et al. Preparation of ultrafiltration membranes using poly(p-phenyleneterephthalamide) as a membrane material [J]. membrane, 1992, 17(2): 78-84. doi: 10.5360/membrane.17.78 [13] ZSCHOCKE P, STRATHMANN H. Solvent resistant membranes from poly-(p-phenylene-terephthalamide) [J]. Desalination, 1980, 34(1/2): 69-75. [14] GAO F F, DU X, HAO X G, et al. An electrochemically-switched BPEI-CQD/PPy/PSS membrane for selective separation of dilute copper ions from wastewater [J]. Chemical Engineering Journal, 2017, 328: 293-303. doi: 10.1016/j.cej.2017.06.177 [15] LAWAL A T, WALLACE G G. Vapour phase polymerisation of conducting and non-conducting polymers: A review [J]. Talanta, 2014, 119: 133-143. doi: 10.1016/j.talanta.2013.10.023 [16] ZHANG X H, WANG S S, LU S, et al. Influence of doping anions on structure and properties of electro-polymerized polypyrrole counter electrodes for use in dye-sensitized solar cells [J]. Journal of Power Sources, 2014, 246: 491-498. doi: 10.1016/j.jpowsour.2013.07.098 [17] GUO Z Y, YUAN X S, GENG H Z, et al. High conductive PPy–CNT surface-modified PES membrane with anti-fouling property [J]. Applied Nanoscience, 2018, 8(6): 1597-1606. doi: 10.1007/s13204-018-0826-5 [18] SHAO L, CHENG X Q, WANG Z X, et al. Tuning the performance of polypyrrole-based solvent-resistant composite nanofiltration membranes by optimizing polymerization conditions and incorporating graphene oxide [J]. Journal of Membrane Science, 2014, 452: 82-89. doi: 10.1016/j.memsci.2013.10.021 [19] LIU J D, TIAN C, XIONG J X, et al. Polypyrrole blending modification for PVDF conductive membrane preparing and fouling mitigation [J]. Journal of Colloid and Interface Science, 2017, 494: 124-129. doi: 10.1016/j.jcis.2017.01.078 [20] JI D W, XIAO C F, ZHAO J, et al. Green preparation of polyvinylidene fluoride loose nanofiltration hollow fiber membranes with multilayer structure for treating textile wastewater [J]. Science of the Total Environment, 2021, 754: 141848. doi: 10.1016/j.scitotenv.2020.141848 [21] ALSALHY Q F. Hollow fiber ultrafiltration membranes prepared from blends of poly (vinyl chloride) and polystyrene [J]. Desalination, 2012, 294: 44-52. doi: 10.1016/j.desal.2012.03.008 [22] TAN Z, CHEN S F, PENG X S, et al. Polyamide membranes with nanoscale Turing structures for water purification [J]. Science, 2018, 360(6388): 518-521. doi: 10.1126/science.aar6308 [23] LI X F, VANDEZANDE P, VANKELECOM I F J. Polypyrrole modified solvent resistant nanofiltration membranes [J]. Journal of Membrane Science, 2008, 320(1/2): 143-150. [24] TURING A M. The chemical basis of morphogenesis [J]. Bulletin of Mathematical Biology, 1990, 52(1/2): 153-197. [25] GHOSH A K, HOEK E M V. Impacts of support membrane structure and chemistry on polyamide-polysulfone interfacial composite membranes [J]. Journal of Membrane Science, 2009, 336(1/2): 140-148. [26] LAI X, WANG C, WANG L M, et al. A novel PPTA/PPy composite organic solvent nanofiltration (OSN) membrane prepared by chemical vapor deposition for organic dye wastewater treatment [J]. Journal of Water Process Engineering, 2022, 45: 102533. doi: 10.1016/j.jwpe.2021.102533 [27] LI H B, SHI W Y, ZHANG Y F, et al. Preparation of hydrophilic PVDF/PPTA blend membranes by in situ polycondensation and its application in the treatment of landfill leachate [J]. Applied Surface Science, 2015, 346: 134-146. doi: 10.1016/j.apsusc.2015.04.027 [28] SHI Q, NI L, ZHANG Y F, et al. Poly(p-phenylene terephthamide) embedded in a polysulfone as the substrate for improving compaction resistance and adhesion of a thin film composite polyamide membrane [J]. Journal of Materials Chemistry A, 2017, 5(26): 13610-13624. doi: 10.1039/C7TA02552A [29] MI Y F, WANG N, QI Q, et al. A loose polyamide nanofiltration membrane prepared by polyether amine interfacial polymerization for dye desalination [J]. Separation and Purification Technology, 2020, 248: 117079. doi: 10.1016/j.seppur.2020.117079 [30] JI D W, XIAO C F, AN S L, et al. Preparation of high-flux PSF/GO loose nanofiltration hollow fiber membranes with dense-loose structure for treating textile wastewater [J]. Chemical Engineering Journal, 2019, 363: 33-42. doi: 10.1016/j.cej.2019.01.111 [31] WANG T, HE X P, LI Y, et al. Novel poly(piperazine-amide) (PA) nanofiltration membrane based poly(m-phenylene isophthalamide) (PMIA) hollow fiber substrate for treatment of dye solutions [J]. Chemical Engineering Journal, 2018, 351: 1013-1026. doi: 10.1016/j.cej.2018.06.165 [32] LIU L F, ZHAO F, LIU J D, et al. Preparation of highly conductive cathodic membrane with graphene (oxide)/PPy and the membrane antifouling property in filtrating yeast suspensions in EMBR [J]. Journal of Membrane Science, 2013, 437: 99-107. doi: 10.1016/j.memsci.2013.02.045 [33] SALEHI E, MADAENI S S. Influence of conductive surface on adsorption behavior of ultrafiltration membrane [J]. Applied Surface Science, 2010, 256(10): 3010-3017. doi: 10.1016/j.apsusc.2009.11.065 [34] LIU H Q, CHEN Y B, ZHANG K, et al. Poly(vinylidene fluoride) hollow fiber membrane for high-efficiency separation of dyes-salts [J]. Journal of Membrane Science, 2019, 578: 43-52. doi: 10.1016/j.memsci.2019.02.029 [35] YE C C, ZHAO F Y, WU J K, et al. Sulfated polyelectrolyte complex nanoparticles structured nanoflitration membrane for dye desalination [J]. Chemical Engineering Journal, 2017, 307: 526-536. doi: 10.1016/j.cej.2016.08.122 [36] 崔月, 许云秋, 姚之侃, 等. 正电型PVC/PEI复合纳滤膜的制备及其盐/染料分离性能 [J]. 功能材料, 2014, 45(24): 24050-24054. doi: 10.3969/j.issn.1001-9731.2014.24.010 CUI Y, XU Y Q, YAO Z K, et al. Fabrication anddye-salt separation of positively charged PVC/PEI composite nanofiltration membranes [J]. Journal of Functional Materials, 2014, 45(24): 24050-24054(in Chinese). doi: 10.3969/j.issn.1001-9731.2014.24.010

[37] 冀大伟. 熔融纺丝-热拉伸法PVDF中空纤维膜结构设计与性能优化[D]. 天津: 天津工业大学, 2021: 43-99. JI D W. tructure design and performance optimization of PVDF hollow fiber membrane by melt spinning-hot drawing method. Tianjin: Tianjin Polytechnic University, 2021: 43-99. (in Chinese)

[38] WANG L, WANG N X, ZHANG G J, et al. Covalent crosslinked assembly of tubular ceramic-based multilayer nanofiltration membranes for dye desalination [J]. AIChE Journal, 2013, 59(10): 3834-3842. doi: 10.1002/aic.14093 [39] YU S C, ZHENG Y P, ZHOU Q, et al. Facile modification of polypropylene hollow fiber microfiltration membranes for nanofiltration [J]. Desalination, 2012, 298: 49-58. doi: 10.1016/j.desal.2012.04.027 [40] ALVENTOSA-DELARA E, BARREDO-DAMAS S, ZURIAGA-AGUSTÍ E, et al. Ultrafiltration ceramic membrane performance during the treatment of model solutions containing dye and salt [J]. Separation and Purification Technology, 2014, 129: 96-105. doi: 10.1016/j.seppur.2014.04.001 [41] ZHONG P S, WIDJOJO N, CHUNG T S, et al. Positively charged nanofiltration (NF) membranes via UV grafting on sulfonated polyphenylenesulfone (sPPSU) for effective removal of textile dyes from wastewater [J]. Journal of Membrane Science, 2012, 417/418: 52-60. doi: 10.1016/j.memsci.2012.06.013 [42] 张钦库, 朱建领, 刘康怀. 膜分离技术处理百草枯生产废水实验研究 [J]. 膜科学与技术, 2014, 34(4): 94-99. doi: 10.3969/j.issn.1007-8924.2014.04.018 ZHANG Q K, ZHU J L, LIU K H. Paraquat wastewater treatment by the membrane-based nanofiltration and reverse osmosis processes [J]. Membrane Science and Technology, 2014, 34(4): 94-99(in Chinese). doi: 10.3969/j.issn.1007-8924.2014.04.018

[43] FREGER V, ARNOT T C, HOWELL J A. Separation of concentrated organic/inorganic salt mixtures by nanofiltration [J]. Journal of Membrane Science, 2000, 178(1/2): 185-193. [44] TSURU T, SUDOU T, KAWAHARA S I, et al. Permeation of liquids through inorganic nanofiltration membranes [J]. Journal of Colloid and Interface Science, 2000, 228(2): 292-296. doi: 10.1006/jcis.2000.6955 [45] 杨兴涛. 纳滤处理电镀废水实验研究[D]. 天津: 天津大学, 2006: 49-55. YANG X T. Experimental study on treatment of electroplating wastewater by nanofiltration[D]. Tianjin: Tianjin University, 2006: 49-55 (in Chinese).

[46] BA C Y, ECONOMY J. Preparation of PMDA/ODA polyimide membrane for use as substrate in a thermally stable composite reverse osmosis membrane [J]. Journal of Membrane Science, 2010, 363(1/2): 140-148. [47] SONG Y J, LIU F A, SUN B H. Preparation, characterization, and application of thin film composite nanofiltration membranes [J]. Journal of Applied Polymer Science, 2005, 95(5): 1251-1261. doi: 10.1002/app.21338 -

下载:

下载: