-

餐饮行业的餐厨垃圾产量逐年递增[1-2]。据联合国粮食及农业组织(Food and Agriculture Organization of the United Nations,FAO)统计,目前全球每年产生的餐厨垃圾约16亿吨,预计到2025年,全球每年餐厨垃圾产量可能会高达25亿吨[3]。“预处理+厌氧消化”因其处理量大、占地面积小、臭味小、废物资源化等优点已成为餐厨垃圾处理的主流工艺[4-5]。但餐厨垃圾厌氧消化过程中会产生大量高COD、高NH4+-N、高SS、高油脂、高盐的餐厨垃圾厌氧沼液[6]。餐厨沼液的资源化、无害化处理成为亟待解决的市政、环境和公共卫生问题[7-9]。目前,餐厨沼液处理多采用“预处理+生化+深度处理”相结合的工艺。生化处理主要包括SBR工艺、A/O工艺、MBR工艺等,但大都具有碳源与碱度不足、脱氮能力有限、处理成本过高、运行维护难度高等问题[10],应探索更高效、节能的餐厨沼液处理工艺[11]。

厌氧氨氧化(anaerobic ammonium oxidation,anammox)因具有节省曝气能耗、无需外加碳源、污泥产量低、运行成本低等优势[12-13],自1995年被发现以来便成为污水处理领域的研究热点[14]。一段式短程硝化-厌氧氨氧化工艺(partial nitrification/anammox,PN/A)是先通过氨氧化细菌(aerobic ammonia-oxidizing bacteria,AOB)将污水中的部分NH4+-N好氧氧化为NO2−-N,再通过厌氧氨氧化菌(anaerobic ammonia oxidizing bacteria,AnAOB)的代谢作用,将剩余的NH4+-N与NO2−-N转化为NO3−-N和N2。该工艺主要应用于垃圾渗滤液[15]、化工废水[16]、养殖废水[17]等高氨氮废水的处理,在餐厨沼液处理方面却鲜有报道。

膜曝气生物膜反应器(membrane aerated biofilm reactor,MABR)是一项颇具节能潜力的技术,凭借其高效脱氮、占地面积小等优势,逐渐成为研究及应用的热点[18]。MABR具有无泡曝气[19]、异向传质[20]、生物膜分层结构[21]三大特点。将一段式PN/A工艺与MABR反应器耦合处理餐厨沼液,可最大限度地发挥厌氧氨氧化工艺与MABR反应器优势。将陶瓷膜作为预处理去除餐厨沼液中大量COD、SS,再通过微氧曝气工艺的精确供氧实现耗氧有机物的进一步脱除,并保留NH4+-N,最终在MABR中进行深度脱氮。

本研究采用“陶瓷膜-微氧曝气-MABR”组合工艺,在MABR单元中耦合一段式PN/A工艺,以餐厨垃圾厌氧沼液为处理对象,探究该组合工艺对餐厨沼液中主要污染物的去除效果,以期为餐厨垃圾厌氧沼液的处理及厌氧氨氧化的工程应用提供参考。

-

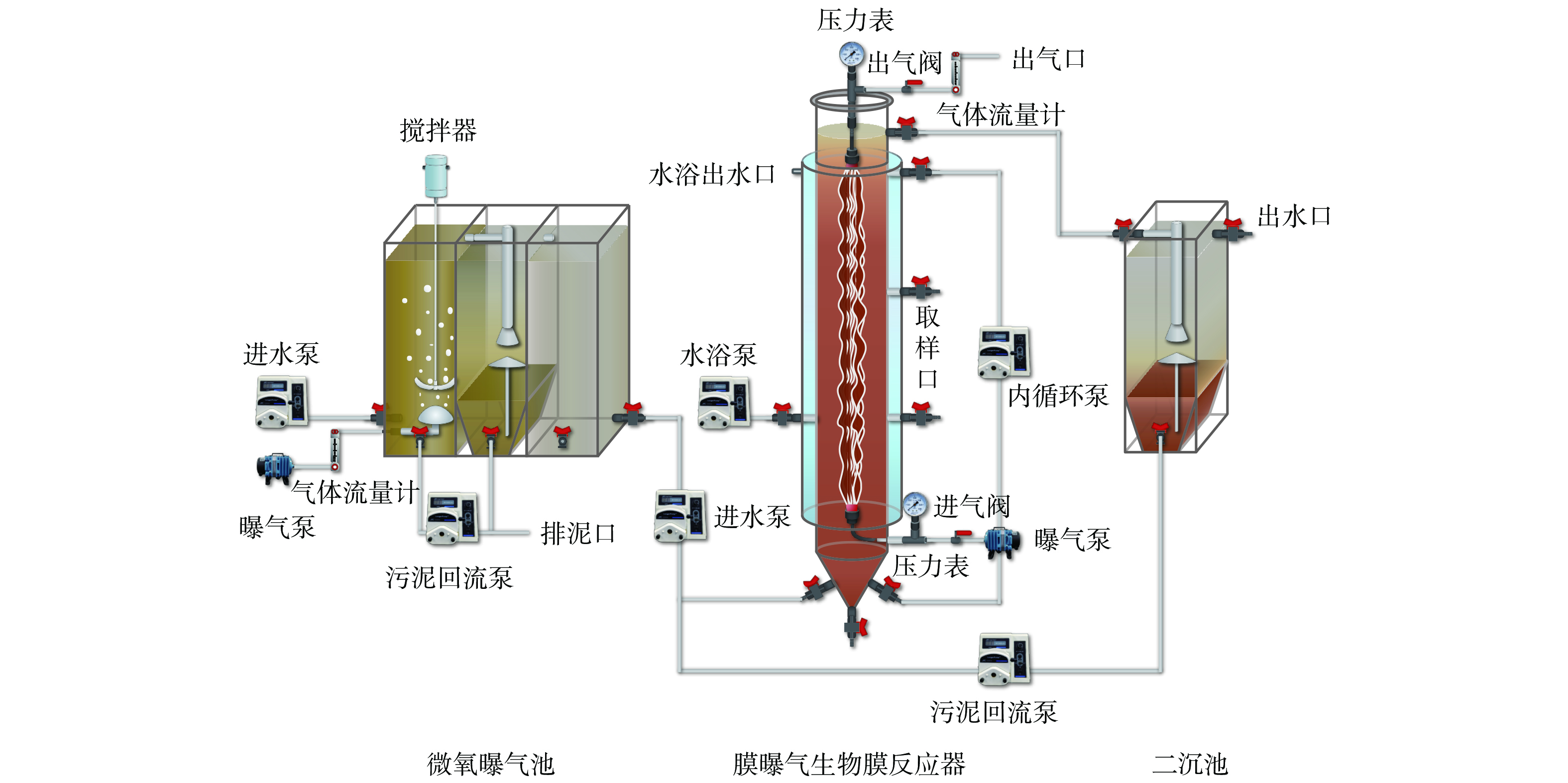

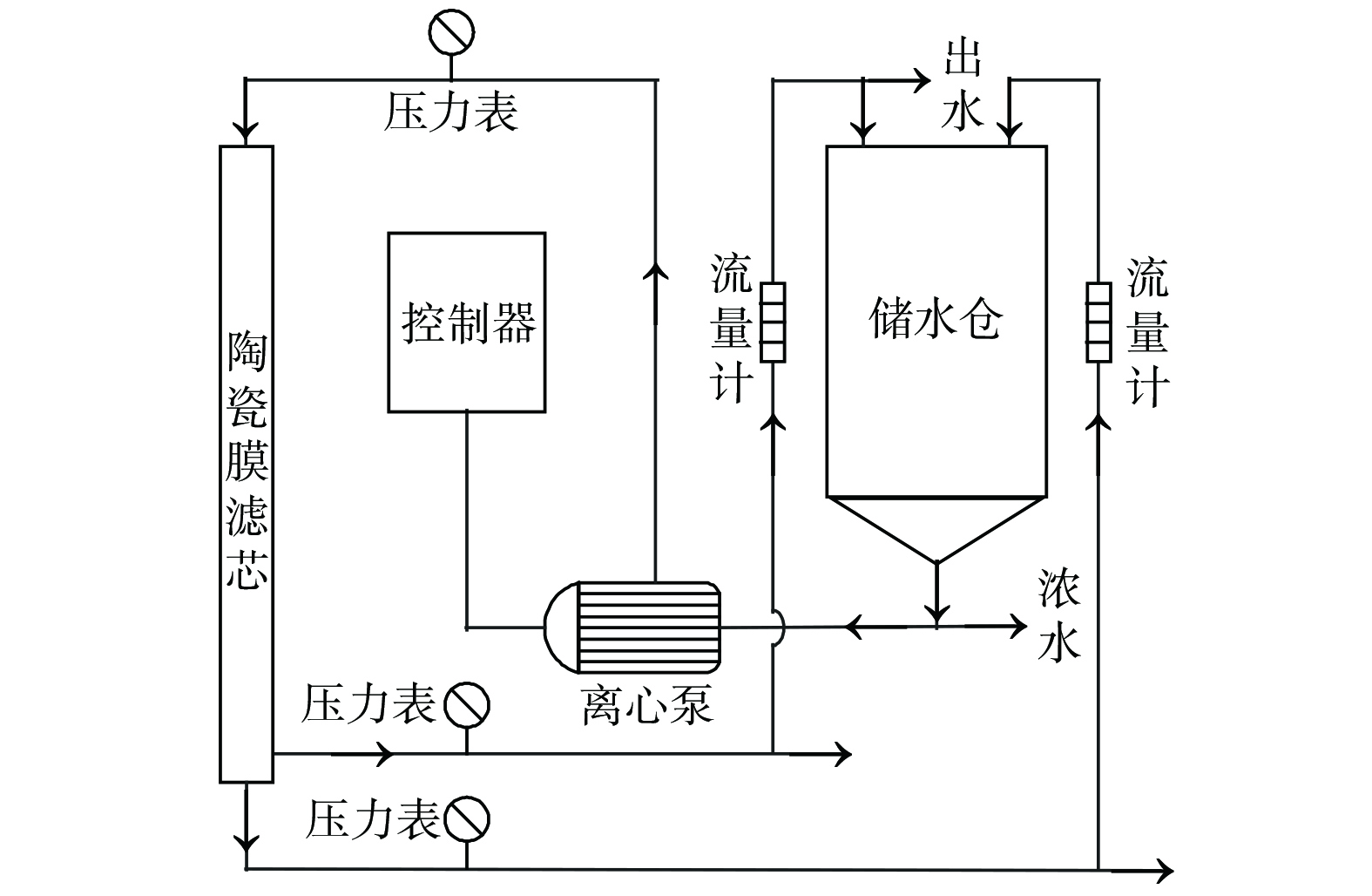

陶瓷膜实验装置如图1所示。装置主体为不锈钢材质,陶瓷膜滤芯为多通道管状,表面积为0.5 m2,储水仓容积为60 L。微氧曝气池与MABR采用连续流运行模式,实验装置如图2所示。各反应器主体均为有机玻璃材质。

微氧曝气池分为3个区域:反应区、沉淀区、中间水池。反应区有效容积为20 L。通过蠕动泵(兰格,BT300-2J)实现进水和污泥回流。由曝气泵(日生,ACO-002)和钛合金曝气头(曝气头孔径为10 μm,直径100 mm,高30 mm)实现连续曝气,曝气量由气体流量计(银环,LZB-3)控制。

MABR有效容积为20 L。微氧曝气池出水和二沉池回流污泥通过蠕动泵进入反应器底部,出水自流至二沉池。设内循环泵优化污泥流化效果。反应器外部设水浴加热层,维持反应器内温度为30~32 ℃。膜组件采用硅胶中空纤维膜,膜丝直径为0.7 mm,自然下垂长度为800 mm,表面积约为0.2 m2。膜组件下方进气口连接曝气泵(日生,ACO-006)向膜丝内腔曝气,进气管一侧连接进气阀和压力表(宜川,YN-60BF),膜组件上方出气管一侧连接压力表、出气阀,通过控制出气阀和尾气压力来实现精准曝气,并连接气体流量计监测尾气流量。

-

微氧曝气池接种污泥为某污水处理厂生化池活性污泥。接种后混合液悬浮固体质量浓度(MLSS)为2 304 mg·L−1,混合液挥发性悬浮固体质量浓度(MLVSS)为1 060 mg·L−1。MABR接种污泥取自某污水处理厂厌氧氨氧化反应器,同时接种厌氧氨氧化颗粒污泥和一段式短程硝化-厌氧氨氧化絮体污泥,体积比为1:1。接种后MLSS为5 886 mg·L−1,MLVSS为3 060 mg·L−1。

实验用水为北京市某餐厨垃圾场内餐厨沼液的气浮池出水,其基本水质指标如下:pH为8.0~8.3,COD为8 000~15 000 mg·L−1,NH4+-N为2 000~3 500 mg·L−1,TN为2 300~3 800 mg·L−1,TP为224~272 mg·L−1,盐度为8~10 g·L−1,TS为25 000~30 000 mg·L−1,VS/TS为52%。

-

首先,使用陶瓷膜对餐厨沼液进行过滤处理。在微氧曝气单元中实现微氧曝气工艺的驯化启动及稳定运行,各阶段运行参数如表1所示。陶瓷膜出水按照一定COD梯度稀释后用作微氧曝气单元的进水。由于餐厨垃圾厂每天处理效果不同及餐厨垃圾季节性差异,故不同批次沼液C/N不同。通过精准曝气、控制SRT来实现微氧曝气单元对沼液中耗氧有机物 (以COD计) 的去除,同时保留大部分NH4+-N。

在MABR中实现一段式短程硝化-厌氧氨氧化工艺的驯化启动及稳定运行,各阶段运行参数如表2所示。待挂膜与污泥驯化成功后逐步提高进水NH4+-N负荷,并通过提高MABR尾气压力来提升供氧能力。在30 ℃、pH为7.8~8.0、水力停留时间为12 h、DO为0.01~0.1 mg·L−1的条件下,探究不同曝气压力下MABR对餐厨沼液的脱氮效果。

-

1) 各项指标测定方法均按照国标法测定[22]。NH4+-N:纳氏试剂分光光度法;NO2−-N:N-(1-萘基)-乙二胺分光光度法;NO3−-N:紫外分光光度法;TN:碱性过硫酸钾消解紫外分光光度法;MLVSS/MLSS:称重法;COD采用美国哈希快速消解法;pH、DO、温度采用德国WTW 3430测定仪测定;盐度采用三信EC 9500型台式电导率仪;TOC:总有机碳测定仪;三维荧光:F-7100型荧光分光光度计。

2) MABR传氧效率计算。

氧气通量的计算公式如式 (1) 所示,氧转移速率如式 (2) 所示。

式中:J为氧气通量,g·d−1·m−2;nin为流入气体的物质的量流量,mol·d−1;nout为流出气体的物质的量流量,mol·d−1;Xin(O2)为进气中氧气的摩尔分数(空气为0.21);Xout(O2)为出气中氧气的摩尔分数(实测);M为氧气分子量,g·mol−1;A为中空纤维膜表面积,m2;OTR为氧气转移速率,g·d−1。

对于气体传输膜,若忽略气体流量沿纤维管腔长度的变化,则氧气传输效率(oxygen transport efficiency,OTE)简单地定义为[23]式 (3) 。

式中:OTE为氧气传输效率;Pin为入口氧气分压,Pa;Pout为出口氧气分压,Pa;

-

在陶瓷膜预处理中,每一批次取300 L餐厨沼液进行过滤。过滤全程不排放浓缩沼液,并向储水仓中不断添加沼液维持60 L高液位,直至所有沼液过滤完毕。可产清水240 L,产水率为80%。陶瓷膜预处理前后餐厨沼液水质指标如表3所示。

-

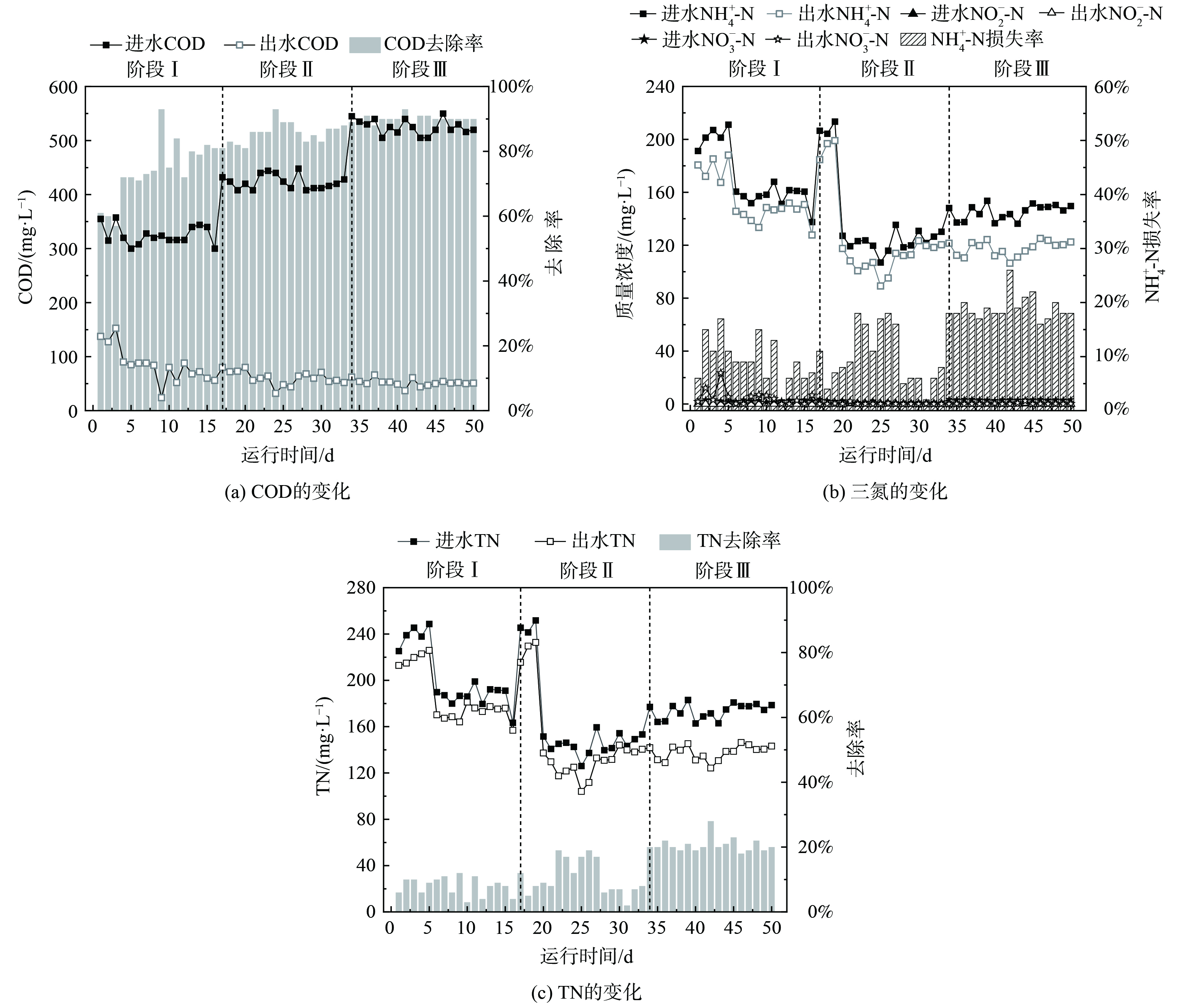

通过精准曝气维持反应区低DO状态,当曝气量较低时,DO会优先被异养菌利用以去除沼液中的耗氧有机物 (以COD计) 。而由于没有足够DO,AOB无法氧化NH4+-N,并将SRT控制在异养菌与AOB的世代时间之间,则可有效淘汰AOB,达到COD降低的同时保留大部分NH4+-N的效果。各阶段的处理效果见图3。

第Ⅰ阶段(1~16 d)为微氧曝气池启动驯化阶段,将进水COD控制在300~350 mg·L−1,曝气量为0.3 L·min−1,污泥回流比为160%。此阶段内,出水COD由137.5 mg·L−1下降到56 mg·L−1,耗氧有机物 (以COD计) 去除率由61.27%上升到81.33%。微氧曝气工艺成功启动,活性污泥中的异养菌可利用餐厨沼液中大量有机物以供自身生长繁殖。反应区DO控制在约0.5 mg·L−1,平均NH4+-N损失率仅有9.33%,达到理想的运行效果。因二沉池DO过低处于缺氧状态,故不可避免发生一部分反硝化反应,导致出水NO3−-N质量浓度极低,TN去除率约为8%。

第Ⅱ阶段(17~33 d)为提负运行阶段,将进水COD控制在400~450 mg·L−1,曝气量提升至0.4 L·min−1,污泥回流比为160%。出水平均COD为60.9 mg·L−1,平均耗氧有机物 (以COD计) 去除率达到85.6%,TN去除率为17%。第20天所用沼液C/N较高,故进水NH4+-N骤降至127 mg·L−1。

第Ⅲ阶段(34~50 d)将进水COD提升至500~550 mg·L−1,曝气量提升至0.5 L·min−1。将污泥回流比上调至180%。此阶段出水COD稳定在约52 mg·L−1,耗氧有机物 (以COD计) 去除率稳定在约90%。此阶段曝气量相对较大,故NH4+-N损失率较前两阶段略有升高,但基本维持在20%以内。硝化反应产生的少量NO3−-N在二沉池内被反硝化去除,TN去除率约为20%。微氧曝气单元达到稳定运行状态,可在去除有机物的同时为MABR单元提供NH4+-N基质。

-

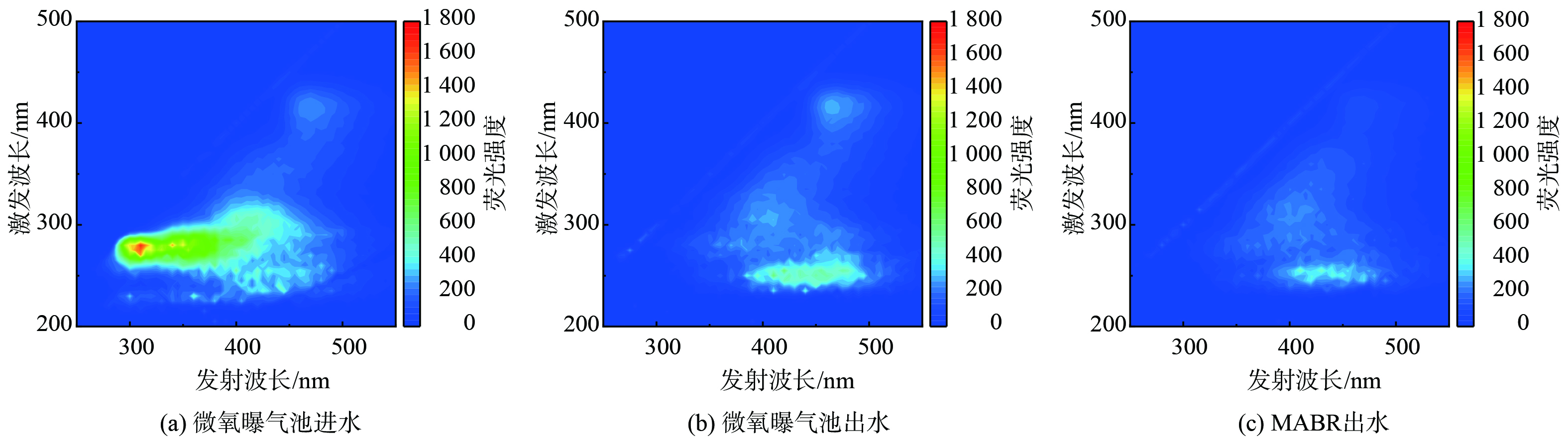

餐厨垃圾厌氧沼液中含有一部分难生物降解溶解性有机物(dissolved organic matter,DOM),使用微氧曝气工艺难以全部去除[24]。为确定其是否会影响后续厌氧氨氧化反应,取微氧曝气池进出水、MABR出水进行三维荧光光谱分析。各单元进出水DOM三维荧光光谱如图4所示。

微氧曝气单元进水三维荧光光谱中有2个较为明显的荧光峰,其位置λex/λem从左至右分别为(270~285) nm/(300~320) nm、280 nm/340 nm,均属于类溶解性微生物代谢产物[25]。微氧曝气池出水和MABR出水三维荧光光谱中均只有一个较为明显的荧光峰,其位置λex/λem分别在(240~260) nm/(400~480) nm、(240~260) nm/(400~470) nm,均属于类富里酸和类腐殖酸,其中包括人造腐殖质[26]、陆生腐殖质[27]、微生物腐殖质[28]。

由图4可知,餐厨沼液中的DOM大部分为类溶解性微生物代谢产物,在经过微氧曝气工艺处理后此类物质几乎完全被去除,这说明微氧曝气单元可大量去除此类物质。微氧曝气池出水中DOM大部分为类富里酸和类腐殖酸,且与MABR出水中DOM的组成无明显差异,又因类富里酸和类腐殖酸难以被生物降解,故可证实微氧曝气池出水中剩余耗氧有机物 (以COD计) 为难生物降解有机物,也说明剩余耗氧有机物 (以COD计) 对MABR中的AnAOB无影响。

-

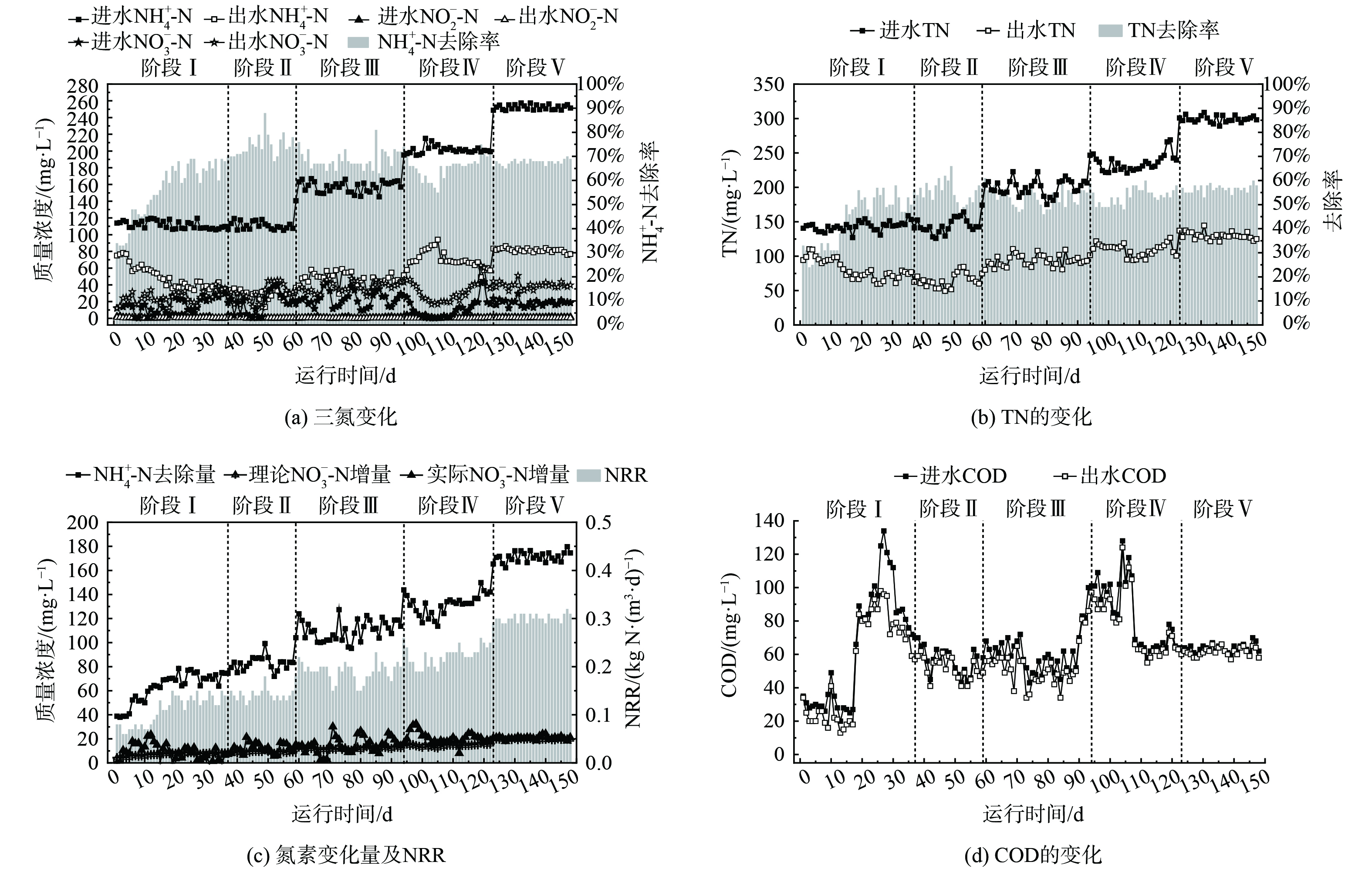

微氧曝气单元第Ⅲ阶段后,开始启动MABR。此后将进出水NH4+-N作为微氧曝气单元的控制指标,为MABR提供稳定的进水NH4+-N。在MABR中接种一段式PN/A活性污泥,通过中空纤维膜组件来实现无泡曝气和生物膜富集,通过阶段性提升进水NH4+-N负荷来探究MABR的脱氮性能。各阶段脱氮效果见图5。

第Ⅰ阶段(1~36 d)为挂膜驯化阶段,进水NH4+-N质量浓度为100 mg·L−1,尾气压力为0.015 MPa。较低的尾气压力有利于生物膜的形成[29],随着AOB和AnAOB在中空纤维膜丝上逐渐富集,NH4+-N去除率也在稳固上升,由34.1%上升至67.8%,TN去除率也由33%上升至50%,NRR为0.15 kg·(m3·d)−1。进出水NO2−-N质量浓度很低,这说明AOB产生的NO2−-N均被AnAOB利用,进而说明一段式PN/A工艺在MABR中成功启动。然而,实际NO3−-N增量有时高于理论NO3−-N增量,这是由于种泥中含有少量NOB,为避免NOB对一段式厌氧氨氧化体系的影响,开始阶段性投加20 mg·L−1的羟胺来抑制NOB的活性,且羟胺可通过提高羟胺氧化酶(hydroxylamine oxidase,HAO)活性来刺激AOB的活性[30-31]。

第Ⅱ阶段(37~58 d)保持进水负荷不变,将尾气压力升高到0.018 MPa。平均NH4+-N去除率为74%,最高达到88%(49 d),平均TN去除率为55%,NRR可达0.18 kg·(m3·d)−1。MABR的特性是动态供氧,AOB消耗多少DO,中空纤维膜丝就会向水中传递多少DO,而提高尾气压力实际上是提高中空纤维膜丝内的空气压力,更有利于O2的传质。但提高尾气压力也会导致水中DO略有升高,不利于NOB的抑制,故仍会出现实际NO3−-N增量高于理论NO3−-N增量的情况。

第Ⅲ阶段(59~93 d)将进水NH4+-N质量浓度提升至150 mg·L−1,尾气压力提升至最大值0.025 MPa,由此可见NRR有显著提升,平均达到0.19 kg·(m3·d)−1。但由于进水NH4+-N较高,平均NH4+-N去除率仅为70%,平均TN去除率为53%。此时进出水NO2−-N仍然极低,这说明AnAOB仍保持较高的活性,限制NH4+-N去除效果的因素为AOB的活性,故提高AOB的活性才能提升MABR的氮去除负荷[32]。

第Ⅳ阶段(94~122 d)将进水NH4+-N质量浓度提升至200 mg·L−1,尾气压力为0.025 MPa。平均NH4+-N去除率为66%,平均TN去除率为54%,平均NRR提升至0.22 kg·(m3·d)−1。尾气压力已达到最大值,但提升进水负荷仍可提高NH4+-N去除量,这说明高浓度的进水基质对反应具有促进作用,同时MABR内AOB的丰度和活性也有一定程度的提升。

第Ⅴ阶段(123~148 d)将进水NH4+-N质量浓度提升至250 mg·L−1,尾气压力为0.025 MPa。平均NH4+-N去除率为68%,平均TN去除率为57%,NH4+-N去除量可达170 mg·L−1,平均NRR提升至0.30 kg ·(m3·d)−1。实际NO3−-N增量与理论NO3−-N增量接近,这说明NOB的活性得到了较好的抑制。较高的进水NH4+-N会产生相对多的游离氨(free ammonia,FA),FA对NOB也具有一定的抑制作用[33]。

由图5(d)可知,在第Ⅰ~Ⅴ阶段,MABR进出水COD无明显变化,耗氧有机物 (以COD计) 去除率仅为8.8%。进出水COD出现不规则波动是由于不同批次餐厨沼液C/N不同导致。由图4 (b)和(c)可知,微氧曝气单元出水和MABR出水的三维荧光光谱图并无明显变化。这说明微氧曝气单元出水中剩余的难生物降解DOM并未参与MABR中的反应,也并未对AnAOB造成不利影响。

-

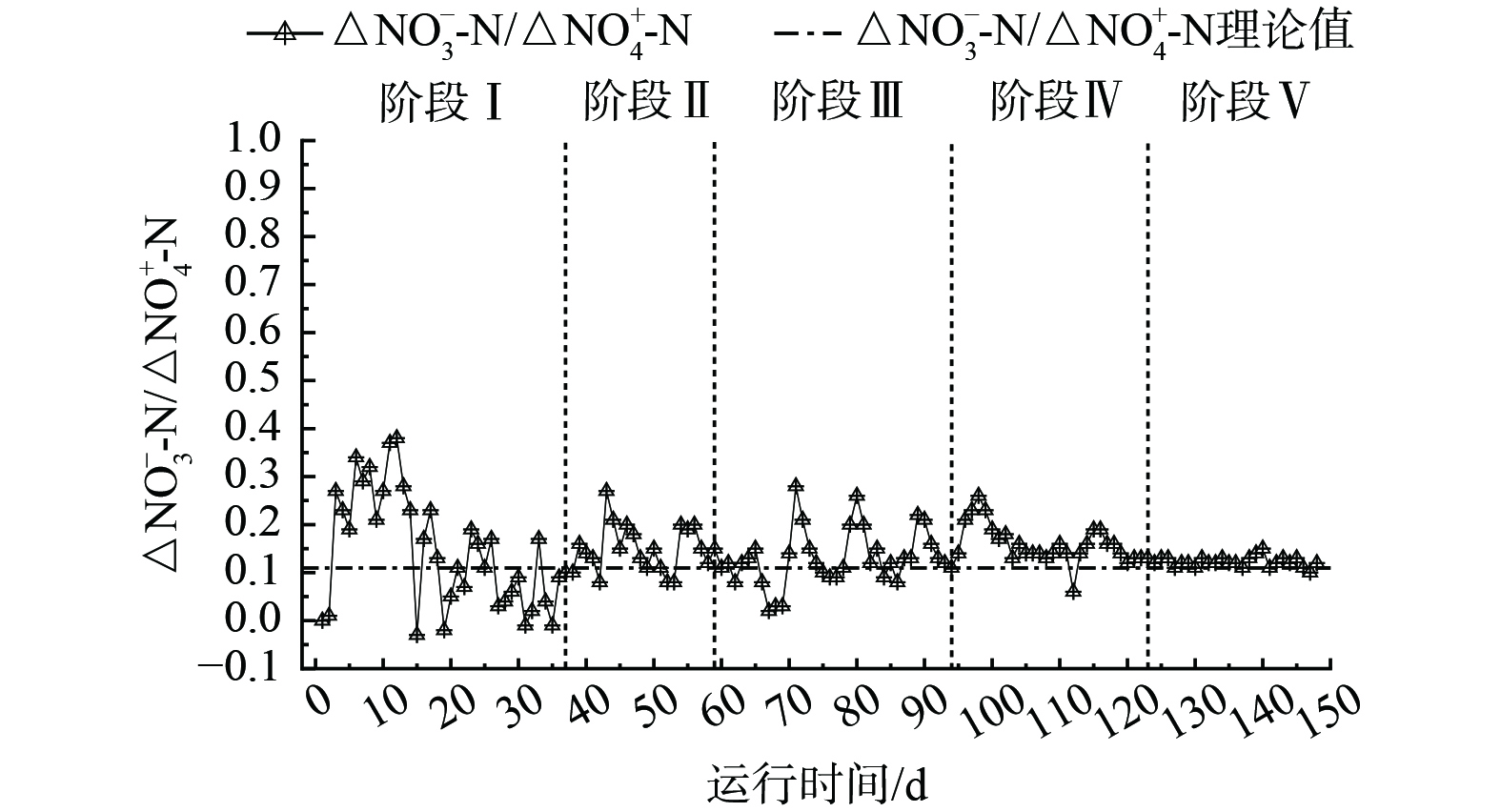

在实验过程中对化学计量比进行分析,由此可判断反应器中发生的反应[34]。由一段式PN/A工艺方程式可知,此反应的理论△NO3−-N/△NH4+-N为0.11。MABR各阶段化学计量比变化如图6所示。

在第Ⅰ~Ⅲ阶段内,△NO3−-N/△NH4+-N波动较大,为0~0.38。△NO3−-N/△NH4+-N在理论值0.11以下说明反应器内发生了反硝化反应[35]。这是由于反应器内DO较低处于缺氧环境,一部分反硝化菌利用微氧曝气池出水中残存的碳源发生反硝化反应。随着尾气压力的提升,这种现象逐渐消失。△NO3−-N/△NH4+-N在理论值0.11以上说明反应器内发生了全程硝化反应[35],NOB活性有所提升,将AOB产生的NO2−-N氧化成NO3−-N,进而导致△NO3−-N/△NH4+-N大于0.11。投加20 mg·L−1的羟胺3~4 d后全程硝化现象会有明显减弱。

在第Ⅳ阶段,出现2次△NO3−-N/△NH4+-N明显大于0.11的情况,投加羟胺后有所改善。在第Ⅴ阶段连续投加10 mg·L−1羟胺来抑制NOB的活性,且此阶段进水NH4+-N较高,较高的FA会抑制NOB的活性。故此阶段运行稳定,△NO3−-N/△NH4+-N可维持在理论值0.11左右。

-

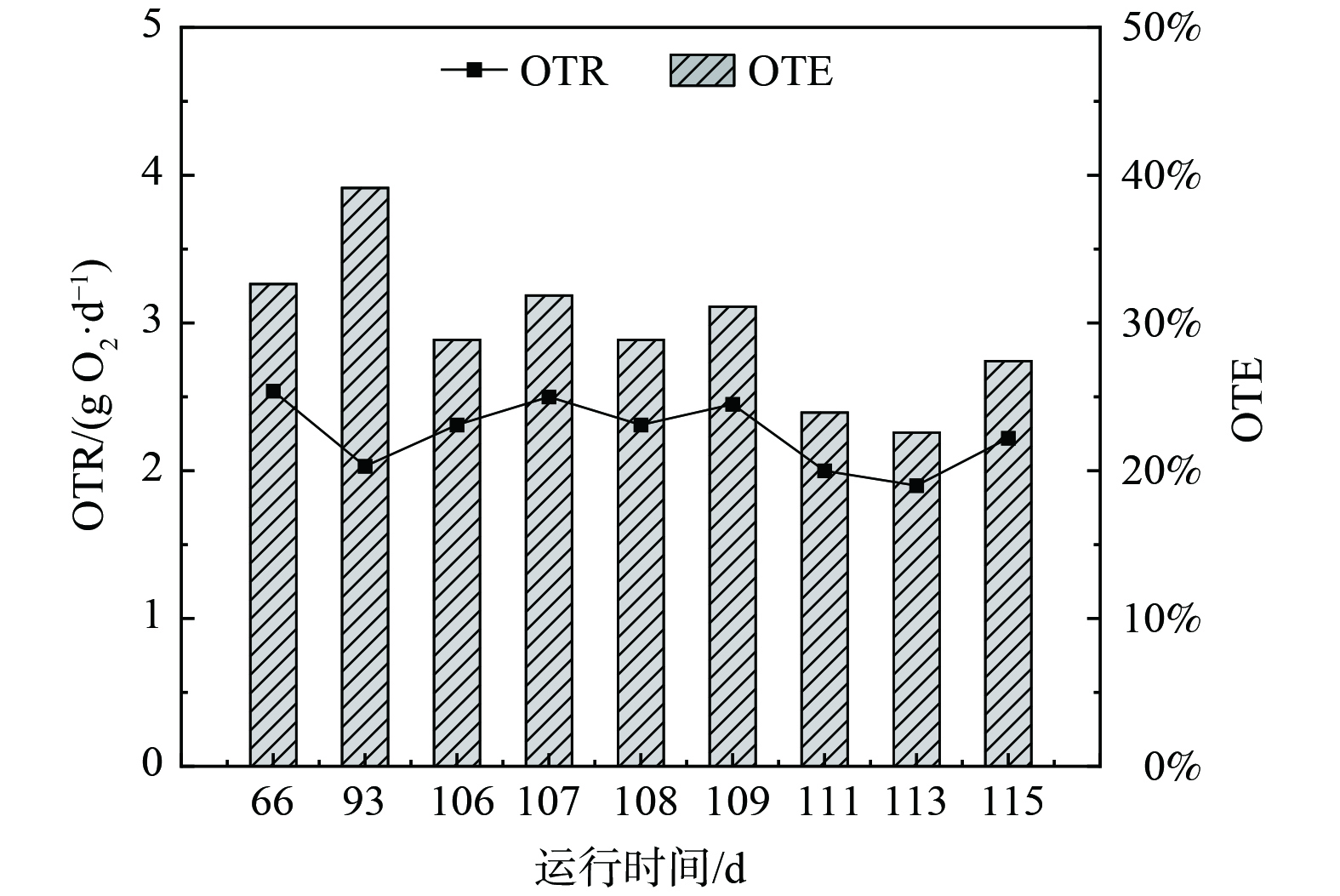

为探究MABR中空纤维膜组件的氧气传质特性,取各阶段膜组件尾气测定氧含量,通过计算得出OTR与OTE,如图7所示。平均OTR为2.25 g·d−1,平均OTE为30%,最高可达39%。目前,实际工程案例多采用贯通式曝气,在较高OTR下,OTE可达到30%~40%[18],与实验结果相符。

传统曝气模式的氧气利用率普遍在20%以下,这是由于曝气时大部分O2以大气泡的形式从水体中逸出进入空气,气相与液相之间的接触面积小、接触时间短,且O2从气态传递到水中的液相传质阻力大,故导致传氧效率低下、曝气能耗过高。而MABR为无泡曝气模式,膜丝中的氧气直接由气相透过膜孔被生物膜利用,不必经过液相传质,大大减小了氧气的传质阻力。将MABR与厌氧氨氧化工艺耦合处理高氨氮废水,可通过膜组件精准控氧,维持水中DO长期处于较低的状态,有利于AnAOB的富集。且MABR的高传氧效率可大幅降低曝气能耗,在餐厨沼液等高氨氮废水的处理中具有独特技术优势。

-

1) 通过逐步提高进水有机负荷、精准曝气和控制SRT的调控方式,成功启动微氧曝气单元,耗氧有机物 (以COD计) 的去除率达90%,平均NH4+-N损失率为12.7%,AOB的活性得到了良好的抑制,在去除有机物的同时为MABR单元提供了NH4+-N基质。微氧曝气单元可完全去除餐厨沼液中的类溶解性微生物代谢产物,而剩余的耗氧有机物 (以COD计) 为类富里酸和类腐殖质,难以被生物降解,且对MABR中的AnAOB无不利影响。

2) 在MABR单元成功启动一段式PN/A工艺,尾气压力为0.025 MPa时处理效果最佳,NH4+-N去除率为68%,TN去除率为57%,NRR为0.30 kg·(m3·d)−1。阶段性投加羟胺对抑制NOB的活性有显著效果,有利于一段式PN/A工艺的稳定运行,△NO3−-N/△NH4+-N稳定在理论值0.11左右。

3) 将MABR与一段式PN/A工艺耦合处理餐厨沼液,耦合单元的OTR为2.25 g·d−1,OTE最高可达39%,较传统曝气模式大大提高了氧气传质效率,其动态供氧的特性有利于一段式PN/A体系的建立与反应器稳定运行。

陶瓷膜微氧曝气MABR强化PN/anammox工艺处理餐厨沼液

Treatment of food waste digestate by ceramic membrane-micro oxygen aeration-MABR enhanced PN/anammox process

-

摘要: 针对餐厨沼液高COD、高氨氮的特点,采用“陶瓷膜-微氧曝气-MABR”组合工艺处理餐厨沼液。将陶瓷膜作为预处理单元对沼液中的TSS及部分耗氧有机物 (以COD计) 、NH4+-N进行去除,出水进入微氧曝气单元后,耗氧有机物被进一步去除,并维持NH4+-N处于较低的硝化率。当微氧曝气单元运行稳定后,在MABR单元中启动一段式短程硝化-厌氧氨氧化工艺,进行深度脱氮研究。结果表明:陶瓷膜对TSS去除率达98%,COD降低了73%,NH4+-N去除率为14%;经过50 d的驯化,在DO低于0.5 mg·L−1的条件下,微氧曝气单元COD降低了90%,平均NH4+-N损失率仅为12.7%;出水三维荧光光谱显示剩余耗氧有机物为类富里酸和类腐殖酸,难以进一步被生物降解;MABR单元经过148 d的驯化启动,成功实现一段式短程硝化-厌氧氨氧化工艺的稳定运行,尾气压力为0.025 MPa时处理效果最佳,NH4+-N去除率为68%,NRR为0.30 kg N·(m3·d)−1,△NO3−-N/△NH4+-N稳定在0.11左右,OTE最高可达39%。本研究可为餐厨沼液的处理及厌氧氨氧化的工程应用提供参考。Abstract: In view of the characteristics of high COD and NH4+-N of food waste digestate, the combined process of "ceramic membrane-micro oxygen aeration-MABR" was used to treat food waste digestate. The ceramic membrane was used as pretreatment unit to remove TSS and some oxygen-consuming organic matter(COD) and NH4+-N. COD in effluent was further removed in the micro oxygen aeration tank and NH4+-N was maintained at a low nitrification rate. When stable operation of the micro-oxygen aeration was reached, the one-stage partial nitrification-anammox process was started in MABR unit to carry out advanced nitrogen removal research. The results showed that the removal rate of TSS, COD and NH4+-N by ceramic membrane was 98%, 73% and 14% respectively. After 50 days of domestication, when DO was lower than 0.5 mg·L−1, the removal rate of COD in micro oxygen aeration unit was 90%, and the average removal rate of NH4+-N was only 12.7%. The three-dimensional fluorescence spectrum of the effluent showed that the remaining COD were fulvic acid and humic acid, which were difficult to be further biodegraded. After 148 days of domestication and start-up, MABR unit successfully realized the stable operation of one-stage partial nitrification-anammox process. The treatment effect was the best when the tail gas pressure was 0.025 MPa, the removal rate of NH4+-N was 68%, the NRR was 0.30 kg N·(m3·d)−1, △NO3−-N/△NH4+-N was stable at 0.11, and the highest OTE was 39%. This study can provide reference for the treatment of food waste digestate and the engineering application of anammox.

-

Key words:

- food waste digestate /

- micro oxygen aeration /

- partial nitrification /

- anammox /

- MABR

-

-

表 1 微氧曝气池运行参数

Table 1. Operating parameters of micro oxygen aeration tank

阶段 时间/d 进水COD/(mg·L−1) 进水NH4+-N/(mg·L−1) 进水TN/(mg·L−1) C/N 曝气量/(L·min−1) 污泥回流比 Ⅰ 1~16 300~350 137~211 160~246 1.42~2.18 0.3 160% Ⅱ 17~34 400~450 107~213 125~249 1.91~3.96 0.4 160% Ⅲ 35~50 500~550 136~154 159~180 3.42~3.90 0.5 180% 注:各阶段SRT均为4~5d,HRT均为10 h,pH均为7.1~7.5。 表 2 MABR运行参数

Table 2. Operating parameters of MABR

阶段 时间/d 进水NH4+-N/(mg·L−1) 进水COD/(mg·L−1) 进水TN/(mg·L−1) C/N 尾气压力/MPa 尾气流量/(L·min−1) Ⅰ 1~36 100 64 116 0.64 0.015 0.80 Ⅱ 37~58 100 61 116 0.61 0.018 0.55 Ⅲ 59~93 150 57 175 0.38 0.025 0.10 Ⅳ 94~122 200 83 232 0.42 0.025 0.10 Ⅴ 123~148 250 63 292 0.25 0.025 0.10 注:各阶段污泥回流比均为200%。 表 3 陶瓷膜对餐厨沼液的处理效果

Table 3. Performance of ceramic membrane on treatment of food waste digestate

水样 COD/(mg·L−1) NH4+-N/(mg·L−1) TN/(mg·L−1) TSS/(mg·L−1) 盐度/(g·L−1) pH 餐厨沼液原水 8 000~15 000 2 000~3 500 2 300~3 800 10 000~14 100 8~10 7.9~8.1 陶瓷膜出水 2 000~4 300 1 600~3 200 1 900~3 400 30~120 6~8 8.1~8.2 去除率/% 73 14 15 98 22 注:COD、NH4+-N、TN、TSS、盐度去除率分别为73%、14%、15%、98%、22%。 -

[1] 胡新军, 张敏, 余俊锋, 等. 中国餐厨垃圾处理的现状、问题和对策[J]. 生态学报, 2012, 32(14): 4575-4584. [2] 王丽华, 李宇宸, 韩聪. 城市餐厨垃圾处理技术分析及思路分析[J]. 中国资源综合利用, 2018, 36(12): 73-75. [3] CONNOR J O, HOANG S A, BRADNEY L, et al. A review on the valorisation of food waste as a nutrient source and soil amendment[J]. Environmental Pollution. 2021, 272: 115985. [4] 邴君妍, 罗恩华, 金宜英, 等. 我国餐厨废弃物厌氧消化技术的物质流分析[J]. 环境工程, 2018, 36(8): 130-133. [5] 庄渊. 高效预处理+厌氧消化工艺处理餐厨垃圾工程实例[J]. 中国资源综合利用, 2018, 36(11): 86-88. [6] 谢苏峰, 尹贞, 薛秋玉, 等. 浅谈餐厨沼液的处理技术[J]. 安徽化工, 2020,46(5):81-84. [7] 成娟. 生活污水稀释餐厨垃圾厌氧消化液培养微藻及氮磷去除的研究[D]. 济南: 山东大学, 2017. [8] 郑炜, 杨兴兴, 万梅, 等. MBR组合工艺处理餐厨垃圾发酵废液的运行特性[J]. 水处理技术, 2018, 44(3): 118-120. [9] 吴健, 赵明星, 阮文权. A/O-MBR处理高COD和高氨氮餐厨废水试验研究[J]. 工业水处理, 2014, 34(4): 66-69. [10] 张春, 郑利兵, 郁达伟, 等. 沼液处理与资源化利用现状与展望[J]. 中国沼气, 2018, 36(5): 36-46. [11] 刘文蓉, 董飞, 王玉军, 等. UASB-MBR-NF-RO处理垃圾渗滤液与餐厨垃圾厌氧消化液[J]. 水处理技术, 2021, 47(9): 77-80. [12] KARTAL B, KUENEN J G, VAN LOOSDRECHT M C M. Sewage treatment with anammox science[J]. Science, 2010, 328(5979): 702-703. doi: 10.1126/science.1185941 [13] YANG W, HE S, HAN M, et al. Nitrogen removal performance and microbial community structure in the start-up and substrate inhibition stages of an anammox reactor[J]. Journal of Bioscience and Bioengineering, 2018, 126(1): 88-95. doi: 10.1016/j.jbiosc.2018.02.004 [14] VAN DE GRAAF A A, MULDER A, DE BRUIJN P, et al. Anaerobic oxidation of ammonium is a biologically mediated process[J]. Applied and Environmental Microbiology, 1995, 61(4): 1246-1251. doi: 10.1128/aem.61.4.1246-1251.1995 [15] WANG G, XU X, ZHOU L, et al. A pilot-scale study on the start-up of partial nitrification-anammox process for anaerobic sludge digester liquor treatment[J]. Bioresource Technology, 2017, 241: 181-189. doi: 10.1016/j.biortech.2017.02.125 [16] KELUSKAR R, NERURKAR A, DESAI A. Development of a simultaneous partial nitrification, anaerobic ammonia oxidation and denitrification (SNAD) bench scale process for removal of ammonia from effluent of a fertilizer industry[J]. Bioresource Technology, 2013, 130: 390-397. doi: 10.1016/j.biortech.2012.12.066 [17] ARRIAGADA C, GUZMÁN-FIERRO V, GIUSTINIANOVICH E, et al. NOB suppression and adaptation strategies in the partial nitrification-Anammox process for a poultry manure anaerobic digester[J]. Process Biochemistry, 2017, 58: 258-265. doi: 10.1016/j.procbio.2017.03.028 [18] 康晓峰, 王黎声, 刘春, 等. 膜曝气生物膜反应器生物脱氮研究进展[J]. 环境工程, 2021, 39(07): 38-45. [19] COTE P, BERSILLON J L, HUYARD A. Bubble-free aeration using membranes-mass-transfer analysis[J]. Journal of Membrane Science, 1989, 47(1/2): 91-106. [20] SYRON E, CASEY E. Membrane-aerated biofilms for high rate biotreatment: performance appraisal, engineering principles, scale-up, and development requirements[J]. Environmental Science & Technology, 2008, 42(6): 1833-1844. [21] YAMAGIWA K, OHKAWA A, HIRASA O. Simultaneous organic-carbon removal and nitrification by biofilm formed on oxygen enrichment membrane[J]. Journal of Chemical Engineering of Japan, 1994, 27(5): 638-643. doi: 10.1252/jcej.27.638 [22] 国家环境保护总局. 水和废水监测分析方法[M]. 4版. 北京: 中国环境科学出版社, 2002. [23] 江兴. 膜曝气生物膜反应器处理低碳氮比市政污水的同步脱氮除碳研究[D]. 广州: 广州大学, 2022. [24] 夏一帆, 王冰洁, 涂凌波, 等. DMBR短程硝化反硝化处理餐厨垃圾厌氧沼液[J]. 中国给水排水, 2021, 37(7): 27-33. [25] YCHEN W, WESTERHOFF P, LEENHEER J A, et al. Fluorescence excitation-emission matrix regional integration to quantify spectra for dissolved organic matter[J]. Environmental Science & Technology, 2003, 37(24): 5701-5710. [26] STEDMON C A, MARKAGER S. Resolving the variability in dissolved organic matter fluorescence in a temperate estuary and its catchment using PARAFAC analysis[J]. Limnology and Oceanography, 2005, 50(2): 686-697. doi: 10.4319/lo.2005.50.2.0686 [27] BAGHOTH S A, SHARMA S K, AMY G L. Tracking natural organic matter (NOM) in a drinking water treatment plant using fluorescence excitation-emission matrices and PARAFAC[J]. Water Research, 2011, 45(2): 797-809. doi: 10.1016/j.watres.2010.09.005 [28] LYON B A, CORY R M, WEINBERG H S. Changes in dissolved organic matter fluorescence and disinfection byproduct formation from UV and subsequent chlorination /chloramination[J]. Journal of Hazardous Materials, 2014, 264: 411-419. doi: 10.1016/j.jhazmat.2013.10.065 [29] 侯飞飞. MABR去除高盐废水中COD和氨氮的基础研究[D]. 天津: 天津大学, 2013. [30] LI J, ZHANG Q, LI X, et al. Rapid start-up and stable maintenance of domestic wastewater nitritation through short-term hydroxylamine addition[J]. Bioresource Technology, 2019, 278: 468-472. doi: 10.1016/j.biortech.2019.01.056 [31] KINDAICHI T, OKABE S, SATOH H, et al. Effects of hydroxylamine on microbial community structure and function of autotrophic nitrifying biofilms determined by in situ hybridization and the use of microelectrodes[J]. Water Science Technology, 2004, 49(11/12): 61-68. [32] SOLIMAN M, ELDYASTI A. Development of partial nitrification as a first step of nitrite shunt process in a sequential batch reactor (SBR) using ammonium oxidizing bacteria (AOB) controlled by mixing regime[J]. Bioresource Technology, 2016, 221: 85-95. doi: 10.1016/j.biortech.2016.09.023 [33] KOUBA V, CATRYSSE M, STRYJOVA H, et al. The impact of influent total ammonium nitrogen concentration on nitrite-oxidizing bacteria inhibition in moving bed biofilm reactor[J]. Water Science and Technology, 2014, 69(6): 1227-1233. doi: 10.2166/wst.2013.757 [34] 王小龙. 基于颗粒污泥的单级自养脱氮系统构建及其脱氮效能研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. [35] MAGRÍ A, VANOTTI M B, SZÖGI A A. Anammox sludge immobilized in polyvinyl alcohol (PVA) cryogel carriers[J]. Bioresource Technology, 2012, 114(1): 231-240. -

下载:

下载: