-

随着我国城市化进程和产业结构调整步伐的加快,大批工业企业相继搬迁或关停,产生大量工业遗留污染场地,对生态环境和周边居民的健康造成严重威胁[1]。在我国污染场地修复产业快速发展的20年间,初期多采用异位修复技术,如固化/稳定化、水泥窑协同处置等,但异位修复时挖掘和运输等过程将导致二次污染风险增大,并且综合考虑生态和社会效益,用于异位修复的资源消耗和能效比并不低[2]。随着污染场地治理修复行业的发展,国家《土壤污染防治行动计划》[3]和《中华人民共和国土壤污染防治法》[4]相继提出污染土壤原则上进行原位修复的要求,污染场地修复技术逐渐由异位修复技术向原位修复技术发展,如原位热处理、原位化学氧化还原、原位生物修复技术等[5]。其中,原位热处理 (In-situ thermal treatment, ISTT) 技术作为一种高效修复技术,具有地下扰动小、适用污染物类型多、作业深度深、修复周期短、污染去除率高等优势,在污染程度重、时间要求紧的场地修复工程中得到了广泛的应用,已成为修复挥发/半挥发性有机污染场地最有效的方法之一[6-9]。

面对全球气候变化形势日趋严峻的现状,多个国家及地区相继提出碳中和目标[10],绿色可持续修复已逐渐成为国际污染场地修复的发展方向[11]。我国于2020年提出“二氧化碳排放力争于2030年前达到峰值,努力争取2060年前实现中和”的目标[12]。在“双碳”战略背景下,亟需加强国内污染场地的绿色可持续修复研究,提升修复技术的发展水平。值得关注的是,ISTT技术由于需要持续的能源输入以达到较高处理温度,被认为是能源密集型技术[13],影响其在“双碳”战略背景下的推广应用。尽管传统ISTT存在能耗和碳排放较高的弊端,但该技术具有修复周期短、效率高、二次污染影响小的特征,合理优化后有望转变为可持续修复技术[14]。为此,本文调研国内外ISTT技术的研究和工程实例,分析ISTT技术应用过程的碳排放和能耗情况及其关键贡献环节,拟提出在现有技术基础上推动ISTT技术低碳发展的主要优化方向,并梳理了借力可再生能源和技术优化等措施的研究进展,以期为业界对“双碳”目标下该技术的研发和应用提供参考。

-

ISTT技术通过就地加热污染介质 (包气带/含水层) ,破坏污染物或增加其挥发和迁移性,促使其以多相态加速迁移至气相或液相中,并通过尾水/尾气将其收集到地表进行处理,实现污染物的去除[15]。根据加热方式可分为电阻加热 (Electrical resistance heating, ERH) 、热传导加热 (Thermal conduction heating, TCH) 、蒸汽强化抽提 (Steam enhanced extraction, SEE) 、射频加热 (Radio frequency heating,RFH) 和阴燃 (Self-sustaining treatment for active remediation, STAR) 等技术。上述技术的特点见表1。目前较常用的技术为ERH、TCH和SEE,在1988~2021年美国的643项原位热修复项目中,ERH技术处于主导地位,超过一半的项目 (57.2%) 涉及ERH,其次是TCH技术,占比为29.5%,SEE、STAR和RFH等技术的占比分别为8.3%、1.9%和1.1%[16]。

-

修复过程的碳足迹是评价一项修复技术是否绿色可持续的重要指标,主要采用全生命周期评价 (Life cycle assessment, LCA) 和环境足迹分析 (Environmental footprint analysis, EFA) 等方法进行量化评估。表2列举了7个典型ISTT案例的碳排放情况,受场地特征和处理技术等因素的影响,不同修复案例的单位碳排放量存在较大差异,最低为0.5 kgCO2-eq·m−3,最高达330.0 kgCO2-eq·m−3。对于特定的污染场地,选择合适的技术是降低修复活动碳排放的重要途径,在2种ISTT技术修复煤焦油污染场地的碳足迹对比研究中,GRANT等[19]发现TCH技术所产生的碳排放总量为4.12×104 tCO2-eq,而STAR技术仅为4.39×103 tCO2-eq,相差近10倍。STAR技术是依靠有机污染物自持燃烧进行修复,无需持续的热量输入,因此能源消耗较常规热处理低[14]。

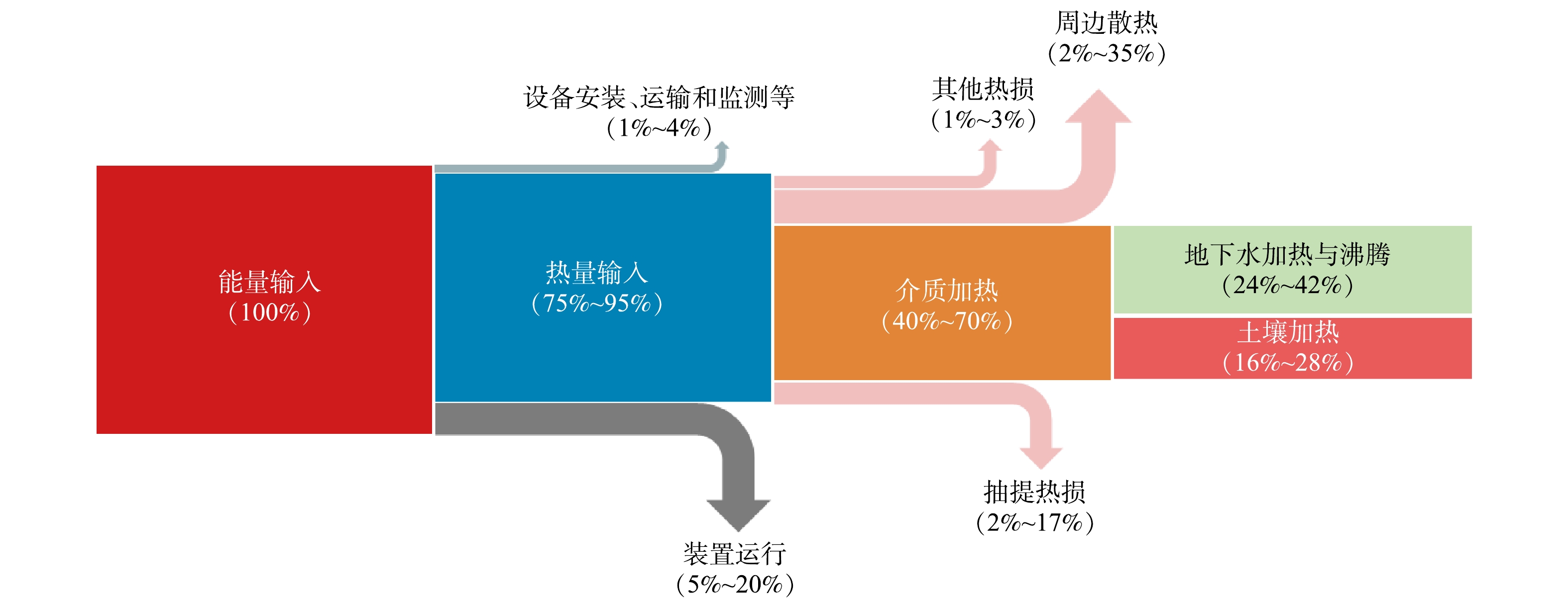

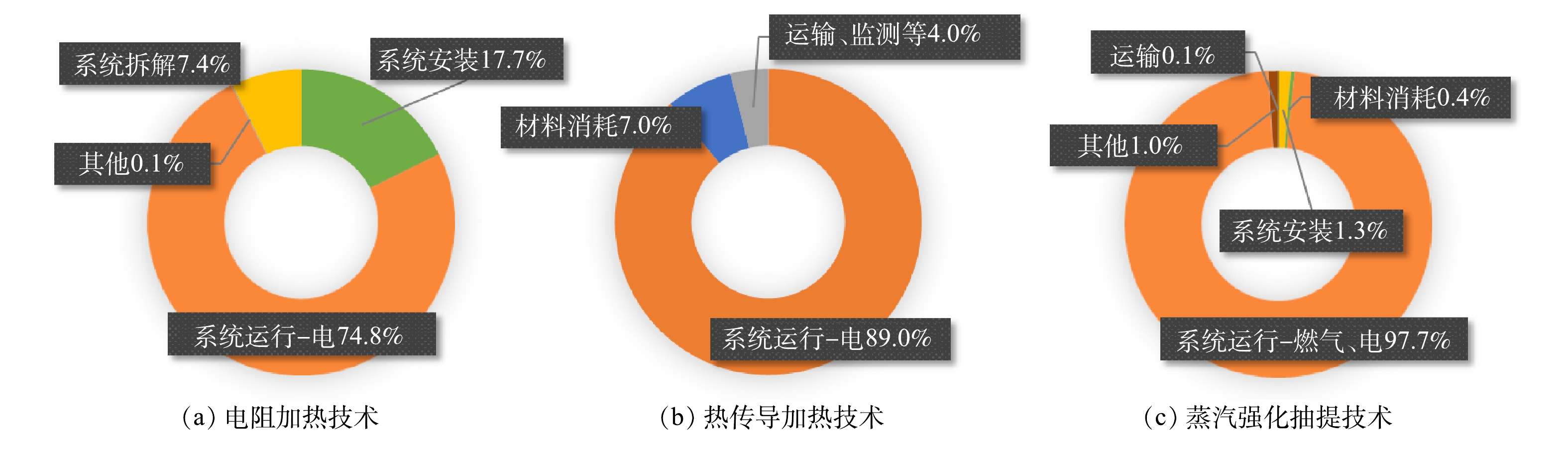

识别ISTT过程关键碳排放环节是技术优化和减排的基础。由图1可以看出,ISTT处理过程的碳排放绝大部分来源于修复系统运行时的不可再生能源消耗,占总排放量的74.8%~97.7%。剩余小部分碳排放主要来源于修复系统安装和拆解 (1.3%~17.7%) 、材料消耗 (0.4%~7.0%) 及运输和监测 (0.1%~4.0%) 等环节。

-

能耗量是反映ISTT过程碳排放的关键指标,表3列举了13个典型ISTT案例的能耗情况,为便于统计分析,利用等效电法[25]将各案例中不同形式的能源消耗量折算为耗电量并计算了单位能耗。与碳排放相似,由于场地特征和处理技术等原因,不同案例的单位能耗差异较大,最低为2.9 kWh·m−3,最高达820.0 kWh·m−3。对于特定污染场地,选择合适的技术有望大幅减少修复能耗,LEMMING等[26]评估了RFH、SEE、ERH和TCH技术分别处理低渗透性三氯乙烯污染场地的能耗情况,发现采用RFH技术时能耗最低,较SEE、ERH和TCH技术分别降低了83.8%、74.4%和70.3%,推测原因是RHF技术通过高频电场加热,不受地下介质热导率和渗透率的影响,升温较快,耗能较少。对于场地特征相似的场地,相同处理技术下,处理规模越大单位能耗越小。有研究对SEE、ERH和TCH技术分别修复场地特征类似的小场地 (1 260 m3) 和大场地 (11 700 m3) 时所需能耗进行了估算,发现修复大场地所需单位能耗较小场地下降了43.4%~67.5%[26]。

识别ISTT过程的关键能耗环节是技术节能降耗的前提。为此,基于实验研究及工程案例[7,22-23,26,28-29],梳理了ISTT技术 (包括ERH、TCH和SEE) 应用过程中各环节的能耗占比,并绘制了简化能流图 (图2) 。由图可知,ISTT过程的能耗以热量输入为主,占总能耗的75%~95%,其次是修复装置运行的耗能 (5%~20%) ,剩余小部分耗能 (1%~4%) 由设备安装、运输和监测等环节组成。输入地下的热量中,大部分被用于加热污染介质,约占总能耗的40%~70% (土壤16%~28%,地下水24%~42%) ,其余则通过抽提热损 (2%~17%) 、周边对流和传导散热 (2%~35%) 及其他热损 (1%~3%) 等途径损失了。值得注意的是,对于以燃气为能源的热传导技术 (Gas thermal remediation, GTR) ,热损失途径还包括燃烧尾气的排放,该环节所产生的热损失可占总热量输入的25%~50%[29]。综上,在“双碳”目标下,今后ISTT技术的优化研究需要围绕减少不可再生能源消耗和降低热量输入需求等方向展开。

-

由前文分析可知,不可再生能源消耗是导致ISTT过程高碳排放的主要原因,占比达74%以上。因此,调整能源结构、借力可再生能源是实现ISTT技术减排的首要途径。可再生能源是指水力能、风能、太阳能、生物质能和地热能等非化石能源,目前在地场修复活动中应用较多的为太阳能和风能。

-

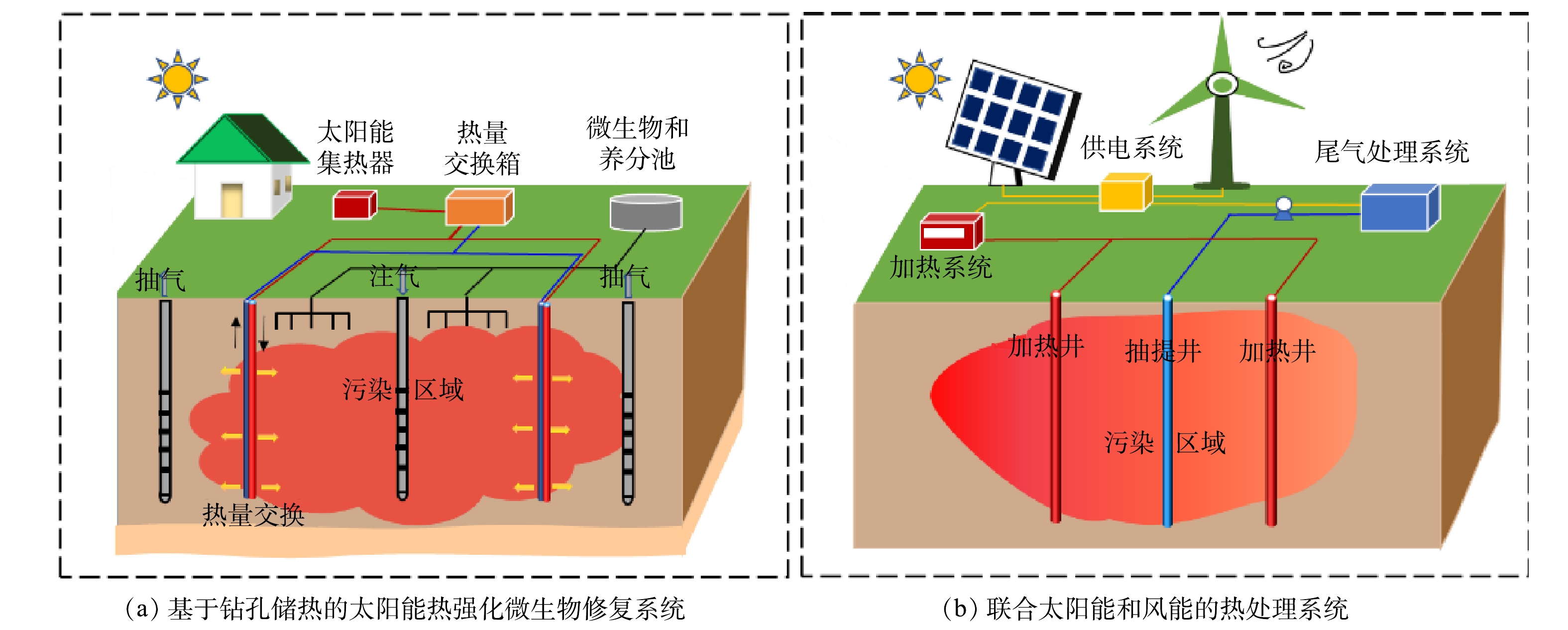

太阳能主要指太阳辐射能,在我国陆地上的年接受量约为1.47×1016 kWh,可折合4.9×1012 t标准煤[30],应用潜力巨大。场地修复活动中,太阳能的应用通常通过光伏发电系统实现,利用太阳能发电驱动抽提、采样和监测装置等小型电力设备[31-33]。也有学者尝试将太阳能直接转化为热能应用,如利用聚光器、太阳能加热炉和太阳能回转窑等装置直接加热污染土壤[34-35]。NAKAMURA等[36]利用光纤将聚光器聚集的太阳光线传输到实验装置中加热三氯乙烯污染土壤,加热至100~200 ℃,成功实现了污染物的完全去除。高冰等[37]的设计则在太阳光线加热的基础上增加了一套注气系统,利用聚集的太阳光线先加热集热管内的气体,再通过流动的气体将热量带入地下环境。太阳光线聚焦所产生的温度很高,还有研究将其用于污染土壤的玻璃化处理[38]。近年来,结合地下储热系统的太阳能热强化微生物修复技术引发了大量关注,该技术通过地下储热系统将太阳能集热模块聚集的热量带入地下环境,用于强化微生物修复 (图3 (a) ) 。地下储热系统主要包括含水层储热和钻孔储热,含水层储热指通过地下水的“抽出-加热-回灌”储存热量,适用于低地下水流、高渗透性、且具有合适厚度的含水层[39];钻孔储热则通过持续加热封闭管道中的循环流体实现热量储存,适用于非饱和带或没有合适含水层的区域[40]。与自然衰减相比,基于地下储热系统的太阳能热强化微生物修复可以显著提高目标区域的微生物活性和污染物去除率[41-42]。太阳能应用途径广,减排潜力也很大,有研究对比了不同能源为电化学修复电解废水过程供电对环境的影响,发现利用太阳能替代传统电网供电可以减少85%以上的CO2排放[43]。

-

风能主要指空气流动所产生的动能,通常通过风力发电系统转换为电能使用。据估计,我国陆地50 m高度内3级以上 (风功率密度≥300 W·m−2) 风能资源的潜在开发量约为2.38×109 kW[28],具有广阔的应用前景。风力发电系统的应用常见于室内电化学修复实验和海水淡化等研究中[44-45],具有较大的减排潜力,有研究对比了不同能源为电化学修复电解废水过程供电对环境的影响,发现风能供电时所产生碳排放量仅为传统电网供电的14.3%[43]。场地修复活动中的风力发电系统常与太阳能发电系统联用 (图3 (b) ) ,以保证足够的能源供应。ROSSMAN等[46]在美国北部开展了一项原位土壤低温加热的中试研究,利用风力和太阳能发电系统同时为电阻加热元件供电,8个月内向土壤中共输入441 kWh的能量,使土壤温度最高上升20 ℃。HELLRIEGEL等[47]利用混合光伏/风力系统为地下水脱盐、脱砷模块供电,供电量为15.2 kWh·d−1,远超处理模块的日平均运行能耗,可以替代126%的不可再生能源消耗。现场应用中,风能和太阳能发电系统易受气候条件限制,往往难以实现连续恒定的供电。对于电化学修复、ERH技术的电动-热耦合模式等需要依靠电场作用的修复技术[48],由于传质过程的可逆性,间歇性供电可能会导致修复效率低下[49]。因此,需要考虑将现场产生的电能进行储存,常见储能装置包括铅酸电池、超级电容器和氧化还原流体电池等[50]。

太阳能和风能等可再生能源储量丰富,已被广泛应用于场地修复活动中,并且具有巨大的减排潜力。对于高能耗的ISTT工艺,适当利用可再生能源替代部分传统电力或燃料供能将成为推进该工艺低碳化发展的重要途径。

-

从技术层面对ISTT工艺进行优化可以从源头上降低热量输入需求,进而减少修复能耗。ISTT工艺技术层面的优化可以分为单项技术的优化、不同技术的耦合和修复过程的热损失控制等。

-

单项技术的优化主要指根据各技术的特点,对加热方式、技术参数等进行优化升级。SEE技术主要通过优化蒸汽注入方式来缩短修复时间、提高修复效益,优化方法包括压力循环注入蒸汽、水力压裂与蒸汽注入相结合、蒸汽和空气共注入、过热蒸汽替代饱和蒸汽等[6,8,51-52]。ERH技术主要通过改变补水方式和供电模式等实现优化[53]。耿竹凝等[54]利用脉动直流电替代交流电为ERH修复三氯乙烯污染土壤供电,发现经过48 h处理,同等电压下脉动直流电体系的污染去除率较交流电体系提升了2.2倍,而能耗仅为该体系的32%,推测其原因是直流电场的电渗析作用增强了污染物的迁移去除。电热-动态剥离也是一种基于ERH的优化技术,该技术在ERH基础上嵌入了注水循环系统,一方面可防止电极过热,另一方面还能保证土壤水分、维持高电流、增加对流传热,进而提高修复效益[18]。TCH技术主要通过动态调控温度和天然气输入流量实现优化。LI等[29]提出了一种基于温度监测的控温策略,分别在加热、沸腾和过热阶段设定加热温度为750、800、1 050 ℃,较恒温 (950 ℃) 处理可减少29%的天然气用量。XU等[55]提出了一种多参数的天然气调控方案,分别在加热、沸腾和过热阶段选择温升率、含水率变化率和温升率作为变量调控天然气输入流量,相比于恒定流量输入,加热时间可缩短50.3%,天然气消耗可减少24%。ZHAI等[56]则在监测数据的基础上考虑了现场布局,设定加热井的目标温度与其到边界的距离成正相关,且随土壤温度的升高和含水率的下降而升高,与常规处理方式相比,预计将降低30%的能耗。此外,不同场地的水文地质条件和污染类型差异较大,修复前均需要对场地特征进行精准刻画,因地制宜的优化布局和相关技术参数,以控制修复能耗和成本[57-58]。

-

国内污染场地复合污染普遍、水文地质条件复杂,单项ISTT技术往往难以实现高能源效益的修复。耦合技术可以利用不同技术的优势、发挥技术间的协同效应,是目前ISTT技术低碳化发展的重要方向。

1) 原位热处理技术与化学处理技术的耦合。热处理去除高沸点污染物 (如多氯联苯、多环芳烃等) 时,需达到300~600 ℃,甚至更高,才能实现污染物的完全去除[59-60],高处理温度意味着高能源消耗[61]。添加化学药剂可以通过改变热处理区域的化学环境,加速污染物溶解、挥发或转化,进而降低加热温度和热量需求[62-63]。MA等[64]在热处理汞污染土壤的过程中添加柠檬酸,增强了汞的解吸和溶解,使处理温度降低200 ℃左右,能耗降低了35%。LIU等[65]在重烃物质热解过程中引入K2CO3,降低了热解过程的平均活化能,大幅降低了处理温度,使修复能耗减少了34.7%。添加化学药剂还可以通过增强传热和加速污染物的去除缩短加热时间。LI等[66]发现,在ERH基础上耦合过硫酸盐再循环系统可以大幅提高ERH的升温速率,并使其升温更加均匀,推测原因是循环过硫酸盐增强了热量的传递和分散。HAN等[67]在ERH处理多环芳污染土壤的过程中添加了过硫酸盐,使污染物去除机理从挥发变为挥发与氧化的耦合效应,将菲和芘的去除率分别提高了43.52%和61.07%,去除过程加速了45.50%。在热处理后期 (修复未达标) 耦合化学处理还有望解决热处理后期能源效率低的问题,大幅缩短加热时间、减少热量输入[68]。此外,化学处理也得益于热处理的耦合,升温可以增强介质中污染物的解吸和溶解,促进其与化学药剂的充分接触[69-70],还可以活化过硫酸盐等氧化药剂,加速化学修复过程[71]。基于ERH技术的电动-热耦合技术还有望通过电渗析和电迁移作用增强氧化剂的迁移扩散,突破化学氧化技术在低渗透性土壤中的应用限制[72]。

2) 原位热处理技术与微生物修复技术的耦合。ISTT技术与微生物修复技术耦合的研究重点在于热强化微生物修复,通过低温加热提高目标区域有机污染物的微生物可利用度、增强微生物活性,进而提高修复效率[73-74]。KOSEGI等[75]开展了热强化微生物修复处理重非水相液体 (DNAPL) 污染地下水的模拟研究,发现将温度从15 ℃提高到35 ℃时,Dhc菌株还原性脱卤基因的丰度增加了1~2个数量级,修复达标时间缩短了70%。PERFUMO等[76]对比了不同温度下微生物修复石油烃污染土壤的效果,发现将温度从18 ℃提高到60 ℃时,污染物去除率增加了26%。推测其原因是温度上升增加了污染物的溶解,并刺激了嗜热降解菌群的生长。近年来,结合可再生能源和地下储热系统的热强化微生物修复技术得到了广泛的研究,欧洲某氯化溶剂污染场地将含水层储热系统与微生物降解相结合,修复污染深度达60~70 m的地下水,据估算修复成本较常规修复方案降低了30%~40%,CO2排放量降低了30%~50%[77]。

3) 原位热处理技术之间的耦合。ISTT技术之间的耦合一般应用于修复复杂污染场地,常用耦合方式为SEE与TCH或ERH技术的组合,SEE技术用于处理高渗透区 (场地深度大于9.1 m时,渗透率下限约为10–5 cm·s−1;深度小于6.1 m时,渗透率下限约为10–3 cm·s−1) ,ERH或TCH技术用于处理低渗透区[78-79]。SEE可以减小地下水流入侵带给TCH或ERH的影响,TCH或ERH则可以防止SEE应用过程中优势流或DNAPL向下迁移的现象[80]。TIMMONS等[81]采用TCH耦合SEE的方法修复DNAPL污染场地,用TCH加热淤泥和粘土层,SEE加热砾石层,在16个月内去除了74.8 t的污染物,去除率高达99%。ERH技术应用过程中,当地下介质的非均质性较强时,会出现升温不均匀的现象,存在修复不完全的风险[79]。ROLAND等[82]提出一种耦合ERH与RFH技术的修复方式,先采用低频的ERH加热,再采用高频的RFH加热,有望解决单一频率电加热处理时饱和区和非饱和区温差大的问题。

-

ISTT过程的热损失最高可占总输入热量的50%左右[29],热损失问题亟待解决。根据热损失途径,热损失控制措施可分为地表热量阻隔、地下水阻隔和高温气体的余热回用3种。

1) 地表热量阻隔。安装地表覆盖层是减少加热区域与地面热量交换的主要途径,通常采用单层低渗透性、低热导性的材料 (如混凝土、泡沫混凝土等) 覆盖于目标区域上方[7,27]。也有学者尝试采用多层材料进行阻隔保温,如LEMMING等[26]在热处理工程中采用的覆盖层是以膨胀聚苯乙烯、轻质膨胀粘土、贝壳等为填料的夹层结构。李丁等[83]提出了一种专门针对GTR技术的多层地表覆盖结构,在待修复区的地表周围设置围挡,围挡内从下到上依次为砾石层、加气砖层、交联聚乙烯发泡材料绝热层和混凝土层,并在阻隔层中嵌入了延伸至地表的抽提井,该结构不仅能实现热量阻隔,还能收集逸散至覆盖层的气体。此外,对于SEE技术,HOGGES和FALTA[84]发现,在安装地表覆盖层的基础上结合蒸汽和空气共注入可以大幅提高对表面热量散失的控制效果,通过空气注入减少高温蒸汽的垂直上升,通过地表覆盖层防止高温气流从注射井附近的地表溢出。

2) 地下水阻隔。地下阻隔降水是减少地下水吸热及流动换热的首要途径,阻隔措施包括设置物理屏障、设置水力屏障井和增设蒸汽注射井等。最常用的阻隔方法是设置物理屏障,通常设置在修复区域四周,一般采用板桩墙或泥浆墙[27,85]。水力屏障井多用于高渗透区域的隔水和降水,在修复区域周边设置抽水井,通过改变该区域的水力梯度来减少地下水流入[86]。增设蒸汽注射井主要适用于TCH和ERH技术,在修复区域边缘或加热井附近设置蒸汽注射井,通过形成高压蒸汽填充区来减小地下水流入侵,是一种极具潜力的阻隔措施[69]。HEGELE和MCGEE[87]研究了应用ERH技术时分别设置单侧物理屏障、水力屏障井和蒸汽注射井对土壤升温效果的影响,结果表明设置蒸汽注射井时升温效果最好,其次为水力屏障井。增设蒸汽注射井为地下水阻隔提供了新选择,但也将产生额外的能源需求,仍需开展系统的研究验证其降耗的可行性。

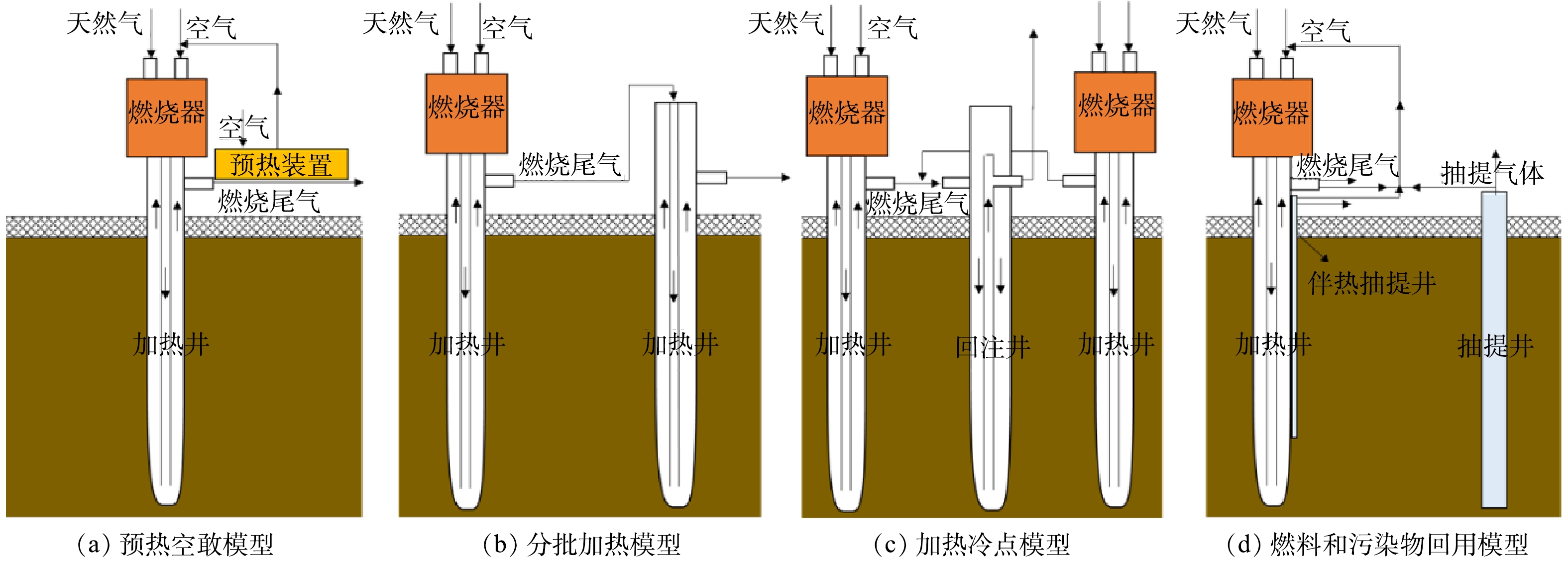

3) 余热回用。余热回用是降低燃烧尾气排放和气相抽提散热的重点方向,目前的研究多集中于GTR技术中[29,88-89],回收利用方式包括:1) 回收热量预热空气,在燃烧尾气排放管路上安装预热装置,加热即将进入燃烧器的冷空气,减少因其进入所导致的热量消耗,如图4 (a) 所示;2) 回收热量预热土壤,将前一批次加热井排出的燃烧尾气注入下一批次的加热井中,预热待修复土壤,降低后续的热量需求,如图4 (b) 所示;3) 回收热量加热冷点区域,在冷点 (多个加热井的中心位置) 安装回注井,并将周边加热井的燃烧尾气注入回注井中加热冷点的土壤,使目标区域受热更均匀,如图4 (c) 所示;4) 回收利用燃料和高热值污染物,将燃烧尾气或抽提尾气按一定比例返回燃烧器中燃烧,提高燃料利用率,充分利用污染物燃烧释放的热量并降低尾气处理负荷,如图4 (d) 所示。余热回用具有较大的降耗潜力,许优等[90]在研究异位热脱附的节能降耗方案时,发现回用回转窑二燃室的高温烟气预干燥污染土壤可以使总能耗降低约20%。在ISTT研究中,LI等[29]发现将GTR加热井的燃烧废气按比例 (10%、20%和30%) 返回燃烧器内燃烧,可以提高3%以上的能源利用率,降耗效果随回用比例的增加而提升。

-

原位热处理技术的优化研究已取得一定进展,但缺乏完善的优化方案及工程应用经验。在绿色可持续修复理念和“双碳”战略背景下,建议未来重点在以下4个方面开展研究工作。

1) 进一步开展原位热处理技术的绿色可持续评估,为技术比选和优化提供参考。针对不同原位热处理技术,开展绿色可持续评估,量化修复过程的环境影响,明确其关键贡献环节。

2) 深入分析原位热处理工艺中可再生能源的应用前景。分析可再生能源在原位热处理过程的适用性,探明其应用途径及关键限制因素,开展现场工程应用研究,提出适用于不同场地条件、不同修复技术的应用实施方案。

3) 进一步开展原位热处理耦合联用工艺的研究。研究耦合联用工艺的修复机理,获取关键技术参数,深入分析不同地质条件下耦合联用工艺的适用性,同时加强耦合技术的节能效益分析,为修复方案的设计与实际工程应用提供指导。

4) 增强原位热处理技术热损失控制工艺及设备研发。开展高保温性能材料的研究,优化地表阻隔与地下阻隔工艺,减少修复区域热量向外扩散;探索燃烧尾气和抽提尾水尾气余热回用的方法,构建完备的余热回用体系,研发与修复技术配套的经济高效、适应性强的余热回用设备,提升能源利用效率。

“双碳”目标下污染场地原位热处理技术发展趋势

Discussion on development trend of in-situ thermal treatment technology for contaminated sites under dual-carbon target

-

摘要: 原位热处理技术可以在低地下扰动的前提下实现污染场地快速高效的修复,已成为高浓度挥发/半挥发性有机物污染场地修复的热门技术之一。然而,传统原位热处理技术存在能耗和碳排放较高的弊端,限制了其大范围推广应用。在“碳达峰、碳中和”的战略目标下,亟需开展原位热处理技术的优化研究以降低其能效比。通过国内外实验研究与工程案例的整理分析,识别原位热处理活动中的碳排放和能耗的关键工艺环节,进而提出该技术低碳化发展的主要方向;同时梳理原位热处理工艺中应用再生能源和技术优化的研究进展,展望“双碳”目标下该技术的重点研究方向。目前已获得的研究结果表明,通过应用可再生能源和技术优化有望实现原位热修复工艺的大幅减排。Abstract: In-situ thermal treatment technology can achieve rapid and efficient remediation of contaminated sites with low underground disturbance, and has become one of the most popular remediation technologies for contaminated sites with high concentration of volatile/semi-volatile organic compounds. However, this technology has the drawbacks of high energy consumption and carbon emissions, which limits its wide-scale popularization and application. Under the strategic target of “carbon peak, carbon neutrality”, it is urgent to carry out process optimization of this technology. Through the analysis of domestic and foreign experimental studies and engineering cases, the key processes of carbon emission and energy consumption in in-situ thermal treatment activities were identified, and the main direction of low-carbon development of the technology was proposed. Then, the application of renewable energy in in-situ thermal treatment and the optimization of in-situ thermal treatment technology at the technical aspects was reviewed. Finally, the future research direction of this technology under the target of “dual carbon” was prospected. The results obtained so far showed that the carbon emissions of in-situ thermal treatment processes were expected to be significantly reduced through renewable energy applications and technological optimization.

-

-

Table 1. Technical characteristics of in-situ thermal treatment technologies

技术类型 最高温度/ ℃ 加热原理 优点 局限性 电阻加热 100 基于欧姆加热原理,通过电流加热污染区域 对地下非均质性不敏感 需要场地具有一定含水量 热传导加热 750~800 以热传导的形式加热污染区域 温度高,适用于难挥发污染物的处理 易受高地下水通量的影响 蒸汽强化抽提 170 以热对流的形式加热污染区域 成本较低,适用于地下水流速较快场地的处理 需要场地具有一定渗透性 射频加热 300~400 通过高频渐变电场作用来加热污染区域 对地下热导率和渗透率无要求 需要场地具有一定含水量,且成本较高 阴燃 1 200 依靠空气注入引发污染介质表面有机污染物的自持燃烧 可以自我维持,高效节能 需要场地具有一定渗透性,且对污染物浓度和热值要求较高 表 2 典型原位热处理案例的碳排放情况

Table 2. Carbon emissions from typical cases applying in-situ thermal treatment

技术类型 评估

方法主要污染物 土方量/

m3总碳排放量/

(tCO2-eq)单位碳排放量/

(kgCO2-eq·m-3)文献 电阻加热 EFA 多氯联苯 5.78×106 2.99×103 0.5 [20] LCA 含氯挥发性有机物 3.36×103 1.11×103 330.0 [21] 热传导

加热LCA 三氯乙烯 700 2.01×102 287.1 [22] — 煤焦油 — 4.12×104 — [19] 蒸汽强化

抽提EFA 石油烃 3.00×106 (3.42~6.10)×104 11.4~20.3 [23] LCA 含氯挥发性有机物 — 1.61×103 — [24] 阴燃 — 煤焦油 — 4.39×103 — [19] 注:EFA表示环境足迹分析,LCA表示全生命周期评价。 表 3 典型原位热处理案例的能耗情况

Table 3. Energy consumption from typical cases applying in-situ thermal treatment

技术类型 能源介质 主要污染物 土方量/m3 总能耗/kWh 单位能耗/ (kWh·m-3) 文献 电阻加热 电、柴油 三氯乙烯 1.26×103 6.81×105 540.5 [26] 电、柴油 三氯乙烯 1.17×104 3.47×106 296.6 [26] — 多氯联苯 5.78×106 1.70×107 2.9 [20] 热传导

加热电、柴油 氯乙烯 0.70×103 2.94×104 420.0 [22] 电、柴油 三氯乙烯 1.26×103 7.65×105 607.1 [26] 电、柴油 三氯乙烯 1.17×104 4.02×106 343.6 [26] 电 含氯挥发性有机物 9.35×104 2.32×107 248.7 [27] 蒸汽强化抽提 电、天然气 石油烃 3.00×105 (1.70~2.46)×108 566.7~820.0 [23] 电、柴油 矿物油、多环芳烃等 1.51×104 5.69×105 37.6 [28] 天然气、柴油 三氯乙烯 1.26×103 9.64×105 765.1 [26] 天然气、柴油 三氯乙烯 1.17×104 6.35×106 542.7 [26] 射频加热 电、柴油 三氯乙烯 0.20×103 1.29×105 645.0 [26] 电、柴油 三氯乙烯 1.17×104 1.03×106 88.0 [26] -

[1] HONG Y, HUANG X, THOMPSON J R, et al. China's soil pollution: urban brownfields[J]. Science, 2014, 344(6185): 691-692. [2] 梁竞, 王世杰, 张文毓, 等. 美国污染场地修复技术对我国修复行业发展的启示[J]. 环境工程, 2021, 39(6): 173-178. doi: 10.13205/j.hjgc.202106026 [3] 中华人民共和国国务院. 土壤污染防治行动计划[Z]. 2016-05-31. http://www.gov.cn/xinwen/2016-05/31/content_5078467.htm. [4] 全国人民代表大会常务委员会. 中华人民共和国土壤污染防治法[Z]. 2020-08-31. http://www.gov.cn/xinwen/2018-08/31/content_5318231.htm. [5] 骆永明, 滕应. 中国土壤污染与修复科技研究进展和展望[J]. 土壤学报, 2020, 57(5): 1137-1142. [6] HERON G, CARROLL S and NIELSEN S G. Full-scale removal of DNAPL constituents using steam-enhanced extraction and electrical resistance heating[J]. Ground Water Monitoring & Remediation, 2005, 25(4): 92-107. [7] HERON G, LACHANCE J and BAKER R. Removal of PCE DNAPL from tight clays using in situ thermal desorption[J]. Groundwater Monitoring & Remediation, 2013, 33(4): 31-43. [8] NILSSON B, TZOVOLOU D, JECZALIK M, et al. Combining steam injection with hydraulic fracturing for the in situ remediation of the unsaturated zone of a fractured soil polluted by jet fuel[J]. Journal of Environmental Management, 2011, 92(3): 695-707. doi: 10.1016/j.jenvman.2010.10.004 [9] ZHAO C, DONG Y, FENG Y P, et al. Thermal desorption for remediation of contaminated soil: A review[J]. Chemosphere, 2019, 221: 841-855. doi: 10.1016/j.chemosphere.2019.01.079 [10] 曲建升, 陈伟, 曾静静, 等. 国际碳中和战略行动与科技布局分析及对我国的启示建议[J]. 中国科学院院刊, 2022, 37(4): 444-458. doi: 10.16418/j.issn.1000-3045.20210829001 [11] 侯德义, 李广贺. 污染土壤绿色可持续修复的内涵与发展方向分析[J]. 环境保护, 2016, 44(20): 16-19. doi: 10.14026/j.cnki.0253-9705.2016.20.003 [12] 新华网. 中共中央 国务院关于完整准确全面贯彻新发展理念做好碳达峰碳中和工作的意见[EB/OL]. http://www.news.cn/2021-10/24/c_1127990632.htm, 2022-09-16. [13] STROO H F, LEESON A, MARQUSEE J A, et al. Chlorinated ethene source remediation: lessons learned[J]. Environmental Science & Technology, 2012, 46(12): 6438-6447. [14] DING D, SONG X, WEI C L, et al. A review on the sustainability of thermal treatment for contaminated soils[J]. Environmental Pollution, 2019, 253: 449-463. doi: 10.1016/j.envpol.2019.06.118 [15] KINGSTON J, JOHNSON P C, KUEPER B H, et al. In situ thermal treatment of chlorinated solvent source zones[J]. New York:Springer, 2014: 510-511. [16] HORST J, MUNHOLLAND J, HEGELE P, et al. In situ thermal remediation for source areas: technology advances and a review of the market from 1988–2020[J]. Groundwater Monitoring & Remediation, 2021, 41(1): 17-31. [17] VIDONISH J E, ZYGOURAKIS K, MASIELLO C A, et al. Thermal treatment of hydrocarbon-impacted soils: a review of technology innovation for sustainable remediation[J]. Engineering, 2016, 2(4): 426-437. doi: 10.1016/J.ENG.2016.04.005 [18] MCGEE B. Electro‐thermal dynamic stripping process for in situ remediation under an occupied apartment building[J]. Remediation Journal, 2003, 13(3): 67-79. doi: 10.1002/rem.10075 [19] GRANT G P, MAJOR D, SCHOLES G C, et al. Smoldering combustion (STAR) for the treatment of contaminated soils: examining limitations and defining success[J]. Remediation Journal, 2016, 26(3): 27-51. doi: 10.1002/rem.21468 [20] HARCLERODE M A, LAL P and MILLER M E. Estimating social impacts of a remediation project life cycle with environmental footprint evaluation tools[J]. Remediation Journal, 2013, 24(1): 5-20. doi: 10.1002/rem.21374 [21] FISHER A. Life-cycle assessment of in situ thermal remediation[J]. Remediation the Journal of Environmental Cleanup Costs, Technologies & Techniques, 2012, 22(4): 75-92. [22] LEMMING G, HAUSCHILD M Z, CHAMBON J, et al. Environmental impacts of remediation of a trichloroethene-contaminated site: life cycle assessment of remediation alternatives[J]. Environmental Science & Technology, 2010, 44(23): 9163. [23] USEPA, Environmental footprint analysis of steam enhanced extraction remedy: EPA 542-R-14-004[EB/OL]. [2022-02-25]. https://clu-in.org/greenremediation/docs/Williams-AFB-Footprint-Evaluation.pdf, 2014. [24] BALDOCK J, CHESHER L, REID D, et al. Assessment of a large scall in-situ thermal project performed at a chlorinated solvent site in the UK[EB/OL]. [2022-02-24]. http://clu-in.info/download/contaminantfocus/fracrock/Baldock-Aqua-paper.pdf,2010. [25] 江亿, 杨秀. 在能源分析中采用等效电方法[J]. 中国能源, 2010, 32(5): 7-13. doi: 10.3969/j.issn.1003-2355.2010.05.001 [26] LEMMING G, NIELSEN S G, WEBER K, et al. Optimizing the environmental performance of in situ thermal remediation technologies using life cycle assessment[J]. Ground Water Monitoring and Remediation, 2013, 33(3): 38-51. doi: 10.1111/gwmr.12014 [27] HERON G, PARKER K, FOURNIER S, et al. World's largest in situ thermal desorption project: challenges and solutions[J]. Ground Water Monitoring & Remediation, 2015, 35(3): 89-100. [28] CAPPUYNS V and KESSEN B. Evaluation of the environmental impact of brownfield remediation options: comparison of two life cycle assessment-based evaluation tools[J]. Environmental Technology, 2012, 33(21): 2447-2459. doi: 10.1080/09593330.2012.671854 [29] LI T T, LI Y Z, ZHAI Z Z, et al. Energy-saving strategies and their energy analysis and exergy analysis for in situ thermal remediation system of polluted-soil[J]. Energies, 2019, 12(20): 1-28. [30] 赵良, 白建华, 辛颂旭, 等. 中国可再生能源发展路径研究[J]. 中国电力, 2016, 49: 178-184. doi: 10.11930/j.issn.1004-9649.2016.08.178.03 [31] COLLINS E, ELMORE A C and CROW M. Using conditional probability to predict solar-powered pump-and-treat performance[J]. Journal of Hazardous, Toxic, and Radioactive Waste, 2013, 17(1): 31-37. doi: 10.1061/(ASCE)HZ.2153-5515.0000144 [32] CONROY J P, ELMORE A C and CROW M. Capture zone comparison for photovoltaic microgrid-powered pump and treat remediation[J]. Journal of Hazardous Toxic & Radioactive Waste, 2014, 18(3): 04014009. [33] GAMAGE K J and PATHIRANA W. A review of green remediation technologies and feasibility study of integrating renewable energy into contaminated site in northern cyprus[C]//Yenilenebilir Enerji Kaynakları Sempozyumu, 2013. [34] SIERRA M J, MILLáN R, FéLIX A, et al. Sustainable remediation of mercury contaminated soils by thermal desorption[J]. Environmental Science& Pollution Research, 2016, 23: 4898-4907. [35] NAVARRO A, CAñADAS I and RODRíGUEZ J. Thermal treatment of mercury mine wastes using a rotary solar kiln[J]. Minerals, 2014, 4(1): 37-51. doi: 10.3390/min4010037 [36] NAKAMURA T, SENIOR C L, BURNS E G, et al. Solar‐powered soil vapor extraction for removal of dense nonaqueous phase organics from soil[J]. Environmental Letters, 2000, 35(6): 795-816. [37] 高冰, 魏明磊, 张康, 等. 污染土壤原位太阳能热脱附修复系统: CN112872007A[P]. 2021-06-01. [38] NAVARRO A, CARDELLACH E, CAADAS I, et al. Solar thermal vitrification of mining contaminated soils[J]. International Journal of Mineral Processing, 2013, 119: 65-74. doi: 10.1016/j.minpro.2012.12.002 [39] PAUL F, BAS G, INGRID S, et al. Worldwide application of aquifer thermal energy storage–A review[J]. Renewable & Sustainable Energy Reviews, 2018, 94: 861-876. [40] RIJNAARTS H, GAANS P V, SMIT M, et al. Biodegradation of cis-1, 2-dichloroethene in simulated underground thermal energy storage systems[J]. Environmental Science & Technology, 2015, 49(22): 13519-13527. [41] MORADI A, M. SMITS K and O. SHARP J. Coupled thermally-enhanced bioremediation and renewable energy storage system: conceptual framework and modeling investigation[J]. Water, 2018, 10(10): 1288. doi: 10.3390/w10101288 [42] KASTNER O, NORDEN B, KLAPPERER S, et al. Thermal solar energy storage in Jurassic aquifers in northeastern Germany: a simulation study[J]. Renewable Energy, 2017, 104: 290-306. doi: 10.1016/j.renene.2016.12.003 [43] FERNáNDEZ-MARCHANTE C M, SOUZA F L, MILLáN M, et al. Improving sustainability of electrolytic wastewater treatment processes by green powering[J]. Science of The Total Environment, 2020, 754: 142230. [44] SOUZA F L, LANZA M, LLANOS J, et al. A wind-powered BDD electrochemical oxidation process for the removal of herbicides[J]. Journal of Environmental Management, 2015, 158: 36-39. [45] BELSKY A A, DOBUSH V S and MALAREV V I. Electro steam thermal complex powered by wind-driven generator for the treatment of the oil formation's bottomhole area[J]. Journal of Physics Conference Series, 2020, 1441: 012020. doi: 10.1088/1742-6596/1441/1/012020 [46] ROSSMAN A J, HAYDEN N J and RIZZO D M. Low-temperature soil heating using renewable energy[J]. Journal of Environmental Engineering, 2006, 132(5): 537-544. doi: 10.1061/(ASCE)0733-9372(2006)132:5(537) [47] HELLRIEGEL U, KURZ E C, LUONG V T, et al. Modular treatment of arsenic-laden brackish groundwater using solar-powered subsurface arsenic removal (SAR) and membrane capacitive deionization (MCDI) in Vietnam[J]. Journal of Water Reuse and Desalination, 2020, 10(4): 513-526. doi: 10.2166/wrd.2020.031 [48] GENG Z N, LIU B, LI G H, et al. Enhancing DNAPL Removal from low permeability zone using electrical resistance heating with pulsed direct current[J]. Journal of Hazardous Materials, 2021, 413(13): 125455. [49] SOUZA F L, LLANOS J, SAEZ C, et al. Performance of wind-powered soil electroremediation process for the removal of 2, 4-D from soil[J]. Journal of Environmental Management, 2016, 171: 128-132. [50] GANIYU S O and MARTíNEZ-HUITLE C. The use of renewable energies driving electrochemical technologies for environmental applications[J]. Current Opinion in Electrochemistry, 2020, 22: 211-220. doi: 10.1016/j.coelec.2020.07.007 [51] PENG S, WANG N and CHEN J J. Steam and air co-injection in removing residual TCE in unsaturated layered sandy porous media[J]. Journal of Contaminant Hydrology, 2013, 153(7): 24-36. [52] JANFADA T S, CLASS H, KASIRI N, et al. Comparative experimental study on heat-up efficiencies during injection of superheated and saturated steam into unsaturated soil[J]. International Journal of Heat and Mass Transfer, 2020, 158: 119235. doi: 10.1016/j.ijheatmasstransfer.2019.119235 [53] 葛松, 孟宪荣, 许伟, 等. 原位电阻热脱附土壤升温机制及影响因素[J]. 环境科学, 2020, 41(8): 3822-3828. doi: 10.13227/j.hjkx.202001092 [54] 耿竹凝, 刘波, 黄菀, 等. 电热耦合强化非均质介质中三氯乙烯DNAPL的迁移去除[J]. 环境科学研究, 2020, 33(8): 1911-1918. doi: 10.13198/j.issn.1001-6929.2020.04.23 [55] XU H J, LI Y Z, GAO L J, et al. Planned heating control strategy and thermodynamic modeling of a natural gas thermal desorption system for contaminated soil[J]. Energies, 2020, 13(3): 642. doi: 10.3390/en13030642 [56] ZHAI Z Z, YANG L M, LI Y Z, et al. Fuzzy coordination control strategy and thermohydraulic dynamics modeling of a natural gas heating system for in situ soil thermal remediation[J]. Entropy, 2019, 21(10): 971. doi: 10.3390/e21100971 [57] XIE Q L, MUMFORD K G and KUEPER B H. Modelling gas-phase recovery of volatile organic compounds during in situ thermal treatment[J]. Journal of Contaminant Hydrology, 2017, 234: 103698. [58] PARKER J, KIM U, KITANIDIS P, et al. Stochastic cost optimization of DNAPL remediation-Method description and sensitivity study[J]. Environmental Modelling & Software, 2012, 38: 74-88. [59] FALCIGLIA PP, GIUSTRA M G and VAGLIASINDI F. Low-temperature thermal desorption of diesel polluted soil: Influence of temperature and soil texture on contaminant removal kinetics[J]. Journal of Hazardous Materials, 2011, 185(1): 392-400. doi: 10.1016/j.jhazmat.2010.09.046 [60] LIU J, ZHANG H, YAO Z H, et al. Thermal desorption of PCBs contaminated soil with calcium hydroxide in a rotary kiln[J]. Chemosphere, 2019, 220: 1041-1046. doi: 10.1016/j.chemosphere.2019.01.031 [61] HU G J, LIU H, RANA A, et al. Life cycle assessment of low-temperature thermal desorption-based technologies for drill cuttings treatment[J]. Journal of Hazardous Materials, 2020, 401: 123865. [62] LU G H, YUE C S, LIU S Y, et al. Na2S leaching assisting thermal desorption for thoroughly and mildly remediating severely Hg-contaminated soil[J]. Journal of chemical engineering of Japan, 2019, 52(10): 805-810. doi: 10.1252/jcej.19we037 [63] MA F J, QIAN Z, XU D P, et al. Mercury removal from contaminated soil by thermal treatment with FeCl3 at reduced temperature[J]. Chemosphere, 2014, 117(1): 388-393. [64] MA F J, PENG C S, HOU D Y, et al. Citric acid facilitated thermal treatment: An innovative method for the remediation of mercury contaminated soil[J]. Journal of Hazardous Materials, 2015, 300: 546-552. doi: 10.1016/j.jhazmat.2015.07.055 [65] LIU Y Q, LI X D, ZHANG W W, et al. Pyrolysis of heavy hydrocarbons in weathered petroleum-contaminated soil enhanced with inexpensive additives at low temperatures[J]. Journal of Cleaner Production, 2021, 302: 127017. doi: 10.1016/j.jclepro.2021.127017 [66] LI J J, WANG L, PENG L B, et al. A combo system consisting of simultaneous persulfate recirculation and alternating current electrical resistance heating for the implementation of heat activated persulfate ISCO[J]. Chemical Engineering Journal, 2020, 385: 123803. doi: 10.1016/j.cej.2019.123803 [67] HAN Z Y, LI S H, YUE Y, et al. Enhancing remediation of PAH-contaminated soil through coupling electrical resistance heating using Na2S2O8[J]. Environmental Research, 2020, 198(22): 110457. [68] MORI P L, KIRKLAND E, FAIRCLOTH H, et al. Combined thermal and zero-valent iron in situ soil mixing remediation technology[J]. Remediation Journal, 2010, 20(2): 9-25. doi: 10.1002/rem.20237 [69] HERON, G, CHRISTENSEN, T H and ENFIELD, C G. Henry's law constant for trichloroethylene between 10 and 95 °C[J]. Environmental Science & Technology, 1998, 32(10): 1433-1437. [70] USMAN M, CHAUDHARY A, BIACHE C, et al. Effect of thermal pre-treatment on the availability of PAHs for successive chemical oxidation in contaminated soils[J]. Environmental Science & Pollution Research, 2015, 23(2): 1-10. [71] PARK S, LEE L S, MEDINA V F, et al. Heat-activated persulfate oxidation of PFOA, 6: 2 fluorotelomer sulfonate, and PFOS under conditions suitable for in-situ groundwater remediation[J]. Chemosphere, 2016, 145: 376-383. doi: 10.1016/j.chemosphere.2015.11.097 [72] HEAD N A, GERHARD J I, INGLIS A M, et al. Field test of electrokinetically-delivered thermally activated persulfate for remediation of chlorinated solvents in clay[J]. Water Research, 2020, 183(13): 116061. [73] NGUELEU S K, REZANEZHAD F, AL-RAOUSH R I, et al. Sorption of benzene and naphthalene on (semi)-arid coastal soil as a function of salinity and temperature[J]. Journal of Contaminant Hydrology, 2018, 219: 67-71. [74] SLEEP B E and MCCLURE P D. The effect of temperature on adsorption of organic compound to soils[J]. Canadian Geotechnical Journal, 2001, 38(1): 46-52. doi: 10.1139/t00-067 [75] KOSEGI J M, MINSKER B S and DOUGHERTY D E. Feasibility study of thermal in situ bioremediation[J]. Journal of Environmental Engineering, 2000, 126(7): 601-610. doi: 10.1061/(ASCE)0733-9372(2000)126:7(601) [76] PERFUMO A, BANAT I M, MARCHANT R, et al. Thermally enhanced approaches for bioremediation of hydrocarbon-contaminated soils[J]. Chemosphere, 2007, 66(1): 179-184. doi: 10.1016/j.chemosphere.2006.05.006 [77] SLENDERS H, DOLS P, VERBURG R, et al. Sustainable synergies for the subsurface combining groundwater energy with remediation: an illustration with 2 cases[C]// First International Conference on Frontiers in Shallow Subsurface Technology. 2010. [78] HIESTER U and SCHRENK V. Thermally enhanced in-situ remediations beneath buildings during their continued usage – new source removal options for urban sites[C]// ConSoil 2008. 2008. [79] US Army Corps of Engineers, Design: in situ thermal remediation: EM 200-1-21[Z]. 2014.https://www.publications.usace.army.mil/. [80] BAKER R S and HERON G. In situ delivery of heat by thermal conduction and steam injection for improved DNAPL remediation[EB/OL]. [2022-02-25]. https://terratherm.com/pdf/white%20papers/paper11-11-6-09.pdf, 2014. [81] TIMMONS D G, SANDLIN S and TRUSSELL S. Combined technologies: thermal conduction heating and steam enhanced extraction removes 99% of estimated contaminant mass[Z]. EPA's Office of Superfund Remediation and Technology Innovation (OSRTI), Technology News and Trends, 2012, No. 61. [82] ROLAND U, HOLZER F and KOPINKE F D. Combining different frequencies for electrical heating of saturated and unsaturated soil zones[J]. Chemical Engineering & Technology, 2011, 34(10): 1645-1651. [83] 李丁, 李瑞海, 张文清, 等. 一种用于原位燃气热脱附修复的地表覆盖结构: CN213134474U[P]. 2021-05-07. [84] HOGGES A R and FALTA R W. Vertical confinement of Injected steam in the vadose zone using cold air injection[J]. Vadose Zone Journal, 2008, 7(2): 732-740. doi: 10.2136/vzj2007.0093 [85] 迟克宇, 李传维, 籍龙杰, 等. 原位电热脱附技术在某有机污染场地修复中的应用效果[J]. 环境工程学报, 2019, 13(9): 2049-2059. doi: 10.12030/j.cjee.201905110 [86] BEYKE G and FLEMING D. In situ remediation of DNAPL and LNAPL using electrical resistance heating[J]. Remediation Journal, 2005, 15(3): 5-22. doi: 10.1002/rem.20047 [87] HEGELE P R and MCGEE B C W. Managing the negative impacts of groundwater flow on electrothermal remediation[J]. Remediation Journal, 2017, 27(3): 29-38. doi: 10.1002/rem.21516 [88] 李书鹏, 焦文涛, 李鸿炫, 等. 燃气热脱附技术修复有机污染场地研究与应用进展[J]. 环境工程学报, 2019, 12(9): 2037-2048. doi: 10.12030/j.cjee.201905108 [89] 李奉才, 胡佳晨, 郑阳, 等. 一种土壤原位热脱附修复系统: CN112872004A[P]. 2021-06-1. [90] 许优, 顾海林, 詹明秀, 等. 有机污染土壤异位直接热脱附装置节能降耗方案[J]. 环境工程学报, 2019, 13(9): 2074-2082. doi: 10.12030/j.cjee.201906011 -

下载:

下载: