-

进入21世纪以来,能源危机和环境问题日益突出,探索可再生和可持续能源以及开发新技术高效去除环境污染物已成为当前缓解能源危机和环境问题的重要研究方向之一[1-5]。其中,环境催化技术是将环境工程与催化技术相结合的一种新技术,而开发高效、稳定和低廉的催化剂是推动环境催化技术应用的关键[6-9]。

纳米材料因具有比表面积大、功能性强、强度高和延展性好等特点而受到了科学界和产业界的广泛关注。其中,纳米纤维是一类直径为纳米尺度而长度较大的具有一定长径比的线状纳米材料。随着纳米材料的发展,利用纳米颗粒填充改性形成的线状材料也可称为纳米纤维。纳米纤维包括纳米线、纳米管、纳米棒等,具有尺寸控制范围大,比表面积丰富和长径比较高的特点,在电子、光学、热学、催化等方面具有更优越的性能[10-17]。目前,制备纳米纤维的方法主要包括化学气相沉积法、模板导向合成法、气固法、液相法、熔体吹制法、自组装法、电沉积和静电纺丝法[11, 18-22]。与其它技术相比,静电纺丝技术能以简单、可控、高效的方法制备具有不同成分或形貌结构多样的纳米纤维[23],但是由于静电纺丝技术受到喷头和纺丝液自身性质的约束,一般情况下难以获得尺寸较小(如低于50 nm)的纳米纤维,因而,在环境领域中多作为一类吸附、富集材料或载体。当应用于催化反应时,将其作为高度分散活性物种的载体,不仅有利于增加催化剂的比表面积,提高空间利用率,增加反应物与活性位点接触的机会,还可根据需要调整修饰方法得到不同类型或具有特定应用的纳米纤维。因此,静电纺丝技术制备的多级结构纳米纤维可以广泛应用于能源和环境催化领域。

本文总结了近几年来利用静电纺丝技术制备不同结构的纳米纤维材料的研究新进展,详细介绍了中空型、wire-in-tube型、tube-in-tube型、多通道型和树枝状型多级结构纳米纤维材料的设计理念和合成手段,重点关注了多级结构纳米材料在催化污染物降解和转化方面的应用,并对当前静电纺丝技术构建适用于环境催化领域的多级结构纳米材料存在的不足和未来的研究方向进行了展望。

-

中空纳米纤维是指纤维轴向具有细管状的空腔结构,含有内外两个表面,从而可以暴露更多的活性位用于催化反应中。尽管普通模板法和化学气相沉积法可以制得中空纤维材料,但合成产量低,合成条件比较苛刻且设备价格昂贵[24-25]。而静电纺丝技术不仅条件易于控制,原料便宜,还能连续、高效的制备中空纳米纤维,因此受到了研究人员的青睐[26]。

单喷嘴静电纺丝技术是制备中空纳米纤维最常见的方法[27-29]。Li等[28]利用单毛细管喷嘴对含有硅酸四乙酯(TEOS)的聚乙烯吡咯烷酮(PVP)进行静电纺丝成功地制备出聚合物纳米管(图1a),通过改变TEOS与PVP比例可以控制纳米管的直径和壁厚。随后,Jing等[29]也通过类似的方法,将Fe(NO3)3、Ni(NO3)2、Sr(NO3)2、Ti(C4H9O)4等高度分散于PVP溶液中,采用单喷嘴静电纺丝制得SrTiO3/NiFe2O4多孔纳米管中空复合材料,并将其应用于催化降解工业污染物罗丹明B,由于多孔和中空结构为氧化离子和罗丹明B分子提供了更多活性位点,且中空结构有利于传质,因此催化性能显著提高。

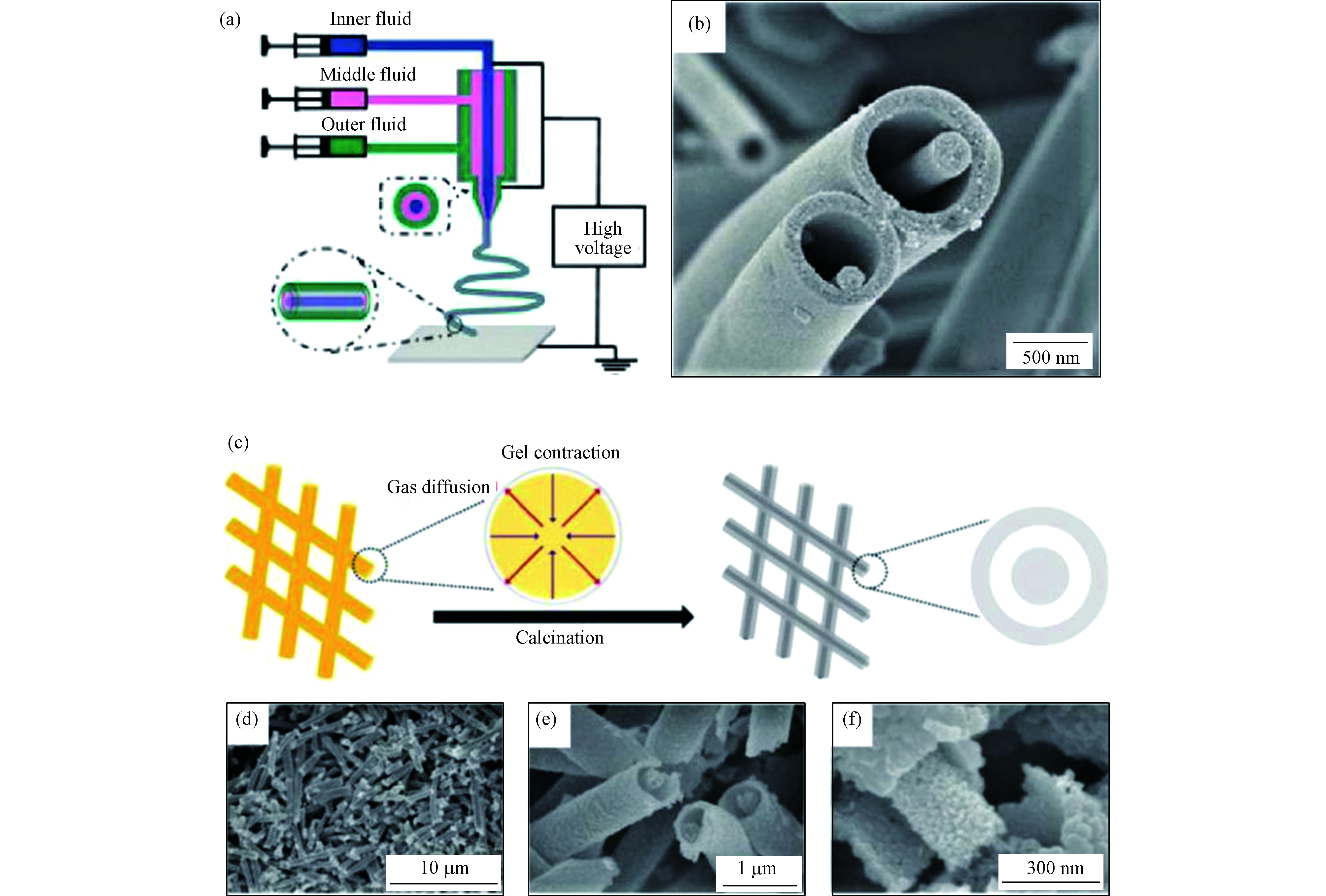

与单喷嘴电纺技术只能使用一种溶液相比,双喷嘴共电纺丝采用同轴排列的内外毛细管组成的特殊喷丝头,可使不同的聚合物溶液同时电纺,因此可以合成出性能更好的中空纳米纤维[30]。Chang等[31]采用含有PVP、Ti(OC4H9)4、乙酸和乙醇的溶液为外层,含有PVP、乙醇和银纳米粒子的溶液为内层,通过调节内外压力控制纳米纤维的直径和壁厚,经煅烧形成镶嵌Ag2O纳米颗粒的介孔TiO2中空纤维。由于TiO2的光催化活性主要受其形貌、粒径、表面积、孔隙率等影响,因此,他们利用贵金属沉积修饰TiO2形成Ag-TiO2复合中空纳米纤维,从而提高电子传递动力学效率。通过实验对比发现,Ag填充TiO2中空纤维对亚甲基蓝的分解具有良好的光催化活性,且降解速率快于其它对比材料,这一研究成果为TiO2中空纤维应用于其它环境污染物的降解奠定了基础。Kang等[32]采用聚丙烯腈(PAN)作为碳纳米纤维的前驱体材料,使用能在300—450 ℃完全分解的聚甲基丙烯酸甲酯(PMMA)作为核(图1b),从而可形成中空型纳米纤维。为了进一步研究制备含有金属锰氧化物的聚合物纳米纤维,他们采用MnAc/PMMA溶液作为纳米纤维核,将MnAc/PMMA溶液通过双喷嘴的内部喷出,PAN溶液通过外部喷出,从而得到双层纳米纤维材料;再通过稳定化、碳化、活化、氧化等热处理步骤,形成含有锰氧化物催化剂的中空活性炭纳米纤维(Mn3O4/HACNFs, 图1c),由于该催化剂具有中空结构和纳米级通道,使其接触比表面积和微孔数量增加,不仅可以提高催化剂对VOCs的吸附能力,还能限制锰氧化物颗粒在反应条件下的聚集,使得催化剂具有较好的分散性和催化性能。

由此可见,利用静电纺丝技术制备中空纳米纤维主要依赖于喷嘴和聚合物纺丝液的物理性质,既可以获得体相型催化剂也可以构建负载型催化剂,其独特的中空结构不仅可以促进反应物与内、外部活性位点接触,还能调控合成手段优化催化剂的分散性和暴露性,避免催化剂在后续性能测试中发生团聚烧结现象,因而在制备先进催化剂方面具有巨大的潜力。然而,使用静电纺丝技术制备的中空纳米纤维直径较大,提供的比表面积相对有限,且管长较长,反应物在管内传输时间较长,难以避免生成物的再吸附和二次反应,因此单一的中空纳米纤维多用于大气或水体中污染物的物理吸附与富集。若想要进一步改善其在污染物降解方面的应用,可考虑减小中空纳米纤维的管径,缩短管长或将管壁制备成多孔形态,便于反应降解后的物质及时排出,从而实现中空纳米纤维在环境污染物的吸附降解方面的广泛应用。

-

Wire-in-tube型纳米纤维,即在中空纳米纤维的内部嵌入一根纳米线的纤维,它是由中空型纳米纤维发展而来,主要目的是调控内部空间结构,提高催化剂的空间利用率,促使扩散到纳米管中的反应物既可以与纳米管的内壁接触,又能与管内纳米线的表面接触,从而为制备多功能催化剂提供了一种有效的方法。

Chen等[33]在2010年利用静电纺丝法成功制备了wire-in-tube型纳米纤维。他们采用一种改进的多流体同轴静电纺丝方法(图2a),引入容易去除的惰性流体作为内外流体之间的隔离层,从而确保内外流体相互不接触,形成三层核/壳结构,然后通过萃取或煅烧等方法将中间层去除,得到wire-in-tube型纳米纤维(图2b)。这种多流体同轴静电纺丝是对传统同轴静电纺丝法在芯/壳复合材料制备中的重要扩展,为制备大比表面积的多功能材料提供了更多的选择。

除此之外,通过控制后期煅烧条件亦可制得wire-in-tube纳米纤维。Cho等[34]首先使用静电纺丝获得TBT-PVP复合纳米纤维,然后调控煅烧气氛,当在O2环境下加热,形成wire-in-tube TiO2纳米纤维,而在空气中加热则会得到实体纳米纤维。2017年,Fan等[35]利用PVP和乙醇作为溶剂,由于具有不同的沸点、以及SnCl2·2H2O在两种溶剂中的溶解度差异,在初始低温处理阶段,沸点较低的乙醇溶液率先蒸发,由于SnCl2·2H2O在乙醇中的溶解度高于它在溶有N,N-二甲基甲酰胺(DMF)的PVP中的溶解度,所以金属前驱体被纳米纤维的外层所吸引,形成外壳。如图2c,随着煅烧温度逐渐升高,DMF开始蒸发,内部的PVP有助于凝胶基质中残留的金属前驱体发生奥斯特瓦尔德熟化效应,并使气相的乙醇和DMF扩散产生外向力,而PVP向内收缩,从而使外壳和内层分离,形成结晶的wire-in-tube SnO2纳米纤维(图2d-f)。由于其具有更大的表面积、管中线结构、高密度的晶界等特性,电催化活性显著增强,因此在电化学还原温室气体CO2的过程中表现出优异的反应活性和稳定性,对C1产物(甲酸和一氧化碳)的选择性高。这种合成方法工艺简单,成本低廉,且得到的SnO2纳米纤维对C1产物的选择性高,化学稳定性好,为CO2的高值化利用提供了广阔的前景。

目前,在环境催化中,采用多流体同轴静电纺丝联合烧结控制构筑不同组分的wire-in-tube型纳米纤维已经得到了比较可喜的成果,然而在实际大规模制备中,稳定静电纺丝喷射工艺仍然存在一定的困难。因此,如何在深入认识静电纺丝多流体工艺和环境催化中活性中心的催化机理基础上,针对性设计wire-in-tube型多功能复合材料是当前需要重点关注的问题。

-

与中空纳米纤维含有内外两个暴露面和wire-in-tube含有3个暴露面相比,tube-in-tube纳米纤维由内外两个同轴空心纳米管组成,暴露面更多,且其独立的通道可以作为微型反应器,利用其空间限域效应实现反应产物选择性调控。

Lang等[36]在前期研究基础上,利用普通的不锈钢针作为喷头,通过调控静电纺丝参数和煅烧条件,合成了具有实心、中空和tube-in-tube结构的TiO2纤维(图3)。由于tube-in-tube结构的TiO2纤维具有较大的比表面积,因此与实心纤维和其它TiO2材料相比,对环境污染物2-氯苯酚和2,4-二氯苯酚的降解具有更好的光催化活性。这种制备纳米纤维的方法简单,可以推广应用于合成管状结构的其它金属氧化物纳米纤维,如ZrO2,SiO2,SnO2和In2O3等。Jin等[37]以二氧化硅中空纳米纤维作为前驱体,在水热作用下将其与镍离子的碱性溶液反应得到硅酸镍中空纳米纤维(NSHNFs),最后利用原位还原法将Au纳米颗粒(AuNPs)均匀固定在NSHNFs表面,形成纳米复合材料(AuNPs-NSHNFs)。由于它具有独特的分层双壁中空结构和高度分散的超细AuNPs,使得AuNPs与反应物充分接触,因此对4-硝基苯酚显示出较高的催化性能。这种合成方法简单、能耗低,且得到的催化剂活性和稳定性好,可重复使用。

尽管tube-in-tube结构的纳米纤维暴露的表面更多,具有4个暴露面,多级结构的空间特性使其在催化等领域中具有重要的应用前景。然而,目前所采用的方法大多只能得到内部和外部组分相同的纤维,且所获得的复合纤维的机械性能较差,严重限制了其实际应用。

-

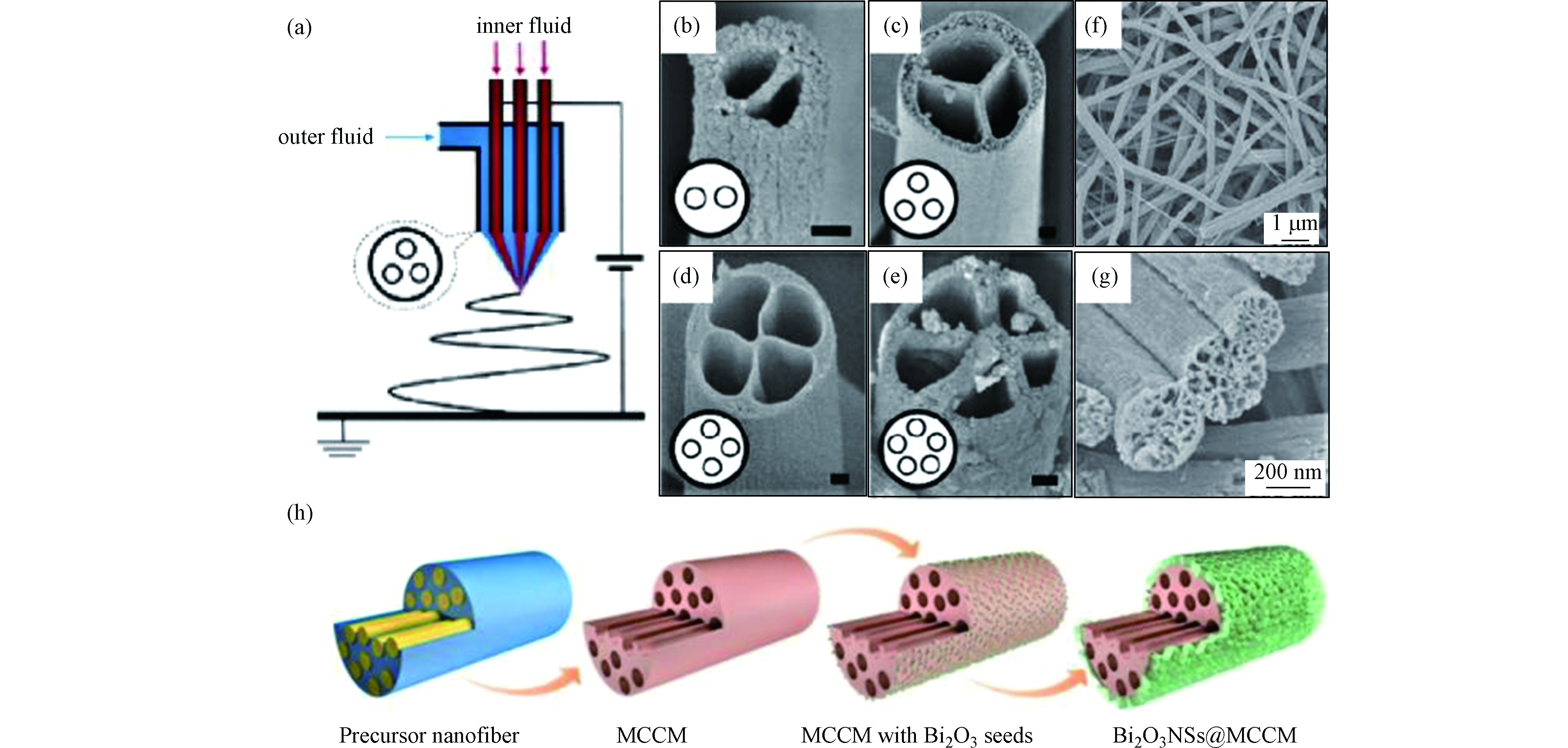

随着静电纺丝技术的进步,Zhao等[38]提出一种多级复合射流静电纺丝技术,这种技术可以简单、直接的制得通道数可控的多通道纳米纤维,它具有多个沿轴向独立平行的中空通道,内部结构与莲藕、秋葵等相似,比表面积大,通道独特,组分多样,结构稳定性好,在环境催化领域具有较大的应用潜力。图4a是以三通道纳米纤维为例的多级复合射流静电纺丝的实验装置图。他们将石蜡油、Ti(OiPr)4和PVP的乙醇溶液作为内液和外液,分别注入内毛细管和外注射器中,通过复合流体静电纺丝后形成纤维膜,经煅烧除去产物中的有机物,得到多通道TiO2纳米纤维。通过改变内部毛细管数量以及使用其它组分的溶液替代毛细管内液等方法,可以得到通道数为2—5的多功能中空纤维(图4(b-e))。由于光催化材料TiO2具有高效利用光、使用方便、无二次污染等显著优点,Zhao等[39]通过TiO2纤维对目标污染物乙醛降解的研究发现,这种多通道结构不仅增加了纤维的表面积,还可以在通道内部捕获更多的气体分子,并对入射光线进行多次反射,使其光催化活性得到有效提高,从而为新型环境修复光催化材料的研究提供了启示。

与控制通道数相比,蜂窝煤状的纳米纤维具有更多的通道。Chen等[40]利用金属烷氧基和石蜡油组成的微乳液中细小的油滴作为软模板,通过改变微乳液的组成和乳化条件等参数精确控制纤维的内部结构,得到均匀布满通道的纳米纤维(图4(f-g)),这是传统制备方法难以实现的。此外,Liu等[41]通过在导电多通道碳基底(MCCM)上生长Bi2O3纳米片,制备了用于电催化CO2还原反应(CO2RR)的层级氧化铋纳米片催化剂(Bi2O3NSs@MCCM),如图4h所示。由于电催化CO2还原反应与可再生能源(如太阳能、风能和潮汐能)结合使用,是缓解温室效应和相关环境危机的最具吸引力的方法之一[42],因此他们将Bi2O3NSs@MCCM应用于CO2RR,在中等过电位条件下可以获得相对较高的电流密度,在较宽的电位窗口下(−1.056到−1.356 V)对甲酸具有接近90%的高选择性和较好的稳定性。这种优越的性能主要归因于交织的多通道碳基底和层级的氧化铋纳米片的协同作用,其中多通道碳基底具有良好的电子转移能力、增强的CO2吸附能力和高比例的吡咯氮和吡啶氮,而超薄的氧化铋纳米片提供了丰富的活性位点和低的功函数。Tang等[43]也通过类似的方法构建了多通道碳纳米纤维(MCCNFs)。通过溶剂热生长尖晶石ZnCo2O4的方式引入高催化活性的钴元素,经高温碳热还原、蒸发后制得钴掺杂的交联多通道碳纳米纤维(Co/IMCCNFs),其独特的多通道结构锚定的高活性钴位点不仅保证了较高的传质速度,还提高了Co活性位点的暴露和有效利用,从而增强燃料电池ORR的电催化活性。由此可见,多通道纳米纤维是一种结构稳定、用途广泛的材料,但由于多液针的制作和稳定的静电纺丝系统的选择存在一定的难度,使得可控通道数结构纳米纤维的制备比较困难,难以满足实际应用中的需求。如何进一步提高多通道纳米纤维的制备工艺稳定性,或者在合成体系中结合其它合成手段,产生具有多级结构的活性中心,从而拓展多功能材料在环境催化领域的应用。

-

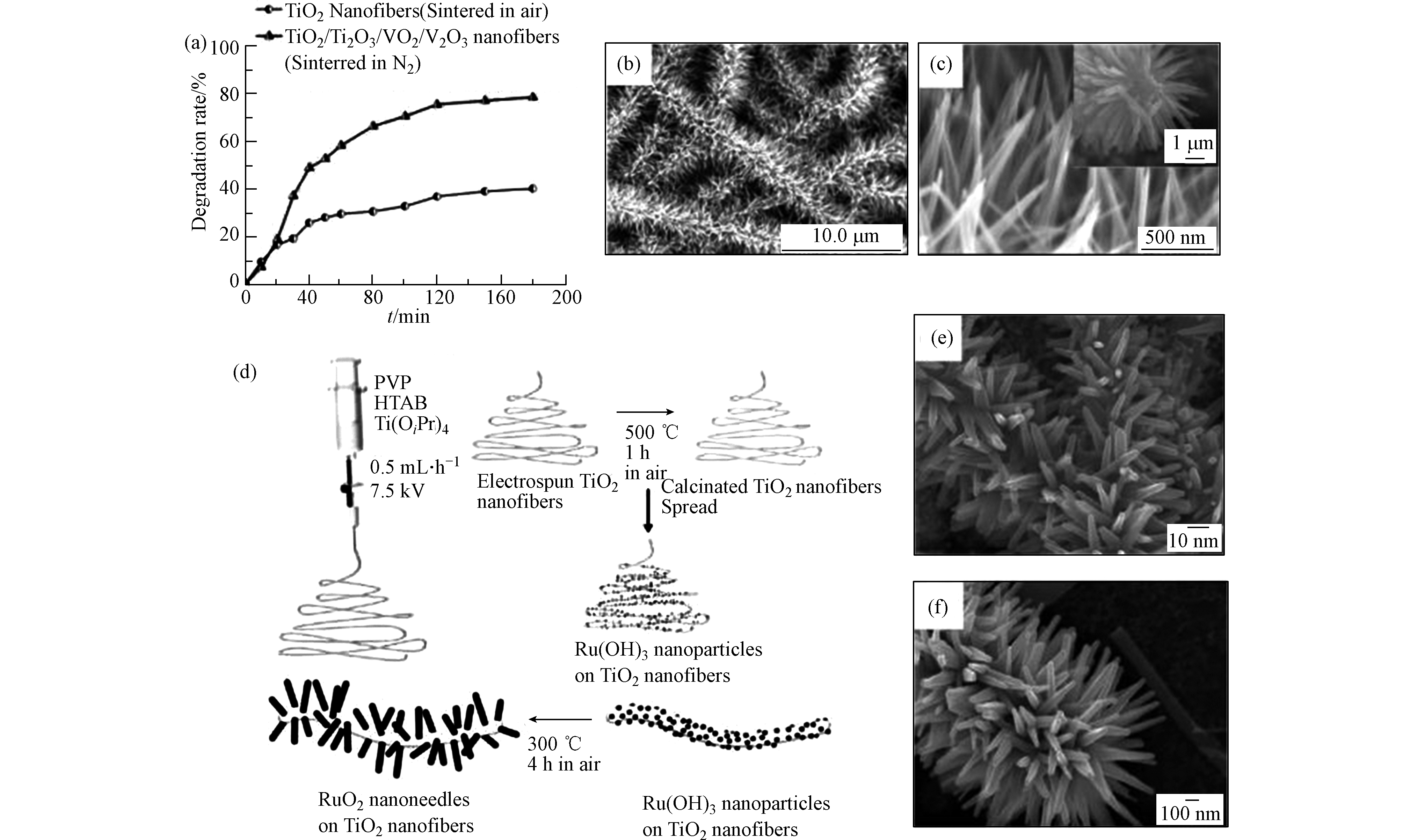

为了充分利用纳米纤维的内部空间,研究者探索了各种各样的内部多层结构,但它的特性还受外表面结构的影响。表面的分支结构改变了纳米纤维的形貌,可以进一步增加材料的比表面积和表面粗糙度,其中TiO2成本低、光催化活性高、环保,在废水处理[44-46]和空气净化[47, 48]等环境催化方面具有广泛的应用。Ostermann等[49]利用静电纺丝技术与煅烧相结合,在TiO2纳米纤维表面生长V2O5纳米棒,形成树枝状纳米纤维,通过调控煅烧条件和反应物组成,改变纳米棒的尺寸。在此基础上,Formo等[50]继续采用一种改进的方法在TiO2纳米纤维的表面生长Pt纳米线。他们将电纺制成的锐钛矿纤维膜浸泡在含H2PtCl6和PVP的乙二醇溶液中,利用沉积法在纤维膜的表面负载Pt纳米粒子,并以此作为晶种生长Pt纳米线。纳米线长度的增加提高了催化剂的比表面积,使其表现出优异的催化性能。Zhao等[51]也将静电纺丝技术与浸渍法相结合制得树枝状的TiO2/ VO2复合纳米纤维。图5a比较了该复合纳米纤维光催化降解甲基橙的速率,经过180 min紫外线照射后,复合纳米纤维解离甲基橙的效率明显高于TiO2纳米纤维。一方面,由于VO2的价带和导带高于TiO2,使得VO2中的光生电子被传递到TiO2的导带,而TiO2中的光生空穴被转移到VO2的价带,使光生电子和空穴在复合纳米纤维中高度分离,从而提高了它们的光催化活性;另一方面,树枝状结构导致其比表面积增大,暴露活性位增加。Wang等[52]以TiCl4作为前驱体,采用水-二氯甲烷界面辅助水热法在电纺锐钛矿TiO2纳米纤维上生长金红石TiO2纳米线。图5(b-c)可以清楚看到纳米线均匀的生长在纳米纤维表面,随着反应时间延长,纳米线密度和长度显著增加,但没有发生聚集。通过光催化降解罗丹明B发现,树枝状结构使光催化剂表面活性位点的数量增加,异质结界面增强了电荷分离,使得树枝状的锐钛矿和金红石纳米纤维的催化活性显著高于原始锐钛矿纳米纤维和金红石粉末。Kim等[53]首次在多晶电纺TiO2纳米纤维上生长了单晶RuO2纳米针。图5(e-f)表明,RuO2纳米针生长良好,完全覆盖在TiO2纳米纤维表面。由于RuO2较高的催化活性和优异的化学和热稳定性,同时与TiO2结合可以产生协同催化效应,因此在电化学传感应用中表现出高效的电催化性能。

上述研究表明,树枝状纳米纤维可以通过调控外部结构,优化材料的表面电子性质和接触空间,增强对反应物的吸附活化,然而其外部的分支结构也容易被破坏或发生重整等不可逆现象,导致稳定性下降。由于其具体的反应机理尚不明确,故需要借助先进的原位表征手段进一步研究其反应历程,从而为树枝状纳米纤维催化剂的设计与发展指明方向。

-

静电纺丝技术是一种简便、有效的方法制备具有多级结构的一维纳米纤维材料。纤维的基体可以由多种不同的聚合物材料制成,直径从纳米到微米不等,形态易于调控,因此广泛应用于光催化、电催化和吸附等领域。

本文从纤维的结构进行分类,总结了近年来利用静电纺丝技术制备的不同结构催化剂的研究进展。与其它技术相比,静电纺丝技术具有工艺简单、规模大、生产条件适中、纤维形貌可调等优点。然而,在实际应用中,仍然存在一些挑战,首先,静电纺丝纳米纤维的层次结构通常与喷嘴的结构有关,而喷嘴基本都是手工制作,稳定性较差,对结构产生很大影响,因此需要精细的机械加工;其次,多级结构纳米纤维的机械性能较差,无法维持相对稳定的结构,限制了其广泛应用;最后,在静电纺丝技术制备多级结构纤维的过程中,通常需要选择两种或两种以上的溶液,为了保证静电纺丝的稳定进行,必须考虑不同溶液的可纺性、相溶性、表面张力等因素,因此需要较强的理论指导。

为了使电纺纳米纤维更具有竞争力,需要进行多方面的尝试和改进,如可考虑改变纤维的内部和外部结构,最大化的增加其比表面积,且不影响纤维的机械性能;或将静电纺丝技术与多种方法相结合,调控催化剂的多功能性,弥补单一方法很难实现多功能调控的缺陷;电纺多级结构纳米纤维还可考虑利用其它物质改性,实现反应物的富集和实时反应,从而实现污染物的一步转化,使其在污染物去除、降解以及作为吸附材料去除重金属和有机物等环境催化领域的进一步发展中发挥主导作用。

多级结构电纺纳米纤维在环境催化领域的应用

Application of hierarchical structure electrospinning nanofibers in the environmental catalysis

-

摘要: 多级结构纳米材料以其形貌多样、比表面积大、空间利用率高以及易于界面传输和吸附富集等特性,在能源催化转化和环境保护等相关领域受到广泛关注。多级结构材料可通过溶剂热合成法、模板法、自组装法、静电纺丝技术等方法合成制得,其中静电纺丝技术是一种简单可控的方法,且可以根据需求构建具有不同成分以及复杂内部和外部结构的纳米纤维。基于此,本文总结了近几年来利用静电纺丝技术制备不同结构的纳米纤维材料的研究进展,详细介绍了中空型、wire-in-tube型、tube-in-tube型、多通道型和树枝状型多级结构纳米纤维材料的制备方法,重点关注了多级结构纳米材料在污染物的降解、环境修复等环境催化领域的应用,并对当前静电纺丝技术构建适用于环境催化领域的多级结构纳米材料面临的挑战和未来的研究方向进行了展望。Abstract: The hierarchical structure nanomaterials have the characteristics of diverse morphology, large specific surface area, high space utilization, easy interface diffusion and adsorptive preconcentration, which have received great attention in the catalytic conversion of energy and environmental protection. It can be synthesized by solvothermal method, template method, self-assembly method, electrospinning technology and other methods. Electrospinning technology has been considered as one of simple and controllable methods, which can construct nanofibers with different compositions and complex internal and external structures as required. Herein, the recent progresses in the preparation of nanofibers with different structures by electrospinning technology have been discussed in detail, including hollow nanofibers, wire-in-tube nanofibers, tube-in-tube nanofibers, multi-channel nanofibers and branched nanofibers, especially in the application of environmental catalysis such as pollutant degradation and environmental remediation. Furthermore, the prospects for the challenges and research directions of designing hierarchical structure nanomaterials by electrospinning technology were proposed to shed light on further development of environmental catalysis in future.

-

Key words:

- electrospinning /

- hierarchical structure /

- nanofibers /

- environmental catalysis

-

进入21世纪以来,能源危机和环境问题日益突出,探索可再生和可持续能源以及开发新技术高效去除环境污染物已成为当前缓解能源危机和环境问题的重要研究方向之一[1-5]。其中,环境催化技术是将环境工程与催化技术相结合的一种新技术,而开发高效、稳定和低廉的催化剂是推动环境催化技术应用的关键[6-9]。

纳米材料因具有比表面积大、功能性强、强度高和延展性好等特点而受到了科学界和产业界的广泛关注。其中,纳米纤维是一类直径为纳米尺度而长度较大的具有一定长径比的线状纳米材料。随着纳米材料的发展,利用纳米颗粒填充改性形成的线状材料也可称为纳米纤维。纳米纤维包括纳米线、纳米管、纳米棒等,具有尺寸控制范围大,比表面积丰富和长径比较高的特点,在电子、光学、热学、催化等方面具有更优越的性能[10-17]。目前,制备纳米纤维的方法主要包括化学气相沉积法、模板导向合成法、气固法、液相法、熔体吹制法、自组装法、电沉积和静电纺丝法[11, 18-22]。与其它技术相比,静电纺丝技术能以简单、可控、高效的方法制备具有不同成分或形貌结构多样的纳米纤维[23],但是由于静电纺丝技术受到喷头和纺丝液自身性质的约束,一般情况下难以获得尺寸较小(如低于50 nm)的纳米纤维,因而,在环境领域中多作为一类吸附、富集材料或载体。当应用于催化反应时,将其作为高度分散活性物种的载体,不仅有利于增加催化剂的比表面积,提高空间利用率,增加反应物与活性位点接触的机会,还可根据需要调整修饰方法得到不同类型或具有特定应用的纳米纤维。因此,静电纺丝技术制备的多级结构纳米纤维可以广泛应用于能源和环境催化领域。

本文总结了近几年来利用静电纺丝技术制备不同结构的纳米纤维材料的研究新进展,详细介绍了中空型、wire-in-tube型、tube-in-tube型、多通道型和树枝状型多级结构纳米纤维材料的设计理念和合成手段,重点关注了多级结构纳米材料在催化污染物降解和转化方面的应用,并对当前静电纺丝技术构建适用于环境催化领域的多级结构纳米材料存在的不足和未来的研究方向进行了展望。

1. 中空纳米纤维(Hollow nanofiber)

中空纳米纤维是指纤维轴向具有细管状的空腔结构,含有内外两个表面,从而可以暴露更多的活性位用于催化反应中。尽管普通模板法和化学气相沉积法可以制得中空纤维材料,但合成产量低,合成条件比较苛刻且设备价格昂贵[24-25]。而静电纺丝技术不仅条件易于控制,原料便宜,还能连续、高效的制备中空纳米纤维,因此受到了研究人员的青睐[26]。

单喷嘴静电纺丝技术是制备中空纳米纤维最常见的方法[27-29]。Li等[28]利用单毛细管喷嘴对含有硅酸四乙酯(TEOS)的聚乙烯吡咯烷酮(PVP)进行静电纺丝成功地制备出聚合物纳米管(图1a),通过改变TEOS与PVP比例可以控制纳米管的直径和壁厚。随后,Jing等[29]也通过类似的方法,将Fe(NO3)3、Ni(NO3)2、Sr(NO3)2、Ti(C4H9O)4等高度分散于PVP溶液中,采用单喷嘴静电纺丝制得SrTiO3/NiFe2O4多孔纳米管中空复合材料,并将其应用于催化降解工业污染物罗丹明B,由于多孔和中空结构为氧化离子和罗丹明B分子提供了更多活性位点,且中空结构有利于传质,因此催化性能显著提高。

与单喷嘴电纺技术只能使用一种溶液相比,双喷嘴共电纺丝采用同轴排列的内外毛细管组成的特殊喷丝头,可使不同的聚合物溶液同时电纺,因此可以合成出性能更好的中空纳米纤维[30]。Chang等[31]采用含有PVP、Ti(OC4H9)4、乙酸和乙醇的溶液为外层,含有PVP、乙醇和银纳米粒子的溶液为内层,通过调节内外压力控制纳米纤维的直径和壁厚,经煅烧形成镶嵌Ag2O纳米颗粒的介孔TiO2中空纤维。由于TiO2的光催化活性主要受其形貌、粒径、表面积、孔隙率等影响,因此,他们利用贵金属沉积修饰TiO2形成Ag-TiO2复合中空纳米纤维,从而提高电子传递动力学效率。通过实验对比发现,Ag填充TiO2中空纤维对亚甲基蓝的分解具有良好的光催化活性,且降解速率快于其它对比材料,这一研究成果为TiO2中空纤维应用于其它环境污染物的降解奠定了基础。Kang等[32]采用聚丙烯腈(PAN)作为碳纳米纤维的前驱体材料,使用能在300—450 ℃完全分解的聚甲基丙烯酸甲酯(PMMA)作为核(图1b),从而可形成中空型纳米纤维。为了进一步研究制备含有金属锰氧化物的聚合物纳米纤维,他们采用MnAc/PMMA溶液作为纳米纤维核,将MnAc/PMMA溶液通过双喷嘴的内部喷出,PAN溶液通过外部喷出,从而得到双层纳米纤维材料;再通过稳定化、碳化、活化、氧化等热处理步骤,形成含有锰氧化物催化剂的中空活性炭纳米纤维(Mn3O4/HACNFs, 图1c),由于该催化剂具有中空结构和纳米级通道,使其接触比表面积和微孔数量增加,不仅可以提高催化剂对VOCs的吸附能力,还能限制锰氧化物颗粒在反应条件下的聚集,使得催化剂具有较好的分散性和催化性能。

由此可见,利用静电纺丝技术制备中空纳米纤维主要依赖于喷嘴和聚合物纺丝液的物理性质,既可以获得体相型催化剂也可以构建负载型催化剂,其独特的中空结构不仅可以促进反应物与内、外部活性位点接触,还能调控合成手段优化催化剂的分散性和暴露性,避免催化剂在后续性能测试中发生团聚烧结现象,因而在制备先进催化剂方面具有巨大的潜力。然而,使用静电纺丝技术制备的中空纳米纤维直径较大,提供的比表面积相对有限,且管长较长,反应物在管内传输时间较长,难以避免生成物的再吸附和二次反应,因此单一的中空纳米纤维多用于大气或水体中污染物的物理吸附与富集。若想要进一步改善其在污染物降解方面的应用,可考虑减小中空纳米纤维的管径,缩短管长或将管壁制备成多孔形态,便于反应降解后的物质及时排出,从而实现中空纳米纤维在环境污染物的吸附降解方面的广泛应用。

2. Wire-in-tube纳米纤维(Wire-in-tube nanofiber)

Wire-in-tube型纳米纤维,即在中空纳米纤维的内部嵌入一根纳米线的纤维,它是由中空型纳米纤维发展而来,主要目的是调控内部空间结构,提高催化剂的空间利用率,促使扩散到纳米管中的反应物既可以与纳米管的内壁接触,又能与管内纳米线的表面接触,从而为制备多功能催化剂提供了一种有效的方法。

Chen等[33]在2010年利用静电纺丝法成功制备了wire-in-tube型纳米纤维。他们采用一种改进的多流体同轴静电纺丝方法(图2a),引入容易去除的惰性流体作为内外流体之间的隔离层,从而确保内外流体相互不接触,形成三层核/壳结构,然后通过萃取或煅烧等方法将中间层去除,得到wire-in-tube型纳米纤维(图2b)。这种多流体同轴静电纺丝是对传统同轴静电纺丝法在芯/壳复合材料制备中的重要扩展,为制备大比表面积的多功能材料提供了更多的选择。

除此之外,通过控制后期煅烧条件亦可制得wire-in-tube纳米纤维。Cho等[34]首先使用静电纺丝获得TBT-PVP复合纳米纤维,然后调控煅烧气氛,当在O2环境下加热,形成wire-in-tube TiO2纳米纤维,而在空气中加热则会得到实体纳米纤维。2017年,Fan等[35]利用PVP和乙醇作为溶剂,由于具有不同的沸点、以及SnCl2·2H2O在两种溶剂中的溶解度差异,在初始低温处理阶段,沸点较低的乙醇溶液率先蒸发,由于SnCl2·2H2O在乙醇中的溶解度高于它在溶有N,N-二甲基甲酰胺(DMF)的PVP中的溶解度,所以金属前驱体被纳米纤维的外层所吸引,形成外壳。如图2c,随着煅烧温度逐渐升高,DMF开始蒸发,内部的PVP有助于凝胶基质中残留的金属前驱体发生奥斯特瓦尔德熟化效应,并使气相的乙醇和DMF扩散产生外向力,而PVP向内收缩,从而使外壳和内层分离,形成结晶的wire-in-tube SnO2纳米纤维(图2d-f)。由于其具有更大的表面积、管中线结构、高密度的晶界等特性,电催化活性显著增强,因此在电化学还原温室气体CO2的过程中表现出优异的反应活性和稳定性,对C1产物(甲酸和一氧化碳)的选择性高。这种合成方法工艺简单,成本低廉,且得到的SnO2纳米纤维对C1产物的选择性高,化学稳定性好,为CO2的高值化利用提供了广阔的前景。

目前,在环境催化中,采用多流体同轴静电纺丝联合烧结控制构筑不同组分的wire-in-tube型纳米纤维已经得到了比较可喜的成果,然而在实际大规模制备中,稳定静电纺丝喷射工艺仍然存在一定的困难。因此,如何在深入认识静电纺丝多流体工艺和环境催化中活性中心的催化机理基础上,针对性设计wire-in-tube型多功能复合材料是当前需要重点关注的问题。

3. Tube-in-tube纳米纤维(Tube-in-tube nanofiber)

与中空纳米纤维含有内外两个暴露面和wire-in-tube含有3个暴露面相比,tube-in-tube纳米纤维由内外两个同轴空心纳米管组成,暴露面更多,且其独立的通道可以作为微型反应器,利用其空间限域效应实现反应产物选择性调控。

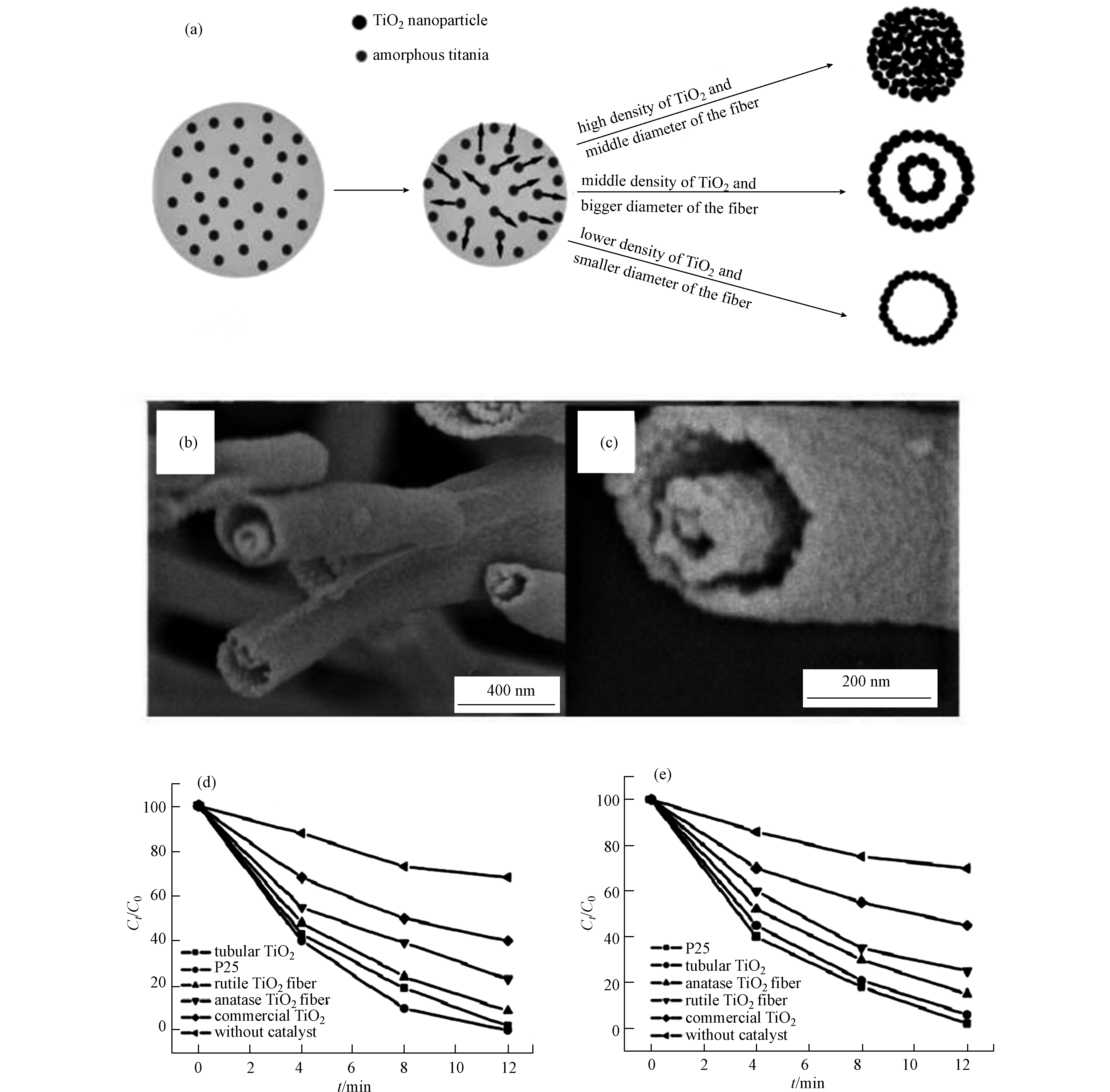

Lang等[36]在前期研究基础上,利用普通的不锈钢针作为喷头,通过调控静电纺丝参数和煅烧条件,合成了具有实心、中空和tube-in-tube结构的TiO2纤维(图3)。由于tube-in-tube结构的TiO2纤维具有较大的比表面积,因此与实心纤维和其它TiO2材料相比,对环境污染物2-氯苯酚和2,4-二氯苯酚的降解具有更好的光催化活性。这种制备纳米纤维的方法简单,可以推广应用于合成管状结构的其它金属氧化物纳米纤维,如ZrO2,SiO2,SnO2和In2O3等。Jin等[37]以二氧化硅中空纳米纤维作为前驱体,在水热作用下将其与镍离子的碱性溶液反应得到硅酸镍中空纳米纤维(NSHNFs),最后利用原位还原法将Au纳米颗粒(AuNPs)均匀固定在NSHNFs表面,形成纳米复合材料(AuNPs-NSHNFs)。由于它具有独特的分层双壁中空结构和高度分散的超细AuNPs,使得AuNPs与反应物充分接触,因此对4-硝基苯酚显示出较高的催化性能。这种合成方法简单、能耗低,且得到的催化剂活性和稳定性好,可重复使用。

图 3 (a)实心、中空、tube-in-tube TiO2纤维的形成机理;(b) tube-in-tube TiO2纤维的SEM图;(c)放大倍数下单根tube-in-tube TiO2纤维的SEM图;(d)紫外光照射下2-氯苯酚的光降解速率;(e)紫外光照射下2, 4-二氯苯酚的光降解速率[36]Figure 3. (a) Possible formation mechanism of solid, hollow and tube-in-tube TiO2 fibers; (b) SEM images of tube-in-tube TiO2 fibers; (c) SEM images of single tube-in-tube TiO2 fibers at magnification; (d) photodegradation rate of 2-chlorophenol under UV irradiation; (e) photodegradation rate of 2, 4-dichlorophenol under UV irradiation[36]

图 3 (a)实心、中空、tube-in-tube TiO2纤维的形成机理;(b) tube-in-tube TiO2纤维的SEM图;(c)放大倍数下单根tube-in-tube TiO2纤维的SEM图;(d)紫外光照射下2-氯苯酚的光降解速率;(e)紫外光照射下2, 4-二氯苯酚的光降解速率[36]Figure 3. (a) Possible formation mechanism of solid, hollow and tube-in-tube TiO2 fibers; (b) SEM images of tube-in-tube TiO2 fibers; (c) SEM images of single tube-in-tube TiO2 fibers at magnification; (d) photodegradation rate of 2-chlorophenol under UV irradiation; (e) photodegradation rate of 2, 4-dichlorophenol under UV irradiation[36]尽管tube-in-tube结构的纳米纤维暴露的表面更多,具有4个暴露面,多级结构的空间特性使其在催化等领域中具有重要的应用前景。然而,目前所采用的方法大多只能得到内部和外部组分相同的纤维,且所获得的复合纤维的机械性能较差,严重限制了其实际应用。

4. 多通道纳米纤维(multi-channel nanofibers)

随着静电纺丝技术的进步,Zhao等[38]提出一种多级复合射流静电纺丝技术,这种技术可以简单、直接的制得通道数可控的多通道纳米纤维,它具有多个沿轴向独立平行的中空通道,内部结构与莲藕、秋葵等相似,比表面积大,通道独特,组分多样,结构稳定性好,在环境催化领域具有较大的应用潜力。图4a是以三通道纳米纤维为例的多级复合射流静电纺丝的实验装置图。他们将石蜡油、Ti(OiPr)4和PVP的乙醇溶液作为内液和外液,分别注入内毛细管和外注射器中,通过复合流体静电纺丝后形成纤维膜,经煅烧除去产物中的有机物,得到多通道TiO2纳米纤维。通过改变内部毛细管数量以及使用其它组分的溶液替代毛细管内液等方法,可以得到通道数为2—5的多功能中空纤维(图4(b-e))。由于光催化材料TiO2具有高效利用光、使用方便、无二次污染等显著优点,Zhao等[39]通过TiO2纤维对目标污染物乙醛降解的研究发现,这种多通道结构不仅增加了纤维的表面积,还可以在通道内部捕获更多的气体分子,并对入射光线进行多次反射,使其光催化活性得到有效提高,从而为新型环境修复光催化材料的研究提供了启示。

图 4 (a)制备三通道纳米纤维的实验装置图;(b-e)通道数为2-5的纤维管的SEM图;(f)微乳液静电纺丝法制备的多通道TiO2纳米纤维的SEM图;(g)多通道TiO2纳米纤维的横截面SEM图;(h)多通道碳纳米基质上构建氧化铋纳米片的合成示意图[38, 40-41]Figure 4. (a) Experimental device for preparing three-channel nanofibers; (b-e) SEM images of fiber tubes with 2-5 channels; (f) SEM images of multi-channel TiO2 nanofibers prepared by microemulsion electrospinning; (g) SEM images of cross section of multi-channel TiO2 nanofibers; (h) schematic diagram of synthesis of bismuth oxide nanosheets constructed on multi-channel carbon nanomatrix[38, 40-41]

图 4 (a)制备三通道纳米纤维的实验装置图;(b-e)通道数为2-5的纤维管的SEM图;(f)微乳液静电纺丝法制备的多通道TiO2纳米纤维的SEM图;(g)多通道TiO2纳米纤维的横截面SEM图;(h)多通道碳纳米基质上构建氧化铋纳米片的合成示意图[38, 40-41]Figure 4. (a) Experimental device for preparing three-channel nanofibers; (b-e) SEM images of fiber tubes with 2-5 channels; (f) SEM images of multi-channel TiO2 nanofibers prepared by microemulsion electrospinning; (g) SEM images of cross section of multi-channel TiO2 nanofibers; (h) schematic diagram of synthesis of bismuth oxide nanosheets constructed on multi-channel carbon nanomatrix[38, 40-41]与控制通道数相比,蜂窝煤状的纳米纤维具有更多的通道。Chen等[40]利用金属烷氧基和石蜡油组成的微乳液中细小的油滴作为软模板,通过改变微乳液的组成和乳化条件等参数精确控制纤维的内部结构,得到均匀布满通道的纳米纤维(图4(f-g)),这是传统制备方法难以实现的。此外,Liu等[41]通过在导电多通道碳基底(MCCM)上生长Bi2O3纳米片,制备了用于电催化CO2还原反应(CO2RR)的层级氧化铋纳米片催化剂(Bi2O3NSs@MCCM),如图4h所示。由于电催化CO2还原反应与可再生能源(如太阳能、风能和潮汐能)结合使用,是缓解温室效应和相关环境危机的最具吸引力的方法之一[42],因此他们将Bi2O3NSs@MCCM应用于CO2RR,在中等过电位条件下可以获得相对较高的电流密度,在较宽的电位窗口下(−1.056到−1.356 V)对甲酸具有接近90%的高选择性和较好的稳定性。这种优越的性能主要归因于交织的多通道碳基底和层级的氧化铋纳米片的协同作用,其中多通道碳基底具有良好的电子转移能力、增强的CO2吸附能力和高比例的吡咯氮和吡啶氮,而超薄的氧化铋纳米片提供了丰富的活性位点和低的功函数。Tang等[43]也通过类似的方法构建了多通道碳纳米纤维(MCCNFs)。通过溶剂热生长尖晶石ZnCo2O4的方式引入高催化活性的钴元素,经高温碳热还原、蒸发后制得钴掺杂的交联多通道碳纳米纤维(Co/IMCCNFs),其独特的多通道结构锚定的高活性钴位点不仅保证了较高的传质速度,还提高了Co活性位点的暴露和有效利用,从而增强燃料电池ORR的电催化活性。由此可见,多通道纳米纤维是一种结构稳定、用途广泛的材料,但由于多液针的制作和稳定的静电纺丝系统的选择存在一定的难度,使得可控通道数结构纳米纤维的制备比较困难,难以满足实际应用中的需求。如何进一步提高多通道纳米纤维的制备工艺稳定性,或者在合成体系中结合其它合成手段,产生具有多级结构的活性中心,从而拓展多功能材料在环境催化领域的应用。

5. 树枝状纳米纤维(Branched nanofibers)

为了充分利用纳米纤维的内部空间,研究者探索了各种各样的内部多层结构,但它的特性还受外表面结构的影响。表面的分支结构改变了纳米纤维的形貌,可以进一步增加材料的比表面积和表面粗糙度,其中TiO2成本低、光催化活性高、环保,在废水处理[44-46]和空气净化[47, 48]等环境催化方面具有广泛的应用。Ostermann等[49]利用静电纺丝技术与煅烧相结合,在TiO2纳米纤维表面生长V2O5纳米棒,形成树枝状纳米纤维,通过调控煅烧条件和反应物组成,改变纳米棒的尺寸。在此基础上,Formo等[50]继续采用一种改进的方法在TiO2纳米纤维的表面生长Pt纳米线。他们将电纺制成的锐钛矿纤维膜浸泡在含H2PtCl6和PVP的乙二醇溶液中,利用沉积法在纤维膜的表面负载Pt纳米粒子,并以此作为晶种生长Pt纳米线。纳米线长度的增加提高了催化剂的比表面积,使其表现出优异的催化性能。Zhao等[51]也将静电纺丝技术与浸渍法相结合制得树枝状的TiO2/ VO2复合纳米纤维。图5a比较了该复合纳米纤维光催化降解甲基橙的速率,经过180 min紫外线照射后,复合纳米纤维解离甲基橙的效率明显高于TiO2纳米纤维。一方面,由于VO2的价带和导带高于TiO2,使得VO2中的光生电子被传递到TiO2的导带,而TiO2中的光生空穴被转移到VO2的价带,使光生电子和空穴在复合纳米纤维中高度分离,从而提高了它们的光催化活性;另一方面,树枝状结构导致其比表面积增大,暴露活性位增加。Wang等[52]以TiCl4作为前驱体,采用水-二氯甲烷界面辅助水热法在电纺锐钛矿TiO2纳米纤维上生长金红石TiO2纳米线。图5(b-c)可以清楚看到纳米线均匀的生长在纳米纤维表面,随着反应时间延长,纳米线密度和长度显著增加,但没有发生聚集。通过光催化降解罗丹明B发现,树枝状结构使光催化剂表面活性位点的数量增加,异质结界面增强了电荷分离,使得树枝状的锐钛矿和金红石纳米纤维的催化活性显著高于原始锐钛矿纳米纤维和金红石粉末。Kim等[53]首次在多晶电纺TiO2纳米纤维上生长了单晶RuO2纳米针。图5(e-f)表明,RuO2纳米针生长良好,完全覆盖在TiO2纳米纤维表面。由于RuO2较高的催化活性和优异的化学和热稳定性,同时与TiO2结合可以产生协同催化效应,因此在电化学传感应用中表现出高效的电催化性能。

图 5 (a) TiO2纳米纤维和TiO2/ VO2复合纳米纤维光催化降解甲基橙的速率;(b-c)不同放大倍数下电纺锐钛矿TiO2 NFs上生长金红石TiO2纳米线的SEM图;(d)单晶RuO2纳米针在电纺TiO2纳米纤维表面的生长过程示意图;(e-f)电纺TiO2纳米纤维表面生长单晶RuO2纳米针的SEM图[51-53]Figure 5. (a) Photocatalytic degradation rate of methyl orange by titanium dioxide nanofibers and titanium oxide/vanadium oxide composite nanofibers; (b-c) SEM image of rutile TiO2 nanowires grown on electrospun anatase TiO2 NFs at different magnifications; (d) schematic diagram of the growth process of single crystal RuO2 nanoneedles on the surface of electrospun TiO2 nanofibers; (e-f) SEM image of single crystal RuO2 nanoneedles grown on the surface of electrospun TiO2 nanofibers[51-53]

图 5 (a) TiO2纳米纤维和TiO2/ VO2复合纳米纤维光催化降解甲基橙的速率;(b-c)不同放大倍数下电纺锐钛矿TiO2 NFs上生长金红石TiO2纳米线的SEM图;(d)单晶RuO2纳米针在电纺TiO2纳米纤维表面的生长过程示意图;(e-f)电纺TiO2纳米纤维表面生长单晶RuO2纳米针的SEM图[51-53]Figure 5. (a) Photocatalytic degradation rate of methyl orange by titanium dioxide nanofibers and titanium oxide/vanadium oxide composite nanofibers; (b-c) SEM image of rutile TiO2 nanowires grown on electrospun anatase TiO2 NFs at different magnifications; (d) schematic diagram of the growth process of single crystal RuO2 nanoneedles on the surface of electrospun TiO2 nanofibers; (e-f) SEM image of single crystal RuO2 nanoneedles grown on the surface of electrospun TiO2 nanofibers[51-53]上述研究表明,树枝状纳米纤维可以通过调控外部结构,优化材料的表面电子性质和接触空间,增强对反应物的吸附活化,然而其外部的分支结构也容易被破坏或发生重整等不可逆现象,导致稳定性下降。由于其具体的反应机理尚不明确,故需要借助先进的原位表征手段进一步研究其反应历程,从而为树枝状纳米纤维催化剂的设计与发展指明方向。

6. 结论与展望(Conclusion and prospect)

静电纺丝技术是一种简便、有效的方法制备具有多级结构的一维纳米纤维材料。纤维的基体可以由多种不同的聚合物材料制成,直径从纳米到微米不等,形态易于调控,因此广泛应用于光催化、电催化和吸附等领域。

本文从纤维的结构进行分类,总结了近年来利用静电纺丝技术制备的不同结构催化剂的研究进展。与其它技术相比,静电纺丝技术具有工艺简单、规模大、生产条件适中、纤维形貌可调等优点。然而,在实际应用中,仍然存在一些挑战,首先,静电纺丝纳米纤维的层次结构通常与喷嘴的结构有关,而喷嘴基本都是手工制作,稳定性较差,对结构产生很大影响,因此需要精细的机械加工;其次,多级结构纳米纤维的机械性能较差,无法维持相对稳定的结构,限制了其广泛应用;最后,在静电纺丝技术制备多级结构纤维的过程中,通常需要选择两种或两种以上的溶液,为了保证静电纺丝的稳定进行,必须考虑不同溶液的可纺性、相溶性、表面张力等因素,因此需要较强的理论指导。

为了使电纺纳米纤维更具有竞争力,需要进行多方面的尝试和改进,如可考虑改变纤维的内部和外部结构,最大化的增加其比表面积,且不影响纤维的机械性能;或将静电纺丝技术与多种方法相结合,调控催化剂的多功能性,弥补单一方法很难实现多功能调控的缺陷;电纺多级结构纳米纤维还可考虑利用其它物质改性,实现反应物的富集和实时反应,从而实现污染物的一步转化,使其在污染物去除、降解以及作为吸附材料去除重金属和有机物等环境催化领域的进一步发展中发挥主导作用。

-

图 2 (a)同轴静电纺丝装置原理图;(b)wire-in-tube TiO2纳米纤维的SEM图;(c) wire-in-tube SnO2纳米纤维的合成机理;(d-f)不同放大倍数下的wire-in-tube SnO2纳米纤维的SEM图像[33, 35]

Figure 2. (a) Schematic diagram of a three-coaxial electrospinning device; (b) SEM image of wire-in-tube TiO2 nanofibers; (c) synthesis mechanism of wire-in-tube SnO2 nanofibers; (d-f) SEM images of wire-in-tube SnO2 nanofibers with different magnification[33, 35]

图 3 (a)实心、中空、tube-in-tube TiO2纤维的形成机理;(b) tube-in-tube TiO2纤维的SEM图;(c)放大倍数下单根tube-in-tube TiO2纤维的SEM图;(d)紫外光照射下2-氯苯酚的光降解速率;(e)紫外光照射下2, 4-二氯苯酚的光降解速率[36]

Figure 3. (a) Possible formation mechanism of solid, hollow and tube-in-tube TiO2 fibers; (b) SEM images of tube-in-tube TiO2 fibers; (c) SEM images of single tube-in-tube TiO2 fibers at magnification; (d) photodegradation rate of 2-chlorophenol under UV irradiation; (e) photodegradation rate of 2, 4-dichlorophenol under UV irradiation[36]

图 4 (a)制备三通道纳米纤维的实验装置图;(b-e)通道数为2-5的纤维管的SEM图;(f)微乳液静电纺丝法制备的多通道TiO2纳米纤维的SEM图;(g)多通道TiO2纳米纤维的横截面SEM图;(h)多通道碳纳米基质上构建氧化铋纳米片的合成示意图[38, 40-41]

Figure 4. (a) Experimental device for preparing three-channel nanofibers; (b-e) SEM images of fiber tubes with 2-5 channels; (f) SEM images of multi-channel TiO2 nanofibers prepared by microemulsion electrospinning; (g) SEM images of cross section of multi-channel TiO2 nanofibers; (h) schematic diagram of synthesis of bismuth oxide nanosheets constructed on multi-channel carbon nanomatrix[38, 40-41]

图 5 (a) TiO2纳米纤维和TiO2/ VO2复合纳米纤维光催化降解甲基橙的速率;(b-c)不同放大倍数下电纺锐钛矿TiO2 NFs上生长金红石TiO2纳米线的SEM图;(d)单晶RuO2纳米针在电纺TiO2纳米纤维表面的生长过程示意图;(e-f)电纺TiO2纳米纤维表面生长单晶RuO2纳米针的SEM图[51-53]

Figure 5. (a) Photocatalytic degradation rate of methyl orange by titanium dioxide nanofibers and titanium oxide/vanadium oxide composite nanofibers; (b-c) SEM image of rutile TiO2 nanowires grown on electrospun anatase TiO2 NFs at different magnifications; (d) schematic diagram of the growth process of single crystal RuO2 nanoneedles on the surface of electrospun TiO2 nanofibers; (e-f) SEM image of single crystal RuO2 nanoneedles grown on the surface of electrospun TiO2 nanofibers[51-53]

-

[1] ZHU Y H, YAO Y, LUO Z, et al. Nanostructured MoO3 for efficient energy and environmental catalysis [J]. Molecules, 2019, 25(1): 18. doi: 10.3390/molecules25010018 [2] WEI M Y, SHI X W, XIAO L, et al. Synthesis of polyimide-modified carbon nanotubes as catalyst for organic pollutant degradation via production of singlet oxygen with peroxymonosulfate without light irradiation [J]. Journal of Hazardous Materials, 2020, 382: 120993. doi: 10.1016/j.jhazmat.2019.120993 [3] BLOEM E, ALBIHN A, ELVING J, et al. Contamination of organic nutrient sources with potentially toxic elements, antibiotics and pathogen microorganisms in relation to P fertilizer potential and treatment options for the production of sustainable fertilizers: A review [J]. Science of The Total Environment, 2017, 607/608: 225-242. doi: 10.1016/j.scitotenv.2017.06.274 [4] 程梦婷, 刘倩, 刘稷燕, 等. 石墨烯在环境有机污染物分析中的应用进展 [J]. 环境化学, 2014, 33(10): 1733-1743. doi: 10.7524/j.issn.0254-6108.2014.10.019 CHENG M T, LIU Q, LIU J Y, et al. Recent advances in application of graphene in analysis of environmental organic pollutants [J]. Environmental Chemistry, 2014, 33(10): 1733-1743(in Chinese). doi: 10.7524/j.issn.0254-6108.2014.10.019

[5] 张长斌. 室内空气污染物催化氧化研究 [J]. 环境化学, 2015, 34(5): 817-823. doi: 10.7524/j.issn.0254-6108.2015.05.2015010509 ZHANG C B. Study of catalytic oxidation of indoor air pollutants [J]. Environmental Chemistry, 2015, 34(5): 817-823(in Chinese). doi: 10.7524/j.issn.0254-6108.2015.05.2015010509

[6] YANG Y L, WU M G, ZHU X W, et al. 2020 Roadmap on two-dimensional nanomaterials for environmental catalysis [J]. Chinese Chemical Letters, 2019, 30(12): 2065-2088. doi: 10.1016/j.cclet.2019.11.001 [7] AHSAN M A, JABBARI V, EL-GENDY A A, et al. Ultrafast catalytic reduction of environmental pollutants in water via MOF-derived magnetic Ni and Cu nanoparticles encapsulated in porous carbon [J]. Applied Surface Science, 2019, 497: 143608. doi: 10.1016/j.apsusc.2019.143608 [8] BARAN N Y. Generation and characterization of palladium nanocatalyst anchored on a novel polyazomethine support: Application in highly efficient and quick catalytic reduction of environmental contaminant nitroarenes [J]. Journal of Molecular Structure, 2020, 1220: 128697. doi: 10.1016/j.molstruc.2020.128697 [9] 陈满堂, 王楠, 朱丽华. X射线光电子能谱在环境催化研究中的应用 [J]. 环境化学, 2017, 36(10): 2140-2146. doi: 10.7524/j.issn.0254-6108.2017030802 CHEN M T, WANG N, ZHU L H. Application of X-ray photoelectron spectroscopy in environmental catalysis research [J]. Environmental Chemistry, 2017, 36(10): 2140-2146(in Chinese). doi: 10.7524/j.issn.0254-6108.2017030802

[10] LI L L, PENG S J, LEE J K Y, et al. Electrospun hollow nanofibers for advanced secondary batteries [J]. Nano Energy, 2017, 39: 111-139. doi: 10.1016/j.nanoen.2017.06.050 [11] LU X F, WANG C, FAVIER F, et al. Electrospun nanomaterials for supercapacitor electrodes: designed architectures and electrochemical performance [J]. Advanced Energy Materials, 2017, 7(2): 1601301. doi: 10.1002/aenm.201601301 [12] MIN L L, PAN H, CHEN S Y, et al. Recent progress in bio-inspired electrospun materials [J]. Composites Communications, 2019, 11: 12-20. doi: 10.1016/j.coco.2018.10.010 [13] WU J, WANG N, ZHAO Y, et al. Electrospinning of multilevel structured functional micro-/nanofibers and their applications [J]. Journal of Materials Chemistry A, 2013, 1(25): 7290-7305. doi: 10.1039/c3ta10451f [14] ZHAO R, LU X F, WANG C. Electrospinning based all-nano composite materials: Recent achievements and perspectives [J]. Composites Communications, 2018, 10: 140-150. doi: 10.1016/j.coco.2018.09.005 [15] SUN M H, HUANG S Z, CHEN L H, et al. Applications of hierarchically structured porous materials from energy storage and conversion, catalysis, photocatalysis, adsorption, separation, and sensing to biomedicine [J]. Chemical Society Reviews, 2016, 45: 3479-3563. doi: 10.1039/C6CS00135A [16] WEI Q L, XIONG F Y, TAN S S, et al. Porous one-dimensional nanomaterials: design, fabrication and applications in electrochemical energy storage [J]. Advanced Materials, 2017, 29(20): 160230. [17] KUMAR P S, SUNDARAMURTHY J, SUBRAMANIAN S, et al. Hierarchical electrospun nanofibers for energy harvesting, production and environmental remediation [J]. Energy & Environmental Science, 2014, 7(10): 3192-3222. [18] HADIA N M A, ALZAID M, MOHAMED W S. Tailoring the physical properties of low dimensional MgO nanostructures using vapor transport deposition [J]. Materials Characterization, 2020, 165: 110392. doi: 10.1016/j.matchar.2020.110392 [19] MENG Z C, GAO L Y, LIU Z Q. Synthesis of Sn nanowire by template electrodeposition and its conversion into Sn nanosolder [J]. Materials Characterization, 2020, 163: 110278. doi: 10.1016/j.matchar.2020.110278 [20] ZHANG Y, NISHI N, AMANO K, et al. One-dimensional Pt nanofibers formed by the redox reaction at the ionic liquid| water interface [J]. Electrochimica Acta, 2018, 282: 886-891. doi: 10.1016/j.electacta.2018.06.024 [21] WANG L, YANG G R, PENG S J, et al. One-dimensional nanomaterials toward electrochemical sodium-ion storage applications via electrospinning [J]. Energy Storage Materials, 2020, 25: 443-476. doi: 10.1016/j.ensm.2019.09.036 [22] JIANG Z X, ZHAO Y, YANG P. Formation of MFe2O4(M = Co, Mn, Ni) 1D nanostructures towards rapid removal of pollutants [J]. Materials Chemistry and Physics, 2018, 214: 1-7. doi: 10.1016/j.matchemphys.2018.04.066 [23] MOHEMAN A, ALAM M S, MOHAMMAD A. Recent trends in electrospinning of polymer nanofibers and their applications in ultra-thin layer chromatography [J]. Advances in Colloid and Interface Science, 2016, 229: 1-24. doi: 10.1016/j.cis.2015.12.003 [24] KIM T, NAOKI W, MIYAWAKI J, et al. Synthesis of surface-replicated ultra-thin silica hollow nanofibers using structurally different carbon nanofibers as templates [J]. Journal of Solid State Chemistry, 2019, 272: 21-26. doi: 10.1016/j.jssc.2019.01.025 [25] LIN J, YANG Y, ZHANG H, et al. Carbon nanotube growth on titanium boride powder by chemical vapor deposition: Influence of nickel catalyst and carbon precursor supply [J]. Ceramics International, 2020, 46(8): 12409-12415. doi: 10.1016/j.ceramint.2020.02.002 [26] 刘朋超, 龚静华, 杨曙光, 等. 静电纺丝法制备陶瓷中空纳米纤维的研究进展 [J]. 无机材料学报, 2013, 28(6): 571-578. doi: 10.3724/SP.J.1077.2013.12625 LIU P C, GONG J H, YANG S G, et al. Research progress on the preparation of ceramic hollow nanofibers by electrospinning [J]. Journal of Inorganic Materials, 2013, 28(6): 571-578(in Chinese). doi: 10.3724/SP.J.1077.2013.12625

[27] BAZILEVSKY A V, YARIN A L, MEGARIDIS C M. Co-electrospinning of core-shell fibers using a single-nozzle technique [J]. Langmuir, 2007, 23(5): 2311-2314. doi: 10.1021/la063194q [28] LI X H, SHAO C L, LIU Y C. A simple method for controllable preparation of polymer nanotubes via a single capillary electrospinning [J]. Langmuir, 2007, 23(22): 10920-10923. doi: 10.1021/la701806f [29] JING P P, DU J L, WANG J B, et al. Hierarchical SrTiO3/NiFe2O4 composite nanostructures with excellent light response and magnetic performance synthesized toward enhanced photocatalytic activity [J]. Nanoscale, 2015, 7(35): 14738-14746. doi: 10.1039/C5NR04819B [30] DUAN N, GENG X, YE L, et al. A vascular tissue engineering scaffold with core-shell structured nano-fibers formed by coaxial electrospinning and its biocompatibility evaluation [J]. Biomedical Materials, 2016, 11(3): 035007. doi: 10.1088/1748-6041/11/3/035007 [31] CHANG G, ZHENG X, CHEN R, et al. Silver nanoparticles filling in TiO2 hollow nanofibers by coaxial electrospinning [J]. Acta Physico-Chimica Sinica, 2008, 24(10): 1790-1797. doi: 10.1016/S1872-1508(08)60073-X [32] KANG S, HWANG J. Fabrication of hollow activated carbon nanofibers (HACNFs) containing manganese oxide catalyst for toluene removal via two-step process of electrospinning and thermal treatment [J]. Chemical Engineering Journal, 2020, 379: 122315. doi: 10.1016/j.cej.2019.122315 [33] CHEN H, WANG N, DI J C, et al. Nanowire-in-microtube structured core/shell fibers via multifluidic coaxial electrospinning [J]. Langmuir, 2010, 26(13): 11291-11296. doi: 10.1021/la100611f [34] CHO J S, HONG Y J, KANG Y C. Electrochemical properties of fiber-in-tube-and filled-structured TiO2 nanofiber anode materials for lithium-ion batteries [J]. Chemistry-A European Jounal, 2015, 21(31): 11082-11087. doi: 10.1002/chem.201500729 [35] FAN L, XIA Z, XU M J, et al. 1D SnO2 with wire-in-tube architectures for highly selective electrochemical reduction of CO2 to C1 products [J]. Advanced Functional Materials, 2018, 28(17): 1706289. doi: 10.1002/adfm.201706289 [36] LANG L, WU D, XU Z. Controllable fabrication of TiO2 1D-nano/micro structures: solid, hollow, and tube-in-tube fibers by electrospinning and the photocatalytic performance [J]. Chemistry-A European Journal, 2012, 18(34): 10661-10668. doi: 10.1002/chem.201200378 [37] JIN R, YANG Y, LI Y F, et al. In situ assembly of well-dispersed gold nanoparticles on hierarchical double-walled nickel silicate hollow nanofibers as an efficient and reusable hydrogenation catalyst [J]. Chemical Communications, 2014, 50(41): 5447-5450. doi: 10.1039/C4CC01286K [38] ZHAO Y, CAO X Y, JIANG L. Bio-mimic multichannel microtubes by a facile method [J]. Journal of the American Chemical Society, 2007, 129(4): 764-765. doi: 10.1021/ja068165g [39] ZHAO T Y, LIU Z Y, NAKATA K, et al. Multichannel TiO2 hollow fibers with enhanced photocatalytic activity [J]. Journal of Materials Chemistry, 2010, 20(24): 5095-5099. doi: 10.1039/c0jm00484g [40] CHEN H Y, DI J C, WANG N, et al. Fabrication of hierarchically porous inorganic nanofibers by a general microemulsion electrospinning approach [J]. Small, 2011, 7(13): 1779-1783. doi: 10.1002/smll.201002376 [41] LIU S B, LU X F, XIAO J, et al. Bi2O3 nanosheets grown on multi-channel carbon matrix catalyze efficient CO2 electroreduction to HCOOH [J]. Angewandte Chemie International Edition, 2019, 58(39): 13828-13847. doi: 10.1002/anie.201907674 [42] ZHANG L, ZHAO Z J, WANG T, et al. Nano-designed semiconductors for electro-and photoelectro-catalytic conversion of carbon dioxide [J]. Chemical Society Reviews, 2018, 47: 5423-5443. doi: 10.1039/C8CS00016F [43] TANG Z M, ZHAO Y X, LAI Q X, et al. Stepwise fabrication of co-embedded porous multichannel carbon nanofibers for high-efficiency oxygen reduction [J]. Nano-Micro Letters, 2019, 33: 11. [44] SIRIRERKRATANA K, KEMCHEEVAKUL P, CHUANGCHOTE S, et al. Color removal from wastewater by photocatalytic process using titanium dioxide-coated glass, ceramic tile, and stainless steel sheets [J]. Journal of Cleaner Production, 2019, 215: 123-130. doi: 10.1016/j.jclepro.2019.01.037 [45] AREERACHAKUL N, SAKULKHAEMARUETHAI S, JOHIR M A H, et al. Photocatalytic degradation of organic pollutants from wastewater using aluminium doped titanium dioxide [J]. Journal of Water Process Engineering, 2019, 27: 177-184. doi: 10.1016/j.jwpe.2018.12.006 [46] YE F, WANG Z H, MI Y Z, et al. Preparation of reduced graphene oxide/titanium dioxide composite materials and its application in the treatment of oily wastewater [J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2019, 586: 124251. [47] MAMAGHANI A H, HAGHIGHAT F, LEE C S. Role of Titanium dioxide (TiO2) structural design/morphology in photocatalytic air purification [J]. Applied Catalysis B:Environmental, 2020, 269: 118735. doi: 10.1016/j.apcatb.2020.118735 [48] AGHIGHI A, HAGHIGHAT F. Evaluation of nano-titanium dioxide (TiO2) catalysts for ultraviolet photocatalytic oxidation air cleaning devices [J]. Journal of Environmental Chemical Engineering, 2015, 3(3): 1622-1629. doi: 10.1016/j.jece.2015.05.019 [49] OSTERMANN R, LI D, YIN Y D, et al. V2O5 nanorods on TiO2 nanofibers: A new class of hierarchical nanostructures enabled by electrospinning and calcination. [J]. Nano Letters, 2006, 6(6): 1297-1302. doi: 10.1021/nl060928a [50] FORMO E, LEE E, CAMPBELL D, et al. Functionalization of electrospun TiO2 nanofibers with Pt nanoparticles and nanowires for catalytic applications [J]. Nano Letters, 2008, 8(2): 668-672. doi: 10.1021/nl073163v [51] ZHAO K, TENG L T, TANG Y F, et al. Branched titanium oxide/vanadium oxide composite nanofibers formed by electrospinning and dipping in vanadium sol [J]. Ceramics International, 2014, 40(9): 15335-15340. doi: 10.1016/j.ceramint.2014.06.079 [52] WANG C H, ZHANG X T, SHAO C L, et al. Rutile TiO2 nanowires on anatase TiO2 nanofibers: A branched heterostructured photocatalysts via interface-assisted fabrication approach [J]. Journal of Colloid and Interface Science, 2011, 363(1): 157-164. doi: 10.1016/j.jcis.2011.07.035 [53] KIM S J, CHO Y K, SEOK J, et al. Highly branched RuO2 nanoneedles on electrospun TiO2 nanofibers as an efficient electrocatalytic platform [J]. ACS Applied Materials & Interfaces, 2015, 7(28): 15321-15330. -

下载:

下载: