-

多相催化技术在环境修复、炼油工艺、能源转化、汽车制造和发电行业等[1-3]领域发挥着至关重要的作用,因此催化技术的发展进步对经济发展和环境保护产生重大的积极影响。自1986年纳米技术的首次提出以来,纳米催化技术得到了快速发展。纳米催化剂由于粒径小、分布均匀、高效的催化效果等特点在各个领域备受欢迎。然而,在这些催化反应过程中,活性位的结构和化学价态变化之间相互影响,很大程度上决定了纳米催化剂的催化性能,往往需要借助先进的表征技术对催化剂的物理化学性质和“质构-能效”关系进行分析。近年来,国内外学者致力于研究提高金属纳米颗粒催化性能的方法,如通过调控金属纳米颗粒的尺寸和形状[4-7]、金属与载体的相互作用[8-14]及金属的氧化状态和配位结构等[2, 15-16]。其中,减小活性相的颗粒尺寸来增大其比表面积和分散度[17],让纳米结构中更多的活性位如表面缺陷、低配位和不饱和原子[18]暴露出来,是目前最常用的方法之一。然而,多数催化反应对纳米结构十分敏感,当金属纳米粒子小于10 nm时,这一点变得尤为明显,因为特定的表面位置,如顶角位、台阶位,以及高度不饱和配位原子[19],使颗粒尺寸成为影响催化性能的主导因素。因此,在分子或原子水平上调控纳米金属颗粒的性质和尺寸,是提高催化性能的关键步骤[17]。

全文HTML

-

制备理想的金属纳米催化剂应达到三个条件,一是粒径可控,二是金属颗粒在载体内均匀分布,三是可重复性强。目前可通过不同的合成方法和反应条件来调控合成不同粒径的纳米催化剂,例如离子交换法[6, 20]、浸渍法[21]、溶胶-凝胶法[22]、静电吸附法[23]等,通过具体的调控因素,如预处理温度、金属负载量、金属与载体相互作用等来合成,既避免金属纳米粒子产生Ostwald熟化或粒子扩散后的团聚现象,也减少纳米粒子的初始尺寸选择的不稳定性。此外直接合成技术如反胶束法、物理气相沉积法、化学气相沉积法、喷雾热解法、光刻法[24-27]也被广泛应用。研究学者基于这些合成方法进行大量研究并取得进展,以下将对上述内容进行阐述。

-

反胶束法是目前合成纳米粒子最具潜力的方法之一,是表面活性分子定向在界面上排列分散在有机介质中的油包水胶体系。尺寸的大小可以通过改变合成参数来调节,特别是W (W=水/表面活性剂)的物质的量比值,表1总结了部分利用反胶束法合成不同粒径的纳米催化剂。

Ahmad等[38]以异辛烷和正辛烷为溶剂,以阳离子CTAB(十六烷基三甲基溴化铵)为表面活性剂,正丁醇为助表面活性剂,直接合成了25—30 nm、80—90 nm尺寸的CuO纳米颗粒。白玉霞等[39]在水/AOT/环己烷反胶束体系中制备粒径可控的 Pt-Sn/C 催化剂,通过调控反胶束溶液中水与表面活性剂的物质的量之比W来合成 2.7—13 nm 的Pt-Sn纳米催化剂,在甲醇溶液中的循环伏安扫描研究表明,甲醇氧化峰电位和峰电流随着W的增加而减小,较小的Pt-Sn颗粒尺寸有利于提高甲醇的电氧化活性。除此之外,Daryoush Afzali团队[30]在反胶束法的基础上改进,用超声辅助反胶束法合成可控的新型Th金属纳米粒子,研究证明,通过超声处理后,Th金属纳米粒子的粒子从之前的27 nm减小到2.8 nm,这种高热稳定性、小粒径、大比表面积的Th基催化剂的制备,可应用于各种工业领域,具有较好的催化性能。

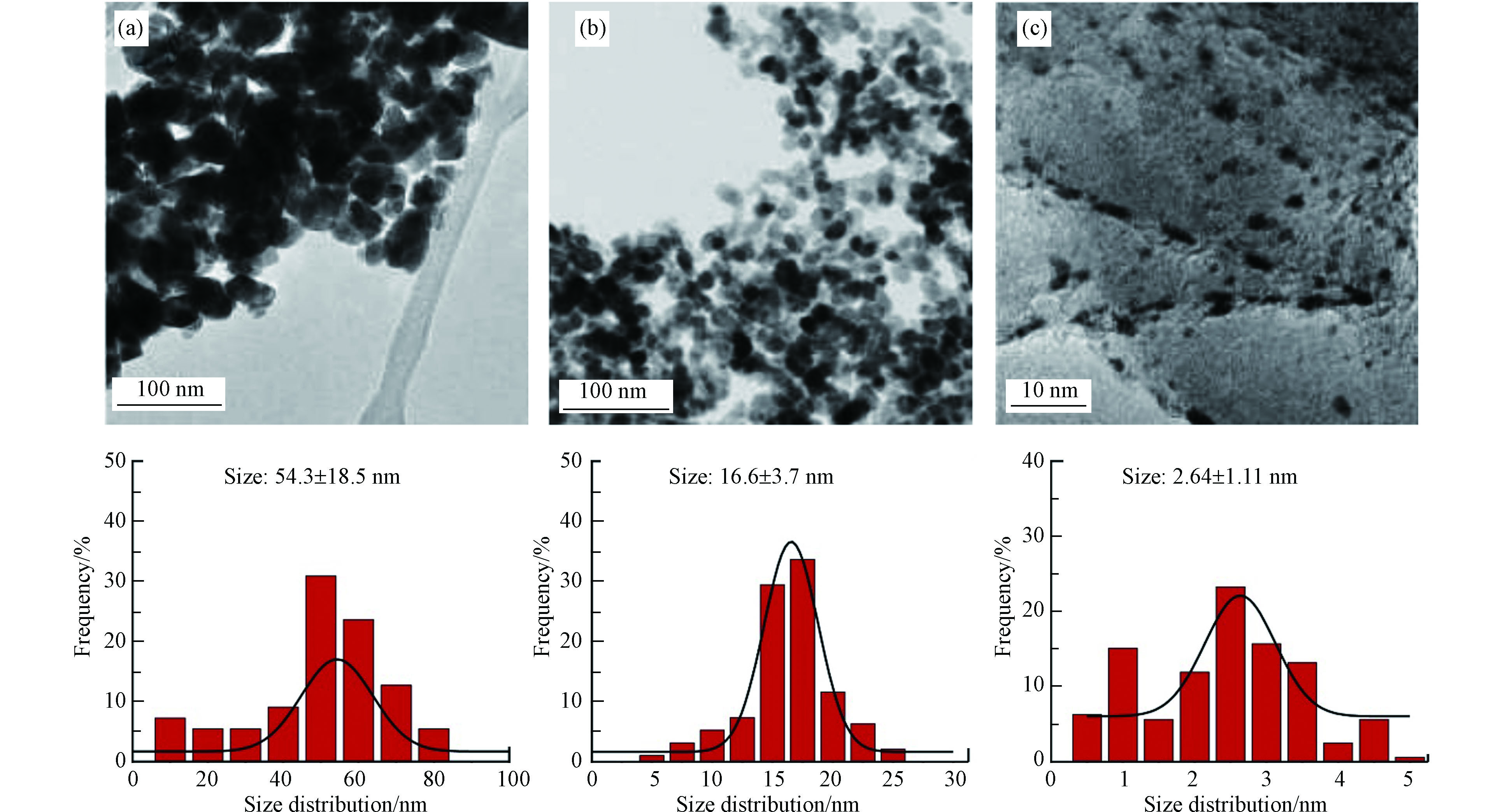

微乳液体系由水相、表面活性剂、油相三部分组成。根据微乳液体系中油水的比例及微观结构,将其分为正相微乳液和反相微乳液。其中反相微乳液中含有油包水的水核,此水核具有形状和大小可调节、水核内的反应物在碰撞中易发生反应等优点,能实现纳米粒子的有效合成、粒径可控和高分散,因而成为制备纳米金属及其化合物最为普遍采用的方法。Zhang等[40]将CO-520与正庚烷混合的钨酸钠水溶液,转移到CO-520与正庚烷混合的盐酸溶液中搅拌均匀,并添加甲醇通过形成两相系统来打破反相微乳液,制备粒径为(2.64 ± 1.11) nm、(16.6 ± 3.7) nm、(54.3 ± 18.5) nm的WO3纳米粒子如图1。在乙烯和反式-2-丁烯交叉歧化反应中表现出明显不同的活性,反应速率随WO3纳米颗粒的减小而增加。

反胶束法具有合成的尺寸分布窄、均匀,不需要特殊仪器或极端条件的特点,并且载体和活性组分之间存在吸附作用,将水分散在油相中会导致形成大量尺寸从纳米到微米的微小液滴,避免了催化剂的团聚现象。但由于表面活性剂、水相pH值、温度、离子强度等因素的影响,反胶团法在商业上不适合大规模生产,纳米粒子合成量不多,在工业规模生产和应用中还需要进一步的研究。

-

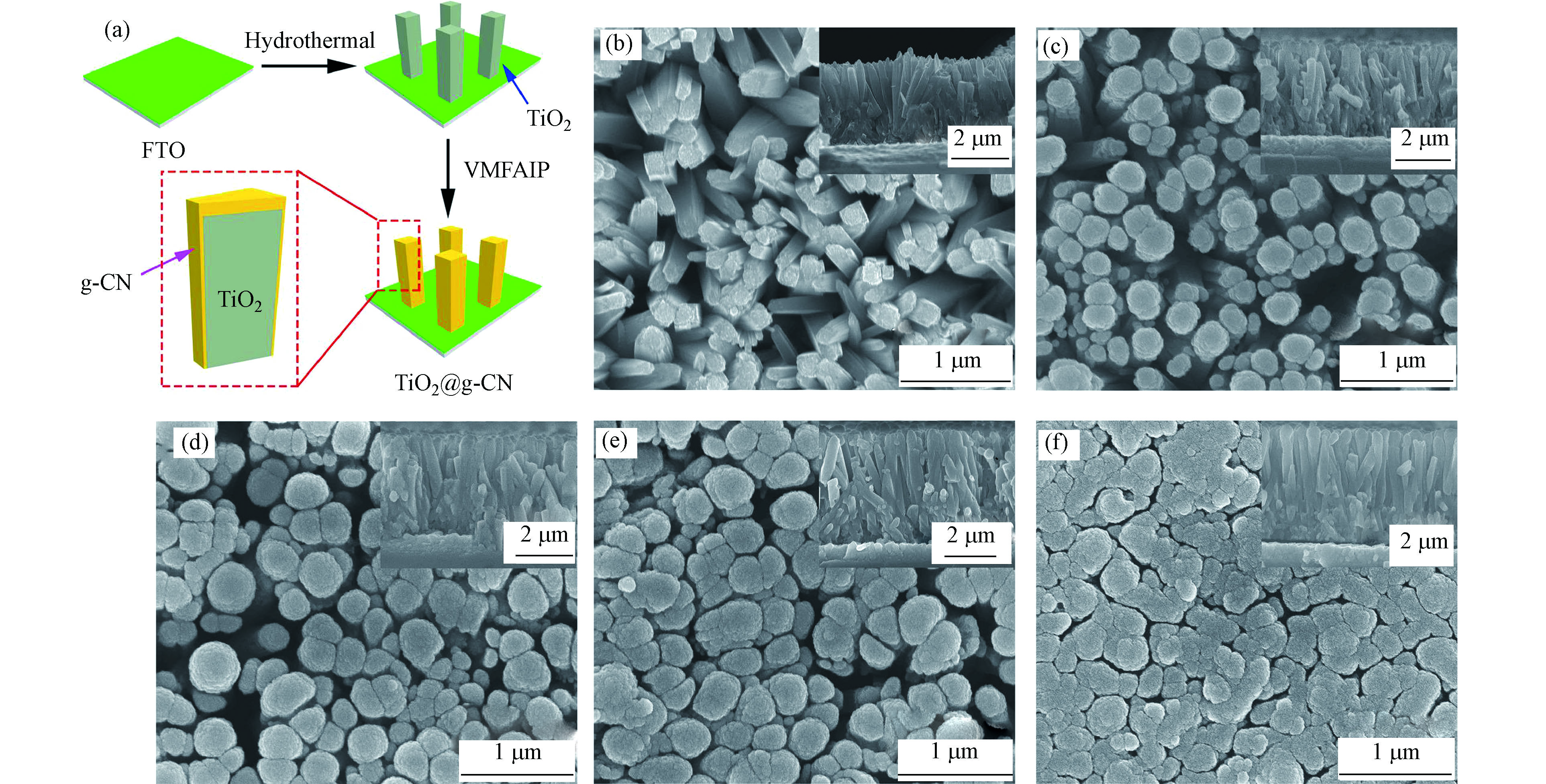

物理气相沉积(PVD)是采用物理方法在真空条件下将固体或液体表面气化成气态分子、原子或离子沉积在基底的一种技术。通过调节沉积位置、沉积温度和沉积时间,可以控制纳米粒子的尺寸。Wang等[41]采用了PVD方法真空磁过滤电弧离子镀来制备TiO2@g-CN纳米小颗粒结构。以石墨靶为碳源,在外加电流作用下产生的碳等离子体通过磁偏转管进入真空室。在此过程中,以氮气为氮源,引入经碳离子冲击电离,产生C-N复合等离子体。腔室内的C-N等离子体沉积在衬底上形成g-CN(如图2A)。将纯TiO2与g-CN偶联沉积,沉积时间为12、24、60、120 min,随着沉积时间的延长,粒径(150—250 nm)显著增加 (图2C-F)。并且TiO2@g-CN纳米粒子增强了有效的电荷分离,活性和稳定性更好。刘明明等[42]利用PVD技术,在玻璃基底上通过改变沉积温度250—350 ℃制备不同尺寸的Alq3纳米材料。物理气相沉积法的原理和方法都比较简单,对环境无污染,耗材少,沉积速率大,与基底的结合力强。但在合成过程中,偶尔会产生一些大颗粒,影响材料的均匀性。

-

化学气相沉积(CVD)是在气态条件下通过加热使固态基体表面与反应物质发生的化学反应生成固体材料的技术。Liu等[43]通过CVD合成小尺寸金石墨纳米颗粒(Au@G),为了控制Au@G的大小,将四乙基正硅酸和四乙基溴铵用作原料和模板,分别在合成的Au纳米颗粒上涂上一层介孔二氧化硅。在高温CVD中,中孔二氧化硅层的存在阻止了Au纳米颗粒的聚集和粒径生长,合成的粒径约为17 nm。Lukowski等[44]在石墨基板上利用CVD,以 MoCl5和S为前驱体、反应温度为525 ℃,合成纳米2H-MoS2。将合成的2H-MoS2通过插层法变为1T-MoS2,转变后的1T-MoS2在电催化析氢反应中需要更低的电极动力和低损耗电荷载,从而使样品催化性能显著提高。

化学气相沉积法装置简单,而且制备同一种材料可以选用不同的化学反应,既能改变和调节反应物的成分,又能方便的控制材料的性质,因此灵活性较大。但缺点是沉积率不高,且在反应过程中参加沉积的反应源和反应后的尾气易燃易爆或有毒,因此需要采取防止环境污染等措施。

-

气溶胶辅助喷雾法可以有效地从液体或泥浆中产生干粉,用简单快速的工艺来生产高纯度粒径可控的产品。此外,这种方法产生的球形颗粒是无团聚的,具有相对单分散尺寸的优点,在干燥食品、肥料和药品的制造中得到广泛应用[45]。Arutanti等[46]采用喷雾热解法合成WO3纳米粒子,将稀释后的前驱体放入粒子产生系统,通过改变合成温度和前驱体浓度来合成微晶可控(18—50 nm)的WO3粒子。Nandiyanto等[47]将二氧化钛纳米颗粒和聚苯乙烯的混合物作为模板,在水溶液中制备具有大孔结构的亚微米锐钛矿颗粒。使用超声波雾化器喷洒混合溶液,将其引入层流管式炉,过滤收集,用氮气推动气溶胶,调节初始前驱体的浓度获得不同尺寸的纳米颗粒。

喷雾热解法可以获得粉体或微细雾化颗粒、颗粒均匀比表面积大、粒径可控制性强,原料消耗少等优点,是制备各种金属氧化物纳米材料的一种有效的方法。

-

光刻法是在感光胶中将颜料或染料分散开通过掩膜曝光,被曝光部分感光胶聚合,变成非水溶性胶膜在显影时留下,其余部分被冲洗掉,制备具有均匀纳米颗粒尺寸和明确空间分布的大比表面积样品的一种方法[48]。Qin等[49]使用微接触印刷将金表面图案化为疏水和亲水烷基硫酸氢钠自组装膜的网格。若将样品垂直放置,液滴蒸发过程中金属盐的积累将发生在亲水区域的下部,导致纳米颗粒远小于亲水区域的大小,制备固体颗粒尺寸50 nm—20 μm的材料。虽然光刻法是制备具有明确空间分布的大表面积样品的一种很好的方法,但它通常成本高昂,大多数的颗粒都是大小的混合物,不适合合成小于20 nm的材料。

在这几种典型方法中见表2,反胶束法可以通过改变合成参数制备出不同粒径的纳米材料,是最为普遍采用的方法;化学气相沉积法与物理气相沉积法相比,当基体需要局部或某一个表面沉积时,化学气相沉积法不如物理气相沉积法更加方便,且成膜时的反应温度仍然高于物理气相沉积技术,因此应用上受到一定的限制。对搭建设备来说,化学气相沉积还要达到耐腐蚀的要求;喷雾热解法相对容易实现机械自动化,粒子可控,产量大,成本低廉,多用于制备复合氧化物和无氧化物纳米材料;光刻法产生的颗粒大多数都是在溶剂或聚合基质中高度分散,但它们在控制尺寸分布和空间布局上的准确性仍然需要改进,以满足应用的要求。

-

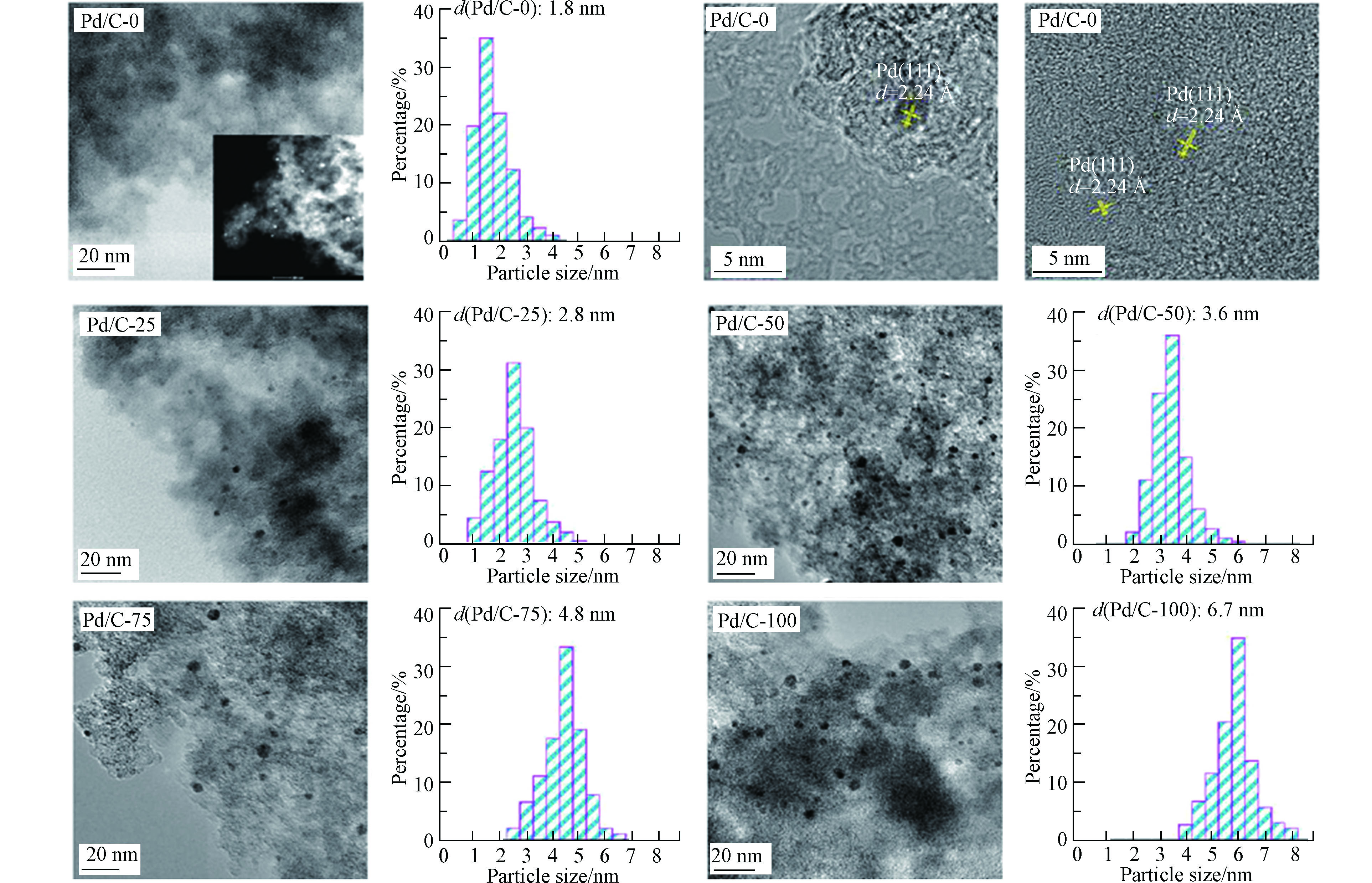

在制备纳米粒子的过程中,改变处理的温度,可以合成不同尺寸的纳米粒子。例如Sun等[50]通过调节催化剂的制备温度成功地调控了Pd的平均粒径,随着制备温度的升高,Pd纳米颗粒的平均粒径从0 ℃制备的1.8 nm增大到100 ℃时的6.7 nm(见图3)。从不同粒径的Pd/C催化剂初始反应速率可以看出,Pd/C催化剂在Pd催化的醇氧化反应中转换频率强烈依赖于Pd的尺寸大小。随着Pd粒径的减小,催化剂的活性显著增加。

同理,Kon等[51]采用浸渍法制备了Pt含量为5%wt的Pt/Al2O3催化剂前驱体,蒸发干燥后在空气中以不同的温度550、600、650、670 ℃煅烧12 h后得到粒径为1.4—12 nm的纳米颗粒,并发现在醇的脱氢反应中,表面Pt的转换频率随Pt粒径的减小而增加。

-

控制负载量也是调控合成纳米颗粒大小的重要因素之一。Li等[52]通过调控负载量来合成不同粒径大小的Pt/SiO2 。随着Pt负载量的增加,Pt颗粒粒径增加,立方八面体和四面体Pt纳米粒子的数量增加,Pt位置提供的吸附位点增加,转换频率也增加。Pt位置与反应活性和选择性之间有直接关联,进而影响活性和化学选择性。较大的Pt纳米颗粒有更多的活性位点,显示出更高的固有活性,优先促进甘油末端碳的氧化。

同理庞洪强等[53]通过调控Pd的负载量制得粒径在 1—5 nm的不同Pd/Al2O3纳米催化剂用于催化乙炔加氢反应,表现出很好的适用性。Liu等[54]改变Pt的含量采用浸渍法,合成Pt颗粒尺寸在1.2—7.5 nm的Pt/CeO2纳米催化剂,并进行了CO氧化试验。研究表明,随着Pt负载量的增加,Pt颗粒尺寸增加,部分Pt物种从Pt-O-Ce固溶体渗透到CeO2基质中,导致CeO2晶胞的收缩。此外,晶格参数随着催化剂中Pt含量的增加而降低,这意味着在高负载Pt的催化剂中形成了更多的Pt-O-Ce固溶体,Pt-O-Ce为活性中心。同时,氧空位浓度与催化剂中的Pt颗粒尺寸存在线性关系,氧空位随着催化剂中的Pt粒径的增加而增加。晶格氧在的Pt颗粒大的催化剂中的迁移比在Pt颗粒小的催化剂中的迁移更明显,氧空位通过形成Pt-O-Ce固溶体加速晶格氧的迁移率,Pt的转换频率与Pt颗粒尺寸成正比,导致更大的速率常数k2,从而提高活性。

-

载体(金属氧化物)和负载相(金属纳米粒子)之间的相互作用,在某些情况下会通过影响纳米粒子在电荷转移过程中的电子结构,来影响金属纳米粒子的尺寸及其催化性能。在转移过程中,人们不仅优化金属颗粒的性质,也可优化载体的性质,达到强相互作用。强相互作用与金属纳米粒子粒径及其催化性能有明显的联系。夏海岸等[55]采用Ag金属作为活性组分,选用不同载体ZrO2、AC、CeO2、Al2O3、TiO2来探究金属载体相互作用对Ag纳米粒子粒径和5-羟甲基糖醛(HMF)氧化性能的影响。结果显示这些纳米催化剂的平均粒径在9.6—13.9 nm之间,表明Ag纳米颗粒的平均粒径和催化剂的载体直接相关。基于XPS数据,催化剂的活性主要和Ag0直接相关,Ag/ZrO2中的Ag0相对含量最高,说明载体的类型不仅会影响Ag纳米粒子的粒径,还会影响其表面化学状态和组成,不同的载体由于其电负性不同,从而导致了不同的金属与载体相互作用,进而影响载体和Ag纳米粒子之间的电荷传递,最后表现出不同的催化活性和选择性。

此外,载体的形貌和晶面会影响纳米颗粒的尺寸。Yi等[56]发现Au颗粒与CeO2载体之间存在强烈的相互作用,CeO2载体的形貌和晶面会影响Au颗粒的尺寸和分散度,分散在CeO2纳米棒(110)面的小于1 nm的Au纳米颗粒有很高的水气转化反应活性,而CeO2立方体(100)面上的约3 nm的Au颗粒则完全失活。又如,沉积在MgO(100)和Fe3O4(111)上的Pd纳米粒子有明显的差异[57]。基于TPD实验,Pd纳米粒子在MgO(100)上的CO结合能表现出正常行为,Pd与MgO(100)相互作用较弱,将纳米粒子尺寸从2 nm增加到5 nm,初始结合能降低33 kJ· mol−1,CO结合更强。相反,对于Pd/Fe3O4(111)体系,观察到相反的趋势Pd纳米粒子与Fe3O4(111)载体的强相互作用,随着纳米粒子尺寸从2 nm增加到4 nm,吸附热增加约30 kJ· mol−1[57]。由此可见,金属与载体的相互作用影响电子结构来改变纳米粒径,并通过电子扰动增强其反应性。

-

在合成材料过程中,通入一些氧化还原性气体或惰性气体可以得到不同粒径大小的催化剂,这种方法多用于合成纳米贵金属材料。例如Van den Reijen等[58]对草酸银分解制备负载Ag催化剂的研究表明,在不改变负载量和催化剂前驱体的情况下,通入不同的气体(H2、N2、O2)得到尺寸在20—500 nm范围内的Ag纳米催化剂。H2预处理产生的Ag纳米催化剂尺寸最小,活性是由小银颗粒上非常低的活性位点产生的,分解乙烯能力最强。Liu等[59]采用热预处理和H2还原法制备了SBA-15负载Pd催化剂。探究不同气氛预处理条件对Pd颗粒的粒径(1.3—10.3 nm)的影响。研究证明,真空条件下制备的纳米催化剂颗粒最小(粒径1.3 nm)。将这些催化剂应用于分子氧氧化苄醇反应中,Pd颗粒最小的催化剂具有最高的转换频率且重复性高。 Cai等[60]在氧化过程中,采用H2O(g)、O2等不同的氧化气体,研究了氧化-氧化-还原(ROR)预处理对20%纳米Co/SiO2粒径的影响。结果表明,采用O2和H2O(g)的ROR处理降低了Co的平均粒径,降低Co的粒径取决于Co的初始粒径。当氧化气体(如H2O(g)或O2)被引入Co还原催化剂中时,可以看出金属Co的氧化首先发生在Co颗粒的晶体表面,在形成表面氧化的氧化钴薄膜后,Co通过氧化膜快速向外扩散,进一步的氧化过程比O2-向内扩散快得多。Co核中产生了空缺,并导致氧化膜内的空洞,氧化过程持续进行,最终在氧化过程完成后形成多晶氧化膜[61]。氧化机制导致钴的运输远离它的原始位置,它分散在载体上,形成的空心膜破裂,导致金属Co相的再分散且粒径变小。

-

还有部分学者同时调控两种或两种以上的因素来合成不同粒径的纳米催化剂,Beerthuis等[5]采用热处理、碳预处理相结合的方法制备了一系列粒径为3—14 nm的Cu/C纳米催化剂。铜颗粒大小由合成方法的组合控制,不仅包括铜负载量(6%wt—16%wt)和最终热处理温度(250—400 ℃)而且还有碳载体的功能化见表3,采用大比表面积的石墨作为惰性催化剂载体,可以消除铜的固有粒径效应。研究表明,在乙酸乙酯加氢反应中铜粒径大于等于8 nm的催化剂最稳定。当铜颗粒尺寸从3 nm增加到10 nm时,TOF增加了约4倍。

除此之外,调控溶液pH值也可以合成粒径不同的纳米催化剂,例如Ding等[62]调节NaOH水溶液浓度为0、0.01、0.05、0.1 mol·L−1,研制出粒径为1.8—4.5 nm的高效低浓度甲醛氧化催化剂Pt/ZSM-5。其中Pt0.05/ZSM-5粒径最小,在30 ℃下HCHO转化率高达99%以上,且具有良好的稳定性。

1.1. 不同制备方法

1.1.1. 反胶束法

1.1.2. 物理气相沉积法

1.1.3. 化学气相沉积法

1.1.4. 喷雾热解法

1.1.5. 光刻法

1.2. 不同处理温度

1.3. 不同金属负载量

1.4. 金属与载体间相互作用

1.5. 不同预处理气氛

1.6. 其他因素

-

纳米催化剂与传统催化剂相比,具有更优异的物理和化学性质,在许多情况下,纳米催化剂的反应性和选择性大大提高。此外,许多吸附质在纳米粒子上的结合能依赖于尺寸,通常小的纳米粒子可能具有更小或更大的结合能[63]。因此,纳米催化剂已经成功应用于当前中国典型的大气环境污染领域CO、NOx和VOCs有害气体的催化降解。

-

CO是排放量最大的大气污染物,因此CO降解一直被广泛关注。催化氧化法被认为是最有效的方法之一,不同尺寸大小的贵金属Au、Pd、Pt等具有优异的催化性能被广泛应用于CO氧化。例如Chen等[64]用胶体沉积法使1.4 nm的Pt纳米粒子负载在惰性衬底(Al2O3)上,结果表明,Pt活性中心的局部结构决定的性能,小尺寸暴露更多表面Pt活性位点以活化O2,然后转化为CO。CO的转化率在30—120 ℃的温度范围内催化活性最高达100%。虽然贵金属有较好的催化性能,但贵金属成本较高且稳定性较差,因此学者们开展大量的研究用过渡金属替代贵金属。Ce基催化剂和Cu基催化剂表现出良好的性能。例如Lee等[65]通过静电纺丝法制备Ce-ZrO2纳米纤维网催化剂,其中Ag通过浸渍负载在催化剂表面。研究发现与CeO2相比,纳米Ce-ZrO2表现出更好的中孔结构和大比表面积。在使用不同Ce/Zr和活性氧比制备的各种催化剂中,Ce0.67Zr0.33和Ag/Ce0.67Zr0.33纳米催化剂尺寸更小且Ce含量更高,其活性位点数量的增加,对CO氧化显示出显著增强的催化活性。Zhang等[66]用水热法成功合成了不同尺寸的CuO-CeO2纳米复合材料。实验证明随着金属Cu含量的增加,催化剂的晶粒尺寸减小,比表面积增大。由于Ce3+- Cux+- Ce4+之间的相互作用和氧空位缺陷的增加,与纯CeO2相比,CuO-CeO2纳米复合催化剂表现出更为活跃的催化性能。Jiang等[67]通过调节不同浓度的浸渍溶液来合成尺寸为50 nm—4 μm的Ni5TiO7纳米线用于CO催化氧化。扫描电镜观察表明,增加硝酸镍溶液的浓度可导致其尺寸相应增加。同时CO氧化活性强烈依赖于纳米晶体的尺寸,CO和O2在Ni5TiO7纳米线表面的解吸会在Ni-O键的作用下相互反应,当Ni5TiO7纳米线的尺寸从4 μm减小到50 nm时,相应的最高转化温度降低了约100 ℃,成为从生物质气化到汽车尾气处理等各种应用的有前途的催化剂。

-

挥发性有机化合物(VOCs)被认为是主要的空气污染物,因为它们会导致臭氧和光化学烟雾等重大环境问题。因此治理VOCs一直是大气环境领域的重点问题。为了使反应在经济上更具竞争力,有必要开发能在较低温度下操作的高性能催化材料。为此研究了各种催化剂,包括负载型贵金属和过渡金属氧化物纳米催化剂。Peng等[6]通过乙二醇还原法发现Pt/CeO2纳米催化剂对甲苯氧化具有明显的尺寸效应。其中。Pt/CeO2-1.8样品表现出最佳的催化活性(T50 = 132 ℃,T90 = 143 ℃)。此外,活性最高的Pt/CeO2催化剂在甲苯氧化过程中非常稳定。Qi等[68]报道了一种纳米铜基多相催化剂,用于烯烃的有氧环氧化和苄醇和烯丙醇的氧化。当使用不同尺寸的铜基金属时,纳米铜基金属表现出最佳的催化活性。在相似的反应条件下,纳米Cu-MOF-2的催化活性进一步扩展到醇的氧化。除此之外,纳米TiO2、Fe2O3、WO3由于其窄的带隙能也被广泛应用于催化降解挥发性有机物,尤其是TiO2纳米材料无毒、光催化性能好被广泛应用于挥发性有机化合物降解中,并且目前商用P25催化剂被作为光催化VOCs最理想的催化剂[69]。

-

随着工业行业的发展,我国部分地区的氮氧化物排放量逐渐增加,为达到我国“脱硝”指标,学者们对方法和催化剂展开研究。烟气脱硝目前在我国应用最广泛,尤其是SCR技术,脱硝率达90%以上。与此同时,催化剂的选择也很重要,20世纪50年代最早的SCR催化剂使用Pt、Rh、Pb等贵金属催化剂。从20世纪60年代末开始,逐渐发展到使用TiO2和过渡金属。通过几十年的工业实践,目前工业上应用最广的是V2O5-WO3/TiO2催化剂[70],但需要的催化温度和材料成本较高,生成的SO2易使催化剂中毒,所以必须研究新的或进一步改性低温降解效率高,稳定性好的催化剂。Yao等[71]采用一步共沉淀法合成 CeO2-MnOx-Al2O3复合纳米催化剂。研究表明,在CeO2晶格中加入Mnn+ 和 Al3+抑制了晶粒生长,导致晶粒尺寸减小。特别是CeO2-MnOx-Al2O3催化剂的晶粒尺寸明显小于CeO2-MnOx催化剂的晶粒尺寸,其比表面积增大,表明Al3+的引入可以增加催化剂的活性。Chen等[72]通过浸渍法制备了一系列Ce/Mo掺杂改性的钒钨钛型催化剂,试图实现选择性催化还原反应区(温度范围为260—420 ℃)中NO和VOCs的协同去除。结果表明,负载10.75% CeO2和4.5% MoO3的钒钨钛催化剂在500 ℃煅烧时对一氧化氮、苯和甲苯的同时去除效果最好。该研究为燃煤电厂污染物减排提供了一种有效的方法。此外Zhao等[73]首次采用纳米铁负载沸石(Fe/ZSM-5)催化剂同时去除烟气中多种污染物。在催化剂用量为0.8 g·L−1,硫酸铵溶液浓度为0.03 mol·L−1,温度为5 ℃和65 ℃的条件下,SO2、NO和Hg的同时去除率分别为100%、72.6%和93.4%。纳米催化剂可以为SCR反应过程提供丰富的反应活性位点以加速分解反应,提供丰富的吸收位点以增加污染物的保留和反应时间,同时降低反应活化能,从而降低反应成本,在去除效率方面表现出较好的性能。

综上所述,在大部分催化反应过程中,金属纳米粒子尺寸的减小,纳米粒子的顶角位和高度不饱和配位原子等的作用逐渐占主导地位,这种强烈的相关性导致了催化性能对尺寸的依赖性。此外,化学吸附活化能随尺寸变化而减小,尺寸相关的活化能势垒由尺寸相关的内聚能产生,而内聚能反过来又由催化剂纳米颗粒中欠配位表面原子的尺寸相关分数所决定。由于配位数较低的金属原子对反应物分子的吸附能较强,可以降低反应物分子解离的激活势垒,从而加速催化的发生。因此,粒径是影响催化性能的一个重要参数,在环境污染防治方面表现出良好的效果。

2.1. CO催化降解

2.2. VOCs的催化降解

2.3. NOx的催化降解

-

近二十年来,金属纳米粒子的合成取得了惊人的进展,金属纳米催化剂具有尺寸小、分布均匀、活性位多等特点。颗粒尺寸的减小可能会增加或减少某一特定反应的催化活性,这是由配位环境和非配位表面原子的电子状态所决定,并伴随纳米颗粒催化剂尺寸的变化。当金属颗粒尺寸减小到纳米范围时,这些影响尤其明显。如今,由数百个原子组成的尺寸在1—10 nm之间的金属纳米粒子的催化性能正在被逐步研究。纳米粒子之间的相互作用可能会产生纳米结构金属催化剂的新的物理和化学性质,表现出良好的催化性能。在醇类氧化、烯烃歧化、氮氧化物和碳氧化物的吸附降解等方面得到广泛的应用。尽管如此,目前仍面临许多挑战:

(1)优化调控合成纳米粒子尺寸的方法(如温度、化学环境、合成时间、成本等),合成最佳尺寸的纳米催化剂提高在反应过程中的吸附选择性,使其可以达到大批量生产的要求;

(2)纳米催化剂在反应时的化学状态可能不是催化剂合成时的状态,因此对于应用的反应原理还需要进一步研究,尽可能寻求在实际反应条件下原位和表征都同步适应的反应环境;

(3)利用我国常见廉价的金属来设计高活性的金属纳米小颗粒催化剂来替代贵金属催化剂,并进一步对活性和稳定性的反应机理做出更深的研究和见解。

因此,研发调控尺寸新的合成方法和优化合成条件是未来的发展方向,对提高催化性能的机理和反应路径做进一步研究。

下载:

下载: