-

在工业化飞速发展的同时伴随着化石燃料的用量急剧增加. 化石燃料的大规模燃烧使其大气中CO2的浓度急剧增加,造成温室效应等一系列危害,严重影响人类的生活环境[1-3]. 在这种严峻的形势下,我国作出了“双碳”(碳达峰和碳中和)的庄严承诺,在2030年前CO2的排放力争达到峰值,努力争取在2060年前实现碳中和,将开启经济社会全面向绿色低碳转型的格局,降碳成为生态环境保护工作的主要任务[4-6]. 为了实现“双碳”目标降低大气中CO2的浓度,采取高效的碳捕获技术是减少碳排放实现“双碳”目标的基础.

在高效的碳捕获技术中(如图1所示),传统的CO2捕获技术有低温蒸馏、变压吸附、变温吸附和化学吸收法,但这些方法不仅能耗巨大,还存在潜在的环境风险,容易造成二次污染[7-9]. 此外,在临界压力下分离动力学直径相近的气体分子,传统的分离方法分离效率极低且能耗巨高. 由此可见,面对传统CO2捕获技术的弊端,急需一种高效绿色环保的气体分离技术,降低环境污染,提高原材料的利用率. 膜(Membranes)分离技术作为一种新型高效环境友好型分离技术,具有低能耗、高效率、操作简单、环境友好等优点,同时在分离过程中即不需要热驱动的相变,也不需要具有一定能源成本的吸附剂[2, 10-12]. 因此,膜分离技术作为高效的碳捕获技术可替代能源密集的传统分离过程,成为未来分离领域研究的热点.

膜材料是膜分离技术的关键,也是膜技术产业化的核心部件. 随着膜分离技术应用领域的不断拓展,行业对膜材料的综合性能提出了更高的要求. 根据膜材料体系的不同,将分离膜分为无机膜、聚合物膜、混合基质膜等. 其中,传统的聚合物膜具有低成本、易加工、机械性能强和化学性质稳定等优点被广泛应用在工业领域[13]. 然而,聚合物膜在渗透率和选择性之间存在“此消彼涨(Trade-off)”的关系,限制了聚合物膜在工业领域的应用[14-15]. 为了突破Trade-off效应的限制,需对膜材料体系进行革新和改进制膜工艺,才能满足工业高性能分离膜的需求. 在膜材料体系中,无机二维(2D)材料是具有原子级厚度的超薄无机纳米材料,已成为膜分离领域的研究热点材料. 高的比表面积和薄的分离层使膜能够缓解渗透性和选择性之间Trade-off效应的限制. 此外,无机2D材料膜通常具有耐高温和耐化学腐蚀的优点,为复杂的工业应用提供了可靠的保障并可长期使用[16-17].

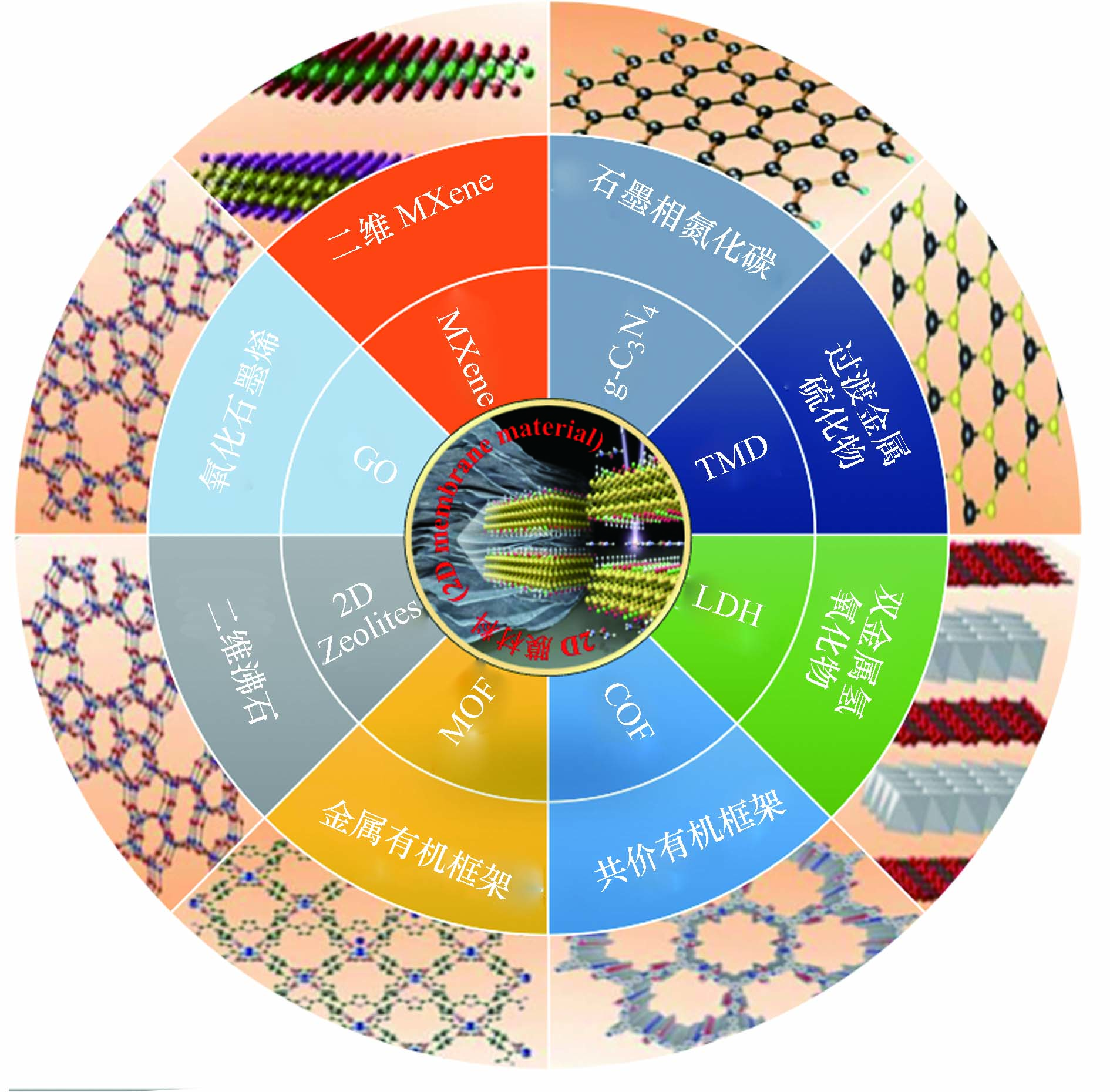

在无机2D材料体系中(图2),2D材料凭借着独特的优势被广泛应用于膜的制备,石墨烯类材料[18]、二维过渡金属碳化物/碳氮化物(MXene)[19]、二维沸石材料[20]、二维金属有机骨架(MOF)[21]、二维共价有机框架(COF)[22]、双金属氢氧化物(LDH)[23]、过渡金属二硫化物(TMD)[24]和石墨相氮化碳(g-C3N4)[25]成为当前膜制备的热点材料. 其中,MXene因其丰富的表面化学性质和独特的物理化学性质而备受关注. 一般来说,MXene由二维过渡金属碳化物、氮化物或碳氮化物组成,分子式为Mn+1XnTx (n=1,2,3). 它通常是由MAX(3种元素组成的天然层状碳氮化物无机非金属材料)前驱体粉末在溶液中选择性刻蚀Al元素而制备. 其中M为过渡金属,X为碳和/或氮,T为表面基团(如—O、—OH、—F),A为ⅢA或ⅣA元素. 将前驱体中的MAX相的A原子剥离,剥离成单片的MXene外表面含有F、OH和/或含氧基团. MXene表面丰富的官能团赋予MXene具有高的表面积、生物相容性、亲水性、低扩散阻力、活化的金属氢氧化物位点、优异的电导率[26],使其应用在电化学储能[27]、电磁屏蔽[28]、多功能聚合物复合材料[29]及气体分离[30]等多个领域. 此外,MXene的层状结构赋予了二维MXene膜具有特殊的质量传输通道,这使气体分子和其他小分子可在层状结构中快速移动[3]. 同时,MXene膜表面丰富的官能团有利于控制层间空间[31]、对特定溶剂的亲和性[32]和电荷分布[33]的调节. 因此,MXene材料因其独特的性质被用于膜分离领域并将展现出良好的应用前景.

化石燃料的燃烧使能源危机及环境污染日益严重,为了实现“双碳”目标,探索新材料降低CO2的浓度成为当前研究的重点课题. MXenes材料凭借优异的特性在膜分离领域取得了一席之地. 为了更好地研究MXenes材料在气体分离膜领域的作用,本文对近年来MXenes基气体分离膜的制备和性能进行了综述. 重点介绍了MXenes基气体分离膜在气体分离领域等方面的研究进展. 并对MXenes材料的进一步研究进行了总结和展望,为MXenes未来的研究和实际应用提供参考依据和理论支持.

-

材料的性质决定材料的用途,MXenes具有原子级的厚度和表面含有丰富的官能团等优点,有望在电化学储能、抗菌、电磁屏蔽及气体分离等多个领域应用. 其中,MXenes材料因其丰富的性质可用于设计高性能分离膜. 因此,在介绍迄今为止研究的高性能气体分离膜之前,了解MXene的成膜特性是不必可少的. 首先,MXene具有二维形态有利于设计膜分离运输通道. 其次,MXene溶液的均匀分散与MXene基膜的化学稳定性密切接相关. 最后,讨论了MXene的机械性和抗菌性能,如表1所示.

-

近年来,超薄二维材料被用于解决膜合成过程中的Trade-off效应. 高纵横比的MXene纳米片赋予膜具有纳米通道,从而延长了溶质运输的扩散路径[34]. MXene纳米片所构建的二维通道是由表面具有针孔、平行和褶皱的纳米片之间相互堆叠所形成的. 溶质扩散路径的延长是二维层状膜具有选择性的基础. 此外,通过调节MXene材料的层间间距,可创建精确的传输通道,从而可实现有效的分子分离. 例如,Zhang等[35]制备了具有柱梁结构的MXene基膜,层间距约为147 nm,允许水分子通过MXene基膜将以实现水的净化. Jin等[3]通过调节MXene基膜的层间距为0.52—0.38 nm之间,能够精确地识别气体分子的大小实现高效的气体分离. 除了调节层间距改变传输通道外,改变蚀刻和剥离条件,可定制6 nm到<1 μm的特定传输通道. 相反,通过调节扩散路径以及膜的厚度,可对MXene基膜的分离性能进行工程设计[36]. 此外,MXene材料表面非平展,具有一定的褶皱,使MXene基膜的微观结构和性能与其他二维分离膜相比略有不同[37].

-

MXene表面丰富的官能团使其具有一定的亲水性,为MXene材料在水介质中的加工奠定了基础. 值得注意的是在多种MXene的制备过程中,使用HCl-LiF制备的MXene纳米片含O/F官能团的量远远高于HF制备的量[38]. 此外,MXene表面的—OH官能团和在插层过程中的Li+和NH4+的存在使MXene纳米片与水分子相互作用力显著增强. 因此,Ti3AlC2 MXene基膜具有高的水浸润性(高亲水性),水接触角约为25°—45°[3]. MXene表面存在的-OH官能团以及额外带负电荷的官能团为MXene的表面修饰提供了可能(通过化学功能化和静电吸引). 例如,Riazi等[39]使用AEAPTMS对MXene表面进行修饰,表面修饰的MXene可成为染料吸附剂、高性能膜和药物载体的制备原料. Hao等[40]利用MXene表面丰富的—OH官能团与有机硅氧烷接枝,制备了含—NH2、—COOR、—C6H6和—C12H26官能团的MXene. MXene的表面接枝能够显著提高膜对溶剂分子的亲和力,进而决定了膜对溶剂的输送性能. 上述不仅证实了MXenes基材料具有可调的浸润性,而且证明了MXenes的化学多功能性,为膜的开发创造了理想条件.

-

MXenes的化学稳定性对于溶液的可加工性和制备膜的性能都是密切相关的. 在惰性气体氛围下,MXenes具有优异的热稳定性,800 ℃时保持着结构完整[41]. 然而,在空气中MXenes表面暴露的金属原子更容易氧化. 为了防止MXenes材料自发氧化,通常将制备的MXenes胶体溶液保存在充满氩气的容器中(低温下),有助于降低MXenes材料的氧化速率[42]. 此外,MXenes材料的化学稳定性还主要受表面化学、掺杂物质、表面缺陷、表面电荷等的影响[43]. 通过EN-MILD方法制备的Ti3C2Tx的导电性显著提高,达到24000 S·cm−1,并产生更大的薄片,缺陷更少,表现出更好的化学稳定性和层间电子传输[44]. MXenes材料的稳定性拓宽了MXenes的应用范围,使MXenes材料具有更大的价值.

-

MXene的力学性能也受到了广泛的关注. 在膜的发展历程中,因MXene具有较高的柔韧性和机械强度. 原始MXenes中的M—X键具有相对较高的机械强度,超过500 GPa. MXenes的力学性能很大程度上依赖于其表面基团. 其中,—O终止的MXenes的机械强度高于—OH和—F终止类型的MXenes,差异是由不同表面官能团MXenes的晶格参数不同所致[43]. 此外,表面功能化的MXenes比裸露的MXenes更灵活. 以Ti2C为例,功能化降低了它的杨氏模量,但在拉伸作用下它能够承受更大的应变,表面端基可成为Ti2C的缓冲层,提高了Ti2C断口处的临界应变值,减缓了Ti2C层的坍塌[45]. 另外,随着MXene层数(n)的增加,碳化物基和氮基MXenes的杨氏模量减小. 其中,MXenes的杨氏模量氮基优于碳化物基[46]. 最后,发现将MXenes与不同类型的聚合物结合,可以不同程度地提高MXene的柔韧性 、抗压强度和抗拉强度. Wu等[47]将Ti3C2Tx纳米片作为纳米填料,将其与亲水性的聚乙烯亚胺(PEI)和疏水的聚二甲基硅氧烷(PDMS)聚合物基质相结合,结果表明制备的SRNF复合膜通过空间位阻效应和/或界面相互作用显著增强了Ti3C2Tx基材料的热/机械稳定性和耐溶剂性. MXenes的力学性能使含MXenes膜的耐用性变强,用途更广.

-

材料具有抗菌性能够提升材料的应用价值,在多种二维材料中,含Ti3C2Tx纳米片的胶体溶液表现出很强的抗菌活性(对革兰氏阴性菌和革兰氏阳性菌),通常抗菌活性超过氧化石墨烯[48]. 对某些特定的膜而言,MXenes的这种抗菌行为在实际的分离应用中是至关重要的. Pandey和同事制备了一种由银纳米颗粒(AgNPs)和MXenes组成的高性能复合膜[49]. 在复合膜中添加21%的AgNPs显著提高了MXene膜的抗菌活性. 可能是由于AgNPs和MXenes的协同抗菌活性,AgNP-MXene杂化膜(Ag@MXene)显示大肠杆菌细胞几乎完全被抑制. MXenes的抗菌性使MXenes材料应用于不同的膜分离领域,展现出不同的价值所在.

-

MXenes材料的制备通常以Ti3AlC3为原料,通过刻蚀剂选择性刻蚀制备MXenes. 在MAX相中,M—A键是一种金属键,键能较弱并具有一定的化学活性,比共价/离子混合的M—X键容易断裂. 因此,使用蚀刻剂可选择性地破坏M—A键,形成MX层(MXenes). 起初,研究者曾使用氯气和高温对MAX相进行刻蚀,不同程度地破坏了M—X键[50]. 随着刻蚀技术的进步,目前已能够通过相对缓和的方法成功剥离MAX. 以下介绍几种常见的MAX刻蚀方法.

-

(1) HF刻蚀法

二维MXenes从母相MAX前驱体中剥离始于2011年尤里·高果奇教授(Yury Gogotsi)课题组,并报道从Ti3AlC3 MAX相中使用HF蚀刻剂选择性蚀刻Al原子层以生成Ti3C2Tx MXene[50]. 此后,HF蚀刻剂被广泛应用于选择性蚀刻生产MXenes. 刻蚀反应如下:

在上述的反应当中,MXene中的Al原子被剥离,暴露的Ti原子在H2O和HF溶液中进行反应(式2和3),生成—OH和—F,所以刻蚀后的MXene外表面含有—OH和—F. 在刻蚀过程有H2产生,在通风的条件下制备有利于快速反应[51]. 然而,HF的腐蚀性强,会造成MXene的上表面产生缺陷(如孔洞)[52],其中游离的碳可能形成碳球,内部可能还存在少量的MAX前驱体没被完全剥离. 此外,HF蚀刻将MAX相转化为手风琴状多层MXenes,其中单个纳米片通过各种相互作用(包括范德华力和氢键)连接在一起[53]. 因此,需要一个额外的分层过程来制备单层的2D MXene纳米片. 与此同时,HF具有强的腐蚀性和高毒性在实验制备中对人体有严重的伤害,在处理HF或倒出HF废物时,必须采取安全预防措施. 因此,寻找一种相对缓和的刻蚀方法刻蚀MAX相制备MXene纳米片成为研究人员追求的最终目标.

(2) LiF和HCl刻蚀法

使用腐蚀性强的HF会使MXene纳米片表面产生缺陷,同时在处理及应用时对人体产生伤害,限制了HF刻蚀法的应用. 在2014年,Ghidiu等使用LiF和HCl的混合物在原位生成HF,通过蚀刻Ti3AlC2 MAX相的Al原子层来合成Ti3C2Tx MXene. 此外,用其他氟化物盐(KF、NaF、CsF、CaF2和四丁基氟化铵)替换LiF或用H2SO4替换HCl仍然会合成MXene纳米片[54]. 在最佳的LiF/HCl比例下刻蚀MAX避免了直接使用HF蚀刻工艺过程中所需的额外插层和分层步骤. 浓HCl和LiF反应生成HF和Li+,其中Li+在MXene的刻蚀中起插层的作用,使MXene的层间距变大,降低MXene中M—A之间的相互作用和层的堆叠. 刻蚀后的MXene在超声剥离时很容易形成单片和少层的超薄MXene纳米片. MXene的刻蚀反应方程如下[55]:

此种刻蚀方法制备的MXene纳米片的产量高、缺陷小、尺寸大和表面干净等优点[56]. 在反应当中LiF的相对含量和超声时间对MXene纳米片的尺寸大小和缺陷都有严重的影响[54].

-

直接用氢氟酸或间接生成氢氟酸(浓HCl和LiF的混合液)刻蚀MXene过程中含有氟,不仅对臭氧层造成损害而且还会对科研工作者的身体有严重的危害[57]. 因此,无HF-MXene刻蚀引起了科研工作者的研究兴趣. 总结出由于碱与Al元素的结合能力强,从Ti3AlC2 MAX相中提取Al元素合成Ti3C2Tx MXene (Tx= —OH和—O)是可行的. Li等[58]采用NaOH作为刻蚀剂,在高浓度的NaOH和高温状态下剥离MXene,选择性地消除了M—A键中的两性金属Al,可以获得纯度为92%的多层MXene纳米片. 然而,碱处理有时可能导致氧化物的形成,而不是产生MXene. 此外,在蚀刻过程中,在刻蚀MAX相的表面形成氧化层(例如,Al元素形成Al(OH)3和AlO(OH)),并阻碍了MAX相的进一步蚀刻. 因此,在碱处理生产MXenes时,必须对刻蚀条件进行严格控制[59]. 这种制备条件虽然比较苛刻,但是制备过程中没有氟的参与,做到了无氟刻蚀,在未来MXene的制备中具有很大的潜力.

-

一些MXenes (如Mo2CTx和Zr3C2Tx)可能很难通过传统的MAX相前驱体获得,但它们可以通过酸蚀非MAX相合成MXenes纳米片. 因此,氟化物水溶液对于蚀刻三元金属氮化物或碳氮化物的A层大多是无效的[60]. 为了克服这个问题,Urbankowski等在2016年探索了一种非水溶液蚀刻法,使用熔融氟化物盐(LiF (29 %wt)、KF (59 %wt)和NaF (12 %wt))的混合物作为高温下的蚀刻剂,合成了第一个二维氮化物MXene (如Ti4N3Tx)[61]. 此外,Soundiraraju等报告了通过使用KF-HCl混合物选择性地蚀刻铝层,从Ti2AlN前驱体合成Ti2N MXenes[62]. Li等[63]团队前期刻蚀MXene发现,氯化锌路易斯酸熔融盐可将铝系MAX相中的铝原子层替换成锌原子层,获得了含锌MAX相,而且高浓度氯化锌熔融盐可进一步将锌原子层刻蚀得到MXene材料. 采用熔融盐刻蚀MAX可以扩大MAX的选择范围,并且这种方法在刻蚀过程中无氟,做到了相对绿色的刻蚀. 但是这种方法制备的MXene表面有较多的缺陷存在并且相对纯度较低,需在未来做进一步的探索.

-

用于MAX相材料蚀刻的湿化学技术本质上都是电化学,其中发生电子转移是反应的一部分(电子从Al转移到其他物种). 在电化学蚀刻过程中,阳极和阴极被分离,电压差驱动腐蚀反应进行. 此外,在化学蚀刻过程中,表面的每个活性区域都涉及到阳极和阴极反应. 然而,电化学刻蚀过程中产生的MXenes非常容易对MAX相进行反刻蚀[64]. 通过去除M层和A层来产生层状碳化物衍生碳(CDCs),这类似于MXenes的过高频蚀刻,或者只去除M层,留下AX结构[65]. 例如,Sun等[66]通过电化学蚀刻法在稀释的HCl电解液中合成MXene,Al从含HCl的Ti2AlC水溶液中去除,从而形成具有表面端点(—Cl、—O和—OH)的Ti2CTx. 一般来说,当使用CV(循环伏安法)进行电化学蚀刻时,来自MAX相的M—A之间的键将断开,并允许去除A层,但供应额外的电压导致进一步蚀刻M层形成CDC[64]. 因此,控制刻蚀电压和刻蚀时间对于实现高效的MAX相刻蚀是至关重要的. 化学刻蚀法制备的MXene具有较大尺寸和相对较少的缺陷等优点,是一种新型的MXene制备方法.

-

不同的制备方法已被证明能够合成有效的MXenes材料,但跨学科应用的发展促进了制备方法的改进和参数的优化,如MXenes材料薄片的厚度和尺寸大小. Xue等[67]报道了通过化学法与物理球磨法相结合制备Ti3C2 MXene,具有分级多孔结构,与其他蚀刻方法相比,物理辅助法制备的Ti3C2 MXene比表面积(38.93 m2·g−1)是传统HF处理Ti3C2 MXene (4.87 m2·g−1)的8倍,这种物理辅助法制备Ti3C2 MXene相比其他刻蚀方法更简单、更环保. 目前为止,已报道了许多用于合成MAX相和MXenes的方法,但为了实现商业规模化的生产,还需要寻找简便、环保和经济可行的方法.

-

在任何情况下,从MAX相合成MXene通常需要至少几个小时到几天,不包括洗涤和分层过程,而且大多数合成方法都涉及使用高度危险的酸[68]. 然而,Ghazaly等[69]报道了一种超快速合成MXene,在高频率激发状态下,将一定量的LiF和MAX相的水溶液混合物暴露于表面声波,水分子解离产生的质子与LiF释放的氟离子结合,协助刻蚀MAX相中的Al层,而声波力有利于使产生的MXene分层. 需要注意的是,在溶液混合物中添加了过量的LiF,以弥补在溶解过程中LiF产生不足的F- (由于LiF在水中的溶解度限制),而理论上需要F-从Ti3AlC2中刻蚀所有MAX相中的Al原子,导致与MXene一起产生LiF粒子. 要去除这些LiF颗粒,需要用1 mol·L−1盐酸和1 mol·L−1 LiCl所去除. 此种方法与传统制备方法相类似.

-

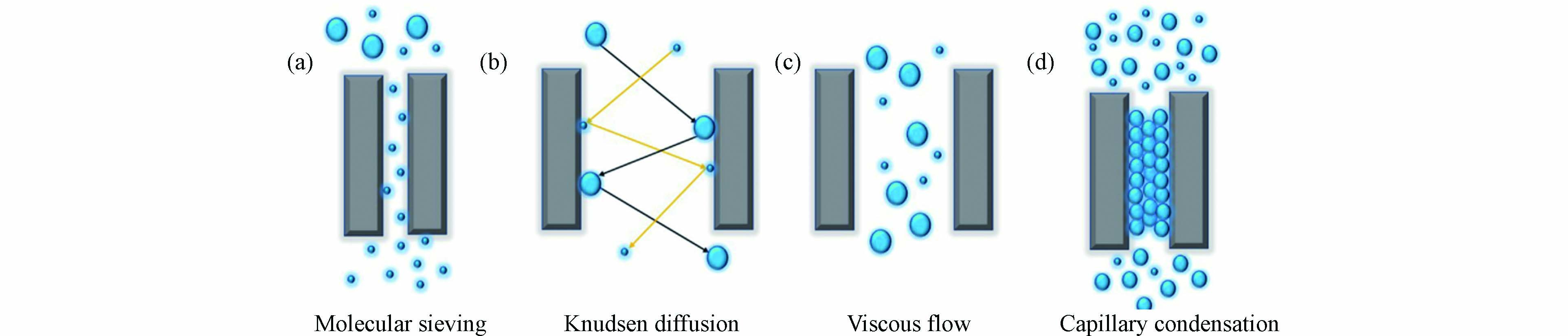

深入研究MXenes膜的分离机理了解分离过程,才可制备高性能气体分离膜. 一般来说,MXenes层由于具有强的氢键和范德华力的相互作用而可自组装. MXenes膜的分离机理与其他二维层状膜相似,MXenes膜内的分离可以发生在3个不同的区域:(i)由相邻MXenes薄片之间的非结构缺陷形成的平面内裂隙状孔隙,(ii)由涂层方法和官能团控制的平面到平面的层间孔道,以及(iii)由MXenes本身平面内气孔(固有缺陷)所形成的运输通道[16]. 但由于气体通过MXenes膜渗透的机制尚未完全明了,渗透性能受膜结构参数、材料特性等多种因素的影响,导致MXenes膜对气体分子有不同的分离机理,如分子筛分、Knudsen扩散、黏流流动和毛细管冷凝[70]. 以下对各种传输机理分别介绍.

-

分子筛分机理是小于气孔的分子或离子将通过分离材料,而较大的分子或离子则被排斥以实现有效的分子或离子的分离[71]. 筛分原理如图3a所示,当膜孔径介于两个不同分子直径之间,混合气中的气体分子与膜接触后,直径小的气体分子通过膜孔,而直径大的气体分子被截留在膜表面,从而实现气体的分离,即所制备的气体分离膜具有筛分效果. 由于不涉及化学作用,排斥完全取决于膜上纳米孔径的大小和通过物种的相对分子或离子大小[72]. 目前,许多二维材料可被用于制备具有筛分功能的膜,但是孔径大小控制相对困难,目前只能用于实验室研究,限制了工业化的应用. 在实际制膜中,膜内的孔径分布和大小是随机的,气体的传递机理是多种多样的,不只是单一的分子筛分.

-

Knudsen扩散发生在孔的直径大于气体分子的动力学直径,但小于气体分子的平均自由程范围内,气体分子通过膜时气体分子之间的相互碰撞作用力弱于气体分子和孔道壁之间的相互碰撞,气体分子与孔道壁之间的相互碰撞是具有弹性的,导致与表面之间的作用非常弱(图3b)[73]. Knudsen扩散气体的选择性非常低,一般不能用于气体分离. 气体流量和分子量相关,气体流量随着分子量的增加反而减小,与分子量的平方呈反比. 因此,提高气体流量最有效的方法就是用最小分子量的物质来构筑气体分离膜,如式(5)所示[74].

其中,J是膜的通量,n是气体的摩尔浓度,r是孔半径,Δp是跨膜压力,R是气体常数,T是温度,τ是孔的弯曲度,l是扩散长度. Dk为克努森扩散系数,定义如式(6)所示[74].

其中,Mw为渗透气体的分子量.

-

黏流流动发生在孔径较大的孔隙中超过分子的平均自由程(分子的平均自由程是指一个气体分子在连续两次碰撞之间可能通过各段自由程的算数平均值),并且分子的传输是通过大量流体带动通过,膜不具备分离功能(图3c)[75].

-

毛细凝聚机理是在多种气体混合物中有一种气体在低温下通过微孔介质时能够部分冷凝从而实现的分离(图3d). 这是在一定相对临界压力下发生的,此时膜孔中有一种气体能够冷凝,阻碍非冷凝组分的渗透,冷凝组分流出管道时又容易气化,从而实现了相应的分离[76]. 毛细凝聚虽然具有高的分离效率但是在实际应用中临界分压、膜的孔径和结构对分离效率具有一定的限制性.

虽然分别进行了讨论,但MXenes膜对离子、气体和有机分子的精确分辨通常依赖于孔径与孔径表面之间的协同作用. 因此,制备具有精确调节孔径和比表面特性的MXenes膜是进一步应用于临界分离的迫切需要.

-

MXenes材料具有结构广泛性和化学多样性,在各种领域显示出巨大的应用潜力,应用在水净化、海水淡化、气体分离、有机溶剂纳滤(OSN)等领域. 其中,为了实现“双碳”目标,MXenes基膜在气体分离方面显示出巨大的应用前景. 一般来说,MXenes基膜有3种制备策略:(1)以MXenes为骨架材料制备层状结构;(2)加入不同的添加剂或者其他纳米材料与MXenes混合制备混合基质膜;(3)MXenes被用作涂层材料来修饰膜支撑层[77]. MXenes材料由于其强氢键和范德华相互作用而易于自组装. 在真空抽滤时,由于其表面丰富的官能团易于形成MXenes薄膜,利用MXenes纳米片的堆叠以及MXenes的物理化学性质可制备具有高选择性的MXenes基膜. 通过二维纳米片制备的二维膜的层间通道大小从亚纳米(<0.7 nm)到微孔(0.7—2 nm)不等,层间通道的大小主要取决于材料性质、制备方法和膜制备方法. 制备不同类型的二维膜可分离不同的气体分子,使膜的应用范围更加广泛[78].

除了纯MXene薄膜外,许多研究都致力于制备由MXene和其他无机或聚合物材料组成的复合材料[79]. 在本节中,将讨论MXene膜的最新研究进展及发展趋势,并提出提高MXene膜的分离性能和稳定性的方法.

(1) MXenes层状膜

MXenes纳米片通过组装堆叠成二维纳米通道,Ti3C2Tx MXene纳米片组装的薄膜厚度约为1.35 nm,层间间距约为0.35 nm,根据气体分子的大小具有优异的分离效果. 二维纳米通道可延长气体分子的传输路径,可显著提高气体分子的选择性. Ding等[72]通过真空抽滤法将Ti3C2Tx MXene纳米片溶液抽滤在阳极氧化铝(AAO)载体上制备了Ti3C2Tx MXene薄膜. 将制备的Ti3C2Tx MXene薄膜从基底上剥离形成自支撑的Ti3C2Tx MXene薄膜,通过万能试验机测得其抗拉强度高达51.5 MPa,杨氏模量高达3.8 GPa,结果表明具有杰出的力学性能. 此外,通过气体渗透装置测得Ti3C2Tx MXene薄膜对H2的渗透率为2402 Barrer,H2/CO2选择性为238,远远超过了2008年Robeson上限,结果表明制备的Ti3C2Tx MXene薄膜具有优异的分离性能. 通过分子动力模拟证实了MXene膜中纳米狭缝的尺寸具有筛选能力,能够筛分不同大小的气体分子. 最终结果表明,分子尺寸为0.35 nm的气体分子透过膜的速率要比H2和He等小分子气体透过膜的速率慢100倍. 此外,考虑到MXenes含有丰富的含氧官能团,可能对渗透的CO2分子产生“捕获效应”. 使CO2与Ti3C2Tx相互作用抑制了CO2气体分子的透过,从而导致CO2具有较低的渗透率. 利用Ti3C2Tx MXene自支撑膜实现H2和CO2气体的分离主要是利用MXene纳米片之间的层间距以及形成较长的气体运输路径实现气体的高效分离.

此外,Fan等[80]通过真空辅助过滤和干燥过程制备了高选择性分子筛MXene膜, 发现这种Ti3C2Tx MXene纳米片在多孔衬底上形成二维层状膜,在高温下甚至320 ℃都具有优异的分离性能. 其主要是由于Ti3C2Tx MXene材料具有稳定的晶体结构和与衬底良好的热膨胀匹配. 随着测试温度从室温逐渐增加到500 ℃时,MXene膜的层间距从0.34 nm逐渐减小到0.27 nm. 在320 ℃时,所制备的二维MXene膜具有前所未有的氢渗透性能,可达2.0×10−7 mol·m−2·s−1·Pa−1,对H2/N2选择性为41. 结果表明,MXene膜具有良好的分离性能和优异的热稳定性,是一种很有前途的高温气体分离材料,有效地解决了传统膜热稳定性差的缺点.

(2) MXenes基混合基质膜

混合基质膜是用无机填料作为分散相,聚合物基质作为连续相,将聚合物和无机物相混合制备成高性能气体分离膜. MXenes表面丰富的官能团赋予MXenes具有高的表面积、生物相容性、亲水性、低扩散阻力、活化的金属氢氧化物位点、优异的电导率等优点,使MXenes成为最受欢迎的无机填料. 在混合基质膜中,通过调节聚合物膜的输运路径,提高MXenes通道的筛分能力,以及通过MXene表面丰富的官能团增加吸附量,可以提高聚合物膜的透气性和选择性. Luo等[81]通过溶液浇铸法制备了高性能Pebax/CMC@MXene MMMs用于天然气和烟道气中CO2的消除. 先将支链状的羧甲基纤维素(CMC)加入到MXene纳米片中形成CMC@MXene填料,之后将CMC@MXene填料与聚合物Peabx基质相结合制备Pebax/CMC@MXene MMMs. 首先,将制备的Pebax/CMC@MXene MMMs通过万能试验机测得其抗拉强度高达0.94 Mpa,断裂伸长率计算为1351.11%,结果表明Pebax/CMC@MXene MMMs具有杰出的机械性能. 其次,通过气体渗透装置测得Pebax/CMC@MXene MMMs在CO2/N2分离过程中,测得CO2的渗透率为521GPU,CO2/N2的选择性为40.1. 同时,在CO2/CH4分离过程中,CO2的渗透CO2为444 GPU,CO2/CH4的选择性为40.4. 将制备的Pebax/CMC@MXene MMMs与其他已报道的Pebax基膜进行相应的比较,结果表明所制备的Pebax/CMC@MXene MMMs具有在保持适当选择性的同时具有优异的渗透性. 最后,通过测试温度对Pebax/CMC@MXene MMMs分离性能的影响,较高的温度不仅加速了气体分子的动态扩散,导致渗透增强,而且促进了N2和CH4分子的灵活旋转和重叠,使更多的N2和CH4分子的渗透,导致选择性降低. 最终结果表明所制备的Pebax/CMC@MXene MMMs具有优异的分离性能,抗拉伸性及稳定性.

此外,Shamsabadi等[82]s通过溶液浇铸法制备了MXenes基混合基质膜用于CO2/N2和CO2/H2分离. 将二维Ti3C2Tx MXene纳米片嵌入到Pebax®-1657基质中形成自支撑和薄膜的混合基质膜(MMMs),所制备的混合基质膜具有优异的CO2分离性能. 在Pebax®-1657基质和二维Ti3C2Tx MXene纳米片填料之间存在氢键的相互作用,导致Ti3C2Tx纳米片在Pebax硬段中形成了规则的气体运输通道. 由于界面相互作用和具有选择性的Ti3C2Tx纳米通道实现了对CO2气体的快速传输和高效选择. 在25℃ 和 4 bar条件进行渗透试验测试,当Ti3C2Tx的负载量增加到0.1% wt时,CO2的渗透性和CO2/N2的选择性均显著增加到126 barrer和96. CO2渗透性的显著增加是由于在较低的Ti3C2Tx负载量下Pebax- Ti3C2Tx MMMs中溶解度和扩散系数的增加所引起. Pebax- Ti3C2Tx MMMs中硬段链和分子筛分通道的破坏促进了CO2的快速运输. 选择性增强主要是归因于Ti3C2Tx纳米片上丰富的官能团,特别是Ti3C2Tx纳米片上的羟基具有出色的CO2吸附能力. 结果表明所制备的Pebax- Ti3C2Tx MMMs高分离性能在CO2捕获与分离方面具有巨大的潜力且成本低廉. 除此之外,Liu等[83]使用MXenes作为填料,将聚醚-聚酰胺嵌段共聚物(Pebax)作为混合基质膜的基质,用于捕获CO2. 在Ti3C2Tx纳米片的负载量为0.15 %wt的条件下,通过旋涂法在PAN载体上制备了高性能混合基质膜. 由于MXene纳米片具有原子厚度和微米级的横向尺寸,使得薄膜具有丰富的二维通道,有利于气体的传输. 同时,具有CO2优先吸附作用的MXene纳米片和Pebax为CO2的运输提供了快速通道,使得所制备的MXene/Pebax膜具有优异的分离性能. 结果表明,MXene/Pebax膜在MXene负载为0.15 %wt的情况下,具有较好的分离性能,CO2渗透率为21.6 GPU,CO2/N2选择性为72.5,在CO2捕获方面具有潜在的应用价值. 重要的是所制备的MXene/Pebax膜在120 h的连续操作中也表现出良好的稳定性.

(3) MXenes修饰膜

MXenes材料表明丰富的官能团赋予MXenes易被修饰,通过物理化学功能化的MXenes材料可显著提高兼容性及分离性能. Jin课题组[3]通过化学交联将硼酸盐和聚乙烯亚胺(PEI)分子很好地互锁在MXene层中,制备了具有可调控气体传输通道的MXene纳米片,实现了MXene纳米片的堆积行为和层间间距的微妙调节. 由于H2的分子尺寸较小,在原始MXene纳米膜内可以形成分子筛分通道,对H2分子表现出高的渗透选择性. 然而,将MXene纳米片用硼酸盐和聚乙烯亚胺(PEI)功能化后,MXene纳米片表现出不同的堆积行为和可调节的层间间距,优先允许CO2分子的渗透. 结果表明在MXene纳米片之间引入硼酸盐和PEI后,MXene纳米片之间的层间间距从0.52 nm减少到0.34 nm,使MXene纳米膜能够对CO2、N2、CH4和C3H8气体的选择分离. 此外,硼酸盐不仅与MXenes上的含氧官能团交联,而且还对CO2气体的渗透起促进作用. 结果表明,CO2的渗透率从67 GPU(原始MXene纳米膜)增加到350 GPU(硼酸盐和PEI功能化的MXene纳米膜),CO2的渗透率显著提高了5.2倍. 此外,硼酸盐和PEI功能化的MXene纳米膜的分离性能显著超过其他已报道的气体分离膜. 这项工作进一步促进了用于精确分子分离的MXene基气体膜的发展.

Jia等[20]通过真空抽滤和滴涂法将一种典型的离子液体1-丁基-3-甲基咪唑四氟硼酸盐([BMIM][BF4])嵌入到磺化MXene片层膜的纳米通道中,制备了一个高性能T@MX/IL膜用于CO2/N2的分离. 其中,磺酸基通过基于金属-邻苯二酚螯合化学的简单方法锚定在MXene纳米片上. 离子液体(IL)嵌入到二维层状膜中用于分离具有相似的动力学直径的气体是一种有效的方法,因为它对某些气体分子具有一定的溶解性. 同时,IL对二维层状膜中的不良缺陷具有弥补能力. 由于MXene内在优势决定了MXene成为构建单元和被磺酸基修饰的主体,所制备的T@MX/IL膜具有最佳的层间间距(~1.8 nm)和最高的IL吸收率(~47%wt). 因此,T@MX/IL膜表现出对CO2的渗透率为519 GPU,对CO2/N2的选择性为210,优于先前所报道的离子液体支撑膜. 此外,在较高的压力条件下(5 bar),在MXene纳米片所形成的通道壁上生长磺酸基后,在7 d内T@MX/IL膜的IL损失率显著降低(从43.2%wt降至9.0%wt),结果证明IL在T@MX/IL膜中具有优异的存储能力.

综上所述,利用MXenes材料表面丰富的官能及一系列手段制备了高性能的MXenes基膜用于气体分离,可显著提高气体的分离性能及稳定性. 总之,二维MXenes材料的发展为气体分离奠定了基础,不仅为气体分离提供了一定的理论支撑并得到相应的实践证明,同时也拓宽了MXenes纳米片的应用前景.

-

MXenes纳米材料表面具有丰富的官能团,高纵横比等优点,有望成为理想的分离材料,以确保工业生产过程中的能源效率和生产效率. 本文综述了MXenes纳米材料的成膜特性、制备、分离机理及MXenes基气体分离膜的应用. 研究了MXenes的独特结构和表面官能团对膜分离性能的影响.

MXenes基的气体分离膜目前仅限于实验室规模的研究,大多数研究都涉及不同的材料体系、分离任务或实验条件. 因此,本文认为MXenes基气体分离膜仍有足够的改进空间. 例如,MXenes纳米材料的氧化问题是否会大大限制MXenes的应用前景;另一个有待解决的问题是MXenes材料所形成的二维纳米通道及层间距的调节是否优于其他二维纳米通道;最后,利用了MXenes材料表面丰富的化学性质以及结构特性,通过模拟/建模方法用于基于MXenes膜的设计. 综上所述,本文认为基于MXenes膜在未来不到5年的时间内将继续快速发展. 希望本综述中提出的分析为膜的概念设计和分离应用做出一定的贡献.

二维MXene材料在气体分离领域的研究进展

Research progress of two-dimensional MXene materials in gas separation

-

摘要: MXenes因其二维层状结构、表面丰富的官能团、亲水性和大比表面积而受到广泛关注,被认为是在气体分离领域极具竞争力的二维层状材料. 本文综述了MXenes纳米材料的成膜特性、制备、分离机理及其在气体分离领域中的最新研究进展;分析了MXene在气体分离领域的发展趋势. MXenes在气体分离领域的应用处于起初阶段,其膜分离性质及机理有待进一步明晰,导致MXenes基气体分离膜面临着许多瓶颈和挑战. 此外,本文还描述了MXenes基膜在气体分离领域的广阔应用前景,为未来该材料的发展提供了一个有价值的方向和平台.Abstract: MXenes is considered to be a highly competitive two-dimensional layered material in the field of gas separation due to its two-dimensional layered structure, rich surface functional groups, hydrophilicity and large specific surface area. In this paper, the film forming properties, preparation and separation mechanism of MXenes nanomaterials and their recent research progress in the field of gas separation are reviewed. The development trend of MXene in gas separation field was analyzed. The application of MXenes in the field of gas separation is at the initial stage, and its membrane separation properties and mechanism need to be further clarified. As a result, MXenes based gas separation membranes are facing many bottlenecks and challenges. In addition, the broad application prospects of MXenes based membranes in the field of gas separation are described. The rapid development of MXenes materials and their applications in membrane separation provide a valuable direction and platform for future applications.

-

Key words:

- MXene /

- membrane separation /

- two-dimensional materials.

-

-

[1] CHEN R, KONG Y. A comprehensive review of greenhouse gas based on subject categories [J]. Science of the Total Environment, 2023, 866: 161314. doi: 10.1016/j.scitotenv.2022.161314 [2] YUAN H M, LIU J G, ZHANG X H, et al. Recent advances in membrane-based materials for desalination and gas separation [J]. Journal of Cleaner Production, 2023, 387: 135845. doi: 10.1016/j.jclepro.2023.135845 [3] SHEN J, LIU G Z, JI Y F, et al. 2D MXene nanofilms with tunable gas transport channels [J]. Advanced Functional Materials, 2018, 28(31): 1801511. doi: 10.1002/adfm.201801511 [4] LIU Z M, CHAKRABORTY A, HE T B, et al. Technoeconomic and environmental optimization of combined heat and power systems with renewable integration for chemical plants [J]. Applied Thermal Engineering, 2023, 219: 119474. doi: 10.1016/j.applthermaleng.2022.119474 [5] ZHANG J F, LIN H F, LI S G, et al. Accurate gas extraction(AGE) under the dual-carbon background: Green low-carbon development pathway and prospect [J]. Journal of Cleaner Production, 2022, 377: 134372. doi: 10.1016/j.jclepro.2022.134372 [6] 曾诗鸿, 李根, 翁智雄, 等. 面向碳达峰与碳中和目标的中国能源转型路径研究 [J]. 环境保护, 2021, 49(16): 26-29. doi: 10.14026/j.cnki.0253-9705.2021.16.008 ZENG S H, LI G, WENG Z X, et al. Research on China’s energy transition path towards the goals of carbon peak and carbon neutrality [J]. Environmental Protection, 2021, 49(16): 26-29(in Chinese). doi: 10.14026/j.cnki.0253-9705.2021.16.008

[7] GÜR T M. Carbon dioxide emissions, capture, storage and utilization: Review of materials, processes and technologies [J]. Progress in Energy and Combustion Science, 2022, 89: 100965. doi: 10.1016/j.pecs.2021.100965 [8] WANG S F, LI X Q, WU H, et al. Advances in high permeability polymer-based membrane materials for CO2 separations [J]. Energy & Environmental Science, 2016, 9(6): 1863-1890. [9] DUBEY A, ARORA A. Advancements in carbon capture technologies: A review [J]. Journal of Cleaner Production, 2022, 373: 133932. doi: 10.1016/j.jclepro.2022.133932 [10] WANG H L, HE S F, QIN X D, et al. Interfacial engineering in metal-organic framework-based mixed matrix membranes using covalently grafted polyimide brushes [J]. Journal of the American Chemical Society, 2018, 140(49): 17203-17210. doi: 10.1021/jacs.8b10138 [11] ZHAO C Y, HUSSAIN W, CHLIB ALKAABY H H, et al. Polymeric nanocomposite membranes for gas separation: Performance, applications, restrictions and future perspectives [J]. Case Studies in Thermal Engineering, 2022, 38: 102323. doi: 10.1016/j.csite.2022.102323 [12] HUANG Z H, YIN C, CORRADO T, et al. Microporous pentiptycene-based polymers with heterocyclic rings for high-performance gas separation membranes [J]. Chemistry of Materials, 2022, 34(6): 2730-2742. doi: 10.1021/acs.chemmater.1c04212 [13] ROBESON L M. Correlation of separation factor versus permeability for polymeric membranes [J]. Journal of Membrane Science, 1991, 62(2): 165-185. doi: 10.1016/0376-7388(91)80060-J [14] GUO M, ZHANG Y W, XU R, et al. Ultrahigh permeation of CO2 capture using composite organosilica membranes [J]. Separation and Purification Technology, 2022, 282: 120061. doi: 10.1016/j.seppur.2021.120061 [15] ZHU B, LIU J D, WANG S F, et al. Mixed matrix membranes containing well-designed composite microcapsules for CO2 separation [J]. Journal of Membrane Science, 2019, 572: 650-657. doi: 10.1016/j.memsci.2018.11.039 [16] ISFAHANI A P, ARABI SHAMSABADI A, SOROUSH M. MXenes and other two-dimensional materials for membrane gas separation: Progress, challenges, and potential of MXene-based membranes [J]. Industrial & Engineering Chemistry Research, 2023, 62(5): 2309-2328. [17] ZHU J Y, HOU J W, ULIANA A, et al. The rapid emergence of two-dimensional nanomaterials for high-performance separation membranes [J]. Journal of Materials Chemistry A, 2018, 6(9): 3773-3792. doi: 10.1039/C7TA10814A [18] ZHU W F, QIN Y, WANG Z M, et al. Incorporating the magnetic alignment of GO composites into Pebax matrix for gas separation [J]. Journal of Energy Chemistry, 2019, 31: 1-10. doi: 10.1016/j.jechem.2018.04.013 [19] GAO L F, LI C, HUANG W C, et al. MXene/polymer membranes: Synthesis, properties, and emerging applications [J]. Chemistry of Materials, 2020, 32(5): 1703-1747. doi: 10.1021/acs.chemmater.9b04408 [20] JIA Y Y, SHI F, LI H Y, et al. Facile ionization of the nanochannels of lamellar membranes for stable ionic liquid immobilization and efficient CO2 separation [J]. ACS Nano, 2022, 16(9): 14379-14389. doi: 10.1021/acsnano.2c04670 [21] FAN H W, PENG M H, STRAUSS I, et al. MOF-in-COF molecular sieving membrane for selective hydrogen separation [J]. Nature Communications, 2021, 12(1): 1-10. doi: 10.1038/s41467-020-20314-w [22] LI J, ZHOU X, WANG J, et al. Two-dimensional covalent organic frameworks (COFs) for membrane separation: A mini review [J]. Industrial & Engineering Chemistry Research, 2019, 58(34): 15394-15406. [23] YUAN H Y, LIU P F, YANG H G. Peculiar double-layered transition metal hydroxide nanosheets [J]. Matter, 2022, 5(4): 1063-1065. doi: 10.1016/j.matt.2022.03.007 [24] WANG D, WANG Z G, WANG L, et al. Ultrathin membranes of single-layered MoS2 nanosheets for high-permeance hydrogen separation [J]. Nanoscale, 2015, 7(42): 17649-17652. doi: 10.1039/C5NR06321C [25] NIU Z H, LUO W J, MU P, et al. Nanoconfined CO2-philic ionic liquid in laminated g-C3N4 membrane for the highly efficient separation of CO2 [J]. Separation and Purification Technology, 2022, 297: 121513. doi: 10.1016/j.seppur.2022.121513 [26] ANASORI B, LUKATSKAYA M R, GOGOTSI Y. 2D metal carbides and nitrides (MXenes) for energy storage [J]. Nature Reviews Materials, 2017, 2(2): 1-17. [27] XU J S, YOU J H, WANG L, et al. MXenes serving aqueous supercapacitors: Preparation, energy storage mechanism and electrochemical performance enhancement [J]. Sustainable Materials and Technologies, 2022, 33: e00490. doi: 10.1016/j.susmat.2022.e00490 [28] LIU H G, WANG Z, WANG J, et al. Structural evolution of MXenes and their composites for electromagnetic interference shielding applications [J]. Nanoscale, 2022, 14(26): 9218-9247. doi: 10.1039/D2NR02224A [29] LI R S, GAO Q, XING H N, et al. Lightweight, multifunctional MXene/polymer composites with enhanced electromagnetic wave absorption and high-performance thermal conductivity [J]. Carbon, 2021, 183: 301-312. doi: 10.1016/j.carbon.2021.07.029 [30] LI R H, FU X F, LIU G Z, et al. Room-temperature in situ synthesis of MOF@MXene membrane for efficient hydrogen purification [J]. Journal of Membrane Science, 2022, 664: 121097. doi: 10.1016/j.memsci.2022.121097 [31] SUN Y Q, LI S L, ZHUANG Y X, et al. Adjustable interlayer spacing of ultrathin MXene-derived membranes for ion rejection [J]. Journal of Membrane Science, 2019, 591: 117350. doi: 10.1016/j.memsci.2019.117350 [32] WU X L, CUI X L, WU W J, et al. Elucidating ultrafast molecular permeation through well-defined 2D nanochannels of lamellar membranes [J]. Angewandte Chemie (International Ed. in English), 2019, 58(51): 18524-18529. doi: 10.1002/anie.201912570 [33] DING L, XIAO D, LU Z, et al. Oppositely charged Ti3C2Tx MXene membranes with 2D nanofluidic channels for osmotic energy harvesting [J]. Angewandte Chemie International Edition, 2020, 59(22): 8720-8726. doi: 10.1002/anie.201915993 [34] KARAHAN H E, GOH K, ZHANG C J, et al. MXene materials for designing advanced separation membranes [J]. Advanced Materials, 2020, 32(29): e1906697. doi: 10.1002/adma.201906697 [35] ZHANG Y M, CHEN X S, LUO C J, et al. Column-to-beam structure house inspired MXene-based integrated membrane with stable interlayer spacing for water purification [J]. Advanced Functional Materials, 2022, 32(22): 2111660. doi: 10.1002/adfm.202111660 [36] DING L, WEI Y Y, WANG Y J, et al. A two-dimensional lamellar membrane: MXene nanosheet stacks [J]. Angewandte Chemie (International Ed. in English), 2017, 56(7): 1825-1829. doi: 10.1002/anie.201609306 [37] SY S, JIANG G P, ZHANG J, et al. A near-isotropic proton-conducting porous graphene oxide membrane [J]. ACS Nano, 2020, 14(11): 14947-14959. doi: 10.1021/acsnano.0c04533 [38] HOPE M A, FORSE A C, GRIFFITH K J, et al. NMR reveals the surface functionalisation of Ti3C2 MXene [J]. Physical Chemistry Chemical Physics:PCCP, 2016, 18(7): 5099-5102. doi: 10.1039/C6CP00330C [39] RIAZI H, ANAYEE M, HANTANASIRISAKUL K, et al. Surface modification of a MXene by an aminosilane coupling agent [J]. Advanced Materials Interfaces, 2020, 7(6): 1902008. doi: 10.1002/admi.201902008 [40] HAO L, ZHANG H Q, WU X L, et al. Novel thin-film nanocomposite membranes filled with multi-functional Ti3C2Tx nanosheets for task-specific solvent transport [J]. Composites Part A:Applied Science and Manufacturing, 2017, 100: 139-149. doi: 10.1016/j.compositesa.2017.05.003 [41] WANG K, ZHOU Y F, XU W T, et al. Fabrication and thermal stability of two-dimensional carbide Ti3C2 nanosheets [J]. Ceramics International, 2016, 42(7): 8419-8424. doi: 10.1016/j.ceramint.2016.02.059 [42] XIONG D B, LI X F, BAI Z M, et al. Recent advances in layered TiC2Tx MXene for electrochemical energy storage [J]. Small, 2018, 14(17): e1703419. doi: 10.1002/smll.201703419 [43] BHARGAVA REDDY M S, KAILASA S, MARUPALLI B C G, et al. A family of 2D-MXenes: Synthesis, properties, and gas sensing applications [J]. ACS Sensors, 2022, 7(8): 2132-2163. doi: 10.1021/acssensors.2c01046 [44] MALESKI K, REN C E, ZHAO M Q, et al. Size-dependent physical and electrochemical properties of two-dimensional MXene flakes [J]. ACS Applied Materials & Interfaces, 2018, 10(29): 24491-24498. [45] WANG Y X, YUE Y, CHENG F, et al. Ti3C2Tx MXene-based flexible piezoresistive physical sensors [J]. ACS Nano, 2022, 16(2): 1734-1758. doi: 10.1021/acsnano.1c09925 [46] BORYSIUK V N, MOCHALIN V N, GOGOTSI Y. Molecular dynamic study of the mechanical properties of two-dimensional titanium carbides Ti(n+1)C(n) (MXenes) [J]. Nanotechnology, 2015, 26(26): 265705. doi: 10.1088/0957-4484/26/26/265705 [47] WU X L, HAO L, ZHANG J K, et al. Polymer-Ti3C2Tx composite membranes to overcome the trade-off in solvent resistant nanofiltration for alcohol-based system [J]. Journal of Membrane Science, 2016, 515: 175-188. doi: 10.1016/j.memsci.2016.05.048 [48] SEIDI F, ARABI SHAMSABADI A, DADASHI FIROUZJAEI M, et al. MXenes antibacterial properties and applications: A review and perspective[J]. Small (Weinheim an Der Bergstrasse, Germany), 2023: e2206716. [49] PANDEY R P, RASOOL K, MADHAVAN V E, et al. Ultrahigh-flux and fouling-resistant membranes based on layered silver/MXene (Ti3C2Tx) nanosheets [J]. Journal of Materials Chemistry A, 2018, 6(8): 3522-3533. doi: 10.1039/C7TA10888E [50] NAGUIB M, KURTOGLU M, PRESSER V, et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2 [J]. Advanced Materials, 2011, 23(37): 4248-4253. doi: 10.1002/adma.201102306 [51] ZHOU J, ZHA X H, ZHOU X B, et al. Synthesis and electrochemical properties of two-dimensional hafnium carbide [J]. ACS Nano, 2017, 11(4): 3841-3850. doi: 10.1021/acsnano.7b00030 [52] NAGUIB M, MASHTALIR O, CARLE J, et al. Two-dimensional transition metal carbides [J]. ACS Nano, 2012, 6(2): 1322-1331. doi: 10.1021/nn204153h [53] ALHABEB M, MALESKI K, ANASORI B, et al. Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene) [J]. Chemistry of Materials, 2017, 29(18): 7633-7644. doi: 10.1021/acs.chemmater.7b02847 [54] GHIDIU M, LUKATSKAYA M R, ZHAO M Q, et al. Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance [J]. Nature, 2014, 516(7529): 78-81. doi: 10.1038/nature13970 [55] HALIM J, KOTA S, LUKATSKAYA M R, et al. Synthesis and characterization of 2D molybdenum carbide (MXene) [J]. Advanced Functional Materials, 2016, 26(18): 3118-3127. doi: 10.1002/adfm.201505328 [56] LIPATOV A, ALHABEB M, LUKATSKAYA M R, et al. MXene materials: Effect of synthesis on quality, electronic properties and environmental stability of individual monolayer Ti3C2 MXene flakes [J]. Advanced Electronic Materials, 2016, 2(12): 1600255. doi: 10.1002/aelm.201600255 [57] SHUCK C E, VENTURA-MARTINEZ K, GOAD A, et al. Safe synthesis of MAX and MXene: Guidelines to reduce risk during synthesis [J]. ACS Chemical Health & Safety, 2021, 28(5): 326-338. [58] LI T F, YAO L L, LIU Q L, et al. Fluorine-free synthesis of high-purity Ti3C2Tx (T=OH, O) via alkali treatment [J]. Angewandte Chemie International Edition, 2018, 57(21): 6115-6119. doi: 10.1002/anie.201800887 [59] ZOU G D, GUO J X, LIU X Y, et al. Hydrogenated core–shell MAX@K2Ti8O17 pseudocapacitance with ultrafast sodium storage and long-term cycling [J]. Advanced Energy Materials, 2017, 7(18): 1700700. doi: 10.1002/aenm.201700700 [60] MESHKIAN R, NÄSLUND L Å, HALIM J, et al. Synthesis of two-dimensional molybdenum carbide, Mo2C, from the gallium based atomic laminate Mo2Ga2C [J]. Scripta Materialia, 2015, 108: 147-150. doi: 10.1016/j.scriptamat.2015.07.003 [61] URBANKOWSKI P, ANASORI B, MAKARYAN T, et al. Synthesis of two-dimensional titanium nitride Ti4N3 (MXene) [J]. Nanoscale, 2016, 8(22): 11385-11391. doi: 10.1039/C6NR02253G [62] SOUNDIRARAJU B, GEORGE B K. Two-dimensional titanium nitride (Ti2N) MXene: Synthesis, characterization, and potential application as surface-enhanced Raman scattering substrate [J]. ACS Nano, 2017, 11(9): 8892-8900. doi: 10.1021/acsnano.7b03129 [63] LI Y B, SHAO H, LIN Z F, et al. A general Lewis acidic etching route for preparing MXenes with enhanced electrochemical performance in non-aqueous electrolyte [J]. Nature Materials, 2020, 19(8): 894-899. doi: 10.1038/s41563-020-0657-0 [64] LUKATSKAYA M R, HALIM J, DYATKIN B, et al. Room-temperature carbide-derived carbon synthesis by electrochemical etching of MAX phases [J]. Angewandte Chemie (International Ed. in English), 2014, 53(19): 4877-4880. doi: 10.1002/anie.201402513 [65] ZHAO M Q, SEDRAN M, LING Z, et al. Synthesis of carbon/sulfur nanolaminates by electrochemical extraction of titanium from Ti2SC [J]. Angewandte Chemie (International Ed. in English), 2015, 54(16): 4810-4814. doi: 10.1002/anie.201500110 [66] SUN W, SHAH S A, CHEN Y, et al. Electrochemical etching of Ti2AlC to Ti2CTx (MXene) in low-concentration hydrochloric acid solution [J]. Journal of Materials Chemistry A, 2017, 5(41): 21663-21668. doi: 10.1039/C7TA05574A [67] XUE N, LI X S, ZHANG M Q, et al. Chemical-combined ball-milling synthesis of fluorine-free porous MXene for high-performance lithium ion batteries [J]. ACS Applied Energy Materials, 2020, 3(10): 10234-10241. doi: 10.1021/acsaem.0c02081 [68] MURALI G, RAWAL J, MODIGUNTA J K R, et al. A review on MXenes: New-generation 2D materials for supercapacitors [J]. Sustainable Energy & Fuels, 2021, 5(22): 5672-5693. [69] GHAZALY A E, AHMED H, REZK A R, et al. Ultrafast, one-step, salt-solution-based acoustic synthesis of Ti3C2 MXene [J]. ACS Nano, 2021, 15(3): 4287-4293. doi: 10.1021/acsnano.0c07242 [70] SIDHIKKU KANDATH VALAPPIL R, GHASEM N, AL-MARZOUQI M. Current and future trends in polymer membrane-based gas separation technology: A comprehensive review [J]. Journal of Industrial and Engineering Chemistry, 2021, 98: 103-129. doi: 10.1016/j.jiec.2021.03.030 [71] CARREON M A. Microporous crystalline molecular sieve membranes for molecular gas separations: What is next? [J]. ACS Materials Letters, 2022, 4(5): 868-873. doi: 10.1021/acsmaterialslett.2c00102 [72] DING L, WEI Y Y, LI L B, et al. MXene molecular sieving membranes for highly efficient gas separation [J]. Nature Communications, 2018, 9(1): 1-7. doi: 10.1038/s41467-017-02088-w [73] JAVAID A. Membranes for solubility-based gas separation applications [J]. Chemical Engineering Journal, 2005, 112(1/2/3): 219-226. [74] WIJMANS J G, BAKER R W. The solution-diffusion model: A review [J]. Journal of Membrane Science, 1995, 107(1/2): 1-21. [75] LOUDON C, McCULLOH K. Application of the Hagen—Poiseuille equation to fluid feeding through short tubes [J]. Annals of the Entomological Society of America, 1999, 92(1): 153-158. doi: 10.1093/aesa/92.1.153 [76] UHLHORN R J R, KEIZER K, BURGGRAAF A J. Gas transport and separation with ceramic membranes. Part I. Multilayer diffusion and capillary condensation [J]. Journal of Membrane Science, 1992, 66(2/3): 259-269. [77] 孙成珍, 罗东, 白博峰. 二维材料气体分离膜及其应用研究进展 [J]. 科学通报, 2023, 68(1): 53-71. doi: 10.1360/TB-2022-0503 SUN C Z, LUO D, BAI B F. Two-dimensional material membranes for gas separation and their applications [J]. Chinese Science Bulletin, 2023, 68(1): 53-71(in Chinese). doi: 10.1360/TB-2022-0503

[78] THOMMES M, KANEKO K, NEIMARK A V, et al. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report) [J]. Pure and Applied Chemistry, 2015, 87(9/10): 1051-1069. [79] LU Z, WU Y, DING L, et al. A lamellar MXene (Ti3C2Tx)/PSS composite membrane for fast and selective lithium-ion separation [J]. Angewandte Chemie (International Ed. in English), 2021, 60(41): 22265-22269. doi: 10.1002/anie.202108801 [80] FAN Y Y, WEI L Y, MENG X X, et al. An unprecedented high-temperature-tolerance 2D laminar MXene membrane for ultrafast hydrogen sieving [J]. Journal of Membrane Science, 2019, 569: 117-123. doi: 10.1016/j.memsci.2018.10.017 [81] LUO W J, NIU Z H, MU P, et al. Pebax and CMC@MXene-based mixed matrix membrane with high mechanical strength for the highly efficient capture of CO2 [J]. Macromolecules, 2022, 55(21): 9851-9859. doi: 10.1021/acs.macromol.2c01532 [82] SHAMSABADI A A, ISFAHANI A P, SALESTAN S K, et al. Pushing rubbery polymer membranes to be economic for CO2 separation: Embedment with Ti3C2Tx MXene nanosheets [J]. ACS Applied Materials & Interfaces, 2020, 12(3): 3984-3992. [83] LIU G Z, CHENG L, CHEN G N, et al. Pebax-based membrane filled with two-dimensional mxene nanosheets for efficient CO2 capture [J]. Chemistry, an Asian Journal, 2020, 15(15): 2364-2370. doi: 10.1002/asia.201901433 -

下载:

下载: