-

废线路板中包含60多种元素[1],由30%左右的金属物质和70%左右的非金属物质组成[2],其中金属物质中既含有回收价值很高的铜、锡、金、银、钯等,也含有铅、镉、砷等对环境可能产生严重危害的有害金属[3 − 7],其会随着废线路板的利用过程释放出来,从而对生态环境和人体健康造成严重影响. 目前,废线路板利用工艺主要有机械物理、湿法冶金、火法冶炼、热解处理、生物浸出、超临界流体氧化法等[8 − 12],在我国实际应用最普遍的仍是机械物理法[13 − 14],包括干法和湿法两种工艺路线. 其中湿法分选工艺使用水作为分选介质,利用过程会产生大量含重金属和有机物的废水,同时,产生的含水非金属富集体较难利用处置. 江苏省已明令禁止使用该工艺对废线路板实施利用[15];而在干法分选工艺过程中,需将废线路板破碎至0.6 mm以下,可实现金属与非金属的完全分离,为后续分选工艺奠定基础[16]. 在破碎和分选过程中,大量附着有重金属和有机污染物的粉尘得以释放,在不同粒径颗粒物中呈现不同的分布特征[17],并伴随着污染物的迁移对生态环境产生影响. 因此粉尘污染控制是干法分选工艺的重点,也是其难点.

废线路板主要包括废弃电器电子产品拆解产生的含电子元器件的废电路板,以及印刷线路板制造产生的报废板和边角料[18]. 在以往的研究中,大多学者以含电子元器件的废电路板为研究对象,分析其拆解、利用过程中存在的风险[19 − 20]. 然而本课题组发现,由于印刷线路板复杂的生产流程及生产中大量含重金属原辅材料的使用,生产过程产生的废线路板和边角料中重金属元素也很复杂,并会随废线路板的利用而释放,从而对生态环境和人体健康产生影响;同时,采用机械物理法利用报废印刷线路板得到的分选产物,较利用脱除元器件的废电路板金属纯度相对较高,后续循环利用价值更高. 本研究以采用干法机械分选工艺、主要利用报废印刷线路板的企业为研究对象,研究废线路板利用过程重金属在灰尘和悬浮颗粒物中的富集特征和污染水平,通过相关性分析和主成分分析等揭示重金属的迁移规律,为精准防控利用过程中重金属污染,保障人民生命健康和生态环境安全提供依据.

-

本研究采样点位于安徽省一家以印刷线路板生产过程中产生的不合格印刷线路板为主要原料的废线路板利用企业. 该企业通过撕碎和二级破碎,将废线路板破碎至0.1 mm左右粒径颗粒,后采用组合干法机械物理分选工艺对废线路板实施利用(图1),得到金属与非金属富集体产物.

采样点位及样品数量见表1所示. 研究采集车间内外不同区域设施设备上积累的灰尘样品,使用刷子轻轻将其刷下并用锡纸包裹起来,置于密封袋中低温保存. 使用100 L·min−1的大流量空气采样器配套石英滤膜,采集车间内外空气中的总悬浮颗粒物(TSP)样品,在各采样点均为连续3 d每天24 h采样,车间外采样点位于车间下风向处,距离车间约8 m的厂界内. 按《土壤环境监测技术规范》(HJ/T 166—2004),沿利用生产线布置方向,在车间外距离车间不同位置处,采集表层土壤样品.

-

准确称取0.1 g固体样品置于干净的聚四氟乙烯消解管,依次加入9 mL硝酸(65%)、3 mL盐酸(38%)、3 mL氢氟酸(40%)以及0.5 mL双氧水,小心摇动消解管释放出刚产生的气体,常温放置12 h后,使用微波消解提取固体样品中的重金属. 微波消解仪(Ethos Up)功率1600 W,升温程序为:从室温起10 min内升至120 ℃,保温5 min;接着以4 ℃·min−1的速度升至160 ℃,保温5 min;最后以2 ℃·min−1升至180 ℃,保温25 min. 消解完毕后,将消解液倒入聚四氟乙烯烧杯中,置于电热板上,以200 ℃赶酸至近干,待冷却后过滤,用2%硝酸定容至40 mL待测. 本研究使用电感耦合等离子体质谱(ICP-MS, Thermo fisher scientific ICAP-RQ)分析样品中Cu、Sn、Pb、Ni、Zn、Cd、Cr、As、V、Mn等浓度.

-

富集因子(enrichment factor,EF)法常用来评价车间内不同功能区域重金属污染水平,同时也可以区分样品中重金属的来源,是人为因素还是自然源. 重金属富集因子的计算方法如下[21 − 23]:

式中,EF为富集因子,Cn为样品中n种重金属元素的实测浓度,mg·kg−1; Cref为样品中参考元素的实测浓度,mg·kg−1; Bn为n种重金属的背景值,mg·kg−1;Bref为参考元素的背景值,mg·kg−1. 本研究选取Mn作为参考元素[20],使用“中国土壤元素背景值”中数据作为背景值计算[24 − 25].

-

除富集因子外,地累积指数(Geo-accumulation index, Igeo)也可以表示样品中重金属的富集特征,同时也可以反映出人为活动对环境的影响[26]. 具体计算公式如下:

其中,Igeo为地累积指数,Csample为样品中重金属元素的实测浓度,单位为mg·kg−1; Cbackground为重金属元素的背景浓度,单位为mg·kg−1. 地累积指数对应的级别和指示的环境质量情况见表2.

-

潜在生态危害指数法(comprehensive potential ecological risk index,RI)是评价土壤重金属污染常用的方法,也常用于评价灰尘中重金属对生态环境的潜在危害[27 − 28]. 计算公式如下:

式中,

$ {C}_{\mathrm{r}}^{i} $ 为重金属i的污染系数;$ {C}_{\mathrm{实}\mathrm{测}}^{i} $ 为重金属i的实测浓度,mg·kg−1;$ {C}_{\mathrm{n}}^{i} $ 为重金属i的背景浓度,mg·kg−1;$ {E}_{j}^{i} $ 为重金属i的潜在生态危害指数;$ {T}_{\mathrm{r}}^{i} $ 为重金属i的毒性系数[29],Cd、As、Pb、Cu、Ni、Cr、Zn、Mn的毒性系数分别为30、10、5、5、5、2、2、1[30];RI为多种重金属综合潜在生态危害指数. 重金属潜在生态风险评价标准[31]见表3. -

使用Origin pro2021b(Academic) 和Microsoft Excel进行数据分析和图表绘制,使用Windows SPSS(版本17.0,SPSS Inc., Chicago, USA)进行Pearson相关性分析和主成分分析.

-

车间内外灰尘和TSP,以及车间周边土壤中重金属浓度见表4. 可见车间内灰尘中重金属平均浓度从大到小依次为Cu>Mn>Zn>Ni>Pb>Sn>Cr>V>As>Cd,而TSP中重金属平均浓度从大到小依次为Cu>Sn>Pb>Zn>Mn>Cr>Ni>As>V>Cd,虽然排序有所不同,但均表现为Cu浓度最高、Cd浓度最低. TSP中Sn、Pb、As、Cd浓度显著大于灰尘中,表明其更倾向于黏附在粒径较小的颗粒上. 对比车间内外灰尘中浓度可以发现,除Cu、Mn和Ni外,其余重金属在车间外窗台灰尘中浓度均高于车间内灰尘,而车间外下风向处TSP中,除Cu、Sn和Pb外,其余重金属浓度也均高于车间内TSP. 企业厂界内车间周边土壤重金属平均浓度从大到小依次为Mn>Cu>V>Cr>Zn>As>Sn>Ni>Pb>Cd.

-

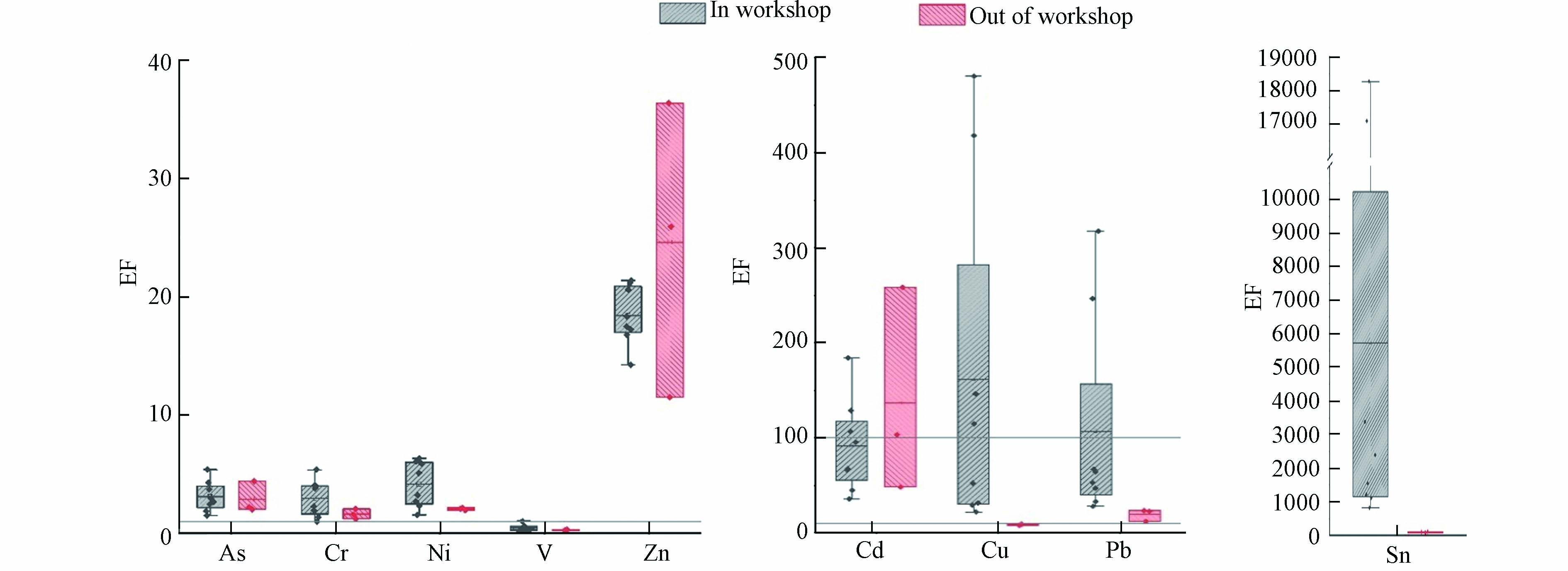

在废线路板的破碎和分选过程中,部分细颗粒物料逸散出来,在车间内以悬浮颗粒存在,同时由于“过粉碎”现象其中不乏可被人体吸入的PM10、PM2.5,甚至粒径更小的PM1[32],其中PM10占TSP、PM2.5占PM10均为70%左右[33]. 计算车间内灰尘和TSP中重金属的富集因子(图2)可见,灰尘中重金属EF值依次为Sn>Cu>Pb>Zn>Cd>Cr>As>Ni>V,TSP中重金属EF值排序依次为Sn>Cu>Pb>Cd>Zn>Ni>As>Cr>V,虽两者排序有所不同,但Sn、Cu、Pb、Cd、Zn均表现出较高的富集程度,且EF值基本均大于10,表明其受人为活动影响较明显;其中Sn、Cu以及Pb在TSP中的EF值大于100,表明其富集主要来源于人为因素. 结合废线路板的元素组成特征[34],可以推定其来源于废线路板的破碎分选过程. 同时发现Sn、Cd和Pb在TSP中的富集程度远高于灰尘中,其在TSP中的平均EF值分别是其在灰尘中的12.99、9.35、2.59倍.

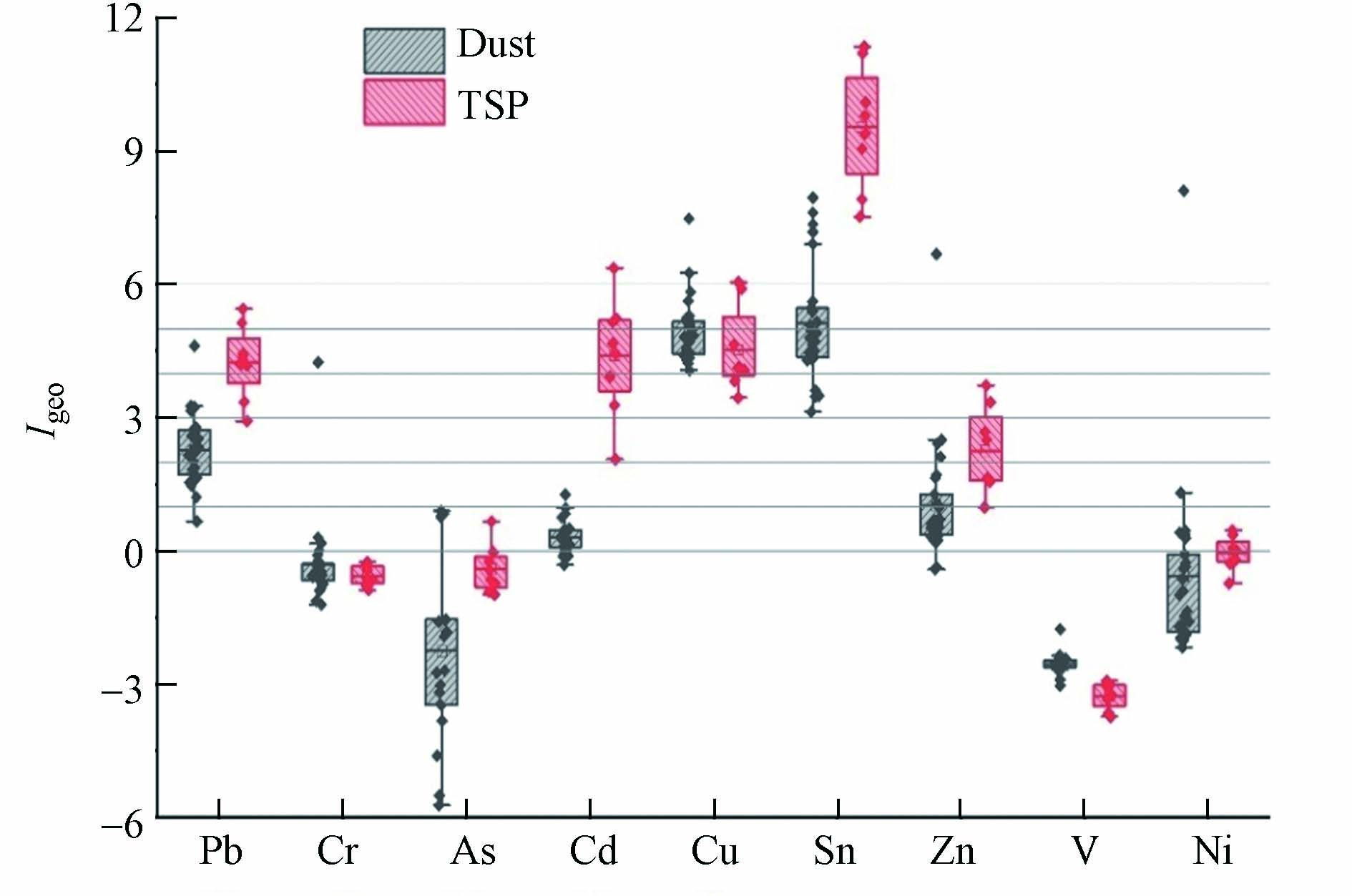

计算并对比车间内灰尘和TSP中重金属Igeo值(图3)发现,Cr、As、V、Ni在灰尘和TSP中的Igeo值均小于1,证明其未表现出明显富集;而Sn、Cu、Pb、Cd、Zn的Igeo值均大于0,表现出不同程度的富集,这与富集因子计算得到的结论一致.

灰尘中重金属Igeo值在−2.55—5.11之间,其中表现出富集的几种重金属Igeo值从大到小依次为Sn(5.11)>Cu(4.99)>Pb(2.26)>Zn(1.02)>Cd(0.29). 其中Sn的Igeo等级为6级,显示极重度富集,指示极重度污染状态;Cu的Igeo等级为5级,显示重度至极重度富集程度,指示重度至极重度污染状态;Pb的Igeo等级为3级,显示中度至重度富集程度,指示中度至重度污染状态;而Zn和Cd的Igeo等级分别为2级和1级,分别表现为中度富集和轻微富集状态.

TSP中重金属Igeo值在−3.28—9.54之间,表现出富集状态的重金属元素Igeo值从大到小依次为Sn(9.54)>Cu(4.52)>Cd(4.39)>Pb(4.24)>Zn(2.25),与富集因子法计算得出的重金属在TSP中排序完全一致. 各重金属元素的地累积指数等级在3—6级之间,其中Sn的Igeo等级为6级,显示极重度富集;Cu、Cd和Pb的Igeo等级均为5级,显示重度至极重度富集; Zn的Igeo等级均为3级,表现出中度至重度富集状态. Sn、Pb、Cd、Zn在TSP中的Igeo值显著大于其在灰尘中的Igeo值,其中Cd在TSP中的Igeo值高于其在灰尘中Igeo值4个等级;而Cu在灰尘中的Igeo值大于TSP.

-

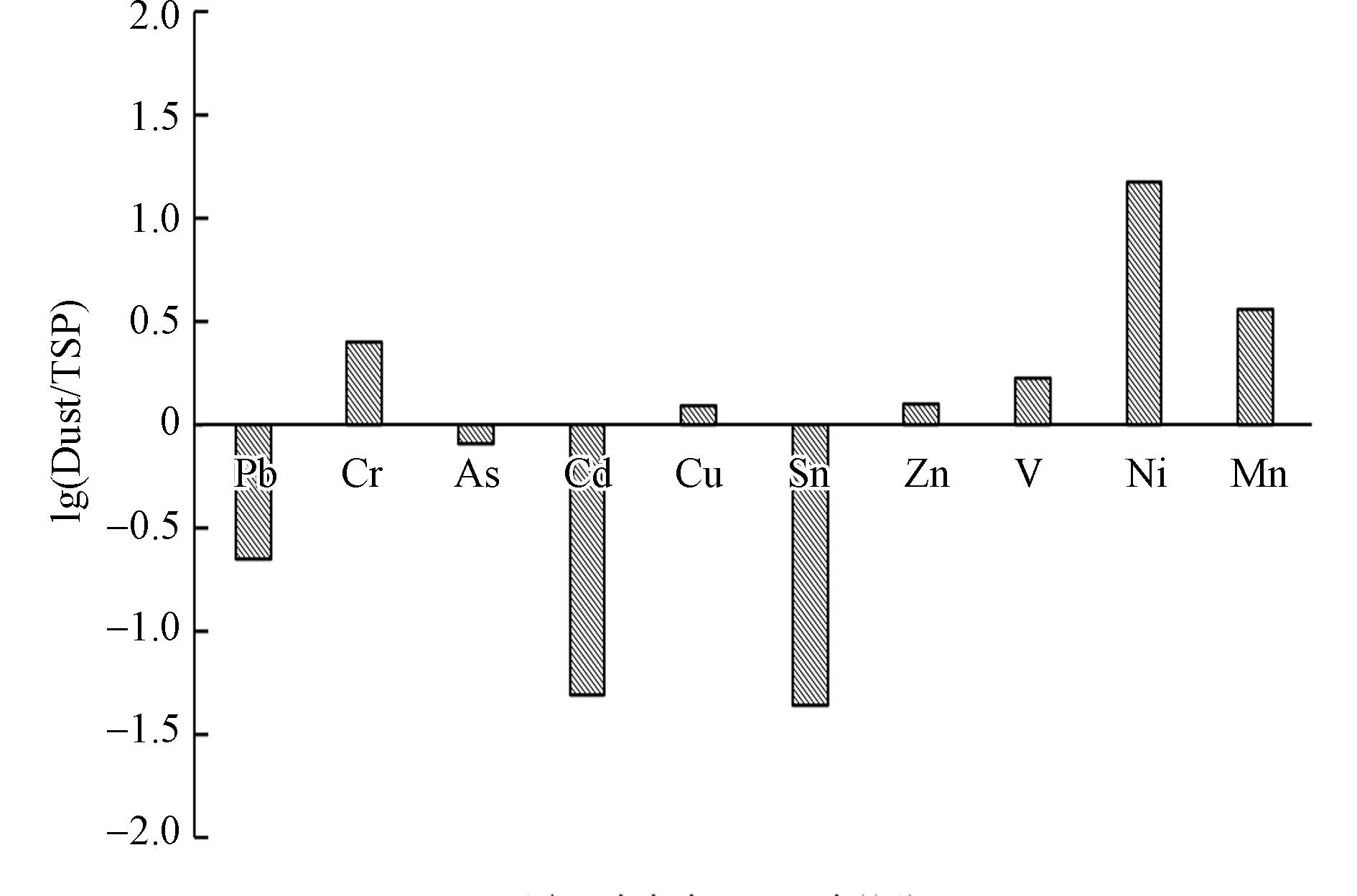

使用两相中浓度比的对数可以表征重金属在车间环境中的分配行为,从而解析利用过程重金属的分配和释放规律[35],计算log(灰尘/TSP)如图4所示. 整个车间范围内,以重金属的平均浓度来看,Sn、Cd、Pb的log(灰尘/TSP)值明显小于0,说明其主要分布于TSP中,其中Pb和Sn主要来源于线路板表面喷锡工序,以焊锡合金存在于废线路板中[36],当废线路板被破碎至0.1 mm左右,部分细颗粒物料的逸散在车间内形成悬浮颗粒,其中粒径大于10 μm的颗粒在自身重力作用以及外界扰动下发生沉降,从而在设施设备表面积累成灰尘,导致部分Pb和Sn随较大颗粒沉降进入灰尘. 而Cd在废线路板中以小颗粒存在,破碎的局部高温使其变为蒸汽形态,从而在颗粒物上附着进入车间环境[33 − 34]. 而Ni、Mn、Cr、V则更多分布于颗粒相对较大的灰尘中,As、Cu和Zn在两相中分布差别不明显.

-

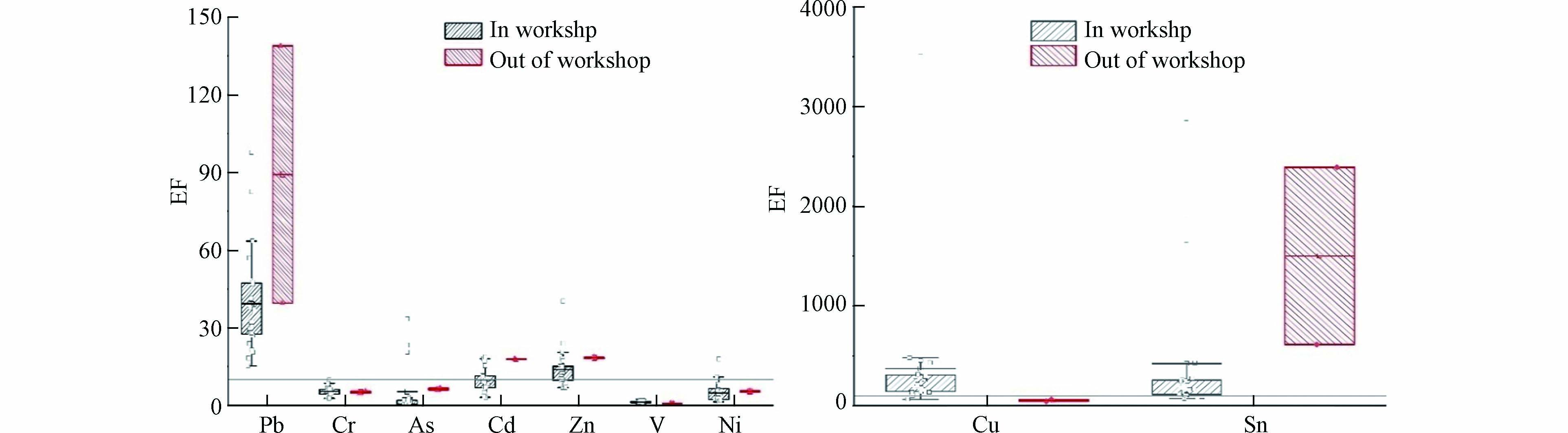

车间内外灰尘中重金属的富集因子对比如图5所示. 除V(0.74)外,车间外灰尘中重金属的EF值均大于1,说明这些重金属在车间外灰尘中有不同程度的富集,且车间外灰尘中的重金属主要来源于人为活动. 但与车间内灰尘相比,车间外灰尘中除Cu(51.84)、Cr(5.15)、V(0.74)外,其他重金属元素的富集因子均较大,说明重金属在粒径较小的粉尘中趋于富集,这与以往报道中粒径较小的颗粒具有较大的比表面积和金属吸附能力相一致[37]. 车间外窗台灰尘中Cu的EF值远低于车间灰尘中Cu的EF值,一是由于铜的韧性使其更易于存在于粒径较大的灰尘颗粒中[37],二是由于一些物料的洒落和逸散至室内灰尘中[35].

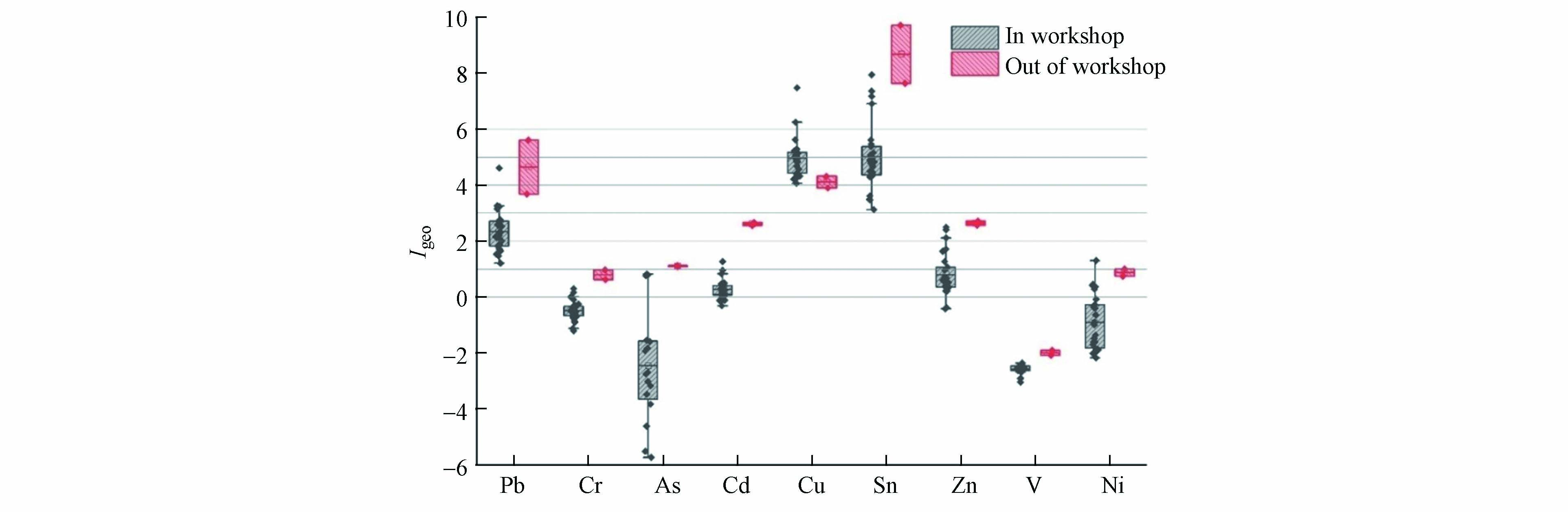

对比车间内外灰尘重金属的Igeo值,如图6示,可以看出车间外灰尘中除Cu外,其余所有重金属元素的Igeo值均高于车间内,这与富集因子表现一致. 车间外灰尘中Sn的Igeo等级为6级,Pb和Cu的Igeo等级均为5级,Pb、As、Cd、Zn的Igeo等级均高出其在车间内两个等级;Cu在车间内外灰尘中Igeo值的差异不如其EF值差异明显,虽然其在车间外灰尘中Igeo值较车间内低,但Igeo 等级均处于5级; Sn在车间内外灰尘中的Igeo等级虽相同,但其在车间外灰尘中的Igeo值显著高于车间内;Cr、As、Ni在车间内灰尘中均无明显富集,但在车间外灰尘中表现为轻微富集至中度富集状态. 可见灰尘中Sn、Pb、As、Cd、Zn在粒径较小的粉尘中趋于富集,同时可能受到外部环境的影响,这与EF的结果相似.

-

对比车间内外TSP中重金属富集因子(图7)发现,除Cd和Zn外,车间外TSP中重金属EF值均小于车间内. 特别是Sn、Cu和Pb,其在车间外TSP中EF值均急剧下降,而这3个元素是废线路板利用的典型重金属污染物,在废线路板原料、灰尘及TSP中均有较高的含量分布. Sn和Pb在车间外灰尘中的EF值明显升高,这是由于灰尘采集于车间外窗台,Sn和Pb附着在粒径较小的灰尘逸散至车间外,并在迁移过程中逐渐发生沉降进入灰尘,表现出较车间内更为明显的富集. 而车间外TSP采样点位于大气下风向处8 m左右的企业厂界内,结合TSP中重金属的富集情况可以推断,废线路板利用过程Sn、Cu和Pb等重金属污染物的释放对车间外区域的影响范围非常有限. 同时可以看出,Cd在TSP中富集程度有所升高,这是由于破碎的局部高温使其变为蒸汽形态,与细小颗粒物形成气溶胶在车间内悬浮. 这与之前研究证实Cd是最易存在于PM10中的重金属[35]是一致的. 因此也表明,其更易吸附在微小颗粒上而随之迁移到更远的地方,影响范围较大.

车间外TSP的Igeo从大到小依次为:Cd(6.24)> Sn(6.02)> Zn(3.95)> Pb(3.70)> Cu(2.60)> As(0.92)> Ni(0.53)> Cr(0.15)> V(−2.44),顺序与车间外颗粒物种重金属EF值排序完全一致. 除V外所有重金属元素的Igeo值均大于0,说明其不同程度的富集对环境均存在一定影响,而V在车间外TSP中无明显富集. 其中Cd、Sn的Igeo指数大于5,且明显高于其他重金属,表现为极重度污染;Zn和Pb的Igeo指数在3—4之间,表现为重度污染;Cu的地累积指数等级为3级,表现为中度至重度污染;As、Ni、Cr的Igeo值在0—1之间,表现为轻微污染.

对比车间内外空气TSP的重金属地累积指数如图8所示,可见车间内外重金属Igeo值排序不同.

车间内Sn和Cu是最主要的污染元素,而在车间外TSP中Cd的富集程度最高,是最主要的污染因子. Pb、Cu、Sn在车间外颗粒物中Igeo值较车间内有所降低,和富集因子表现出的变化特征一致;而Cd、Zn、As、Cr、V和Ni在车间外TSP中Igeo值较车间内升高,这与富集因子有所不同. 这是由于地累积指数法把环境对重金属的敏感性也一并作为考虑因素,Cd、Cr、As和Ni等对环境的敏感程度总体较高,也是其与富集因子的变化特征有所区别的原因之一. 另外,可以发现Pb和Sn在车间外TSP中的Igeo值低于车间内,这与灰尘中Pb和Sn表现出恰好相反的变化特点,说明Pb和Sn随着TSP的迁移其对环境的污染程度有所降低.

-

对车间内灰尘、车间内外TSP和车间周边土壤中不同重金属元素之间的相关性进行Pearson相关性分析(表5). 可以看出Zn、Mn、Ni、Cr、V相互之间,Sn和As之间均呈显著正相关关系,表明其来源相同;同时,Sn和Zn、Mn、Ni、Pb、Cr也表现出较好的相关性,说明存在着相同的污染来源;但Cu和Cd与其他重金属元素之间相关性较差. 这也说明灰尘中重金属元素含量和分布受到影响较多,来源相对复杂,还可能受到车间内机械设备、物料运输等其他污染源释放的影响. 表6可以看出,TSP中Cu与Sn和Pb在0.05级别上显著型相关,相关系数分别为0.987和0.989,同时大多数重金属元素之间都呈现出较好的相关性,表明他们有着共同的污染来源,主要来源于废线路板利用过程重金属的释放. 虽然Cu主要以单质形态富集于粒径较大的灰尘中,但由于受到破碎过程机械作用,部分Cu与Sn发生了合金化反应[32],这也印证了Cu在灰尘和TSP中富集特征显示出的结果. 表7可看出土壤中Cu与Sn和Pb,Cr和V、As,V和Pb,Sn和Pb均呈现出显著正相关,可以推断其来源于同一污染源. Pb和Sn在3种环境介质中均呈现出较好的相关性,考虑是由于线路板生产过程表面处理时仍使用含铅喷锡,在废线路板利用过程中得以释放进入环境介质中.

-

本研究使用主成分分析(PCA)法对车间内灰尘、TSP以及土壤中重金属污染进行来源分析[38 − 42]. 表8和表9分别给出了车间内灰尘和TSP、土壤的PCA因子载荷系数,各提取了2—3个成分.

室内灰尘中,2个主成分分别占方差的60.506%和19.31%,共占总方差的79.816%. 其中Zn、V、Mn、Ni和Cr具有较高的成分1荷载,成分2中Cu和As的载荷较高. 结合重金属相关性分析结果,其来自于同一污染源,结合EF值分析,V、Mn、Ni、Cr均主要来自于自然源,推断成分1为自然源;而Cu和As在破碎区灰尘中浓度较高,且Cu和As主要分布于细颗粒上[17],推断成分2为废线路板破碎工艺.

TSP中,3个主成分分别占方差的63.52%、19%和10.65%,共计占总方差的93.17%. Mn、Zn、V、Ni、Cr、As和Cd均具有较高的成分1荷载,成分2中Pb和Sn的载荷较高. 而Ni和V具有较高的成分3载荷值. 结合重金属在室内外TSP的富集特征,推断成分1为自然源. 由重金属相关性分析可知,Pb和Sn显著相关,来自同样的污染源,结合不同区域TSP中重金属浓度分布发现Pb和Sn的浓度在破碎分选区显著高于车间内其他工艺区域,因此推断成分2为废线路板的破碎分选工艺源. 而成分3中Ni、V和Cr相对来说荷载较高,结合Igeo数据分析,成分3为在风力、人为带动及其他带动下飞扬而进入大气的地面扬尘.

土壤中重金属3个主成分分别占方差的47.21%、24.06%和11.47%,累计占总方差的82.74%. Cu、Pb、Sn均具有较高的成分1荷载,成分2中Cr和As的载荷较高,而As具有较高的成分3载荷值,Ni具有较高成分3的负载荷. 结合土壤中重金属相关性分析,Cu、Sn和Pb有高度同源性,结合TSP中重金属分布特征,发现成分1是室内TSP迁移至车间外较大颗粒发生的沉降;而相关性分析表明Cr和As显著相关,结合EF值分析发现,Cr和As的富集因子在1—10之间,而As在破碎区EF值最高,说明土壤中Cr和As的富集轻微受到人为活动的影响,但以自然来源为主,推断成分2为自然源;Ni主要来自自然源[42],而As主要来源于焚烧过程,结合相关性分析,Ni和As不同源,推断成分3为焚烧过程[43].

-

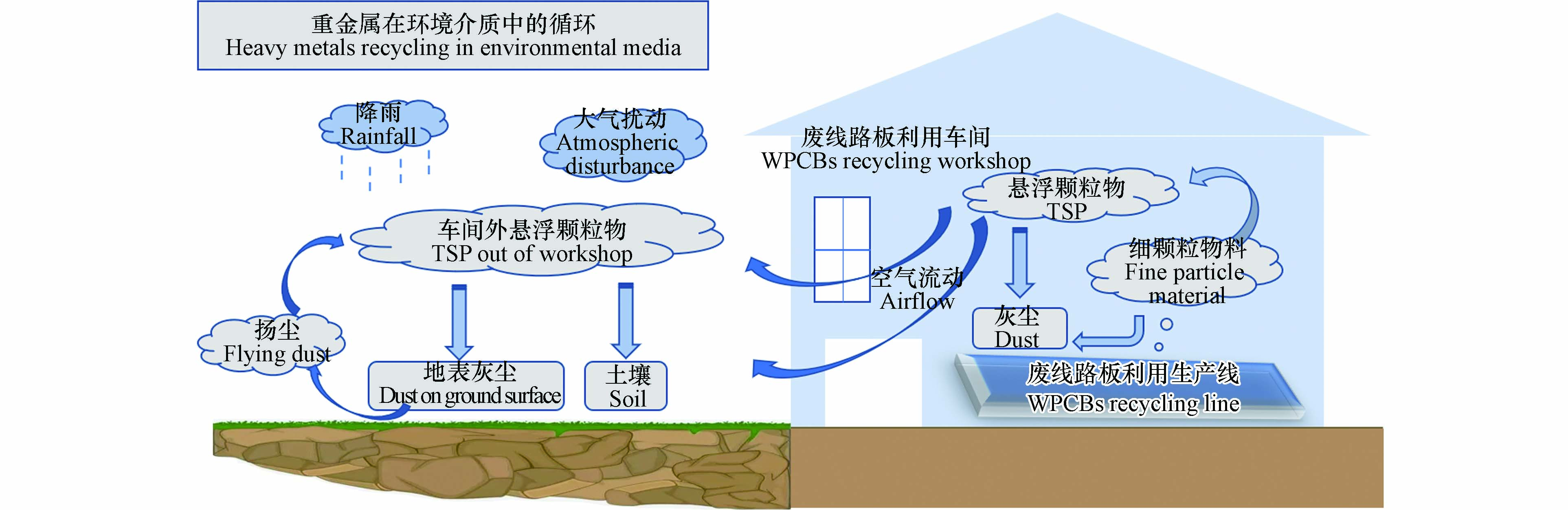

基于对重金属分布和富集特征、相关性分析以及主成分分析结果,考虑废线路板利用过程主要重金属的总体迁移规律如图9所示. 废线路板在破碎分选过程中产生大量附着有Cu、Sn、Pb、Cd等重金属、粒径小于100 μm的细颗粒物料,细颗粒物料逸散出来在车间内形成悬浮颗粒,其中粒径大于10 μm的细颗粒物在自身重力作用以及外界扰动下在车间内发生沉降,从而在设施设备表面积累成为灰尘;而粒径小于10 μm的细颗粒物以悬浮态存在,并在空气流动、物料运输、人员进出等外界扰动的作用下向车间外迁移. 迁移过程中发生黏附、聚集,并在降水、大气流动和扰动等作用下,部分相对粒径较大的颗粒沉降于地表灰尘或土壤中,一部分以气溶胶态或是细颗粒悬浮于厂区周边空气中,并随大气扰动继续发生迁移. 同时,在车间内机械振动[33]、物料运输、人员走动等作用下,积累在地面、设施设备表面的灰尘部分会再次进入悬浮颗粒物中;而在车间外,由于空气流动、交通运输和其他带动的作用下,地表灰尘和土壤也会形成扬尘,再次进入大气中.

具体来看,经破碎后Cu大多以单质沉降并富集于相对粒径较大的灰尘中,但也有部分在破碎过程与Sn发生机械合金化反应,以Cu-Sn合金在车间内悬浮颗粒物中存在,并迁移至车间外,在外界作用下沉降于地表灰尘或土壤中;Pb、Sn以焊锡合金形式存在于废线路板中,主要通过吸附在悬浮颗粒物上发生迁移,并在外界作用下随较大粒径颗粒物沉降并富集于灰尘中;而Cd在废线路板中以小颗粒存在,破碎的局部高温使其变为蒸汽形态,附着在细颗粒物上迁移至车间外,在外界环境的作用下,与其他污染物质和细颗粒物形成气溶胶,并受到交通运输等影响[44],在悬浮颗粒物中进一步富集.

-

评估废线路板利用车间内灰尘、TSP以及车间周边土壤中重金属潜在生态风险(表10),可见车间内灰尘平均RI值为385.95,表明存在强生态风险,最大RI值达1444.18,表明车间内部分灰尘有很强的生态风险,最小值为233.97,表现出中等生态风险,RI值的变化范围较大. Cu是灰尘中生态风险最大的元素,在灰尘中表现为强至极强生态风险,其对RI的贡献率达71.84%,明显高于其他重金属元素,且在部分点位Ej值达1334.75,存在极强的生态风险,最低的Ej值也在80—160之间,表现强生态风险;而Cd由于其毒性系数较高,对生态影响较大,其对灰尘重金属RI值的贡献率位列第二,达14.44%,总体来说,Cd存在中等生态风险,在部分点位Ej值高达108.28,表现出强生态风险;灰尘中的Pb也表现出对生态的轻微风险至中等风险,部分点位Pb的Ej值达71.91,对生态有中等风险. 因此,在定期对车间内设施设备上积累的灰尘进行清理时,应考虑灰尘中重金属污染物给生态环境带来的潜在风险,收集后妥善处置,不可将其直接倾倒在土壤或环境中.

相较于灰尘,车间内TSP生态风险明显较大,其RI均值为1705.67,存在很强的生态风险,最小值为390.94,表明车间内TSP至少存在强生态风险. Cd、Cu和Pb是对生态产生影响最大的元素,这与灰尘的表现一致,其对RI的总贡献率达98.2%. 但与灰尘不同的是, TSP中Cd的生态风险显著高于其他元素,处于极强风险等级,其对RI的贡献率达76.17%;Cu和Pb均处于很强风险等级. 可见,在废线路板利用车间内以Cd、Cu、Pb为主的重金属元素会对生态环境产生明显影响. 因此保持利用车间相对密闭和微负压状态,并对车间内环境空气集中收集后采用布袋除尘器处理,可有效控制车间内TSP向外迁移,大大减小对车间外生态环境的影响. 与此同时, TSP中的PM10、PM2.5,甚至PM1对车间内员工健康会产生一定影响,因此要求员工做好劳动防护也非常重要.

土壤中重金属RI均值为79.09,最高为131.12,最低为60.41,存在轻微生态风险,但总体风险较小;Cd和As的Ej值相对高于其他重金属元素,除一个点位处于中等生态风险外,其余均呈现轻微生态风险,Cd和As对RI的总贡献率大于80%,与灰尘和TSP中主要对生态产生风险的元素不同,结合PCA分析,发现土壤中Cd和As的生态风险并非主要受到废线路板利用的影响.

-

(1)废线路板利用车间内的灰尘和TSP中,Cu的浓度最高,Cd的浓度最低;Sn、Cu、Pb、Cd、Zn均表现出不同程度的富集,Sn、Pb、Cd、Zn在TSP中的地累积指数均显著大于灰尘,Sn、Cd、Pb主要分布于悬浮颗粒物中.

(2)Cu在车间内灰尘中的富集程度显著高于车间外,而其余所有金属则表现相反的富集特点;而在TSP中,Sn、Cu和Pb在车间外富集程度和污染水平明显较车间内低,但Cd的污染水平明显升高,可见Sn、Cu和Pb随颗粒物的释放对车间外区域的影响范围非常有限,Cd更易以蒸汽态吸附在微小颗粒上迁移至更远的地方,影响范围较大.

(3)废线路板重金属的迁移规律总为:废线路板破碎过程逸散出来的小颗粒物料在车间内形成悬浮颗粒,其中粒径较大的在车间内发生沉降,积累形成灰尘;粒径较小的以悬浮态存在,并在空气流动、物料运输、人员进出等外界扰动的作用下向车间外迁移,最终部分沉降于地表灰尘或土壤中,部分以细颗粒状态悬浮于车间周边环境空气中,并随大气扰动继续发生迁移,部分灰尘也会在外界扰动下再次进入大气. Cu大多以单质沉降并富集于相对粒径较大的灰尘中,部分以Cu-Sn合金在车间内悬浮颗粒物中存在,并迁移至车间外;Pb、Sn以焊锡合金存在,吸附在悬浮颗粒物上发生迁移;Cd则以蒸汽态附着在细颗粒物上迁移至车间外,并在交通等因素影响下,在细颗粒中进一步富集.

(4)车间内灰尘和TSP的潜在生态风险均主要来自Cu、Cd、Pb,与灰尘相比,TSP的潜在生态风险明显更高,处于很强生态风险等级,土壤的潜在生态风险较轻微.

废线路板利用过程重金属污染特征、迁移及风险评估

Pollution and migration characteristics and potential ecological risk assessment of heavy metals in waste circuit boards recycling process

-

摘要: 电子工业的发展和电器电子产品更新换代的加速使得废线路板产生量逐年增加. 废线路板虽然资源回收价值高,但伴随其利用,重金属等污染物的释放会对生态环境和人体健康造成严重危害. 因此,研究废线路板利用过程重金属的污染特征和迁移规律可为精准防控利用过程的重金属污染,保障人民群众健康和生态环境安全提供依据. 本研究以采用机械分选工艺利用报废印刷线路板的企业为研究对象,通过采集车间内外不同环境介质样品,运用富集因子法和地累积指数法评价了废线路板利用过程重金属的富集和污染特征,并结合Pearson相关性分析、主成分分析等统计分析方法,阐明利用过程重金属的迁移规律,使用潜在生态风险指数法(RI)分析了潜在生态风险. 结果表明,废线路板利用车间内灰尘和总悬浮颗粒物(TSP)中Cu浓度最高,Cd浓度最低; Sn、Cu、Pb、Cd、Zn在灰尘和TSP中表现出不同程度的富集;Sn、Cd、Pb在车间内主要分布于TSP中,但在车间外的富集程度和污染水平明显降低,表明其对车间外区域的影响范围有限. Cu、Pb、Sn、Cd等元素性质和在颗粒中的存在形态不同,其迁移特征也有所差异,但废线路板利用过程重金属的迁移规律总体可以总结为:破碎的小颗粒物料—车间内TSP—车间内灰尘/车间外—地表灰尘或土壤—扬尘—TSP. 车间内灰尘和TSP的RI值分别为386、1706, Cu、Cd、Pb均是贡献最高的因子. 因此,妥善处置定期清理的灰尘,保持车间相对密闭和微负压状态,并对收集的废气进行处理可有效控制废线路板利用过程重金属污染.Abstract: The annual generation of waste printed circuit boards (WPCBs) has increased over the last decade due to the rapid development of the electronic information industry and the acceleration of the replacement of electrical and electronic products. While waste printed circuit boards (WPCBs) have high recycling values, their recycling can also pose a threat to ecological safety and human health due to the presence of harmful heavy metals such as Pb, Cd, and As. Therefore, researching the pollution and migration characteristics of heavy metals in the recycling process of WPCBs can provide a foundation for precise pollution prevention and control measures for protecting both human health and environmental safety. In this study, a WPCB recycling enterprise, which mainly uses defective WPCBs, with mechanical separation was taken for the research object, environmental media samples of dust, total suspended particulates (TSP) and soil were collected. The enrichment factor and geo-accumulation index were used to evaluate the enrichment and pollution characteristics of heavy metals, and statistical analysis methods such as Pearson correlation analysis, and principal component analysis were used to expound and reveal the migration regularity in the recycling process. Additionally, a comprehensive potential ecological risk index (RI) was used to estimate the potential ecological risk of heavy metals. It showed that the concentration of Cu was the highest and Cd was the lowest in dust and TSP in the workshop. Sn, Cu, Pb, Cd and Zn showed varying enrichment in both dust and TSP. When compared with distribution mainly in dust, Sn, Cd, and Pb were predominantly distributed in TSP. While, the impact on the environment outside the workshop of Sn, Cu and Pb in TSP was demonstrated rarely limited. Due to different properties and morphology in particles, Cu, Pb, Sn and Cd expressed different migration characteristics. In general, the migration characteristics of heavy metals in WPCBs recycling were presented as follows: crushed WPCBs with small particle size-TSP in the workshop-dust in the workshop and TSP outside the workshop-surface dust or soil-flying dust-TSP. The RIs of dust and TSP in the workshop were 386 and 1706, respectively, among which Cu, Cd and Pb contributed more. Therefore, several measures for managing and controlling pollution caused by heavy metals were proposed for recycling enterprises. These measures include the proper disposal of cleaned dust within the workshop, utilizing a closed and slightly negative pressure workshop, and installing a set of gas collection and treatment facilities.

-

-

表 1 采样点位及样品数量

Table 1. Sampling sites and samples quantity

样品类型

Sample types采样点位数

Numbers of Sampling sites采样点位布置/点位数

Sampling location /Numbers of sampling sites样品数量

Samples quantity灰尘 7 车间内不同区域/5

车间外窗台/226 TSP 4 车间内不同区域/3

车间外下风向/112 土壤 15 车间外1 m / 7

车间外6 m/ 6

车间外8 m临街厂界/ 215 表 2 地累积指数类型及其指示的环境污染状况

Table 2. Igeo classes and their pollution status with respect to dust quality

地累积指数

Igeo地累积指数等级

Class of Igeo污染程度

Pollution level≤0 0 无污染 0—1 1 轻微污染 1—2 2 中度污染 2—3 3 中度至重度污染 3—4 4 重度污染 4—5 5 重度至极重度污染 >5 6 极重度污染 表 3 重金属潜在生态风险评价标准表

Table 3. Potential ecological risk assessment criteria of heavy metals

$ {E}_{j}^{i} $ RI 生态风险程度

Ecological risk level<40 <150 轻微 40—80 150—300 中等 80—160 300—600 强 160—320 ≥600 很强 ≥320 极强 表 4 灰尘、TSP和土壤中重金属浓度(mg·kg−1)

Table 4. Concentrations of heavy metals in dust,TSP and soil in and out of the workshop(mg·kg−1)

区域

Zones介质

Media重金属浓度/(mg·kg−1)

Concentration of heavy metalsPb Cr As Cd Cu Sn Zn V Mn Ni 车间内 灰尘 平均值 222.19 130.93 8.95 0.18 12724.01 212.48 656.31 21.31 740.60 454.36 标准方差 169.77 327.19 11.96 0.05 10662.82 247.17 2203.47 3.75 3113.40 2177.55 TSP 平均值 848.17 62.01 13.49 4.20 9608.93 4169.83 645.63 12.98 273.47 40.17 标准方差 471.76 10.13 5.91 3.57 7350.89 3593.92 445.64 2.51 173.75 10.00 车间外 灰尘 平均值 1201.65 159.87 36.08 0.89 5896.47 2026.37 693.93 31.03 295.53 74.24 标准方差 991.94 26.89 0.87 0.04 1210.31 1767.56 51.17 2.64 16.45 9.39 TSP 平均值 544.58 111.00 32.43 12.79 2150.16 266.86 2074.88 23.49 629.62 59.63 标准方差 260.69 60.10 7.48 7.27 733.34 107.89 1572.19 6.33 194.34 16.20 车间外 车间周边土壤 平均值 21.72 67.11 36.26 0.11 111.84 30.15 57.62 100.81 271.95 22.21 标准方差 9.59 2.68 4.72 0.03 186.58 44.17 10.09 7.06 63.89 1.76 表 5 灰尘中重金属Pearson相关系数

Table 5. Pearson correlation coefficient of heavy metals in dust in workshop

Cu Sn Zn V Mn Ni Pb Cr As Cd Cu 1 Sn 0.295 1 Zn 0.118 0.447* 1 V −0.183 0.275 0.835** 1 Mn 0.12 0.455* 0.998** 0.828** 1 Ni 0.124 0.458* 0.998** 0.825** 1.000** 1 Pb −0.128 0.466* −0.187 −0.003 −0.185 −0.19 1 Cr 0.109 0.452* 0.997** 0.833** 0.999** 0.999** −0.165 1 As 0.458 0.957** 0.463 0.048 0.473 0.48 −0.399 0.458 1 Cd −0.145 0.128 0.24 0.19 0.241 0.24 0.068 0.245 0.398 1 * P<0.05, ** P<0.01. 表 6 TSP中重金属Pearson相关系数

Table 6. Pearson correlation coefficient of heavy metals in TSP in and outside workshop

Cu Sn Zn V Ni Mn Pb Cr As Cd Cu 1 Sn 0.987* 1 Zn −0.681 −0.744 1 V −0.79 −0.807 0.954* 1 Ni −0.669 −0.761 0.967* 0.867 1 Mn −0.779 −0.847 0.977* 0.928 0.984* 1 Pb 0.989* 0.984* −0.614 −0.706 −0.638 −0.74 1 Cr −0.712 −0.746 0.981* 0.990* 0.903 0.941 −0.626 1 As −0.629 −0.691 0.997** 0.948 0.951* 0.956* −0.553 0.982* 1 Cd −0.609 −0.682 0.995** 0.926 0.967* 0.961* −0.541 0.966* 0.997** 1 *P<0.05, ** P<0.01. 表 7 土壤中重金属Pearson相关系数

Table 7. Pearson correlation coefficient of heavy metals in soil around workshop

Cr Ni Cu Zn V As Sn Cd Pb Cr 1 Ni 0.288 1 Cu −0.246 0.36 1 Zn −0.216 0.063 0.405 1 V 0.806** 0.175 −0.650** −0.39 1 As 0.671** −0.108 −0.056 −0.112 0.371 1 Sn −0.16 0.385 0.985** 0.36 −0.566* 0.018 1 Cd 0.096 0.523* 0.474 0.503 −0.276 0.165 0.428 1 Pb −0.284 0.342 0.975** 0.411 −0.694** −0.072 0.934** 0.519* 1 *P<0.05, ** P<0.01. 表 8 车间内灰尘和TSP中重金属主成分分析

Table 8. Principal component analysis of heavy metals in workshop dust and TSP

灰尘

DustTSP 成分1 成分2 成分1 成分2 成分3 Cu 0.163 0.756 −0.775 0.554 0.141 Sn 0.716 0.584 −0.773 0.606 0.03 Zn 0.979 −0.139 0.865 0.434 0.001 V 0.805 −0.557 0.86 −0.059 0.39 Mn 0.98 −0.133 0.918 0.187 −0.02 Ni 0.982 −0.126 0.807 0.201 0.436 Pb −0.416 −0.291 −0.516 0.844 0.004 Cr 0.978 −0.153 0.824 0.339 0.342 As 0.609 0.721 0.847 0.228 −0.435 Cd 0.693 −0.164 0.713 0.283 −0.629 方差贡献率% 60.506 19.31 63.52 19 10.65 表 9 土壤中重金属主成分分析

Table 9. Principal component analysis of heavy metals in soil

成分1 成分2 成分3 Cr −0.426 0.863 0.081 Ni 0.346 0.599 −0.694 Cu 0.947 0.142 0.103 Zn 0.567 −0.006 0.07 As −0.211 0.673 0.674 Sn 0.9 0.215 0.125 Cd 0.596 0.491 −0.122 Pb 0.955 0.11 0.099 V −0.78 0.538 −0.186 方差贡献率% 47.21 24.06 11.47 表 10 重金属潜在生态风险评价

Table 10. Potential ecological risk assessment of heavy metals in dust and soil

评价对象

ObjectEj RI Pb Cr As Cd Cu Zn Ni Mn 灰尘 最大值 71.91 3.69 26.59 108.28 1334.75 8.46 18.54 0.45 1444.18 最小值 17.31 1.30 0.28 36.27 125.26 1.13 1.67 0.08 233.97 平均数 38.18 2.17 6.75 55.74 277.27 2.97 4.91 0.22 385.95 标准方差 15.59 0.56 9.68 16.18 243.90 1.99 3.98 0.09 242.77 对RI贡献率/% 9.89 0.56 1.75 14.44 71.84 0.77 1.27 0.06 TSP 最大值 327.85 2.52 23.66 3706.63 496.29 19.81 10.29 0.96 4001.76 最小值 56.62 1.63 7.58 187.86 81.41 2.96 4.51 0.18 390.94 平均数 163.11 2.03 12.04 1299.26 212.59 8.70 7.47 0.47 1705.67 标准方差 90.72 0.33 5.28 1103.66 162.63 6.01 1.86 0.30 1096.27 对RI贡献率/% 9.56 0.12 0.71 76.17 12.46 0.51 0.44 0.03 土壤 最大值 10.04 2.36 45.38 52.14 14.52 1.11 4.91 0.64 131.12 最小值 3.08 2.08 27.95 22.22 0.44 0.63 3.71 0.31 60.41 平均数 4.18 2.20 32.38 32.49 2.47 0.78 4.13 0.47 79.09 标准方差 1.84 0.09 4.21 8.56 4.13 0.14 0.33 0.11 13.85 对RI贡献率/% 5.28 2.78 40.94 41.08 3.13 0.98 5.22 0.59 -

[1] YANG J S, WANG H F, ZHANG G W, et al. Recycling organics from non-metallic fraction of waste printed circuit boards by a novel conical surface triboelectric separator[J]. Resources, Conservation and Recycling, 2019, 146: 264-269. doi: 10.1016/j.resconrec.2019.03.008 [2] HADI P, XU M, LIN C S K, et al. Waste printed circuit board recycling techniques and product utilization[J]. Journal of Hazardous Materials, 2015, 283: 234-243. doi: 10.1016/j.jhazmat.2014.09.032 [3] 顾明事, 李兴福, 赵泽华, 等. 江苏省废线路板处置利用现状及管理对策研究[J]. 污染防治技术, 2017, 30(5): 90-94. GU M S, LI X F, ZHAO Z H, et al. Studies on waste circuit boards disposal and management countermeasures in Jiangsu Province[J]. Pollution Control Technology, 2017, 30(5): 90-94 (in Chinese).

[4] PANT D, JOSHI D, UPRETI M K, et al. Chemical and biological extraction of metals present in E waste: A hybrid technology[J]. Waste Management, 2012, 32(5): 979-990. doi: 10.1016/j.wasman.2011.12.002 [5] 葛亚军, 金宜英, 聂永丰. 电子废弃物回收管理现状与研究[J]. 环境科学与技术, 2006, 29(3): 61-63, 118. GE Y J, JIN Y Y, NIE Y F. Recovery and management of electronic wastes: Status quo and needs for improvement[J]. Environmental Science & Technology, 2006, 29(3): 61-63, 118 (in Chinese).

[6] HUANG K, GUO J, XU Z M. Recycling of waste printed circuit boards: A review of current technologies and treatment status in China[J]. Journal of Hazardous Materials, 2009, 164(2/3): 399-408. [7] YAMANE L H, de MORAES V T, ESPINOSA D C R, et al. Recycling of WEEE: Characterization of spent printed circuit boards from mobile phones and computers[J]. Waste Management, 2011, 31(12): 2553-2558. doi: 10.1016/j.wasman.2011.07.006 [8] 杨春刚, 戈保梁, 李飞, 等. 废旧印刷线路板的再资源化技术及新进展[J]. 矿产综合利用, 2016(5): 6-9. YANG C G, GE B L, LI F, et al. Resource recovery technology of and new progress of WPCB[J]. Multipurpose Utilization of Mineral Resources, 2016(5): 6-9 (in Chinese).

[9] 董卿, 尤飞, 蒋军成, 等. 废弃FR1酚醛树脂印刷线路板热解特性及动力学分析[J]. 安全与环境学报, 2016, 16(3): 279-284. DONG Q, YOU F, JIANG J C, et al. Pyrolysis characteristics and dynamic analysis of the waste FR1 phenol resin PC board[J]. Journal of Safety and Environment, 2016, 16(3): 279-284 (in Chinese).

[10] 马硕, 刘万福, 马洪亭, 等. 废弃印刷线路板热解过程传热特性实验研究[J]. 环境科学学报, 2018, 38(12): 4760-4768. MA S, LIU W F, MA H T, et al. Experimental investigation on the heat transfer characteristics of waste printed circuit boards during pyrolysis[J]. Acta Scientiae Circumstantiae, 2018, 38(12): 4760-4768 (in Chinese).

[11] 杨崇, 朱能武, 崔佳莹, 等. 胞外聚合物对生物浸出线路板金属粉末中铜的作用[J]. 环境工程学报, 2015, 9(9): 4503-4508. YANG C, ZHU N W, CUI J Y, et al. Extracellular polymeric substances’ role in bioleaching copper from metal concentrates of waste printed circuit boards[J]. Chinese Journal of Environmental Engineering, 2015, 9(9): 4503-4508 (in Chinese).

[12] FENG P, WANG Z, MENG L, et al. Supergravity-enhanced liquation crystallization for metal recovery from waste printed circuit boards[J]. Chemical Engineering and Processing - Process Intensification, 2022, 173: 108813. doi: 10.1016/j.cep.2022.108813 [13] ROCCHETTI L, AMATO A, BEOLCHINI F. Printed circuit board recycling: A patent review[J]. Journal of Cleaner Production, 2018, 178: 814-832. doi: 10.1016/j.jclepro.2018.01.076 [14] VANEGAS P, PEETERS J R, CATTRYSSE D, et al. Ease of disassembly of products to support circular economy strategies[J]. Resources, Conservation and Recycling, 2018, 135: 323-334. doi: 10.1016/j.resconrec.2017.06.022 [15] 江苏省市场监督管理局. 废线路板综合利用污染控制技术规范: DB32/T 3942—2021[S]. 南京: 江苏省市场监督管理局, 2021. Technical specifications for pollution control of comprehensive utilization of waste printed circuit boards: DB32/T 3942—2021[S]. Nanjing: Market Supervision Administration of Jiangsu Province, 2021 (in Chinese).

[16] GUO C, WANG H, LIANG W, et al. Liberation characteristic and physical separation of printed circuit board (PCB)[J]. Waste Management, 2011, 31(9/10): 2161-2166. [17] 谭淑妃, 郭杰, 许振明. 废电路板热拆解过程中颗粒污染物的排放特征[J]. 环境科学与技术, 2019, 42(12): 74-80. TAN S F, GUO J, XU Z M. Emission characteristics of particulate pollutants from the thermal disassembly of waste printed circuit boards[J]. Environmental Science & Technology, 2019, 42(12): 74-80 (in Chinese).

[18] 王建波. 废旧电路板上元器件的环境友好拆解及铝电容器和晶体管的资源化回收[D]. 上海: 上海交通大学, 2017. WANG J B. Environmetally friendly disassembly of electronic components from waste printed circuit boards and resources recovery of aluminum electrolytic capacitors and transistors[D]. Shanghai: Shanghai Jiao Tong University, 2017 (in Chinese).

[19] 吴文成, 宋清梅, 刘谞承, 等. 电子废物拆解区典型用地土壤重金属分布特征[J]. 中国环境科学, 2018, 38(7): 2632-2638. WU W C, SONG Q M, LIU X C, et al. Distribution pattern of heavy metals in soils with respect to typical land uses in electronic waste recycling region[J]. China Environmental Science, 2018, 38(7): 2632-2638 (in Chinese).

[20] 缪雄谊. 重金属污染的扩散迁移及其健康风险评价: 以三角洲和河流为例[D]. 合肥: 中国科学技术大学, 2020. MIAO X Y. The conversion, migration and health risk assessment of heavy metals pollution— a field study in typical delta and river[D]. Hefei: University of Science and Technology of China, 2020 (in Chinese).

[21] CHENG Z, CHEN L J, LI H H, et al. Characteristics and health risk assessment of heavy metals exposure via household dust from urban area in Chengdu, China[J]. Science of the Total Environment, 2018, 619/620: 621-629. doi: 10.1016/j.scitotenv.2017.11.144 [22] LI H M, WANG J H, WANG Q G, et al. Chemical fractionation of arsenic and heavy metals in fine particle matter and its implications for risk assessment: A case study in Nanjing, China[J]. Atmospheric Environment, 2015, 103: 339-346. doi: 10.1016/j.atmosenv.2014.12.065 [23] LOSKA K, WIECHUŁA D, PELCZAR J. Application of enrichment factor to assessment of zinc enrichment/depletion in farming soils[J]. Communications in Soil Science and Plant Analysis, 2005, 36(9/10): 1117-1128. [24] 魏复盛, 杨国治, 蒋德珍, 等. 中国土壤元素背景值基本统计量及其特征[J]. 中国环境监测, 1991, 7(1): 1-6. WEI F S, YANG G Z, JIANG D Z, et al. Basic statistics and characteristics of background values of soil elements in China[J]. Environmental Monitoring in China, 1991, 7(1): 1-6 (in Chinese).

[25] ZHOU L, LIU G J, SHEN M C, et al. Characteristics and health risk assessment of heavy metals in indoor dust from different functional areas in Hefei, China[J]. Environmental Pollution, 2019, 251: 839-849. doi: 10.1016/j.envpol.2019.05.058 [26] LOSKA K, CEBULA J, PELCZAR J, et al. Use of enrichment, and contamination factors together with geoaccumulation indexes to evaluate the content of Cd, Cu, and Ni in the Rybnik water reservoir in Poland[J]. Water, Air, and Soil Pollution, 1997, 93(1): 347-365. [27] HAKANSON L. An ecological risk index for aquatic pollution control. a sedimentological approach[J]. Water Research, 1980, 14(8): 975-1001. doi: 10.1016/0043-1354(80)90143-8 [28] WANG J Y, CHEN H, XIA W Y, et al. Heavy metal pollution in the surface dust from E-waste disposal place and its ecological risk assessment[J]. Advanced Materials Research, 2011, 347-353: 2360-2364. doi: 10.4028/www.scientific.net/AMR.347-353.2360 [29] 徐争启, 倪师军, 庹先国, 等. 潜在生态危害指数法评价中重金属毒性系数计算[J]. 环境科学与技术, 2008, 31(2): 112-115. XU Z Q, NI S J, TUO X G, et al. Calculation of heavy metals’ toxicity coefficient in the evaluation of potential ecological risk index[J]. Environmental Science & Technology, 2008, 31(2): 112-115 (in Chinese).

[30] 杨舒珺. 重金属工业废水渗坑的风险评价及渗坑废水处理研究[D]. 天津: 天津大学, 2018. YANG S J. The risk assessment and treatment of industrial heavy-metal wastewater ponds[D]. Tianjin: Tianjin University, 2018 (in Chinese).

[31] 陈润甲, 田艳梅, 张钧, 等. 山西省某焦化厂周边土壤中重金属污染评价及特征分析[J]. 天津农业科学, 2020, 26(6): 79-84. CHEN R J, TIAN Y M, ZHANG J, et al. Evaluation and characteristic analysis of heavy metal pollution in soil of a coking plant in Shanxi Province[J]. Tianjin Agricultural Sciences, 2020, 26(6): 79-84 (in Chinese).

[32] 汪锐. 废旧电路板破碎过程中污染物的生成释放及转化机理研究[D]. 上海: 上海交通大学, 2020. WANG R. Study on the formation, release and conversion mechanism of pollutants in process of crushing waste printed circuit boards[D]. Shanghai: Shanghai Jiao Tong University, 2020 (in Chinese).

[33] ZHOU P, GUO J, ZHOU X Y, et al. PM2.5, PM10 and health risk assessment of heavy metals in a typical printed circuit noards manufacturing workshop[J]. Journal of Environmental Sciences, 2014, 26(10): 2018-2026. doi: 10.1016/j.jes.2014.08.003 [34] 刘方方. 物理法从废线路板中回收铜合金粉末新技术研究[D]. 广州: 华南理工大学, 2020. LIU F F. Investigation of a novel technology of recycling copper alloy powders from waste printed circuit boards by physical method[D]. Guangzhou: South China University of Technology, 2020 (in Chinese).

[35] 周啸宇. 印刷电路板生产、回收拆解及废弃堆置过程中重金属与溴系阻燃剂的污染、释放规律及人体暴露研究[D]. 上海: 华东理工大学, 2014. ZHOU X Y. Occurrence and emssion of heavy metals and brominated flame retardants in printed circuit board production, recycling and disposal processes and human exposure assessment[D]. Shanghai: East China University of Science and Technology, 2014 (in Chinese).

[36] 刘伟锋, 胡晓丽, 张杜超, 等. 废线路板破碎分选产物的工艺矿物学[J]. 中国有色金属学报, 2022, 32(9): 2703-2713. LIU W F, HU X L, ZHANG D C, et al. Process mineralogy of waste printed circuit board crushing and sorting products[J]. The Chinese Journal of Nonferrous Metals, 2022, 32(9): 2703-2713 (in Chinese).

[37] WANG Q, ZHANG B G, YU S Q, et al. Waste-printed circuit board recycling: Focusing on preparing polymer composites and geopolymers[J]. ACS Omega, 2020, 5(29): 17850-17856. doi: 10.1021/acsomega.0c01884 [38] GONZÁLEZ-MARTÍN J, KRAAKMAN N J R, PÉREZ C, et al. A state–of–the-art review on indoor air pollution and strategies for indoor air pollution control[J]. Chemosphere, 2021, 262: 128376. doi: 10.1016/j.chemosphere.2020.128376 [39] REIS A M, CAVE M, SOUSA A J, et al. Lead and zinc concentrations in household dust and toenails of the residents (Estarreja, Portugal): A source-pathway-fate model[J]. Environmental Science. Processes & Impacts, 2018, 20(9): 1210-1224. [40] SHI T R, WANG Y H. Heavy metals in indoor dust: Spatial distribution, influencing factors, and potential health risks[J]. Science of the Total Environment, 2021, 755: 142367. doi: 10.1016/j.scitotenv.2020.142367 [41] 陶红, 张小红, 王亚娟, 等. 银川市城区地表灰尘重金属污染分布特征及健康风险评价[J]. 环境化学, 2022, 41(8): 2573-2585. doi: 10.7524/j.issn.0254-6108.2021042501 TAO H, ZHANG X H, WANG Y J, et al. Pollution characteristics and health risk assessment of heavy metals of surface dust in urban areas of Yinchuan[J]. Environmental Chemistry, 2022, 41(8): 2573-2585 (in Chinese). doi: 10.7524/j.issn.0254-6108.2021042501

[42] 周利. 室内颗粒物的环境化学特征、来源识别及风险评价: 以合肥市为例[D]. 合肥: 中国科学技术大学, 2022. ZHOU L. Environmental chemical characteristics, source identification and risk assessment of indoor particulates— a case in Hefei, China[D]. Hefei: University of Science and Technology of China, 2022 (in Chinese).

[43] 黄波涛. 典型危废处置利用企业周边土壤重金属分布特征、来源及风险评价[J]. 环境化学, 2023, 42(2): 435-445. doi: 10.7524/j.issn.0254-6108.2022062403 HUANG B T. Distribution characteristics, sources analysis and potential ecological risk assessment of heavy metals in soils surrounding typical hazardous waste disposal and utilization plants[J]. Environmental Chemistry, 2023, 42(2): 435-445(in Chinese). doi: 10.7524/j.issn.0254-6108.2022062403

[44] WANG S B, YAN Q S, ZHANG R Q, et al. Size-fractionated particulate elements in an inland city of China: Deposition flux in human respiratory, health risks, source apportionment, and dry deposition[J]. Environmental Pollution, 2019, 247: 515-523. doi: 10.1016/j.envpol.2019.01.051 -

下载:

下载: