-

截至2019年底,全国城镇累计建成污水处理厂超过1×104座,污泥的年产生量近6×107 t (以含水率80%计)。厌氧消化是国际上大力推行的污泥处置利用技术[1-2],然而,由于我国城镇污泥中有机质的含量偏低(40%~60%),厌氧消化产甲烷的效能低[3],导致目前配备厌氧消化设施的污水处理厂的比例不足30%。与此同时,随着餐饮业的快速发展,餐厨垃圾的产生急剧增多。据报道,我国目前餐厨垃圾的年产量已达6×107 t[4]。餐厨垃圾中易腐有机质含量高(>80%),厌氧消化过程中常出现挥发性脂肪酸积累、酸化抑制产甲烷的现象[5]。鉴于此,有研究者提出了将污泥与餐厨垃圾混合厌氧消化的技术思路[6-8]。从长沙、大连、襄阳等地的污泥-餐厨垃圾厌氧消化的工程运行实效来看,该方式可显著提升厌氧消化的稳定性和甲烷产率(500 t·d−1的处理条件下,标准状况下产气可达3×104 m3·d−1)。然而,混合厌氧消化后所产生的消化产物的含水率一般仍很高(>95%),从而给后续的转运、堆肥、焚烧以及土地利用等带来了很大的困难。如何促进污泥-餐厨垃圾厌氧消化物的高效脱水是一个亟需解决的技术难题。

近10年来,过硫酸盐高级氧化在促进城镇污泥脱水时具有快速、简便等特点,受到了众多研究者的广泛关注。其原理为:通过能量(光、热)或过渡金属(Fe0, Co2+等)活化,过一硫酸盐(PMS)或过二硫酸盐(PDS)产生高活性

${\rm{SO}}_4^ - $ ∙(E0(${\rm{SO}}_4^ - $ ∙/${\rm{SO}}_4^{2 - }$ )=2.43 V,以NHE计),氧化裂解污泥细胞和降解胞外聚合物(EPS),促使大量结合态水的释放(转化为自由水),进而提升脱水性能。KIM等[9]发现,热活化PDS(投加量2 mmol∙g−1 VSS)可提高剩余活性污泥脱水,在80 ℃下、处理60 min,污泥CST可降低77%。宋秀兰等[10]发现,Fe2+活化PDS可使浓缩污泥的过滤比阻(SRF)下降96%。NI等[11]发现,通过Fe0活化PDS亦可明显改善好氧消化污泥的脱水性能,处理30 min后,CST从119.1 s降至21.9 s。然而,与剩余活性污泥和浓缩污泥相比,污泥-餐厨垃圾混合厌氧消化产物的碱度更高、絮体粒径尺寸更小[12],因此,相对而言更难脱水。目前,关于过硫酸盐氧化促进污泥-餐厨垃圾厌氧消化物脱水的报道还相对较少,对于相关作用机理的认识也十分有限。为此,本研究以污泥-餐厨垃圾厌氧消化物为研究对象,探究了热活化过硫酸盐处理对其脱水性能的影响,并从处理体系中过硫酸盐分解、自由基的产生、胞外聚合物(EPS)含量和组成的变化以及消化物微观形貌等方面分析其可能的作用机制,旨在为污泥-餐厨垃圾厌氧消化物的高效脱水提供参考。

全文HTML

-

供试污泥取自南京某城镇污水处理厂的污泥浓缩池。该污水处理厂采用AO工艺,日处理水量达2×105 m3。污泥pH为7.3、含水率为97.5%、有机质含量为48.3%。餐厨垃圾取自南京农业大学校园餐厅,实验前去除纸巾、塑料等杂物并机械破碎至粒径5 mm左右。污泥-餐厨垃圾混合厌氧消化物来自于本实验室长期运行的中温湿式厌氧消化反应器,污泥与餐厨垃圾按1∶1(以挥发性固体含量VS计)序批式进料。消化周期为30 d、温度为(35±1) ℃。供试消化物的基本特性为:pH为8.4、含水率97.2%、有机质含量43.7%、多糖和蛋白质的含量分别为300.3和636.1 mg·L−1。

-

为探讨热活化温度的影响,根据KIM等[9]的报道和本研究前期预实验的结果,本研究设置了50、60、70、80 ℃ 4组处理,固定PDS(过硫酸钠Na2S2O8)的投加量为4 mmol·g−1 (以干物质计)。具体实验步骤为:将厌氧消化物置于500 r·min−1转速下搅拌并分别加热至上述温度,随后添加Na2S2O8。反应过程中分别在30、60、120、180、240 min取样,经冰浴淬灭3 min后,分别测定其pH、CST、Na2S2O8含量等指标。

-

采用CST分析仪(304M型,Triton Electronics)测定消化物毛细吸水时间(capillary suction time, CST);采用NaHCO3/KI法[13]测定PDS浓度;采用电子自旋共振波谱仪(EPR) (EMX10/12,德国Bruker公司)测定自由基种类;采用扫描电子显微镜(SEM)(S-3400N,日本Hitachi公司)观察消化物处理前后的微观形貌。

EPS的提取参考SHENG等[14]的三层提取方法,分别为:溶解型EPS(SL-EPS)、松散型EPS(LB-EPS)和紧密型EPS(TB-EPS)。EPS化学组分中的蛋白质采用修正的Folin-Lowry法测定,多糖采用蒽酮比色法[15]测定。

1.1. 供试样品

1.2. 温度对热活化过硫酸盐氧化促进污泥-餐厨垃圾厌氧消化物脱水影响的实验设计

1.3. 分析方法

-

在不同温度条件下的热活化PDS处理过程中,厌氧消化物CST的变化如图1(a)所示。由图可知,热活化PDS氧化可显著提高污泥-餐厨垃圾厌氧消化物的脱水性能,且随着温度的升高,脱水的改善效果愈显著。具体而言:随着反应的进行,4组不同温度下的处理体系的CST均呈现下降趋势,但下降的速率有较大的不同。在50、60、70、80 ℃条件下,处理240 min时,CST从初始1 064.9 s分别下降到657、296.6、39.4、39 s,降低了33%、72%、96%、96%。KIM等[9]利用热活化PDS调理剩余活性污泥的过程中发现,在80 ℃条件下反应60 min,污泥CST可降低77%。此外,从厌氧消化物沉淀后的上清液的浊度来看(图1(b)),80 ℃条件下反应60 min,上清液浊度为228 NTU;进一步延长反应时间至120 min,浊度可降至1.4 NTU,水质清澈。与此同时,在70 ℃下,处理240 min,厌氧消化物CST也可降至39 s,此时的上清液水质也较为清澈透明(浊度1.46 NTU)。另外,从最终压滤泥饼的含水率来看,70 ℃、处理240 min和80 ℃、处理120 min的样品含水率分别为60.1%和59.5%。因此,在脱水性能改善程度基本相近的条件下,综合考虑今后实际工程处理时控温所需的能耗成本,本研究推荐热活化PDS促进污泥-餐厨垃圾厌氧消化物脱水的最佳条件为70 ℃、240 min。

-

已有报道[16]证实,热活化过硫酸盐氧化为吸热反应,当加热量大于140.2 kJ∙mol−1时,过硫酸盐中的O—O键可断裂,生成强氧化性的

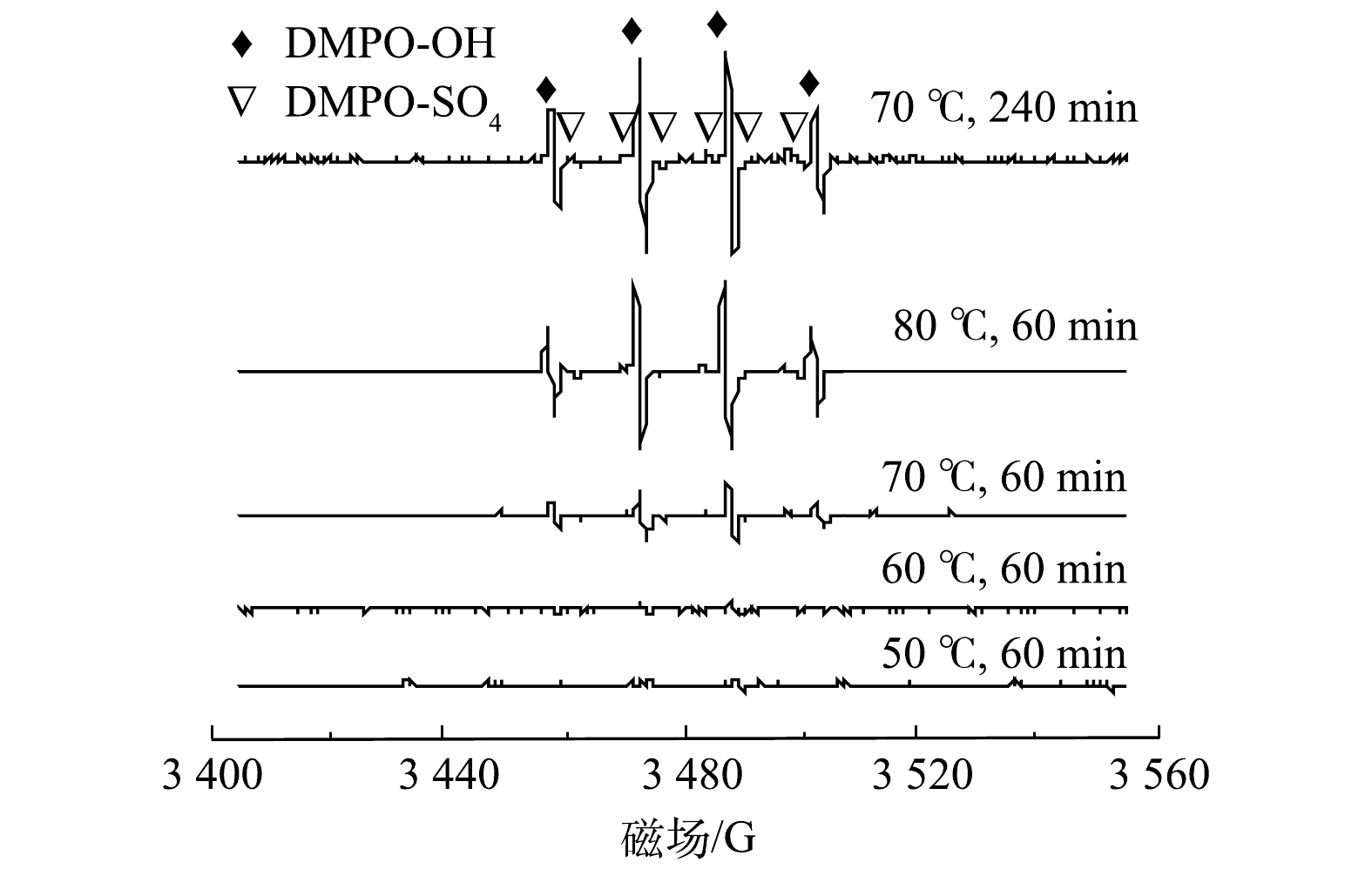

${\rm{SO}}_4^ - $ ∙。由图2可知,升高温度明显促进了反应体系中PDS的分解,这与前人的研究结果一致[16-17]。例如:50 ℃条件下反应240 min,PDS的浓度仅从4.00 mmol·g−1(以DS计)降到3.07 mmol·g−1,分解极为缓慢;而在相同时间,在80 ℃的反应条件下,PDS浓度则从4.00 mmol·g−1大幅降至0.05 mmol·g−1,减少了98.8%。EPR检测的自由基信号强度也证实了这一结果。如图3所示,热活化PDS体系在80 ℃条件下反应60 min检测出2种自由基特征峰,其中峰型为1∶2∶2∶1的特征峰是典型的DMPO捕获∙OH产生的超精细分裂图谱,同时还检测出较强的硫酸根自由基的特征峰[18];而50 ℃的反应条件下体系中并未检测到明显的自由基特征峰。此外,值得关注的是,在70 ℃条件下延长反应时间至240 min,体系中产生的${\rm{SO}}_4^ - $ ∙和∙OH自由基的峰强与80 ℃条件下反应60 min基本相当。这也解释了图1(a)中所观测到的70 ℃条件下反应240 min的脱水性能与80 ℃条件下反应60 min基本一致的原因。热活化过硫酸盐反应体系中自由基的产生的机理见式(1)~式(3)[16]。一些研究[18-19]表明,强氧化性的自由基${\rm{SO}}_4^ - $ ∙和∙OH攻击污泥絮体、降解高度亲水性的EPS,可促进絮体细胞中的结合水转变为自由水,进而提高厌氧消化物脱水性能。 -

不同热活化温度下处理体系中EPS的组成如图4所示。从图4(a)中可以看出,原始消化物EPS中蛋白质含量主要集中在SL层和TB层中。在50和60 ℃条件下反应240 min,TB层蛋白质浓度分别从327.5 mg·L−1降至146.9和95.0 mg·L−1,SL层和LB层蛋白质浓度增多,EPS中的蛋白质浓度分别从636.1 mg·L−1增加到748.6和670.5 mg·L−1。这说明,加热使絮体细胞破解,释放EPS,一部分TB层蛋白质转移到SL层和LB层。在70 ℃下反应240 min和80 ℃下反应120 min的条件下,TB层蛋白质浓度分别从327.5 mg·L−1减少至76.7和77.4 mg·L−1;EPS中的蛋白质浓度从636.1 mg·L−1降至331.8和340.5 mg·L−1。此时污泥脱水速率提高可能的原因为:首先加热破解污泥细胞,释放EPS,并且一部分TB层蛋白质转至SL层,同时体系中产生的

${\rm{SO}}_4^ - $ ∙和∙OH会破坏微生物细胞,氧化分解蛋白质,此时蛋白质分解消耗的速率远大于其释放的速度[20]。有研究指出,EPS中的蛋白质因含有大量的亲水基团,具有更强的持水能力,故EPS中蛋白质含量被广泛认为是影响污泥脱水性能的关键[9,11]。据此可以推测,TB-EPS中蛋白质的大幅削减可能是本研究中厌氧消化物脱水提高的重要原因之一。EPS中的多糖含量在不同活化温度下变化趋势与蛋白质含量总体一致(图4(b))。在50、60、70、80 ℃条件下,EPS中总的多糖浓度由300.3 mg·L−1分别增加到853.2、818.4、656.4、507.3 mg·L−1。这表明,在热活化PDS处理过程中,微生物细胞破裂,胞内物质释放到胞外并被自由基的攻击、降解。EPS中多糖总量随着温度的升高,呈先上升后下降的趋势。但由于多糖的亲水性不如蛋白质,所以多糖含量的变化可能并不是影响污泥脱水性能提高的关键[21]。

-

不同热活化温度处理条件下PDS氧化前后的厌氧消化物的微观结构特征如图5所示。由图可见,原始样品(图5(a))的絮体表面是光滑致密的,孔隙较少;而经过70 ℃条件下PDS反应240 min(图5(b))和80 ℃条件下反应120 min(图5(c)),厌氧消化物絮体变得较为松散,且其表面和内部都出现了大量的孔洞。这些大量增加的过滤通道对絮体内部的水分释放、排出十分有利,脱水性能进而得到较大的改善,这与许多研究学者的观测结果一致[19,22]。

2.1. 热活化过PDS对污泥-餐厨垃圾厌氧消化物脱水性能的影响

2.2. 不同热活化温度条件下处理体系中PDS的分解及自由基的产生

2.3. 不同热活化温度条件下处理前后厌氧消化物EPS含量及组成

2.4. 热活化过PDS处理前后污泥-餐厨垃圾厌氧消化物的形貌特征

-

1)热活化PDS氧化可大幅度提高污泥-餐厨垃圾厌氧消化物的脱水性能,且随着温度从50 ℃升至80 ℃,脱水的改善效果也相应提高。

2)在过硫酸钠的投加量4 mmol·g−1、温度70 ℃、处理时间240 min的条件下,厌氧消化物CST可从初始1 064.9 s降至39.4 s。

3)热活化PDS过程中产生

${\rm{SO}}_4^ - $ ∙和∙OH自由基攻击厌氧消化物,促使其絮体结构破坏和物质释放并降解,这可能是脱水性能提高的主要原因。

下载:

下载: